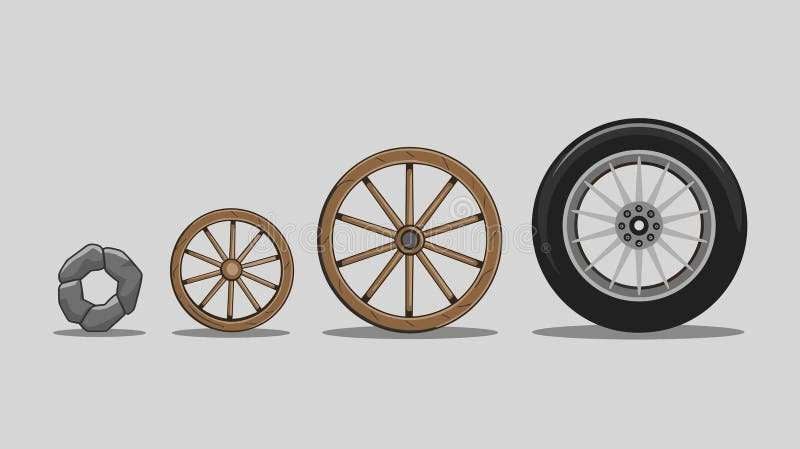

Tire evolution spans over 5,000 years of human innovation, beginning with simple wooden disks around 3500 BC [8]. These early wheels bore little resemblance to the advanced rubber technology we depend on today. For thousands of years, transportation relied on these basic wooden designs before any major developments occurred.

The history of tires took a dramatic shift in the mid-19th century with the development of the first rubber tires [10]. The most significant breakthrough came in 1845 when Robert Thomson invented the pneumatic tire, greatly improving both comfort and durability [11]. John Boyd Dunlop later popularized this innovation in 1888 when he patented pneumatic tires for bicycles [10], the same year Carl Benz created a new type of tire for his automobile [12].

Several key developments stand out as true game-changers in the tire evolution timeline. Charles Goodyear's discovery of vulcanization in 1839 gave rubber unprecedented elasticity and durability [8]. DuPont's successful production of synthetic rubber in 1931 changed the industry forever [12] [12]. Michelin's introduction of radial tires in 1946 [11] and tubeless radial tires in the late 1940s [12] created the foundation for modern tire manufacturing we see today.

These innovations, from wooden wheels to smart rubber, have changed how we travel and enabled the creation of vehicles that can produce a complete tire every 28 seconds [12]. We'll explore the fascinating history of one of transportation's most essential components and how each breakthrough has shaped the way we drive.

Image Source: Dreamstime

The concept of the wheel emerged around 3500 BC in Mesopotamia [1]. These earliest versions bore little resemblance to today's tires, yet they established the foundation for one of humanity's most practical inventions.

Early wheels started as remarkably simple devices—solid wooden disks cut from tree trunks with parallel faces [12]. These primitive structures demanded substantial trees and created heavy, uncomfortable rides. Craftsmen developed more sophisticated designs as civilizations advanced.

The spoked wheel appeared around 2000 BC [3], allowing for larger diameter wheels built from smaller trees. This design significantly reduced weight while maintaining strength. The innovation required precise calculations and spacing, creating a new profession—specialized wheelwrights dedicated to wheel construction [13].

Wooden wheels faced serious durability challenges as transportation needs grew. Around 1000 BC, wheelwrights began applying iron bands to wooden wheels to increase their longevity [8]. This process demanded skillful craftsmanship. A wheelwright would heat the iron in a forge fire until it expanded, place it over the wheel, then quench it in water. The metal contracted upon cooling, creating a tight-fitting protective band [14].

Despite this improvement, these wheels provided notoriously uncomfortable rides. "Bone-crushers" earned their nickname from both their jarring ride quality and tendency to throw riders [15]. The iron bands helped with durability but did nothing for comfort.

True tire evolution began in the mid-19th century with solid rubber strips fitted to wagon wheels, offering slightly improved comfort [10]. Robert William Thomson patented what appears to be the first standard pneumatic tire in 1845, though this design never entered production [14].

The breakthrough came in 1888 when John Boyd Dunlop, a Belfast veterinary surgeon, invented practical pneumatic tires for his son's tricycle after watching him struggle on cobblestone streets [10]. That same year, Karl Benz introduced the first petrol-powered automobile, which used Dunlop's pneumatic design [9]. This timing proved perfect—the automobile and modern tire were born together.

"The invention of the vulcanization process revolutionized the rubber industry" — Charles Goodyear, Inventor of vulcanized rubber, foundational figure in the modern tire industry

Image Source: Country Life

The mid-19th century brought three remarkable innovators who solved critical problems that had plagued wheel technology for centuries. Each breakthrough built upon the previous one, creating the foundation for modern tire technology.

Charles Goodyear faced a problem that had stumped inventors for decades. Natural rubber became brittle in cold weather and turned into sticky goo when hot. After years of financial struggles and countless experiments, Goodyear accidentally discovered the solution in 1839 while working at the Eagle India Rubber Company in Massachusetts. He noticed that combining rubber with sulfur over a hot stove created a completely different material [8].

This breakthrough process, which Goodyear named vulcanization after Vulcan, the Roman god of fire, allowed rubber to maintain its flexibility across temperature extremes [9]. When Goodyear received his patent in 1844 [8], he had essentially unlocked rubber's potential. Most importantly for tire development, this process made rubber impermeable to air—a crucial requirement for the pneumatic tires that would follow [10].

Despite creating an industry worth millions, Goodyear died in 1860 still owing more than $200,000 [11]. His invention would prove far more valuable than he ever realized.

Scottish inventor Robert William Thomson tackled the next challenge just one year after Goodyear's patent. At only 23 years old, Thomson created the first pneumatic tire in 1845 [12]. His "Aerial Wheel" featured a hollow belt of India-rubber filled with air, protected by a leather outer casing bolted to the wheel [12].

Thomson's design proved remarkably effective during London demonstrations in Regent's Park in 1847. One set of his tires lasted an impressive 1,200 miles without showing deterioration [12]. The problem wasn't performance—it was economics. Rubber remained expensive, and demand for advanced wheel technology was limited. Thomson's innovation stayed largely a curiosity rather than a commercial success [3].

Practical application came forty-three years later when Scottish veterinarian John Boyd Dunlop faced a simple parenting challenge. His son struggled to ride his tricycle smoothly over Belfast's rough cobblestone streets. In 1887, Dunlop wrapped the wheels in thin rubber sheets, glued them together, and inflated them with a football pump [13].

Dunlop's backyard experiments revealed the clear advantages of his design. When he rolled his pneumatic wheel alongside a traditional metal one across his yard, the pneumatic version continued rolling until it hit his gatepost [14]. He patented this practical solution in 1888 [15], establishing what would become the Dunlop Rubber Company.

The timing couldn't have been better. Dunlop's innovation coincided perfectly with the bicycle boom, and his tires quickly proved their superiority in cycling competitions [9]. This success laid the groundwork for automotive applications that would follow.

The early 20th century marked a turning point in tire development as manufacturers began implementing crucial innovations that shaped our modern driving experience.

Prior to 1905, tires featured smooth surfaces that offered limited grip on road surfaces. The introduction of tread patterns that year solved this critical safety issue by providing improved stability and longevity [16]. These patterns protected the tire carcass from direct road contact while significantly improving the tire's friction coefficient [4]. This seemingly simple design change created the foundation for safer driving on various road conditions.

Low-pressure balloon tires emerged in 1923 with a greater contact area with road surfaces [4]. These larger tires absorbed road imperfections more effectively than their predecessors, offering drivers a smoother ride quality. However, they presented new challenges. Automobile engineers discovered they increased resistance to steering, particularly at curbs, and created a "galloping action" at high speeds [6]. Despite these drawbacks, balloon tires represented an important step toward improved comfort.

Building on earlier developments, DuPont's industrialization of synthetic rubber in 1931 [16] became critical during WWII when the United States lost access to 90% of the world's natural rubber [2]. This innovation addressed supply limitations that could have crippled transportation. By 1945, America was producing about 920,000 tons annually, with 85% being synthetic [2]. Mass production capabilities ensured tire availability during crucial periods.

Michelin's radial tire design in 1946 [16] arranged cords vertically to the driving direction with steel belts underneath the tread [4]. Unlike conventional designs, radials provided superior fuel economy through uniform road contact and delivered better handling even at high speeds [4]. This engineering breakthrough established the standard for modern tire construction.

BF Goodrich secured a patent for tubeless tires in 1952, eliminating the need for inner tubes [16]. The design featured continuous ribs molded into the tire bead that air pressure forced against the wheel rim, creating an airtight seal [17]. This advancement offered significant safety benefits—if punctured, tubeless tires deflated gradually rather than suddenly bursting [17]. The improvement reduced dangerous blowouts and provided drivers with better control during tire failures.

Image Source: New Atlas

Modern tire technology has reached an exciting era of innovation. Safety and sustainability now drive the industry forward, creating solutions that would have seemed impossible just decades ago.

Run-flat tires (RFT) first appeared in the mid-1980s and have changed roadside safety forever. These tires feature reinforced sidewalls that allow drivers to continue traveling up to 50 miles at speeds of 50 mph after complete air pressure loss [18]. Unlike conventional tires, they maintain stability during punctures, helping drivers keep better control in emergency situations [18].

Many new vehicles now come equipped with run-flat technology paired with tire pressure monitoring systems (TPMS) [19]. This combination eliminates dangerous roadside tire changes and provides peace of mind for drivers.

Tire manufacturers are developing eco-friendly alternatives using sustainable materials that deliver real-world benefits. The Department of Energy estimates that 4 to 11 percent of fuel consumption comes from tire rolling resistance [5]. A 10 percent reduction in rolling resistance can improve fuel economy by about 1 percent [5].

Companies like Goodyear have created demonstration tires containing up to 90% sustainable materials, including recycled PET bottles, bio-oils, and rice husk silica [7]. These advances prove that environmental responsibility doesn't require performance sacrifices.

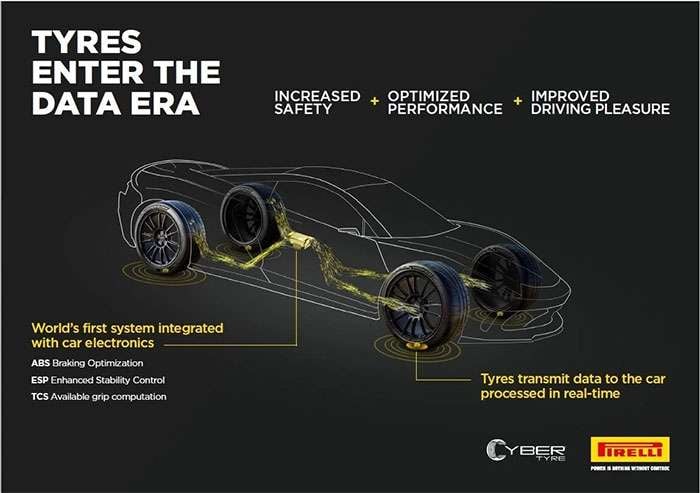

Smart tire technology now incorporates sensors that monitor pressure, temperature, and tread wear [20]. These IoT-connected devices transmit data to mobile applications, allowing drivers to track tire health in real-time [21].

Tire companies are using AI for development processes, with manufacturers like Nexen creating virtual reality simulations to test performance without physical prototypes [22]. This technology acceleration means better tires reach the market faster than ever before.

Graphene stands out among innovative materials for extraordinary tire enhancement. Adding less than 1% by volume can increase tensile strength by 40% and improve abrasion resistance by up to 500% [23]. Graphene also improves thermal conductivity, helping tires dissipate heat more effectively [23].

This wonder material enhances key attributes without traditional tradeoffs between traction, wear, and durability [23]. For drivers, this means longer-lasting tires that perform better in all conditions.

The tire has traveled an incredible distance from its wooden beginnings in ancient Mesopotamia. Solid wooden disks evolved to iron-banded wheels, but the real momentum came with Goodyear's vulcanization process. This discovery made rubber durable enough for practical use, setting the stage for Thomson and Dunlop's pneumatic innovations that changed transportation forever.

Tire technology accelerated dramatically throughout the 20th century. Tread patterns improved grip and safety significantly. Balloon tires enhanced comfort despite steering challenges. Synthetic rubber production solved critical supply issues during wartime shortages. Radial designs and tubeless construction created the foundation for modern tires we depend on today.

Recent decades have brought even more impressive advancements. Run-flat technology has eliminated many dangerous roadside tire changes. Eco-friendly materials address growing environmental concerns. Rolling resistance improvements translate directly to better fuel economy, making every journey more efficient.

Today's smart tires show how far we've come from those primitive wooden wheels. Equipped with sensors that monitor everything from pressure to tread wear, these technological marvels communicate vital information directly to drivers. Advanced materials like graphene push performance boundaries that were previously impossible.

Tire evolution reflects our persistent drive to improve, adapt, and overcome limitations. Though often overlooked, these circular innovations have carried human progress forward. The next time you drive, take a moment to appreciate these engineering marvels that connect you to the road – they represent thousands of years of innovation in circular form.

The evolution of tires spans over 5,000 years of human innovation, transforming from simple wooden disks to sophisticated smart technology that revolutionizes modern transportation.

• Vulcanization breakthrough: Charles Goodyear's 1839 discovery made rubber durable and air-impermeable, enabling all modern tire development.

• Pneumatic revolution: John Boyd Dunlop's 1888 air-filled tires provided the comfort and performance foundation for today's vehicles.

• Radial design advantage: Michelin's 1946 radial tires improved fuel economy and handling through superior road contact and steel belt construction.

• Smart tire integration: Modern tires use IoT sensors and AI to monitor pressure, temperature, and wear in real-time for enhanced safety.

• Sustainable innovation: Advanced materials like graphene increase tire strength by 40% while eco-friendly compounds reduce rolling resistance and fuel consumption.

The tire industry continues pushing boundaries with run-flat technology, synthetic materials, and smart connectivity, proving that even the most fundamental transportation components can drive remarkable technological progress.

Tire technology has progressed significantly from wooden wheels to modern smart rubber. Key advancements include the vulcanization process, pneumatic tires, radial designs, and the integration of sensors and AI for real-time monitoring. Recent innovations focus on eco-friendly materials and improved performance characteristics.

Rubber tires were first introduced in the mid-19th century. The breakthrough came in 1845 when Robert Thomson invented the pneumatic tire, which was later popularized by John Boyd Dunlop in 1888 for bicycles. These innovations laid the foundation for modern rubber tires.

Rubber is used for tires because of its durability, elasticity, and grip. It can withstand wear and tear better than materials like wood, provides a smoother ride, and offers better traction on various surfaces, including wet roads. The vulcanization process also makes rubber impermeable to air, which is crucial for pneumatic tires.

Radial tires, introduced by Michelin in 1946, revolutionized tire technology. They arrange cords vertically to the driving direction with steel belts under the tread, providing better fuel economy through uniform road contact and improved handling at high speeds. This design has become the standard for modern tires.

Smart tires incorporate sensors that monitor pressure, temperature, and tread wear in real-time. These IoT-connected devices transmit data to mobile applications, allowing drivers to track tire health. Additionally, the integration of AI in tire development and the use of advanced materials like graphene are enhancing tire performance, safety, and sustainability.

[1] - https://www.tyrescart.ae/en/blog/how-tires-have-evolved-from-early-designs-to-modern-solutions

[2] - https://thetireterminal.com/tires/a-brief-history-of-the-automobile-tire/

[3] - https://www.airlandtyre.com/knowledge/tyreguide/the-history-of-vehicle-tires.html

[4] - https://martintire.com/the-incredible-evolution-of-tires/

[5] - https://dyler.com/blog/68/tire-evolution-from-a-piece-of-rubber-to-ultrahigh-performance-in-a-century

[6] - https://en.wikipedia.org/wiki/Wheel

[7] - https://www.tellurerota.com/en/evolution-industrial-wheels-over-centuries

[8] - https://www.britannica.com/technology/wheel

[9] - https://en.wikipedia.org/wiki/Wheelwright

[10] - https://en.wikipedia.org/wiki/Tire

[11] - https://www.intrans.iastate.edu/news/two-wheels-a-history/

[12] - https://whattyre.com/news/reinventing-the-wheel-a-brief-history-of-tires/

[13] - https://en.wikipedia.org/wiki/Charles_Goodyear

[14] - https://reightgoodbikes.co.uk/history-pneumatic-tire-inner-tube/

[15] - https://www.rubbernews.com/assets/PDF/RN10851616.PDF

[16] - https://connecticuthistory.org/charles-goodyear-and-the-vulcanization-of-rubber/

[17] - https://en.wikipedia.org/wiki/Robert_William_Thomson

[18] - https://www.historic-uk.com/HistoryUK/HistoryofScotland/Robert-William-Thomson/

[19] - https://www.dunloptires.com/about-us/our-brand

[20] - https://en.wikipedia.org/wiki/John_Boyd_Dunlop

[21] - https://www.invent.org/inductees/john-boyd-dunlop

[22] - https://trust-bridges.com/important-dates-in-the-history-of-tires/

[23] - https://burtbrothers.com/tips/history-of-tires-3/

[24] - https://www.nytimes.com/1924/04/27/archives/balloon-tires-in-crease-motor-industry-problems-how-manufacturers.html

[25] - https://www.applerubber.com/blog/how-is-synthetic-rubber-made/

[26] - https://en.wikipedia.org/wiki/Tubeless_tire

[27] - https://www.bridgestonetire.ca/learn/tire-technology/run-flat-tires/

[28] - https://www.michelin.ca/en/auto/learn/tires-101/runflat-tires

[29] - https://www.consumerreports.org/cars/tires/low-rolling-resistance-tires-can-save-you-money-at-pump-a1547901110/

[30] - https://www.prnewswire.com/news-releases/goodyear-unveils-90-sustainable-material-demonstration-tire-approved-for-road-use-301713430.html

[31] - https://www.velvetech.com/case-studies/smart-tires-iot-product-development/

[32] - https://www.bitdefender.com/en-us/blog/hotforsecurity/smart-tires-use-iot-sensors-send-vital-data-right-phone

[33] - https://newsroom.nexentire.com/press-releases/nexen-tire-utilizes-virtual-reality-and-artificial-intelligence-in-r-d/s/686aaddf-b1e8-415f-977d-bb0ca2502994

[34] - https://www.thegraphenecouncil.org/page/Rubber