Off-road wheels are one of the most critical upgrades you can make to your 4x4. Swapping wheels from stock to aftermarket is one of the most common mods wheelers make to their 4x4s. The question "How do I choose the right off-road wheels?" comes up constantly among off-road enthusiasts, and the answer isn't always straightforward. Your trail experience depends heavily on one crucial measurement: off-road wheel offset.

Wheels and tires rank as the most important components of any overland build, second only to suspension. Size selection becomes critical when choosing off-road wheels. Many experienced wheelers prefer smaller wheels—17" instead of 18" or 20"—to mount tires with thicker sidewalls. Larger-diameter wheels reduce sidewall height when using the same overall tire size. The 15-inch wheel has largely disappeared from the market, with 17-inch-diameter wheels becoming the standard for midsize trucks and SUVs.

Here's what many people don't realize: a difference of just half an inch can determine whether a wheel will work properly on your 4x4. Most off-road applications perform best with wheels between 15 and 20 inches, providing the right balance between performance and durability. Serious off-road enthusiasts typically choose +1mm, +0mm, and -12mm offsets for optimal trail performance. We'll guide you through these essential decisions to help you select the perfect wheels for your off-road adventures.

Material selection makes the difference between wheels that perform reliably and those that fail when you need them most. Off-road wheels come in three primary materials—steel, cast aluminum, and forged aluminum—each offering distinct advantages for different off-road applications.

Steel wheels remain the go-to choice for serious off-roaders who prioritize durability and field repairability. These rugged options start at just $50 compared to alloy wheels that begin at $75. This significant cost advantage becomes important when you're also investing in lift kits, larger tires, and other essential upgrades.

Steel's biggest advantage lies in how it responds to impact. Unlike aluminum, which cracks under extreme stress, steel typically bends. This behavior proves invaluable on remote trails where a bent steel wheel can often be hammered back into usable condition with basic tools.

Contrary to popular belief, steel wheels aren't always heavier than aluminum alternatives. Mopar steel wheels weigh 24.85 lbs compared to similar-sized Method aluminum wheels at 27.8 lbs. Most steel wheels do carry extra weight, creating both benefits and drawbacks:

Enhanced winter traction from additional mass

Decreased fuel efficiency and acceleration

Increased unsprung weight affecting suspension performance

Steel's primary weakness involves corrosion resistance. Salt, chemicals, and moisture will eventually cause rust without proper maintenance. Modern protective coatings like Accuride's Steel Armor™ can extend wheel life by up to 24 months (approximately 200,000 miles) before refinishing becomes necessary.

Cast aluminum wheels offer the middle ground for most off-road enthusiasts. The manufacturing process begins with molten aluminum heated to approximately 1200°F before being poured into wheel-shaped molds. Two primary methods exist—gravity casting and low-pressure casting, with low-pressure creating denser material and fewer inconsistencies.

Low-pressure cast aluminum wheels account for approximately 90% of Original Equipment wheels on vehicles today. Their widespread use stems from delivering significant weight savings over steel while keeping costs reasonable. This weight reduction improves handling, acceleration, and fuel efficiency noticeably.

Cast aluminum enables more intricate designs than steel, creating visually appealing options for off-road enthusiasts. Aluminum naturally resists corrosion better than steel, though it can still corrode when exposed to salt and other chemicals.

The main limitation of cast aluminum involves its brittleness compared to steel. Under extreme stress, cast aluminum typically cracks rather than bends, making field repairs nearly impossible.

Forged aluminum wheels represent the premium choice for dedicated off-road enthusiasts. The forging process starts with solid aluminum blocks (typically aerospace-grade 6061-T6) subjected to extreme pressure—often 8,000-10,000 tons. This intense compression creates a denser, stronger material structure than any casting method can achieve.

The result delivers wheels approximately 25-30% lighter than comparable cast alternatives while providing superior strength. This weight reduction at the wheel matters significantly—adding 10 pounds of wheel weight to a 4x4 equals adding 100 pounds of cargo.

Forged wheels excel at heat dissipation, transferring heat three times more effectively than steel. This property extends tire life, brake performance, and overall component longevity.

Forged aluminum wheels carry premium pricing that can be prohibitive for many off-road enthusiasts. Limited availability also means fewer design options compared to cast aluminum wheels.

Your wheel material choice should match your specific off-road activities and budget. Steel excels for rock crawling and budget builds, cast aluminum provides good balance for most trail riding, while forged aluminum delivers ultimate performance for serious enthusiasts ready to invest in the best equipment.

Wheel size selection affects everything from traction to trail durability. The diameter you choose requires balancing clearance, sidewall height, and performance demands for your specific off-road activities.

Seventeen-inch off-road wheels have earned their reputation among serious off-road enthusiasts for good reason. While the Jeep Sahara comes with 18-inch wheels from the factory, Jeep engineers specifically chose 17-inch wheels for the more capable Rubicon model. Off-road wheel sizes typically range from 16-18 inches, with larger diameters sacrificing durability when tackling rough terrain.

Factory engineers know what works. The Tacoma TRD Pro, Wrangler Rubicon, and F-150 Raptor all come standard with 17-inch wheels. These aren't arbitrary choices—they represent the optimal balance between performance and durability for serious trail use.

Seventeen-inch wheels provide these key advantages over 18-inch alternatives:

Better shock absorption and impact resistance

Increased sidewall flex when aired down

Superior durability under heavy off-road stress

Reduced unsprung weight improving handling and efficiency

The relationship between wheel diameter and sidewall height directly impacts your off-road experience. Larger wheel diameters mean less sidewall height when using the same overall tire size. A 35-inch tire mounted on a 17-inch wheel provides 9 inches of sidewall, while the same tire on a 20-inch wheel leaves only 7.5 inches of sidewall.

This sidewall difference matters significantly on the trail. When traversing rocks, roots, or uneven surfaces, taller sidewalls act as additional suspension, conforming to terrain and absorbing impacts. This translates to reduced harshness and improved traction—particularly important when tackling mud, sand, or snow.

Larger wheels create greater rolling inertia, requiring more engine power and reducing fuel efficiency. They also increase unsprung weight, negatively affecting handling and acceleration—similar to running with ankle weights.

Most off-road applications perform best with 17-inch wheel diameter. The Mickey Thompson Baja Classic Lock 17x9 with a -12 offset represents an excellent example of wheels engineered specifically for off-road performance. This combination allows mounting larger tires while maintaining adequate brake clearance.

Here's a useful rule: your wheel diameter should never exceed half your tire's diameter. For 33-inch tires, use 16 or 16.5-inch wheels. For 35-inch tires, 17-inch wheels work ideally.

Brake compatibility creates practical limitations on minimum wheel size. Modern vehicles have become heavier and faster, requiring manufacturers to install larger brakes that need bigger wheel diameters. Many newer vehicles like the Land Rover Defender offer no wheel options under 18 inches, even on base models.

The perfect wheel size balances your specific off-road activities with practical considerations. For most enthusiasts, 17-inch wheels with appropriate tires deliver the ideal combination of performance, durability, and versatility.

Getting your wheel position right is crucial for off-road performance. Offset and backspacing determine exactly where your wheels sit relative to your suspension and fenders, affecting everything from ground clearance to handling characteristics.

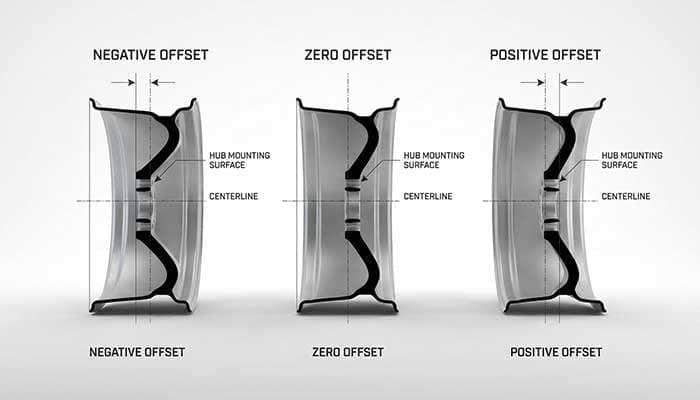

Wheel offset measures the distance between the wheel's mounting surface and the wheel's centerline, expressed in millimeters. This seemingly small measurement can make or break your off-road setup. Get it wrong, and you'll face rubbing issues, poor handling, or even suspension damage.

Today's off-road market has standardized on offset measurements rather than backspacing, making wheel comparisons much simpler. When manufacturers design wheels with predetermined offsets, you can easily compare options and predict how they'll fit your specific vehicle.

Understanding the three types of offset helps you choose the right positioning for your needs:

Positive offset (+mm) pushes wheels inward toward the suspension. Most modern trucks and SUVs come with positive offset wheels from the factory. This configuration works well for street driving but may limit off-road tire clearance.

Zero offset (0mm) places the mounting surface exactly at the wheel's centerline, creating a neutral position. This balanced approach suits many off-road applications.

Negative offset (-mm) pushes wheels outward, creating a wider stance that many off-road enthusiasts prefer. The more aggressive look comes with improved stability, but extreme negative offset (-44mm) can stress suspension components and require fender modifications.

Most off-road setups benefit from slight to moderate negative offset. This positioning provides the clearance needed for larger tires while maintaining reasonable stress on suspension components.

Backspacing measures the distance from the wheel's mounting surface to its back edge, typically expressed in inches. While related to offset, backspacing approaches wheel positioning from a different perspective.

More backspacing moves the wheel further inward, potentially creating clearance problems with suspension components during turns or suspension articulation. This becomes particularly problematic when you're running larger tires or have lifted your vehicle.

Off-road enthusiasts typically choose wheels with less backspacing to prevent tire rubbing against suspension parts. This configuration also allows room for larger tires and better clearance when tackling obstacles. If you've experienced tire rubbing during sharp turns after installing bigger tires, insufficient backspacing is likely the cause.

Finding the right balance proves essential. Too little backspacing pushes wheels too far outward, stressing wheel bearings and potentially requiring fender modifications. Too much backspacing causes interference with suspension components during articulation. The key is selecting measurements that provide adequate clearance for your specific off-road activities while maintaining proper suspension geometry.

Your off-road activities determine which wheels will work best for your vehicle. Different types of off-road driving require specific wheel characteristics to deliver optimal performance and reliability.

Daily drivers who occasionally hit trails need wheels that balance comfort with capability. Cast aluminum wheels in the 17-inch range provide the ideal solution for weekend warriors. Rock crawlers face different challenges entirely—beadlock wheels prevent tire separation when running extremely low pressures between 2-10 PSI. Overlanders require durability above all else for extended trips across remote terrain. Steel wheels excel for overlanding due to their field repairability when you're hundreds of miles from the nearest tire shop.

Wheel width directly impacts both handling and traction. Your tire's tread width should approximately match your wheel width for optimal performance. Wider wheels help plant the entire tire tread against the surface for maximum grip. Many experienced wheelers choose slightly narrower wheels to protect the wheel's bead from sharp rocks and debris. The balance matters—excessive width creates "tire scrub" that causes wandering and steering instability.

Method Race Wheels, KMC, and Black Rhino consistently rank among the top choices for serious off-road enthusiasts. These brands engineer their wheels with reinforced construction and advanced bead retention systems. Performance Plus Tire carries the best selection of off-road wheels at Off-Road Wheels for your specific vehicle. The right wheel combines proper size, offset, and construction to match your particular off-road activities.

Choosing the wrong off-road wheels can turn an exciting trail adventure into a dangerous situation. Even experienced off-roaders make costly mistakes when selecting wheels that put safety and performance at risk.

Load ratings tell you exactly how much weight each wheel can safely support. Many enthusiasts make the dangerous mistake of thinking tire and wheel load ratings work the same way. This becomes a serious problem when you add modifications like armor plating, larger tires, or roof-mounted gear that increase your vehicle's weight. Passenger vehicles typically have load index values ranging from 70 to 110, which translates to 739 to 2337 pounds per wheel.

Here's what happens when you ignore load ratings: wheels can fail catastrophically under stress, leading to loss of control and potential accidents. Make sure your chosen wheels can handle your fully loaded vehicle's weight.

Looking good matters, but performance should always come first. Many off-road beginners prioritize flashy appearance over actual capability. Those impressive-looking wheels might turn heads in the parking lot, but they can crack or fail completely when you hit real trail conditions. Budget wheels present another temptation—they seem economical initially, but low-quality alloys often crack under stress.

We always recommend choosing wheels based on your actual off-road activities first, then finding options that match your style preferences within that functional category.

This mistake can stop you before you even hit the trails. You must verify brake system clearance before making any wheel purchase. Larger brake components need additional clearance, especially when you choose higher-offset wheels that sit closer to suspension components. You need at least 3mm of space between the caliper and wheel spokes because wheels flex during hard cornering.

Don't assume that if a wheel is the right diameter, it will automatically clear your brakes. Always check this measurement to avoid costly returns or dangerous situations.

Bolt patterns must match your vehicle exactly—there's no room for approximation here. This measurement includes both the number of lug studs and the bolt circle diameter. Wrong bolt patterns prevent proper installation and create extremely dangerous driving conditions.

Even if you can force incompatible wheels onto your vehicle, they won't seat properly and can come loose while driving. Always verify your vehicle's exact bolt pattern before shopping for new wheels.

Selecting the right off-road wheels comes down to matching your specific needs with the right combination of materials, size, and fitment. We've covered how wheel materials impact your trail experience—steel delivers unbeatable repairability, cast aluminum offers the best balance of cost and performance, while forged aluminum provides premium strength for serious enthusiasts.

The 17-inch diameter has proven to be the sweet spot for most off-road applications. Proper offset and backspacing ensure your wheels fit correctly without causing clearance issues or compromising suspension performance.

Function must always come first when choosing off-road wheels. The best wheel combines durability with performance characteristics that match your specific activities, whether you're rock crawling, overlanding, or hitting weekend trails. Performance Plus Tire carries the best selection of Off-Road Wheels at the lowest prices Off-Road Wheels for your specific vehicle.

We recommend taking time to verify load ratings, brake clearance, and bolt patterns before making your purchase. These details make the difference between a frustrating trail experience and years of reliable off-road performance. Your wheels create the crucial connection between your 4x4 and the terrain—choose the right ones, and they'll deliver excellent performance for countless adventures ahead.

Selecting the right off-road wheels requires balancing material, size, and fitment to match your specific terrain and driving needs.

• Choose 17-inch wheels for optimal off-road performance - They provide the best balance of sidewall flex, durability, and brake clearance for most applications.

• Prioritize function over esthetics - Steel wheels offer field repairability, while forged aluminum provides premium strength for serious enthusiasts.

• Verify offset and load ratings before purchase - Proper offset prevents suspension interference, while adequate load ratings ensure safety with heavy modifications.

• Match wheel width to tire tread width - This maximizes traction while preventing excessive tire scrub that causes steering instability.

• Always check brake clearance and bolt patterns - Even 3mm clearance is essential, and mismatched bolt patterns create dangerous driving conditions.

The right wheels serve as your vehicle's crucial connection to terrain - investing time in proper selection pays dividends in performance, safety, and durability on every trail adventure.

The best wheel materials for off-roading depend on your specific needs. Steel wheels offer durability and repairability, cast aluminum provides a balance of cost and weight, while forged aluminum offers premium strength and performance. Choose based on your off-road activities and budget.

Generally, 17-inch wheels are considered better for off-road use. They offer a better balance of performance, durability, and versatility. The smaller diameter allows for more sidewall, which improves shock absorption and traction when aired down for off-road driving.

Wheel offset significantly impacts off-road performance by determining how your wheels sit relative to the suspension. A slight to moderate negative offset is often preferred for off-roading as it creates a wider stance, improving stability. However, extreme negative offsets can cause excessive stress on suspension components.

Load ratings are crucial when selecting off-road wheels as they determine how much weight each wheel can safely support. This is especially important for off-road vehicles that may carry additional weight from modifications like armor plating or roof-mounted gear. Ignoring load ratings can lead to dangerous wheel failures.

To ensure your new wheels fit your vehicle's brakes, always check the brake clearance before purchasing. This is particularly important with larger brake components or higher-offset wheels. A minimum of 3mm space between the caliper and wheel spokes is necessary to account for wheel flex during cornering.