Off-road wheels are essential components that determine whether you conquer challenging terrain or find yourself stranded miles from civilization. When it comes to serious off-road performance, the right wheels make all the difference between a successful adventure and a costly recovery situation.

Understanding off-road wheels is important before making a purchase. Most off-roaders know that upgrading from stock wheels ranks among the most popular modifications, but selecting the best off-road rims requires more than just visual appeal. The best off-road wheels combine advanced engineering with practical features that deliver real performance benefits. Aluminum wheels provide an exceptional strength-to-weight ratio, while forged wheels represent the premium choice due to their superior strength and weight savings. Specialized features like beadlock technology keep tires securely mounted at low pressures—a crucial advantage when tackling demanding surfaces.

We'll guide you through the engineering principles behind top-performing off-road wheels and explain the key factors that separate average options from exceptional ones. From material composition to load ratings, you'll get the expert knowledge needed to make the right choice for your off-road adventures.

The material composition of off-road wheels directly determines their performance capabilities on challenging terrain. Understanding these materials helps you select wheels that match your specific off-road requirements without compromising safety or durability.

Steel and aluminum represent the two primary materials used in off-road wheel construction, each offering distinct advantages for different applications. Steel wheels excel in durability and can withstand tremendous abuse on rugged terrain. When damaged, steel wheels can often be hammered back into shape right on the trail—a critical advantage in remote locations.

However, this durability comes with a significant weight penalty: steel wheels typically weigh approximately 2.5-3 times more than comparable aluminum wheels. This additional unsprung weight negatively impacts vehicle handling, braking response, and fuel economy. Adding 10 pounds of wheel weight to a 4x4 is equivalent to adding 100 pounds of cargo weight to the vehicle.

Aluminum alloy wheels provide an excellent alternative with their superior strength-to-weight ratio. Despite being considerably lighter, modern aluminum wheels deliver impressive durability levels. Aluminum's lighter weight improves acceleration, fuel efficiency, and allows your suspension to respond more effectively to terrain changes.

Aluminum wheels are also available in a greater variety of designs and finishes compared to steel, with options ranging from polished to matte-black and even exotic colors.

The manufacturing process dramatically influences performance characteristics across aluminum wheels:

Cast aluminum wheels, created by pouring molten aluminum into molds, represent the most common and affordable option. This process can create inconsistencies in the metal structure (porosity), potentially leading to cracks under extreme impacts. Manufacturers compensate for this weakness by using more material, resulting in heavier wheels.

Flow formed wheels (sometimes marketed as "flow forged") offer a middle-ground solution. These wheels begin as cast aluminum blanks, but the barrel portion undergoes a heating and spinning process that compresses and stretches the metal. This process creates a denser structure with increased tensile strength, allowing for thinner, lighter designs that maintain structural integrity. Flow formed wheels deliver better impact resistance and higher load capacity than cast wheels.

Forged wheels stand as the premium option, manufactured by compressing a billet of aluminum under extreme pressure. This process creates the strongest and lightest wheels available. The forging process allows manufacturers to use 30-35% less material while achieving superior strength. Unlike cast wheels that tend to crack upon impact, forged wheels typically bend rather than break—a significant safety advantage. This superior performance commands a higher price point.

Off-road adventures frequently expose wheels to corrosive elements including mud, water, and salt. Steel wheels, though durable, require protective coatings to prevent rust formation. Once scratched, steel begins to oxidize, potentially leading to structural weakness over time.

Aluminum possesses natural corrosion resistance even in damp or salt-saturated environments. This inherent property makes aluminum wheels particularly suitable for coastal regions or areas with frequent precipitation.

Aluminum wheels also dissipate heat more effectively than steel, which helps extend the lifespan of brakes, bearings, and other critical components. Steel wheels tend to retain heat, potentially increasing wear on these parts during extended off-road excursions.

The best off-road wheel material depends on your specific usage scenario, terrain challenges, and budget considerations. For hardcore rock crawling, steel's bendable nature might prove advantageous, while aluminum's weight savings benefits faster off-road driving and overall vehicle performance.

Material selection tells only part of the story. Advanced design features separate ordinary wheels from top-performing off-road wheels. These engineering elements deliver critical advantages when tackling demanding terrain.

The tire-to-wheel connection determines success or failure when running low air pressures on challenging terrain. Beadlock wheels use an outer ring bolted into the wheel face that clamps the tire bead securely regardless of air pressure. This system proves essential when airing down to improve traction, allowing safe operation at lower pressures without risking tire separation on rocks or obstacles.

Bead Grip technology offers an alternative that bridges street legality with off-road capability. Method's patented Bead Grip® features small grooves on both inner and outer bead seats that engage the tire bead for stronger hold under extreme side loads and lower air pressures. These wheels also incorporate a more aggressive "safety hump" profile that further stabilizes the tire bead.

The key difference: beadlock wheels physically clamp the tire with an external ring, while Bead Grip wheels rely on strategically placed grooves to secure the tire bead. Bead Grip wheels maintain highway legality while offering enhanced off-road performance.

Top off-road wheel brands have developed specialized impact-resistant designs to handle punishing conditions. Giant's Impact Resistant Design combines carefully selected materials with strategic structural reinforcement. This approach creates exceptionally tough wheels capable of handling big drops and rocky descents.

Increased rim bead width helps disperse impact loads and enhances structural strength without adding unnecessary weight. Precise reinforcement around each spoke hole provides support exactly where needed.

Advanced engineering includes smoother transitions between rim components through optimized carbon layering, creating more durable structures with superior impact resistance. These refined manufacturing techniques maximize strength at critical stress points.

Split-spoke wheels have gained popularity among off-road enthusiasts for their combination of striking appearance and functional benefits. Dividing spokes into two parts increases wheel strength without adding excess weight. This design creates unique window patterns with distinctive contours.

Deep dish wheels feature thick rims and substantial profiles that offer both visual appeal and practical advantages. Their design provides enhanced resistance to impacts when driving over uneven terrain. The deep lip construction offers additional structural integrity at the wheel's perimeter—a critical area subject to trail damage.

Many premium off-road wheels incorporate mesh spoke designs with wide hollow windows that combine visual appeal with functional performance. These openings reduce weight while maintaining structural integrity through strategic material placement.

When choosing off-road wheels, consider how these design features align with your specific terrain challenges and driving style rather than focusing solely on appearance.

Image Source: Reno Off Road

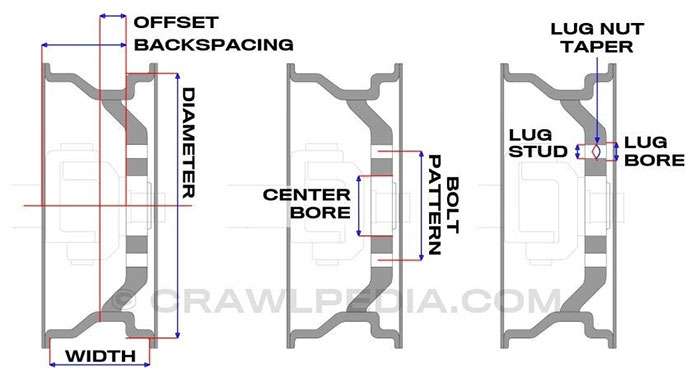

Proper wheel fitment determines whether your off-road wheels perform as intended or create expensive compatibility problems. When it comes to selecting custom wheels, there are a few important factors to consider for your specific vehicle and terrain requirements.

Wheel diameter directly impacts your tire's sidewall height—a crucial factor for off-road performance. Smaller diameter wheels paired with larger tires provide more sidewall cushion for superior trail capability. A 35" tire on a 17" wheel delivers 9 inches of sidewall, while the same tire on a 20" wheel offers only 7.5 inches. This extra sidewall acts like additional suspension when you air down for better traction and terrain conformity.

Wheel width must match your tire width for optimal performance. If your rim is too wide, the tire bead can pop off easily. If too narrow, you'll get poor traction and uneven wear patterns. For most mid-sized trucks and SUVs, a diameter of 17" with width around 8.5" works best with popular 33" and 35" tires.

Offset measures where your wheel sits relative to the hub mounting surface, expressed in millimeters from the wheel's centerline. The three types are:

Positive offset moves the mounting surface toward the street side, tucking the wheel closer to suspension components

Zero offset places the mounting surface exactly at the wheel's centerline

Negative offset pushes the mounting surface toward the hub side, moving the wheel outward

Off-road applications typically benefit from negative offset, creating a wider stance and clearance for larger tires. Rock crawlers especially need more negative offset and lower backspacing to fit big tires without rubbing suspension parts. However, excessive negative offset stresses wheel bearings, ball joints, and other front-end components.

Bolt patterns must exactly match your vehicle's hub configuration. The pattern combines the number of lugs with their circle diameter, and common off-road setups include 5, 6, and 8-lug arrangements.

Measuring techniques vary by lug count. For even patterns (6 or 8 lugs), measure from one lug center to the center directly opposite. For 5-lug patterns, measure from the outside edge of one hole to the center of the hole across from it.

Vehicle types use specific bolt patterns. Mid-sized trucks commonly feature 6-lug patterns like 6x139.7mm (6x5.5"), while heavy-duty trucks use 8-lug configurations such as 8x165.1mm (8x6.5") for higher load capacity. Always verify your exact bolt pattern before purchasing—even slight variations between similar vehicles can make wheels incompatible.

Image Source: Reika Wheels

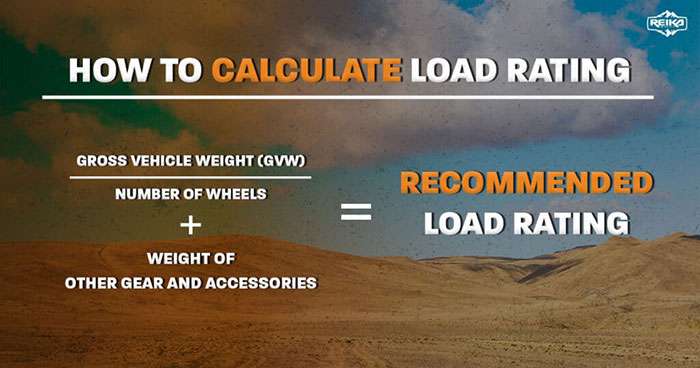

Load ratings determine the maximum weight your off-road wheels can safely support—a critical specification that directly impacts your safety on the trail. When it comes to wheel selection, understanding load capacities makes the difference between reliable performance and catastrophic wheel failure.

Load rating specifications appear as "MAX LOAD" followed by a weight figure in pounds or kilograms, typically stamped on the wheel's back side near the bolt pattern or spokes. To calculate your required load rating, take your vehicle's Gross Axle Weight Rating (found on the door jamb sticker), select the higher GAWR (front or rear), and divide by two. Each wheel supports half the weight of its respective axle.

Industry standards like SAE, JWL, and VIA establish rigorous testing protocols—including radial fatigue tests, cornering fatigue tests, and impact tests—to verify wheels can handle specified loads under real-world conditions. For off-road applications, you'll want load ratings that exceed the minimum calculated requirement, as trail conditions create stresses beyond typical highway driving.

Forged wheels excel in demanding off-road scenarios, offering load capacities ranging from 2,500 to 3,500 pounds per wheel. The forging process creates a denser, more uniform metal structure that resists deformation even after repeated impacts. Cast wheels typically manage around 2,000 pounds, insufficient for heavily built rigs or those carrying substantial gear.

Method Race Wheels' forged options feature impressive 4,000 pound ratings, while other premium manufacturers like KIPARDO achieve 2,600 pounds (1,175 kg).

Exceeding wheel load ratings can lead to catastrophic structural failure—including cracks, bending, or complete wheel collapse. These failures create immediate safety hazards and potential legal liability issues.

Off-road excursions subject wheels to unique challenges including sudden weight transfers during articulation and shock loads from drops and jumps. Properly rated wheels help maintain suspension geometry, especially important since taller tires increase leverage on the wheel center, effectively reducing its load capacity.

Adequate tire load ratings don't compensate for insufficient wheel capacity—both components must meet or exceed your requirements.

When choosing off-road wheels for your truck, consider factors such as the type of terrain you will be driving on, your budget, and the style of wheels that match your vehicle. The right selection can make all the difference between a successful adventure and getting stuck in challenging conditions.

Different terrains require specific wheel characteristics to maximize performance and safety. For rocky terrain, beadlock wheels offer crucial tire security during low-pressure crawling. These wheels physically clamp the tire bead, preventing separation when you're navigating jagged obstacles and need maximum traction.

Muddy conditions demand wheels with wider offset that push tires outward, improving stability while preventing mud buildup. The extra clearance helps maintain traction through deep muddy sections where standard wheels would struggle.

Sand requires wider wheels with low profiles that create broader surface area, reducing the likelihood of getting bogged down. The additional width distributes your vehicle's weight more effectively across loose sand surfaces.

We offer wheels across three primary budget tiers to fit any budget:

Entry-Level Steel ($75-100/wheel): Durable but heavy; easily repairable on trails

Mid-Range Alloy ($90-400/wheel): Good balance of weight, strength, and affordability

Premium Forged ($400-1000+/wheel): Exceptional strength-to-weight ratio; highest performance

Casual weekend warriors often find mid-range aluminum alloys provide excellent performance at reasonable prices, delivering 80% of premium performance at 50% of the cost.

Method Race Wheels stands out with their "Lighter. Stronger. Faster." approach and patented Bead Grip® technology. Their wheels handle extreme conditions while maintaining lightweight construction for improved handling and fuel efficiency.

KMC Wheels brings over 40 years of engineering excellence with rigorous testing in harsh environments like the Simpson Desert. Many customers report their KMC wheels still perform excellently after 100,000 miles of hard use.

Black Rhino offers solid performance at reasonable prices, making quality off-road wheels accessible to more enthusiasts. Whether you're looking for budget-friendly options or premium performance, Performance Plus Tire's extensive selection of specialized off-road wheels has the perfect match for your vehicle and terrain needs.

By considering these factors, you can select the right off-road wheels for your vehicle and tackle any terrain with confidence.

Selecting the right off-road wheels makes the difference between conquering challenging terrain and finding yourself stranded when it matters most. We've covered how material composition determines real-world performance—steel provides durability and trail repairability, while aluminum delivers weight savings and improved handling. Forged wheels represent the premium choice with their exceptional strength-to-weight ratio and impact resistance.

Design features matter just as much as materials. Beadlock technology keeps tires secure at low pressures, while advanced spoke designs balance strength with weight reduction. Proper fitment specifications—diameter, width, offset, and bolt pattern—ensure your wheels work with your vehicle's suspension and provide adequate clearance.

Load ratings require serious consideration for safety and performance. Exceeding these specifications can lead to wheel failure exactly when you need reliability most. Your terrain challenges should guide your selection process—rock crawling demands different wheel characteristics than sand or mud driving.

Quality off-road wheels are available across all budget ranges. Whether you choose entry-level steel, mid-range alloy, or premium forged wheels, the right selection can significantly enhance your vehicle's off-road capabilities. For those ready to upgrade their setup, Performance Plus Tire's extensive selection of off-road wheels offers specialized options from top manufacturers to match your specific needs.

The best off-road wheels combine proven engineering with practical features designed for real-world challenges. With this knowledge about materials, construction methods, fitment requirements, and load ratings, you can confidently choose wheels that enhance both safety and performance. When you're miles from civilization tackling demanding terrain, your wheels become one of the most critical components connecting you to the trail ahead.

Understanding the engineering behind off-road wheels helps you make informed decisions that directly impact your vehicle's performance and safety on challenging terrain.

• Material matters most: Forged aluminum wheels offer the best strength-to-weight ratio, while steel wheels provide durability and trail repairability at the cost of added weight.

• Beadlock technology prevents tire separation: These wheels physically clamp tire beads, allowing safe low-pressure driving crucial for traction on rocks and sand.

• Proper load ratings prevent catastrophic failure: Calculate your vehicle's axle weight and divide by two to determine minimum wheel capacity requirements for safe operation.

• Fitment specifications must match terrain needs: Smaller diameter wheels with larger tires create more sidewall cushion, while negative offset provides clearance for bigger tires.

• Budget tiers offer distinct advantages: Entry-level steel ($75-100), mid-range alloy ($90-400), and premium forged ($400-1000+) wheels each serve different performance and durability needs.

The right off-road wheels transform your vehicle's capabilities, but only when material construction, design features, and fitment specifications align with your specific terrain challenges and driving style.

The main factors to consider are material (steel vs aluminum), construction method (cast, flow-formed, or forged), design features like beadlock technology, proper fitment (size, offset, bolt pattern), and load ratings suitable for your vehicle and terrain.

Forged wheels are significantly stronger and lighter than cast wheels, offering superior performance and durability for demanding off-road conditions. They can withstand higher impacts and typically bend rather than crack, though they come at a higher price point.

Beadlock technology uses a ring to physically clamp the tire bead to the wheel, preventing tire separation when running at very low air pressures. This is crucial for maintaining traction in challenging off-road terrain like rocks and sand.

Negative offset pushes wheels outward, creating a wider stance and more clearance for larger tires. This can improve stability and allow for better articulation in off-road situations, but excessive negative offset may stress suspension components.

Both have advantages. Steel wheels are extremely durable and can be bent back into shape if damaged, making them ideal for remote adventures. Aluminum wheels are significantly lighter, improving handling and fuel efficiency, and offer better corrosion resistance in wet environments.