Forged wheels represent the pinnacle of wheel technology, delivering the strongest and lightest construction available on the market. These premium upgrades command serious attention from performance enthusiasts, but they come with an equally serious price tag. We're talking thousands of dollars just to get started.

What makes forged wheels special? Despite using the same aluminum as standard wheels, the manufacturing process sets them apart completely. These wheels undergo an intense pressure process that hammers solid aluminum billet into precise shape, eliminating porosity and weak points that compromise lesser options.

The performance benefits are real. Forged wheels reduce unsprung mass, which directly improves acceleration, braking, and cornering capabilities. However, this performance comes at a premium cost. Major wheel manufacturers typically price forged options at $10,000+ per set, though some smaller companies offer entry-level options starting around $3,000.

The critical question becomes value versus investment. Spending half your vehicle's worth on wheels alone makes little sense if you're driving a $10,000 daily driver. The equation changes dramatically when you own a high-performance vehicle valued over $70,000 or $100,000. At those price points, forged wheels become a logical performance enhancement.

Throughout this guide, we'll examine what makes forged wheels exceptional, explore their genuine performance advantages, and help you determine whether they deserve a place on your specific vehicle. Understanding the technology and benefits helps you make the right decision for your performance goals and budget.

Forged wheels get their name from an intensive manufacturing process that fundamentally differs from standard wheel production methods. This process explains why performance enthusiasts consistently choose forged options when maximum strength and weight savings matter most.

Forged wheel production starts with a solid block of aerospace-grade 6061-T6 aluminum alloy. This choice of material immediately sets forged wheels apart from cast alternatives that begin as liquid metal. The forging process maintains aluminum in its solid state throughout the shaping phase.

The aluminum billet first undergoes controlled heating to achieve malleability without melting. This temperature management proves critical for maintaining the metal's structural integrity during the next phase.

Extreme pressure defines the core forging process. Hydraulic presses apply between 8,000 to 10,000 tons of force to the heated aluminum. This immense pressure compresses and shapes the metal into a rough wheel form called a "forging". During compression, the aluminum's internal structure changes dramatically - grain flow aligns with the wheel's final shape, creating denser, stronger material.

Computer Numerical Control (CNC) machines then precisely machine away excess material to create the final design specifications, including exact width, offset, and spoke patterns. The transformation can be dramatic - a Forgeline wheel might start at 100 pounds but finish at approximately 19.5 pounds after complete machining.

Final treatments enhance the wheel's performance and durability:

Heat treatment for enhanced mechanical properties

Micro shot-blasting for additional material compaction

Chromation treatment preventing rust formation

Finishing with paint or specialized coatings

This multi-stage process preserves the aluminum's natural grain alignment while eliminating potential failure points that plague other manufacturing methods.

Understanding the differences between wheel manufacturing methods helps explain performance variations and pricing structures:

Cast Wheels represent the most common production method. Manufacturers pour molten aluminum into molds and allow cooling and hardening. This affordable process creates wheels with granular aluminum structure that can fracture catastrophically upon severe impact.

Flow Formed Wheels offer a hybrid approach, starting with a cast wheel face but applying heat and rotational pressure to the barrel section. This process stretches and compresses the aluminum, creating wheels stronger than cast but not matching forged durability.

Forged Wheels achieve superior results through the compression process detailed above, delivering the strongest and lightest construction available.

Performance testing reveals significant differences between these methods. Fully forged wheels demonstrate approximately 3 times the strength of cast wheels while achieving 25-30% weight reduction. The uniform grain structure in forged wheels provides superior fatigue resistance and improved impact behavior - when damaged, forged wheels typically bend rather than shatter.

Manufacturing complexity directly correlates with cost differences. Forged wheel production requires specialized equipment, skilled technicians, and extended production time. Higher-grade raw materials and extensive machining processes add additional costs.

These manufacturing distinctions create a clear performance hierarchy. Forged wheels occupy the premium position, flow formed wheels provide middle-ground performance, and cast wheels serve as the baseline option for most vehicle applications.

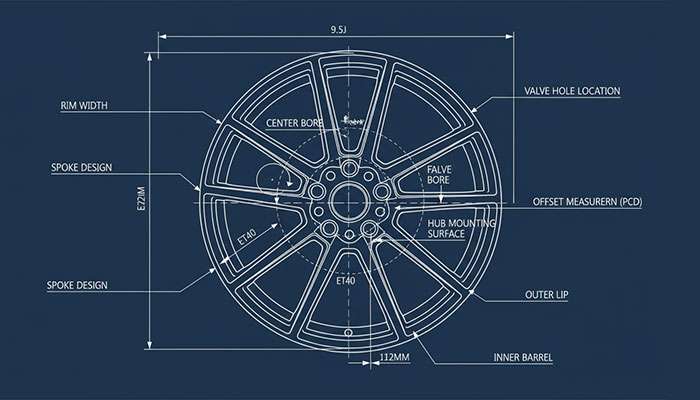

Image Source: ASM Tuning

Forged wheels deliver performance advantages that go far beyond appearance and status. When you're considering such a significant investment, understanding these genuine benefits helps determine whether they make sense for your vehicle and driving style.

The forging process creates wheels with exceptional resilience that cast alternatives simply cannot match. This compressed grain structure makes forged wheels approximately three times stronger than cast wheels while providing superior resistance to impacts and fatigue. The result? Wheels that can handle significantly more abuse before showing damage.

Impact testing reveals impressive durability advantages. Forged wheels withstand about 2.5 times as many curb hits before exhibiting serious damage. When damage does occur, forged wheels typically bend rather than shatter like cast wheels, making them potentially repairable. Racing teams report approximately 80% fewer wheel-related problems during extended competitions, which speaks volumes about their reliability under extreme conditions.

Here's where forged wheels really shine. They achieve superior strength while reducing weight by 25-30% compared to cast wheels. This weight reduction creates a cascade of performance improvements because rotating mass affects vehicle dynamics more than stationary weight.

Real-world testing confirms these performance gains:

• 60-0 mph braking distances improved by 1.2 car lengths • Lateral grip increased by 4.2% in skidpad tests

• Lap times reduced by up to 1.7 seconds at the Nürburgring circuit

The science behind these improvements centers on reduced rotational inertia and unsprung mass. Some wheel manufacturers estimate that every pound of unsprung weight reduction effectively mimics a 20-pound reduction in overall vehicle weight.

Surprisingly, forged wheels often improve both performance and comfort simultaneously. Their lighter construction allows suspension components to react more quickly to road imperfections, maintaining up to 18% better tire contact on uneven surfaces. This translates to measurable handling improvements during dynamic maneuvers.

Drivers consistently report more direct steering feel after installing forged wheels. The reduced unsprung mass requires less energy to change direction, creating more responsive handling without compromising ride quality. During high-speed transitions, drivers experience an 8-12% boost in responsiveness when moving through corners.

Beyond performance, forged wheels offer customization possibilities that cast wheels cannot achieve. The forging process enables intricate spoke patterns, deeper concavity, and sharper design elements without compromising structural integrity.

Many manufacturers provide virtually unlimited color options through high-quality powder coating. Multi-piece configurations allow different colors for the center, inner rim, and outer rim portions. Nearly every aspect—diameter, width, offset, finish, and spoke profile—can be tailored to your specific preferences.

Whether you're looking for subtle elegance or aggressive styling, forged wheels deliver options that complement any vehicle's personality while providing genuine performance benefits.

Image Source: Car tuning at Renegade Design

While forged wheels deliver impressive performance advantages, several important drawbacks deserve careful consideration before making such a substantial investment.

Let's address the obvious concern first - the price tag. Forged wheels typically start at thousands of dollars just to get your foot in the door. A complete set might cost between USD 1,000-5,000 or more—approximately half the retail cost. This premium pricing becomes especially challenging for vehicles in lower price brackets. If you drive a USD 10,000 daily vehicle, spending half that amount on wheels alone becomes questionable.

Selection presents another challenge. Not all designs are available in forged options, potentially limiting your aesthetic choices. Many forged wheels are custom made-to-order, resulting in longer wait times. This means you can't simply walk into a shop and drive out with your new wheels the same day.

Most everyday drivers won't experience the performance benefits that justify forged wheels' substantial cost. Unless you regularly track your vehicle or tackle harsh off-road conditions, the advantages remain largely theoretical. The vast majority of drivers won't experience sufficient performance gains to warrant the premium.

Consider this: the money saved by choosing more affordable wheel options could fund other modifications with more noticeable impacts—brake upgrades, suspension improvements, or higher-quality tires. These alternatives might deliver better value for typical driving conditions.

When damage occurs, fixing forged wheels presents unique challenges. The high-pressure manufacturing process creates tightly compressed metal molecules that complicate conventional repair methods. Even minor damage typically requires specialized skills and equipment, making repairs both costly and time-consuming.

Replacement can be equally problematic. Custom-ordered wheels may not be readily available off the shelf, potentially leaving you without your vehicle for extended periods. Some owners purchase spare wheels upfront to mitigate this risk, further increasing the total investment.

Aftermarket wheels are prime targets for thieves, and forged options with their premium price tags become especially attractive. The annual value of tires stolen nationwide exceeds USD 1 million. Experienced thieves can remove wheels in under 5 minutes, making them untraceable and pure profit.

Insurance companies typically increase premiums for vehicles with forged wheels due to:

Higher replacement costs

Increased theft risk

Potential performance modifications

Many insurers view aftermarket modifications unfavorably, sometimes resulting in premium increases up to 20% after theft-related claims. This ongoing cost adds to the total ownership expense beyond the initial purchase price.

Image Source: Forged Wheels

Selecting the right forged wheel construction depends on your specific requirements, driving habits, and performance goals. The construction method significantly impacts both performance characteristics and customization possibilities.

Monoblock forged wheels are machined from a single piece of aluminum, delivering unmatched strength-to-weight ratios. These one-piece designs excel in structural integrity since there are no seams or joints that could potentially fail. Multi-piece alternatives provide different advantages:

Monoblock wheels: Lightest available option; fixed size and offset limitations; complete replacement required if damaged; generally more affordable

2-piece wheels: Center section attached to barrel; moderate customization options; individual components can be repaired; balanced performance and style

3-piece wheels: Center plus separate inner and outer barrels; maximum customization of width, offset, and finish; heavier construction but highly repairable

Multi-piece construction allows mixing different components, creating virtually unlimited combinations of widths and offsets from a single wheel design.

Manufacturers typically categorize their forged offerings based on intended use. Track-focused wheels prioritize weight reduction and structural integrity above all other considerations. APEX's "Sprint Line" represents their lightest forged wheels, specifically engineered to improve lap times.

Street-oriented options like "Touring Line" wheels balance aesthetics with performance, optimizing designs without compromising visual appeal. For harsh driving conditions, "Enduro Line" wheels feature reinforced construction with higher load ratings and stronger inner lips designed to withstand abuse.

Factory-installed forged wheels undergo extensive testing to meet manufacturer specifications. OEM wheels prioritize reliability and balanced performance for typical driving conditions. They integrate seamlessly with vehicle systems but command premium pricing.

Aftermarket alternatives range dramatically in quality—from budget options to premium wheels that exceed OEM standards for specific applications. Premium aftermarket wheels often utilize multi-piece construction, offering greater design flexibility.

The fundamental difference? OEM wheels provide consistent quality and seamless integration, while aftermarket options deliver superior customization and potential performance gains. Your choice depends on whether factory reliability or enhanced performance matters more for your specific application.

Forged wheels aren't for everyone, but certain vehicle owners will find them to be the perfect upgrade. The decision comes down to your specific driving style, vehicle type, and performance goals.

Track enthusiasts and serious performance drivers see the biggest returns on forged wheel investments. The strength-to-weight advantages translate directly into lap time improvements and enhanced handling precision. Racing professionals choose forged wheels almost exclusively - you'll find them on championship-winning vehicles reaching speeds of 341.68 mph.

Regular track day participants and competitive motorsports drivers notice immediate handling improvements. The reduced unsprung mass makes a measurable difference when you're pushing your vehicle to its limits, making the investment worthwhile for serious performance driving.

Owners of premium vehicles valued over $70,000 represent the ideal forged wheel customer. High-end sports cars and luxury vehicles often come equipped with quality OEM wheels, so choosing anything less than forged would actually be a step backward.

Luxury manufacturers like Forgeline engineer wheels specifically for prestigious vehicles including the Hennessey Venom F5 and Ford GT. These applications benefit from both the performance gains and the extensive customization options that complement exclusive vehicles. When you own a six-figure car, forged wheels become a logical enhancement rather than an extravagance.

Daily drivers and entry-level sports cars rarely justify the premium cost. Cast or flow-formed alternatives deliver adequate performance for normal street use at significantly lower prices. One manufacturer puts it simply: "If you're daily driving an entry-level sports car, you likely won't realize the performance gains of forged wheels".

The durability benefits remain mostly theoretical for average street driving. Unless you're dealing with competitive environments or challenging terrain regularly, alternative wheel types make more economic sense. The money saved could fund brake upgrades, suspension improvements, or high-quality tires that deliver more noticeable benefits for everyday driving.

Forged wheels deliver genuine performance advantages that set them apart from standard wheel options. The manufacturing process creates wheels that are stronger, lighter, and more durable than cast alternatives . This isn't marketing hype – it's measurable engineering that translates to real performance gains.

The value equation comes down to your specific vehicle and driving needs. Track enthusiasts and performance car owners will notice substantial improvements in handling, braking, and acceleration. The reduced unsprung weight makes a meaningful difference during aggressive driving, and the enhanced durability provides confidence when pushing limits.

For daily drivers, the math changes completely. Cast or flow-formed wheels offer adequate performance for street use at a fraction of the cost. The money saved could fund brake upgrades, suspension improvements, or high-quality tires that deliver more noticeable benefits for everyday driving.

Our recommendation is straightforward: consider forged wheels if you regularly participate in track events or own a high-performance vehicle where the investment makes proportional sense. For most drivers, alternative wheel types provide better value for normal driving conditions.

When selecting any wheel type, consider your specific vehicle requirements, driving style, and performance goals. The right choice balances performance needs with budget reality. Whether you choose forged, flow-formed, or cast construction, proper fitment and quality materials matter more than the manufacturing method for most applications.

Understanding these differences helps you make informed decisions that enhance your vehicle's performance and appearance within your budget. We're here to help you find the perfect wheels for your specific needs and driving style.

Forged wheels offer superior performance but come with significant trade-offs that make them suitable only for specific applications and budgets.

• Forged wheels are 3x stronger and 25-30% lighter than cast wheels, delivering measurable performance gains in braking, handling, and acceleration

• The premium price tag of $3,000-$10,000+ per set makes financial sense only for high-performance vehicles valued over $70,000 or track enthusiasts

• Manufacturing process uses 8,000-10,000 tons of pressure to compress solid aluminum, creating aligned grain structure that bends rather than shatters on impact

• Daily drivers rarely justify the cost since cast or flow-formed wheels provide adequate performance for street use at fraction of the price

• Multi-piece forged designs offer maximum customization but monoblock versions provide the best strength-to-weight ratio for pure performance applications

For most drivers, the performance benefits don't translate to noticeable improvements in everyday driving. However, for serious performance enthusiasts and luxury car owners, forged wheels represent a worthwhile investment that delivers tangible handling improvements and enhanced durability under stress.

Forged wheels offer superior strength-to-weight ratio, being approximately 25-30% lighter yet 3 times stronger than cast wheels. This results in improved performance, including better acceleration, braking, and handling. They also provide enhanced durability and customization options.

For most daily drivers, forged wheels are often unnecessary and difficult to justify cost-wise. The performance benefits are rarely noticeable in everyday driving conditions. Cast or flow-formed wheels typically provide adequate performance at a much lower price point for regular street use.

With proper care and maintenance, forged wheels can last 10 years or more. Their durability and resistance to fatigue make them a long-lasting option, especially for performance-oriented drivers who subject their wheels to more stress.

Forged wheels are most beneficial for performance car owners, track enthusiasts, and luxury vehicle owners. They make sense for cars valued over $70,000 or those regularly used in high-performance driving scenarios where the strength and weight advantages translate to noticeable improvements.

Forged wheels outperform cast wheels in several areas. They're significantly lighter, which reduces unsprung mass and improves overall vehicle dynamics. Forged wheels also offer better strength and durability, especially under high-stress conditions. However, for typical street driving, the performance difference may not be as noticeable to justify the higher cost.