The first cars rolled on tires much like bicycles, until Michelin invented the pneumatic tire. Today's modern tire designs are only about 70 years old, a dramatic evolution from solid rubber that offered minimal cushioning.

Understanding car wheel components is crucial for every vehicle owner. Worn shock absorbers can increase your braking distance by 2 meters at just 30mph because your tires lose contact with the road. Your tire's performance directly affects how your vehicle handles different road conditions.

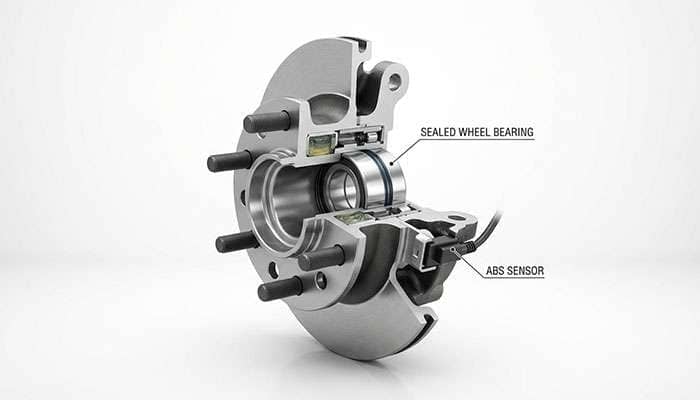

We'll break down every car wheel component from the outer tire to the central hub in this visual guide. The hub serves as the connection point where your wheel attaches to the vehicle's axle and houses critical elements like brake pads, calipers, and rotors. We'll also examine how wheel bearings provide low friction between turning wheels and stationary vehicle parts, allowing your wheels to spin freely.

Whether you're an automotive enthusiast or simply want to understand your vehicle better, this detailed breakdown of car wheel anatomy will give you the knowledge needed for proper maintenance and troubleshooting decisions.

Your wheel's outer structure combines several critical components that deliver traction, stability, and controlled air pressure. Each part serves specific functions that directly impact your vehicle's performance.

Your tire's tread pattern makes direct contact with the road surface, providing essential traction for acceleration, braking, and cornering. Different tread designs maximize grip, resist wear, and channel water away from the contact patch. The sidewall connects the tread to the bead area using flexible rubber compounds that add lateral stability while protecting internal components from road debris. Sidewall flexibility affects ride quality significantly—stiffer sidewalls handle heavier loads but create a firmer ride experience.

Modern wheels use two primary materials: steel or aluminum alloy. Steel wheels deliver exceptional durability at budget-friendly prices, typically ranging from $50-$150 each. Aluminum alloy wheels cost more but offer important advantages—they're lighter, dissipate brake heat better, and allow more intricate styling options, with prices ranging from $125-$500 per wheel. Premium options include carbon fiber wheels for extreme weight savings and titanium wheels for superior corrosion resistance, though both can cost thousands per wheel.

Tire beads create the secure anchor points between your tire and rim, forming an airtight seal against the wheel's mounting surface. Flanges—the flared edges on both sides of the wheel barrel—prevent tire slippage during cornering and impact situations. These components function as energy transfer points throughout your vehicle. Any imperfections here generate vibrations that you'll feel throughout the entire vehicle, particularly at highway speeds. Most wheels include mounting humps, which are small ridges circling the barrel to prevent tire movement away from the flanges.

Your valve stem provides the access point for adding or removing air from your tire. This component includes three main parts: the valve body, the pressure-regulating core with its spring-loaded pin, and the protective cap. The valve cap serves a crucial function by keeping dirt and moisture from entering the valve core, which can cause corrosion and air leaks. We recommend replacing valve stems with every tire installation since rubber components deteriorate over time.

Moving deeper into the wheel assembly reveals components that handle structural support and vehicle attachment. These hidden parts keep your wheels firmly connected while managing the stresses of daily driving.

Spokes form the essential connections between the rim and central plate, absorbing impacts from minor road hazards while providing structural integrity. Spoke designs vary extensively—from classic five-spoke patterns to intricate three-spoke configurations. Stability and strength depend heavily on both design and material choices.

The center cap sits where spokes meet, serving dual functions. It protects wheel components from dirt and harmful sunlight effects. Center caps also create a more uniform, finished appearance. Most wheel rims don't require center caps for proper function, but they remain worthwhile investments for vehicles parked in public areas.

Lug holes create a bolt circle on the centered disk where lug nuts attach. The diameter of this imaginary circle formed by these holes is called the bolt circle diameter. 4-bolt patterns measure straight across center-to-center, while 5-bolt patterns require special tools for accurate measurement.

Lug nuts serve as fasteners that screw onto threaded wheel studs, securing the wheel to the vehicle's axle. Cars typically have five lug nuts per wheel, while larger vehicles may have six or eight. The conical seat lug nut with a 60-degree or 45-degree taper remains the most common type, self-centering into the wheel's cone-shaped lug hole.

The wheel hub assembly attaches car wheels to the vehicle and enables free rotation. It plays a vital role in both anti-lock braking systems (ABS) and traction control systems (TCS). The hub frames the wheel's center, houses brake components, and secures tires using bolts and lug nuts.

Wheel studs come in two main configurations: hub-centric and lug-centric. Hub-centric designs rely on the center bore for accurate wheel positioning, while lug-centric designs use the lug nuts themselves for centering. Most factory wheels use hub-centric mounting for optimal balance and reduced vibration.

The connection between your wheels and vehicle chassis relies on precision-engineered components that handle massive forces while maintaining smooth rotation. Understanding these systems helps identify problems before they become dangerous.

Wheel bearings reduce friction between stationary and rotating parts, allowing your wheels to spin freely at highway speeds. Modern vehicles typically use sealed bearing units that require no maintenance during their service life. However, these bearings eventually wear out—usually between 85,000 and 100,000 miles depending on driving conditions.

Signs of bearing wear include grinding or humming noises that change with vehicle speed, steering wheel vibration, and uneven tire wear. Catching these symptoms early prevents more expensive damage to surrounding components.

Your hub assembly does more than just hold the wheel—it integrates directly with your braking system. The hub provides mounting points for brake rotors and houses sensors for ABS and stability control systems. This integration means hub problems can affect braking performance and trigger warning lights on your dashboard.

When replacing hub assemblies, technicians must ensure proper sensor alignment and brake component fitment. Aftermarket hubs may require additional hardware for complete compatibility with factory systems.

The axle transfers power from your transmission to the wheels while supporting vehicle weight. Front-wheel-drive vehicles use CV (constant velocity) axles with flexible joints that allow for suspension movement and steering angles. Rear-wheel-drive vehicles typically use solid axles or independent rear suspensions with half-shafts.

The spindle provides the mounting point for wheel bearings and connects to suspension components. Spindle damage from impacts or accidents requires immediate professional assessment—bent spindles cause alignment problems that no adjustment can correct.

Regular inspection catches problems early and prevents costly repairs. Knowing what symptoms indicate specific issues helps you communicate effectively with service technicians.

Tread depth directly affects your safety on wet roads. Use a tread depth gauge or try the quarter test—when Washington's head stays partially covered, you still have at least 4/32" of tread. A pickup truck stopping from 70 mph takes 122 feet longer with worn 2/32" tread versus 4/32" depth. Watch for these wear patterns that signal specific problems:

Inner or outer edge wear: Camber alignment needs adjustment

Center tread wear: Your tires are overinflated

Both edges worn: Underinflation is the culprit

Cupping or scalloping: Suspension components are wearing out

These services solve different problems. Wheel alignment adjusts your wheel angles to manufacturer specs, stopping pulling and preventing uneven tire wear. Looking for new wheels that maintain proper alignment? Get the best deal on your car wheels at Performance Plus Tire. Balancing fixes weight distribution by adding small metal weights, eliminating annoying vibrations. Check alignment twice yearly or every 6,000 miles. Balance your wheels every 5,000-7,000 miles.

Bent rims cause the most wheel problems, especially during pothole season. Replace wheels immediately if they have:

Major cracks or fractures

Previous failed repairs

Heavy corrosion affecting the tire seal

Any damage that compromises safety

Light scratches, small dents, or cosmetic damage can usually be repaired. Consider the costs—steel wheels typically cost under $100 to replace, while alloy wheels start at twice that amount.

Monthly inspections catch problems before they become expensive. Look for unusual smooth areas, irregular wear patterns, and embedded objects in your tires. Check rims for cracks, corrosion, or bending. Verify lug nuts have proper torque—loose nuts create dangerous vibrations while over-tightened ones strip threads. Beads and flanges work as "energy transfer points," so even small imperfections here create vibrations throughout your vehicle at highway speeds.

Understanding car wheel components helps you make better maintenance decisions and spot problems before they become expensive repairs. Each part serves a specific purpose—from tire tread that grips the road to the hub that connects everything to your vehicle's axle. This knowledge allows you to make informed choices about repairs versus replacements when issues arise.

Regular inspection of your wheel components prevents costly damage and keeps you safe on the road. Check your tires monthly for unusual wear patterns that signal alignment issues. Pay attention to your wheel bearings, as they directly affect how smoothly your vehicle handles during turns and at highway speeds.

Wheel technology has evolved dramatically from wooden wheels to today's advanced assemblies. Modern wheels balance strength, weight efficiency, and style whether you choose traditional steel wheels or lightweight aluminum alloys. Proper maintenance extends their lifespan significantly.

Consider your driving habits, local road conditions, and budget when making wheel-related decisions. You can get the best deal on your car wheels without compromising quality or safety when you understand exactly what your vehicle needs.

Your wheels carry the weight of your entire driving experience. Taking care of them through regular inspections, proper inflation, and timely maintenance saves money and ensures safety on every journey. While some wheel issues require professional attention, this guide has equipped you with the knowledge to better understand your vehicle's connection to the road.

Understanding your car wheel components is crucial for vehicle safety, maintenance decisions, and cost-effective repairs. From the tire tread that provides road grip to the hub assembly that connects to your axle, each part plays a vital role in your driving experience.

• Tire tread depth directly impacts safety - vehicles need at least 4/32" tread depth, as worn tires can increase braking distance by 122 feet at highway speeds

• Regular visual inspections prevent costly repairs - check monthly for unusual wear patterns, cracks, or embedded objects that indicate alignment or suspension issues

• Wheel alignment and balancing serve different purposes - alignment prevents pulling and uneven wear, while balancing eliminates vibrations through proper weight distribution

• Know when to repair versus replace wheels - minor cosmetic damage can be repaired, but cracks, fractures, or safety-compromising damage requires immediate replacement

• Proper maintenance extends wheel lifespan significantly - maintaining correct tire pressure, checking lug nut torque, and addressing issues early saves money and ensures road safety

Understanding these fundamentals empowers you to make informed decisions about wheel maintenance, recognize warning signs before they become dangerous, and communicate effectively with mechanics about necessary repairs.

A car wheel consists of several key parts, including the tire, rim, hub, spokes, and valve stem. The tire provides traction, the rim supports the tire, the hub connects the wheel to the axle, spokes offer structural support, and the valve stem allows for air pressure control.

It's recommended to check your tire tread depth monthly. A simple way to do this is the quarter test - if Washington's head is partially covered when inserted into the tread, you have at least 4/32" of tread remaining, which is considered safe for most driving conditions.

Wheel alignment adjusts the angles of your wheels to manufacturer specifications, preventing pulling and uneven tire wear. Wheel balancing, on the other hand, corrects weight distribution by adding small metal weights to wheels, eliminating vibrations. Alignment should be checked twice yearly, while balancing is recommended every 5,000-7,000 miles.

You should replace your wheels if they have major cracks or fractures, significant corrosion affecting the tire seal, or any damage that compromises safety. Minor issues like light scratches or small dents can often be repaired. However, if the repair cost approaches the price of a new wheel, replacement might be more cost-effective.

Signs of a bad wheel bearing include unusual noises like grinding or humming, especially when turning or accelerating. You may also experience vibrations in the steering wheel or through the floorboard, or notice your vehicle pulling to one side while driving. If you suspect a bad wheel bearing, it's important to have it checked by a professional as it can affect your vehicle's handling and safety.