A lug bolt is a single-piece fastener that secures your wheel directly to the vehicle's hub through threaded holes. These fasteners combine the functions of both wheel studs and lug nuts into one component, making them a popular choice among European manufacturers for their efficiency and strength.

The basic design features a hex head (sometimes star or Allen pattern) that works with standard lug wrenches and sockets. Most lug bolts include a V-shaped flange at the head that fits precisely into the wheel's mounting holes. This design helps center the wheel on the hub and distributes clamping pressure evenly across the contact surface.

Lug bolts are constructed from high-strength steel to handle the demanding forces of vehicle operation. They must maintain wheel stability during high-speed driving, hard braking, aggressive cornering, and sudden acceleration. The robust construction also resists loosening from constant vibration and temperature changes that occur during normal driving.

European manufacturers like BMW, Audi, Mercedes-Benz, Volkswagen, and Saab choose lug bolts over traditional stud-and-nut systems. This preference comes from engineering advantages including fewer failure points and reduced manufacturing complexity. American and Japanese vehicles typically use lug nuts on wheel studs, reflecting different regional engineering approaches.

Installing wheels with lug bolts requires a specific technique since there are no protruding studs to guide wheel placement. You must position the wheel against the hub first, then align the holes carefully before threading the bolts. Proper installation technique is crucial for wheel safety and vehicle performance.

You can easily identify a lug bolt system by examining your wheel mounting area. Look for smooth holes where fasteners enter the hub - if you don't see any studs protruding from the hub, your vehicle uses lug bolts. The absence of fixed studs is the clear indicator of this fastener system.

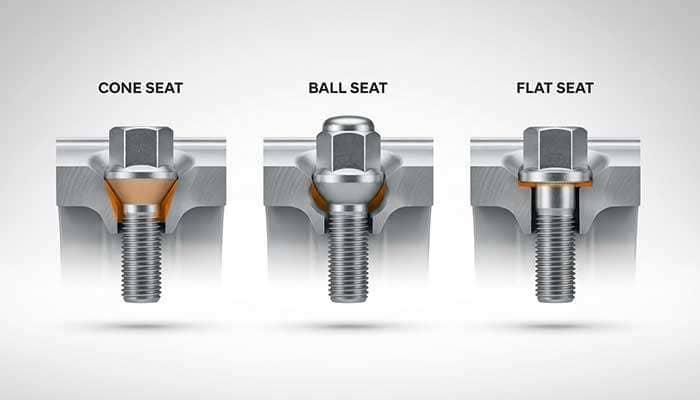

When selecting lug bolts for your wheels, the seat design makes all the difference between secure mounting and potential failure. Each seat type creates a specific contact interface that must match your wheel's mounting holes perfectly. Using the wrong seat type can lead to catastrophic wheel failure due to improper load distribution. Getting mismatched seat types causes dangerous over-stressing of the fastener.

Cone seat lug bolts feature a precise 60-degree tapered end that creates the most reliable connection for aftermarket wheels. This conical design offers superior clamping force distribution across a larger contact area, making it the preferred choice for performance applications. The tapered shape automatically centers your wheel on the hub, eliminating vibration issues and ensuring perfect alignment. Most aftermarket wheel manufacturers design their products for cone seat lug bolts, typically requiring a 19mm hex head for installation. Performance enthusiasts choose cone seat bolts because they provide the most even clamping force distribution available.

Ball seat lug bolts use a rounded end that fits into spherical recesses found on many European OEM wheels. While they provide secure mounting, ball seats typically offer less contact area than cone seats. European manufacturers like Audi, BMW, Mercedes-Benz, and Volkswagen commonly use ball seat designs on their factory wheels. These bolts come in two critical specifications: R13 with a smaller radius curve and R14 with a larger radius. Using the incorrect radius specification creates weak contact points that can lead to fastener failure.

Flat seat lug bolts, also known as "Mag Seat" bolts, feature a flat seating surface that sits flush against the wheel. This design typically incorporates a washer system rather than relying on tapered contact points. Flat seat bolts deliver secure mounting with excellent contact area distribution. You'll find these fasteners primarily on older American-made vehicles from GM and Chrysler.

Spline drive lug bolts represent the latest advancement in wheel fastener technology. These bolts feature specialized splines running from top to base, requiring a specific spline drive socket for installation. This innovative design creates significantly more contact surface area with the drive tool. The enhanced contact provides more uniform torque distribution, reducing the likelihood of loosening from vibration. SplineDrive designs weigh 30% less than traditional socket-style lug nuts while delivering superior performance.

Proper lug bolt installation is essential for wheel safety and vehicle performance. The installation process requires attention to detail and specific techniques to ensure your wheels stay securely attached under all driving conditions.

Each vehicle has a manufacturer-specified torque requirement for lug bolts, typically listed in your owner's manual. Most vehicles require around 100 pound-feet of torque, though this varies by make and model. Under-tightening allows wheels to work loose, while over-tightening can strip threads or crack wheel mounting surfaces.

The torque specification applies only to clean, dry threads. Never lubricate lug bolt threads or seats, as this changes the friction coefficient and leads to inaccurate torque readings. Clean threads ensure consistent clamping force every time.

Start by threading all lug bolts by hand to ensure smooth engagement. This prevents cross-threading and identifies any damaged threads before applying force.

Tighten lug bolts in a star or criss-cross pattern to distribute clamping force evenly around the wheel's contact surface. This technique prevents the wheel from cocking on the brake rotor and ensures the wheel sits flush against the hub. The star pattern equalizes tension across all mounting points, creating uniform contact pressure.

Never use an impact wrench for final tightening, as this can weaken lug bolts or apply inconsistent torque. Use a calibrated torque wrench set to your vehicle's specification instead. Apply torque gradually, repeating the star pattern until you reach the specified value.

A quality torque wrench ensures accurate, repeatable results. Digital torque wrenches often provide the most precise readings for critical fasteners like lug bolts.

After installation, visually inspect that the wheel sits completely flush against the hub surface. Any gaps indicate improper seating or damaged components.

Re-torque lug bolts after driving 50-100 miles to account for metal compression and thermal expansion. This follow-up check catches any settling that occurs during initial operation and ensures continued safety.

Remember that proper installation technique protects both your investment in wheels and tires and, more importantly, your safety on the road.

Understanding whether your vehicle uses lug bolts is essential for proper wheel maintenance and aftermarket wheel selection. European manufacturers have largely adopted this fastener system for specific engineering and manufacturing reasons.

German manufacturers have embraced wheel bolts more enthusiastically than their Japanese and American counterparts. BMW, Mercedes-Benz, Volkswagen, Audi, and Porsche routinely equip their vehicles with lug bolts rather than lug nuts. This design choice extends beyond luxury vehicles to include more affordable European brands like Citroën, Renault, Peugeot, Volvo, and Saab. Even American-market vehicles built on European platforms, as exemplified by the Mercedes-based Chrysler Crossfire, often feature lug bolts.

When shopping for wheels or performing maintenance, knowing your vehicle's fastener type prevents costly mistakes and ensures proper fitment.

Vehicles using lug bolts feature a fundamentally different hub design than those with lug nuts. The hub contains threaded holes instead of protruding studs. This creates a cleaner hub appearance yet requires more technique during wheel installation. Although mechanically distinct, both systems serve the same wheel-securing function.

Interestingly, vehicles designed for lug bolts can be converted to stud systems using aftermarket conversion kits that add permanent studs to the hub. This conversion appeals to some enthusiasts who prefer the easier installation process of lug nut systems.

The preference for lug bolts stems primarily from manufacturing efficiency and cost reduction. Manufacturers simplify the hub design, reduce parts count, and streamline assembly processes by eliminating pressed-in studs.

Some engineers argue that lug bolts provide more consistent clamping force, which enhances wheel balance and stability—particularly valuable at high autobahn speeds. Additionally, lug bolts don't stretch as much under load as stud-and-nut combinations, allowing more precise torque application.

These engineering benefits explain why European manufacturers continue to specify lug bolts across their vehicle lines, from economy cars to high-performance machines.

Understanding lug bolts is essential for proper wheel maintenance and safety, especially for European vehicle owners who encounter this fastener system regularly.

• Lug bolts are single-piece fasteners that screw directly into threaded hub holes, combining the functions of both wheel studs and lug nuts into one component.

• European manufacturers like BMW, Audi, Mercedes-Benz, and Volkswagen predominantly use lug bolts instead of traditional lug nut systems for cost efficiency and engineering preferences.

• Proper installation requires following the RIST method: using correct torque specifications (typically ~100 lb-ft), tightening in a star pattern, and using a calibrated torque wrench for final tightening.

• Different seat types (cone, ball, flat, spline) must match your wheel's design exactly - using mismatched types can cause catastrophic failure due to improper load distribution.

• Always re-torque lug bolts after 50-100 miles of driving to account for metal compression and thermal stresses that occur during initial use.

Recognizing whether your vehicle uses lug bolts versus lug nuts is crucial for safe wheel maintenance and proper aftermarket wheel selection.

Lug bolts are single-piece fasteners that screw directly into threaded holes in the wheel hub, combining the functions of wheel studs and lug nuts. Lug nuts, on the other hand, are separate components that thread onto protruding wheel studs.

Lug bolts are commonly found on European-manufactured vehicles, including brands like BMW, Mercedes-Benz, Volkswagen, Audi, and Porsche. Some American-market vehicles built on European platforms may also use lug bolts.

Proper installation of lug bolts involves using the correct torque specification (typically around 100 lb-ft), tightening in a star pattern, using a calibrated torque wrench for final tightening, and checking for proper seating. It's also important to re-torque the bolts after driving 50-100 miles.

There are four main types of lug bolt seat designs: cone seat, ball seat, flat seat, and spline drive. Each type has a specific profile that must match the wheel's design for proper fitment and load distribution.

Manufacturers may prefer lug bolts for several reasons, including manufacturing efficiency, cost reduction, simplified hub design, and potentially more consistent clamping force. Some engineers believe lug bolts provide better wheel balance and stability, especially at high speeds.