Aftermarket wheels have come a long way from being just a style statement. Today, they're genuine performance upgrades that can transform how your vehicle handles the road. Here's something that might surprise you: wider aftermarket wheels create a larger contact patch with the road, which means substantially better handling, improved stability, and enhanced traction when you need it most—especially during those tricky weather conditions.

We know that buying a new set of wheels represents a considerable investment. That's exactly why getting the fitment right matters so much when you're selecting custom wheels. After years of helping customers with their wheel choices, we've watched too many people run into fitment problems that could have been completely avoided with the right guidance upfront.

Custom wheels come in an impressive range of materials and sizes—we're talking everything from 15 inches all the way up to 32 inches. This variety makes shopping exciting, but it can also feel overwhelming when you're trying to make the best choice for your specific vehicle and driving needs.

Whether you want to give your ride a fresh new look or boost its performance capabilities, understanding the technical side of wheel fitment will save you time, money, and frustration down the road.

This guide covers everything you need to know about choosing the perfect aftermarket wheels for your vehicle. We'll walk through bolt patterns and offsets, help you pick the right lug nuts, and make sure you get proper clearance. Ready to find your ideal wheels?

Image Source: Tire Pirates

Custom wheels come in many forms, but they're definitely not all created equal. Getting familiar with aftermarket wheel basics will help you make smart purchasing decisions that you'll be happy with for years to come.

Aftermarket wheels are manufactured by third-party companies instead of your vehicle's original manufacturer. You might hear them called "replica wheels" when they copy OEM styles, but they offer alternatives to those factory-installed options. Here's the thing: unlike factory wheels, aftermarket wheels aren't built specifically for your exact vehicle model—though they can absolutely be compatible when you get the fitment right.

Most aftermarket wheels use aluminum as their base material, often mixed with other metals like magnesium to create stronger, more durable alloys. Quality varies quite a bit between brands and models. Premium aftermarket wheels can actually outperform factory wheels in construction and materials, while budget options might cut corners in ways that affect safety.

Price ranges run the full spectrum. You can find reputable brand sets starting around $887, while high-end options with specialized features can push past $1,672. For those looking at premium materials, you'll find carbon fiber, magnesium alloy, titanium, and various composite options that each bring their own performance characteristics and price points.

The differences between factory and aftermarket wheels go much deeper than just who makes them. OEM wheels focus on cost-effective mass production and meeting universal safety standards, while aftermarket wheels prioritize customization and specialized performance features.

When it comes to pricing, OEM wheels typically cost more because of brand association and guaranteed compatibility. Aftermarket wheels give you much more flexibility with price points that fit different budgets.

The variety difference is huge. OEM wheels offer limited options, but aftermarket wheels come in practically endless designs, finishes, and sizes. You can choose from multi-spoke, mesh, or split-spoke designs, plus finishes like chrome, painted, matte, or polished. Some even feature directional patterns and different lip sizes.

Quality and fitment tell different stories too. OEM wheels guarantee perfect fit and consistent quality standards, while aftermarket wheel quality can vary significantly between manufacturers. Some aftermarket wheels might need additional accessories or minor modifications for proper installation.

Performance characteristics also differ. OEM wheels meet manufacturer safety and performance specifications, but certain aftermarket wheels offer enhanced features like reduced weight for better handling or improved aerodynamics.

Vehicle owners choose aftermarket wheels for several compelling reasons. The biggest draw is visual transformation—aftermarket wheels instantly change your vehicle's appearance with distinctive designs that manufacturers simply don't offer.

Car enthusiasts love the personalization aspect. Aftermarket wheels let you make a statement that reflects your individual style. You can go classic, aggressive, modern, or whatever direction helps your vehicle express your personality.

Performance gains provide another strong motivation. Lighter wheel construction improves handling, acceleration, and braking by reducing unsprung mass. Specialized wheels also deliver superior durability for challenging conditions, especially if you do any off-road driving.

Quality aftermarket wheels can actually boost your vehicle's resale value, making them more of an investment than just an expense. Daily drivers benefit too—upgrading wheel size within manufacturer recommendations improves both looks and performance without sacrificing safety.

Sometimes it comes down to practical needs. Certain drivers require specialized wheels for specific driving conditions that factory wheels simply weren't designed to handle. This includes extreme weather situations or particular performance requirements that standard wheels can't meet.

Image Source: Reno Off Road

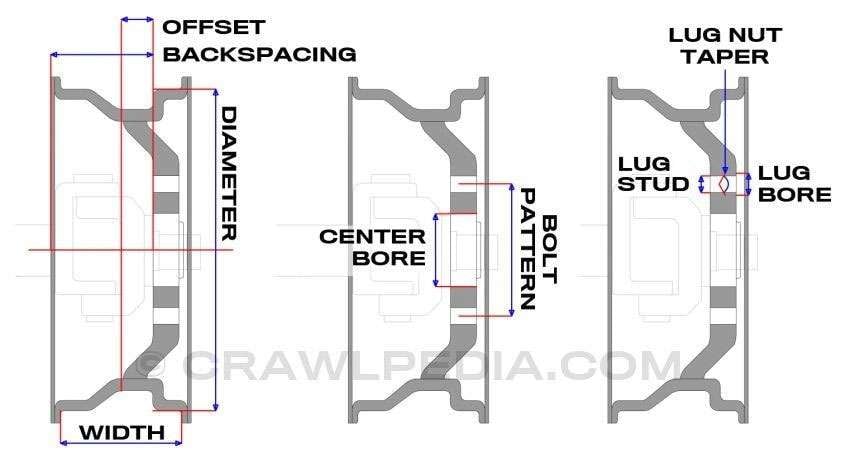

Getting the right aftermarket wheels means nailing down some key technical specs that determine whether your new wheels will actually fit your vehicle properly. Trust us—getting these measurements wrong can lead to expensive headaches and even safety issues.

Think of the bolt pattern as the foundation of wheel compatibility. You're looking at two important numbers here: how many lug holes your wheel has and the diameter of the circle those holes create. When you see something like "5x114.3," that tells you there are five lug holes arranged in a circle that measures 114.3mm across.

The hub bore is just as critical—this is the center hole that slides over your vehicle's hub. Getting this right ensures your wheel sits centered properly. You'll encounter two main types:

Hub-centric: The wheel's bore matches your hub diameter exactly, giving you the best safety and smoothest ride

Lug-centric: The bore is bigger than the hub, so the wheel centers itself using the lug nuts, which can sometimes cause alignment issues

When your wheels have larger bores than needed, hub-centric rings act as spacers to fill that gap between your hub and wheel.

These two measurements control how your wheels sit inside the wheel wells. While they're related, they work differently:

Offset tells you the distance (in millimeters) between where the wheel mounts and its centerline. You'll see three types:

Positive offset: The mounting surface sits toward the front/street side—most front-wheel-drive cars use this

Zero offset: The mounting surface lines up exactly with the centerline

Negative offset: The mounting surface sits toward the back/brake side—this creates that aggressive stance look

Backspacing measures the distance (in inches) from the mounting surface to the wheel's back edge. Here's a quick example: an 8-inch wide wheel with 0mm offset would have 4 inches of backspacing.

Pick the wrong offset and your wheels might stick out too far or rub against suspension parts. Most factory wheels use high positive offset (around +45mm) to keep wheels tucked close to the body, while aftermarket wheels often use lower offsets for a more aggressive appearance.

When you're measuring wheel size, focus on these key dimensions:

Diameter: Measure straight across from lip to lip

Width: Find the distance between bead seats (that's where your tire seals to the wheel)

Bolt pattern: For 5-lug patterns, measure from the outside edge of one hole to the center of the opposite hole

Offset: Find your wheel's centerline by measuring the width and dividing by two, then measure from the mounting pad to that centerline

Backspacing: Place a straightedge across the wheel's back and measure down to the flange

Before you place that order, double-check all your measurements at normal ride height and think about how your suspension moves. Keep this in mind: the advertised wheel width (measured between bead seats) isn't the same as the actual width (measured lip to lip)—the actual width is typically at least an inch more.

Image Source: Race Technologies

Test fitting is your final checkpoint before committing to aftermarket wheels. Even when all your measurements look perfect on paper, physical testing catches potential problems that calculations simply can't predict. The good news? You can do thorough testing without mounting tires first—saving you both time and money if adjustments are needed.

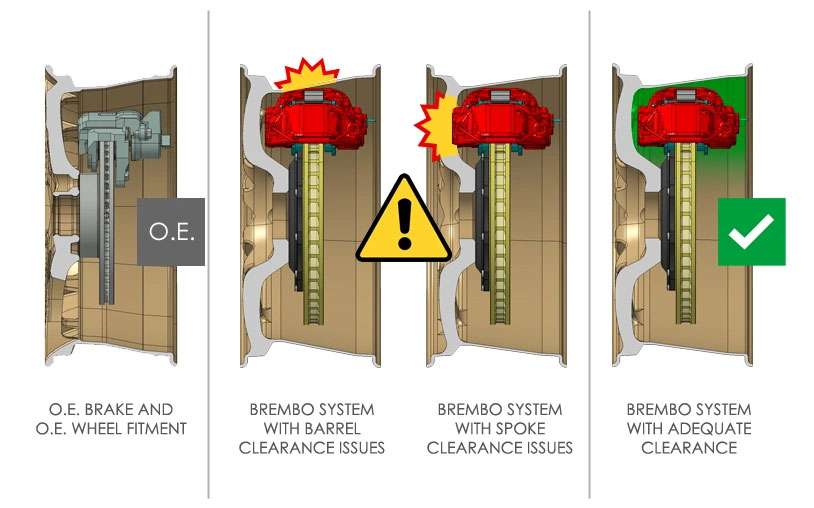

Start by placing the bare wheel onto your vehicle's hub to confirm basic fitment works. The bolt pattern should line up perfectly with your vehicle's studs, and the wheel needs to make full contact with the hub's mating surface. Once you've temporarily installed the wheel, check that lug nuts engage properly and maintain at least 3-4mm clearance between your wheels and brake components.

With the wheel mounted, take a careful look around brake calipers, inner valve stems, and wheel weights for adequate clearance. Rotate the wheel slowly by hand to make sure every section has enough space. Pay special attention to the outer edge of the disk brake caliper—it shouldn't touch the inside of the rim or make contact with wheel balancing weights.

Large performance brakes can technically work with just 1-2mm clearance, but experienced mechanics recommend at least 3mm in all directions from the caliper to the wheel. This extra breathing room accounts for thermal expansion, since brake calipers actually expand when they heat up during driving.

Next, check for fender, suspension, and overall clearance issues. Have someone slowly turn the steering wheel fully in both directions while you watch for clearance throughout the entire range of motion. Keep your eyes open for any contact with fenders, suspension components, or wheel wells during this test.

Don't forget that suspension compresses while driving, which can reduce clearance. The most common problem with aftermarket wheels is interference with the front strut at full steering lock—definitely a dangerous situation you want to avoid. Also, during heavy cornering, tires can tuck into the wheel well and risk hitting the fender or liner.

Many aftermarket wheels feature larger hub bores so they can fit multiple vehicle applications. A small gap between the hub bore and vehicle hub is totally normal, but larger gaps might require hub rings to properly center the wheel until the lugs get tightened.

Hub rings come in plastic or aluminum materials—aluminum typically offers better longevity and reliability. The inside diameter must match your vehicle's hub diameter, while the outside matches your wheel's hub bore. These rings don't bear any load after the lugs are tightened, since the weight gets supported by friction between the wheel and axle mounting surface.

Most importantly, complete your test fitting before mounting tires. This step prevents wasted time and money on tires that won't ultimately fit. Test fitting reveals issues that specifications alone can't predict, like spoke design interference with brake calipers.

If you're dealing with marginal clearance, wheel spacers might solve the problem by moving wheels outward from calipers. Just make sure that wider track allows tires to clear fenders in all positions. No matter how good your calculations and templates look, always physically test fit wheels before moving forward.

Image Source: Amazon.com

Lug nuts might look like small, simple parts, but they're absolutely critical for safely mounting your aftermarket wheels. These components are literally the only thing connecting your expensive new wheels to your vehicle—get them wrong, and you're looking at serious safety issues.

Different wheel designs require specific lug nut styles, and matching them correctly is non-negotiable. Conical (acorn) lug nuts feature a 60-degree tapered end that automatically centers itself when you tighten it down, making them the go-to choice for most aftermarket wheels. Ball seat lug nuts have a rounded end designed to fit spherical wheel holes—you'll typically see these on European vehicles. Mag lug nuts come with an extended shank and flat washer that helps center the wheel properly. When your wheels need extra thread engagement, extended thread (ET) lug nuts give you that additional threaded area for a more secure connection.

Thread specifications come down to two critical measurements: diameter and pitch. The most common metric sizes you'll encounter are 12mm×1.25, 12mm×1.5, and 14mm×1.5, while standard SAE options include 7/16"-20, 1/2"-20, and 9/16"-18. Getting your vehicle's exact thread pattern right isn't optional—use the wrong threads and you can permanently damage your wheel studs.

Seat design has to match your wheel's lug holes exactly. You've got three main seat styles to work with: conical (60-degree taper), flat (needs a washer), and radius/ball. Mix up these seat types and you'll prevent proper wheel centering, which can lead to vibration, loosening, or even wheel damage.

Locking lug nuts add a layer of theft protection by requiring a special key for removal. These security devices come in several styles including shank, radius/ball, and cone seat designs. For the best protection, look for systems with unique key patterns that offer lifetime guarantees against wheel theft. You can install just one locking lug per wheel, or go with multiple ones for enhanced security. Just remember to keep that key in a safe place—replacement options depend on the manufacturer.

Image Source: SafetyCulture's Public Library

Getting your new aftermarket wheels properly installed and maintained is what separates a great investment from potential problems down the road. These steps might seem straightforward, but they make all the difference in keeping your wheels secure and looking fantastic for years to come.

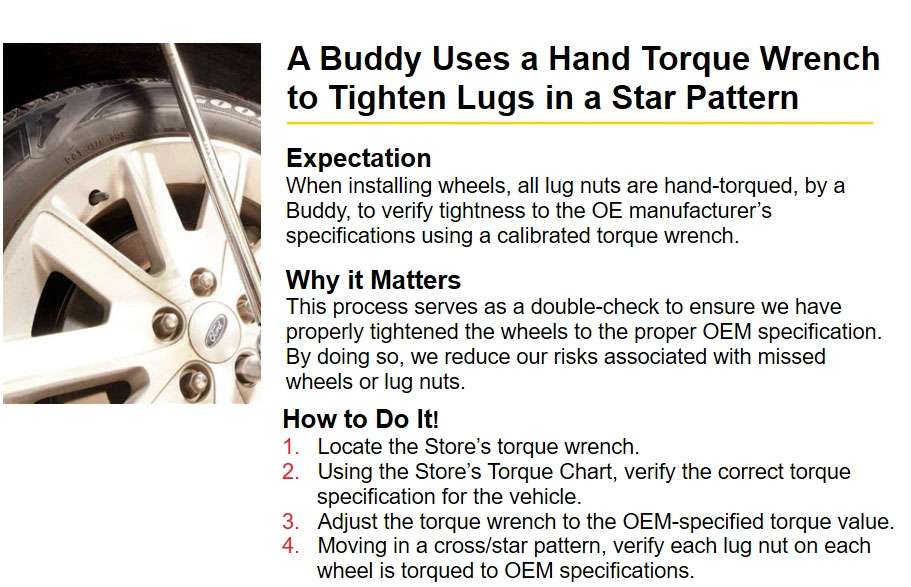

Here's a technique that every wheel professional swears by: always tighten your lug nuts in a star pattern, never in a circle. This method ensures your wheel centers correctly and eliminates those annoying vibration issues that can develop later. Start by hand-tightening all the nuts, then use a torque wrench to reach the final specification.

One critical mistake we see customers make? Using an impact gun for final tightening. These tools can deliver up to 3X more force than your wheels actually need, which can damage threads or create uneven pressure distribution.

Your vehicle's owner manual contains the exact torque specifications you need—don't guess on this one. Keep those threads clean and dry before installation; oil or debris can throw off your torque readings.

Here's the step that many people skip but shouldn't: re-torque your wheels after driving the first 50-100 miles. This isn't just a suggestion—it's essential because wheels naturally settle into position during initial use, which can reduce the clamping force. Just remember to let hot wheels cool down to room temperature before checking torque specs.

Regular cleaning with mild soap and water keeps your wheels looking their best. Different finishes need different care approaches:

Chrome wheels: Use quality chrome polish or wax, and don't forget the backside

Painted or clear-coated wheels: Stick with vehicle wax that's specifically safe for clear coats

Polished aluminum: Plan on periodic re-polishing sessions to maintain that bright luster

Never attempt to clean wheels while they're still hot from driving—this can cause cleaning products to streak or even damage certain finishes.

Monthly tire pressure checks are your best friend, but only when tires are cold. Keep this in mind: pressure changes about one to two pounds for every 10-degree temperature swing. Regular tire rotation every 5,000-8,000 miles prevents uneven wear patterns and extends tire life.

Choosing the right aftermarket wheels goes way beyond just finding something that looks good on your car. We've covered a lot of ground here, from understanding what makes aftermarket wheels different from factory options to getting into the nitty-gritty of bolt patterns, hub bores, and offsets.

Test fitting really is where the rubber meets the road—literally. This step catches clearance problems with brake calipers, suspension parts, and fenders that you'd never spot just by looking at spec sheets. Getting the right lug nuts with proper thread patterns and seat types keeps everything locked down tight and safe.

The installation process matters just as much as the selection. That star pattern tightening method and hitting the right torque specs will keep your wheels performing well for years. Don't forget about the maintenance side either—regular cleaning, proper protection, and that crucial re-torque after your first 50-100 miles will keep everything running smoothly.

We've helped lots of customers upgrade their wheels over the years, and the ones who get the best results are always the ones who take time to understand these technical details upfront. Your wheels do double duty as both a style upgrade and a critical safety component, so getting the details right really pays off.

Sure, the whole process might feel like a lot to take in at first. But now you've got the knowledge you need to choose, install, and maintain the perfect set of wheels for your ride. The right wheels don't just make your car look better—they can actually improve how it handles and performs, making this one of the most satisfying upgrades you can do.

Understanding proper wheel fitment is essential for both safety and performance when upgrading to aftermarket wheels.

• Master the critical measurements: Bolt pattern, offset, and hub bore determine compatibility—getting these wrong leads to expensive mistakes and safety hazards.

• Always test fit before mounting tires: Physical testing reveals clearance issues with brakes, suspension, and fenders that specifications alone can't predict.

• Use proper lug nuts and installation technique: Match thread patterns and seat types exactly, then tighten in star pattern to manufacturer torque specs.

• Re-torque after 50-100 miles: Wheels settle during initial driving, requiring retightening to maintain proper clamping force and prevent loosening.

• Consider hub-centric rings for optimal fitment: These inexpensive accessories ensure proper wheel centering when aftermarket wheels have larger hub bores than your vehicle.

When done correctly, aftermarket wheels offer significant benefits beyond esthetics—including improved handling through reduced unsprung weight and enhanced performance characteristics that factory wheels often can't match.

Q1. What are the key factors to consider when choosing aftermarket wheels? The main factors are bolt pattern, offset, hub bore, wheel diameter, and width. Ensure these specifications match your vehicle's requirements for proper fitment and safety.

Q2. How important is test fitting before purchasing aftermarket wheels? Test fitting is crucial. It reveals potential clearance issues with brake calipers, suspension components, and fenders that specifications alone might not predict. Always physically test fit wheels before finalizing your purchase.

Q3. What's the significance of wheel offset in aftermarket wheels? Offset determines how the wheel sits within the wheel well. Incorrect offset can cause wheels to protrude excessively or rub against suspension components. It's best to stay close to your vehicle's original offset for optimal performance and safety.

Q4. Are locking lug nuts necessary for aftermarket wheels? While not mandatory, locking lug nuts provide an extra layer of security against wheel theft. Consider installing at least one locking lug per wheel, especially if your new wheels are valuable.

Q5. How often should I re-torque my aftermarket wheels? Re-torque your wheels after the first 50-100 miles of driving. This is critical as wheels settle into place, potentially reducing clamping force. Always follow manufacturer-specified torque values and use a torque wrench for accurate tightening.