Custom rims can dramatically transform your vehicle's appearance and performance. Safety rims dominate passenger cars for their reliability, while split rims handle the demanding needs of heavy-duty vehicles, and beadlock rims excel in off-road adventures where standard wheels would fail.

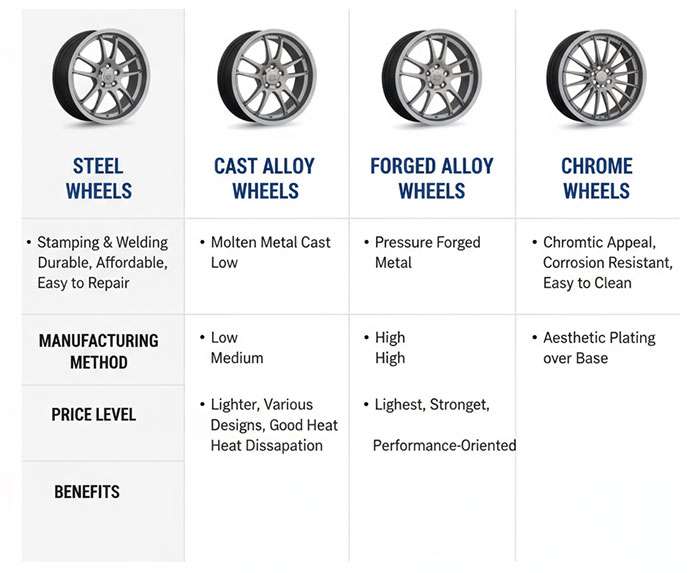

At Performance Plus Tire, we understand that rim materials play a crucial role in your selection process. Steel wheels deliver exceptional durability for everyday drivers through their robust, welded construction, though they carry more weight than other options. Aluminum alloy rims provide superior handling benefits with their lighter weight construction while offering unique designs and finishes that let you personalize your ride. For ultimate performance enthusiasts, forged wheels represent the pinnacle of strength-to-weight engineering.

We know choosing the right rim type can feel overwhelming with so many options available. Our expert team is ready to help you find the perfect match for your vehicle, whether you're prioritizing long-lasting durability, eye-catching style, enhanced performance, or budget-friendly value. This guide will walk you through each rim type so you can make the best choice for your specific driving needs.

Safety rims serve as the backbone of modern passenger vehicle wheel technology. These specialized wheels feature distinctive inward bumps or "humps" that extend from the outer contoured surface toward the opposite tire bead seat. This unique design creates a mechanical advantage that secures the tire to the rim even when conditions turn dangerous.

The primary function of these bumps is straightforward yet critical - they hold the tire bead firmly in place while keeping it away from the outer rim edge. This simple design element provides an essential safety feature that prevents dangerous situations on the road.

Federal Motor Vehicle Safety Standards (FMVSS) strictly regulate safety rim construction. FMVSS No. 110, which applies specifically to passenger cars, requires these rims to meet two fundamental standards:

Construction must follow dimensions specified by recognized organizations like the Tire and Rim Association, The European Tire and Rim Technical Organization, or the Japan Automobile Tire Manufacturers Association

During emergency situations - particularly rapid inflation pressure loss while traveling at 60 miles per hour in a straight line - the rim must retain the deflated tire until the driver can safely stop with controlled braking

Unlike rims for other motor vehicles, passenger car safety rims don't require specific markings under federal standards. This distinction highlights different regulatory approaches between passenger and commercial vehicle wheels.

Safety rims dominate passenger vehicles because of their exceptional performance during emergency situations. Their ability to retain a deflated tire at high speeds gives drivers crucial control during potentially catastrophic tire failures.

These rims gained widespread adoption through their compatibility with tubeless tire technology, which dominates today's passenger vehicle market. Together, they create a system that maintains structural integrity even under compromised conditions. This combination has proven particularly effective at reducing accidents related to sudden tire deflation.

The regulatory framework established by the National Highway Traffic Safety Administration (NHTSA) played a significant role in standardizing safety rims across the passenger vehicle industry. Setting specific performance requirements without mandating particular design elements allowed manufacturers to innovate while ensuring baseline safety standards.

Extensive testing demonstrates the design's effectiveness. Safety rims enable drivers to travel up to 5 miles at 5 mph on a completely flat tire. While this capability has limitations, it represents a vital safety margin that can mean the difference between a controlled stop and dangerous loss of vehicle control.

Safety rims excel in everyday driving conditions where unexpected road hazards pose constant threats. Their primary advantage becomes apparent during sudden tire pressure loss scenarios - precisely when drivers need reliable wheel performance most.

These rims prove especially valuable for:

Daily commuting vehicles where tire damage might occur from road debris or potholes

Family cars where safety redundancies provide peace of mind

Urban driving environments with frequent curb contact that might damage wheels or tires

The effectiveness of safety rims depends heavily on proper tire maintenance. As tire pressure decreases, the rim's ability to hold the tire bead securely diminishes. Regular tire pressure checks remain essential even with safety rim technology.

Many safety rims now incorporate additional protection features for drivers concerned about potential rim damage from curbs and road hazards. Some designs include raised ribs adjacent to the bead area on their lower sidewalls, while others feature deeply recessed bead areas that partially envelop the wheel flange. These design innovations provide extra protection for both the tire and the more expensive alloy wheels commonly found on today's vehicles.

Safety rims represent the default choice for passenger vehicles, but they may not suit all applications. Heavy-duty vehicles, off-road enthusiasts, and specialized equipment often benefit from alternative rim types better suited to their particular demands. Split rims offer advantages for larger vehicles, though they come with their own safety considerations.

Safety rims deliver an optimal balance between everyday usability, emergency performance, and regulatory compliance for most passenger vehicles. Their widespread adoption reflects both their practical benefits and their proven track record for enhancing road safety across millions of miles driven daily.

Split rims take a fundamentally different approach from the one-piece wheels found on passenger vehicles. These multi-piece wheels excel in commercial and industrial applications where heavy-duty performance and easy serviceability matter more than appearance.

Split rims consist of separate components that work together to secure the tire. The basic design includes a rim base and a detachable side ring or locking ring that holds the tire in place. This allows tire changes without removing the entire wheel from the vehicle—a crucial advantage in demanding work environments.

Split rim configurations vary based on application needs:

Two-piece split rims: Feature a rim base and detachable side ring for straightforward assembly and disassembly.

Three-piece split rims: Include base rim plus side rings and lock rings for enhanced security under heavy loading conditions.

Four-piece splits: Add bead seat rings to base rings, side rings, and lock rings for maximum tire security and slip prevention.

The locking mechanism distinguishes these wheels from standard designs. Many use a split side ring with a gap that sits between rim and tire, functioning as the lock ring. Other designs feature dual bolt systems—one set secures the wheel to the hub while another fastens the split rim components together.

These specialized wheels rarely appear on passenger cars. Instead, they dominate trucks, tractors, forklifts, and heavy equipment in construction and mining operations. Several practical reasons drive this application focus.

Maintenance efficiency tops the list of advantages. Industrial environments demand frequent tire replacements due to intense wear and tear. Split design allows mechanics to change tires quickly without removing the entire wheel assembly, reducing downtime and keeping equipment operational.

The robust construction handles high pressure and weight loads that overwhelm standard one-piece rims. This strength proves essential for vehicles carrying substantial cargo or operating in harsh environments where wheel failure isn't an option.

Split rims also offer remarkable versatility across vehicle types—from agricultural equipment to military vehicles. This adaptability becomes invaluable in remote worksites where specialized equipment availability may be limited.

Cost benefits come through the modular design. When damage occurs, operators can replace individual components instead of entire wheel assemblies. For fleet operators in construction, mining, or agriculture, this component-level repair capability significantly reduces maintenance budgets.

Split rims present serious safety hazards that require strict protocols. The primary danger involves catastrophic failure under pressure.

These rims can explosively separate, violently releasing high-pressure air and ejecting components at extreme speeds. The explosive force compares to small explosive devices, with parts potentially traveling at speeds up to 130 mph. Such violent separations cause serious injuries and fatalities.

Several factors create these dangerous failures:

Mismatched components increase risk dramatically. Documented incidents show split side rings with illegible markings from paint led to catastrophic accidents when paired with incompatible rim bases.

Improper assembly or inadequate ring seating creates conditions where pressurized air forcefully ejects components.

Corrosion, wear, or component damage compromises structural integrity, causing unexpected failures even after months of normal operation.

Reinflating tires run below 80% recommended pressure without proper inspection and disassembly.

Proper safety protocols are absolutely essential:

Use restraining devices or tire cages during inflation to contain explosive separations

Completely deflate tires before removing fasteners or disassembling components

Follow proper inspection procedures, marking damaged parts as unserviceable

Use appropriate tools including special tire spoons and non-marring hammers designed for split rim work

Ensure training and certification for all personnel working with these assemblies

Many modern tire shops refuse split rim service, referring customers to specialized heavy truck or agricultural facilities with proper training and equipment. When handled correctly by trained professionals with appropriate safety equipment, split rims continue providing valuable service in industries where their advantages outweigh inherent risks.

Serious off-road enthusiasts know that standard wheels simply can't handle the extreme conditions where beadlock rims truly shine. Originally developed for military use as "combat wheels," these specialized rim types have become essential equipment for tackling the most demanding terrain where conventional wheels would leave you stranded.

Beadlock wheels excel where conventional wheels fail - specifically when extremely low tire pressures are necessary for maximum traction. Off-road drivers frequently "air down" their tires to as low as 5-8 PSI when traversing challenging terrain like rock crawling, sand dunes, or mud bogs. Standard wheels risk having the tire bead slip off the rim at these drastically reduced pressures, potentially causing sudden deflation and loss of vehicle control.

The defining feature of true beadlock wheels is their mechanical clamping system rather than relying solely on air pressure to maintain the tire bead against the rim. This design creates a physical barrier that prevents the tire bead from moving inward under lateral forces, maintaining seal integrity even when internal pressure drops significantly.

True beadlock wheels feature a functional external clamping ring that physically secures the tire bead to the wheel. This outer ring is removable and typically uses between 24-32 bolts to create the necessary clamping force. This construction differs completely from "fake" or simulated beadlock wheels that merely mimic the appearance without providing actual mechanical bead retention.

Beadlock wheels are most commonly used in:

Rock crawling and extreme off-road trails

Desert racing and high-performance off-road competition

Military applications requiring tire integrity in combat situations

Situations where maximizing traction through very low tire pressure is essential

The mechanics of beadlock wheels follow a straightforward but precise process that physically prevents tire dismounting under load. Unlike conventional wheels where air pressure pushes the tire bead against the rim flange, beadlocks use direct mechanical force to secure the tire.

Installation follows a specific process:

The tire's inner bead is mounted normally on the wheel's inner bead seat

The outer bead is positioned against the wheel's outer mounting surface

A beadlock ring is placed over the tire's outer bead

Multiple bolts are installed in a specific pattern and torqued to specification

This creates a mechanical clamp that physically prevents the tire from separating from the wheel

This clamping mechanism proves particularly valuable in two critical situations. First, during extreme off-road maneuvers where lateral forces might otherwise push the tire bead inward. Second, at very low tire pressures that would normally be insufficient to maintain the bead seal.

The physics become clear when understanding conventional tire mounting. Without a beadlock, the tire relies entirely on air pressure forcing the beads outward against the wheel flanges. As pressure decreases, this force diminishes until the bead can slip inward, causing immediate deflation. With beadlocks, even at pressures as low as 5 PSI, the mechanical clamp maintains a perfect seal.

Despite their performance advantages, beadlock wheels face significant regulatory hurdles for on-road use. Most beadlocks with external clamping rings are not street-legal because they fail to meet Federal Motor Vehicle Safety Standard (FMVSS) 139, which governs pneumatic tires for light vehicles.

The primary regulatory concern stems from two requirements in the CFR (Code of Federal Regulations) Title 49:

Wheels must be constructed to dimensions listed by tire manufacturers as suitable

During rapid pressure loss at highway speeds (60 mph), the rim must retain the deflated tire until the vehicle can be stopped with controlled braking

Traditional external beadlock designs typically cannot meet these requirements. However, some newer technologies like internal beadlock systems from companies such as Hutchinson have developed DOT-compliant alternatives. These place the beadlock mechanism inside the wheel where it doesn't interfere with DOT testing protocols.

Weight represents another significant consideration with beadlock wheels. The additional hardware required to secure the locking ring adds substantial heft compared to conventional wheels. Some Mopar beadlock wheels weigh approximately 37.4 pounds with the ring and screws installed, with the ring alone accounting for 3.3 pounds. Other models range from 34-46 pounds depending on design and materials.

This added weight creates several practical implications:

Increased unsprung weight affecting handling

Reduced fuel economy

Additional stress on suspension components

Maintenance demands further complicate beadlock ownership. Unlike conventional wheels that are essentially maintenance-free after installation, beadlocks require:

Regular bolt torque checks before and after off-road use

Periodic bolt replacement due to fatigue

Meticulous installation with proper torque specifications to prevent failure

Beadlock wheels represent a specialized solution for specific off-road challenges rather than an everyday upgrade for most drivers. Their unique capabilities must be weighed against their legal limitations, added weight, and ongoing maintenance requirements.

Alloy rims represent today's most popular wheel upgrade, combining stunning visual appeal with genuine performance improvements. These sophisticated wheels have transformed from luxury items to mainstream options, now appearing on everything from compact cars to high-performance vehicles.

Alloy wheels are crafted from a blend of aluminum with other metals such as magnesium, nickel, or silicon. This precise mixture creates wheels that deliver an optimal balance of strength and reduced weight. Two distinct manufacturing processes create these wheels:

Casting: Molten metal is poured into molds, allowing for complex and lightweight designs

Forging: High pressure shapes solid metal pieces, resulting in stronger, lighter wheels that cost more than cast alternatives

The term "alloy" refers to this mixture of metals, with aluminum and magnesium serving as the primary materials. Many enthusiasts call magnesium-heavy alloy wheels "mag wheels," recognizing this element's crucial role in wheel construction.

What sets alloy wheels apart from traditional steel options is their advanced construction method. Steel wheels are pressed from sheet metal and welded together, often showing visible seams that require covers to hide. Alloy wheels allow for intricate designs with clean, finished appearances right from manufacturing.

Alloy wheels deliver impressive performance gains primarily through weight reduction—they're approximately 40% lighter than comparable steel wheels. This significant weight difference creates several real-world improvements:

Lighter wheels reduce unsprung mass (weight not supported by the suspension), allowing your suspension to respond more quickly to road surface changes for better grip and handling. This weight advantage improves acceleration, braking efficiency, and cornering precision.

The thermal properties of alloy wheels provide crucial benefits for braking performance. Alloys conduct heat more effectively than steel, helping dissipate brake-generated heat faster. This superior heat management prevents brake fade during demanding driving and extends brake component life.

Visually, alloy wheels transform your vehicle's appearance through:

Complex spoke designs impossible with steel construction

Various finishes including polished, machined, or painted options

Customizable patterns that complement your vehicle's styling

The aesthetic impact goes beyond looks—alloy wheels often increase your vehicle's perceived value. They remain one of the most popular aftermarket upgrades for drivers seeking to personalize their rides.

Ready to explore premium options? You can browse premium alloy rims for your vehicle at https://www.performanceplustire.com/ where you'll find designs that enhance both performance and appearance.

Alloy wheels do present some notable drawbacks. They typically cost more than steel wheels due to complex manufacturing processes. You'll need to weigh this higher initial investment against the performance benefits and visual appeal.

While alloys offer excellent performance characteristics, they're not as durable as steel wheels in certain situations. They're more susceptible to cracking and bending from pothole impacts or curb contact. When damaged, alloy wheels are generally more difficult and expensive to repair than steel alternatives.

Proper maintenance is essential for preserving your alloy wheels' appearance and performance. Follow this care routine:

Use pH-neutral cleaners specifically designed for alloys—avoid harsh chemicals that can damage finishes

Apply protective coatings after cleaning to create barriers against brake dust and road grime

Inspect regularly for damage, especially after encountering potholes or rough terrain

Winter conditions pose particular challenges for alloy wheels. Road salt and de-icing chemicals can severely damage finishes if not cleaned regularly. Many owners use separate steel wheels during winter months to protect their more expensive alloy sets.

Alloy wheels represent a compelling balance of performance advantages, aesthetic benefits, and maintenance requirements. Their popularity continues growing—now appearing on economy cars where they were once considered premium options. With proper care, they offer an outstanding upgrade for virtually any vehicle, enhancing both appearance and driving dynamics.

Steel rims are the reliable workhorses of the wheel world, built to handle whatever the road throws at you. These proven performers have been serving drivers for decades where dependability takes priority over looks. We believe steel rims offer unmatched value for drivers who need wheels that simply won't quit.

Steel rims earn their reputation through outstanding strength and resilience that's hard to beat. Their robust construction makes them nearly impossible to crack, giving you confidence when facing harsh driving conditions. When damage does occur, steel rims can often be repaired rather than replaced—sometimes as simple as hammering bent sections back into proper shape.

We carry steel rims at the lowest prices while delivering exceptional durability. Steel rims consistently cost less than alloy alternatives, making them perfect for budget-conscious drivers who don't want to sacrifice quality. This affordability extends well beyond the initial purchase since steel rims require minimal maintenance and cost very little to replace when necessary.

Steel rims demonstrate impressive resistance to environmental challenges that would damage other wheel types. With proper paint application, they effectively resist rust and corrosion. Their straightforward construction means fewer potential failure points compared to more complex wheel designs.

Winter driving conditions highlight where steel rims truly shine. Their added weight provides crucial traction advantages in snow and ice, helping your vehicle maintain stability when conditions get slippery. Many smart drivers switch to steel rims during winter months to improve both safety and performance.

Steel rims show superior resilience against winter's harsh elements. Road salt and de-icing chemicals that quickly damage expensive alloy wheels have minimal effect on properly finished steel rims. Their resistance to corrosive environments makes them ideal for coastal areas with salt air exposure.

Heavy-duty applications benefit from steel's inherent strengths:

Exceptional load-bearing capacity for commercial trucks and work vehicles

Superior durability for off-road use and rough terrain

Better heat dissipation properties preventing brake fade

At Performance Plus Tire, we stock durable steel rims for all seasons at Performance Plus Tire with options specifically designed to handle various challenging environments.

Steel rims do face some notable limitations that you should consider. Their substantial weight—significantly heavier than alloy alternatives—creates several drawbacks. This extra mass requires more energy to accelerate and maintain speed, potentially reducing fuel efficiency. The increased unsprung weight can sometimes affect vehicle handling and suspension performance.

When it comes to appearance, steel rims typically feature simple, utilitarian designs that many drivers find plain. Their manufacturing process limits design complexity, often resulting in basic black finishes that lack the visual impact of alloy wheels. This explains why many vehicles come with hubcaps designed to cover steel rims' practical appearance.

Steel rims also face size restrictions. Most are only available up to 16 inches in diameter, limiting their use in vehicles designed for larger wheel sizes. This constraint means they can't be used on all vehicle types, particularly modern performance cars and luxury vehicles requiring larger diameter wheels.

Steel rims aren't the right choice for every driver, but they continue to provide the ideal balance of strength, affordability, and functionality for many practical applications. Our experienced team can help you determine if steel rims are the perfect match for your specific driving needs and budget.

We've organized the key characteristics of each rim type to help you make the best choice for your vehicle. This comparison highlights the essential factors you need to consider when selecting the right wheels for your specific driving needs and budget.

| Rim Type | Primary Use/Application | Material/Construction | Key Benefits | Main Limitations/Risks | Maintenance Requirements |

|---|---|---|---|---|---|

| Safety Rims | Passenger vehicles | Features inward bumps/humps on outer contoured surface | - Retains deflated tire at high speeds - Can travel up to 5 miles at 5mph on flat tire - Compatible with tubeless tires |

Effectiveness decreases with low tire pressure | Regular tire pressure checks required |

| Split Rims | Heavy-duty vehicles, trucks, tractors, forklifts | Multi-piece construction with detachable components | - Quick tire changes - High durability - Handles high pressure/weight loads |

Risk of catastrophic failure under pressure with potential for serious injury | - Regular bolt torque checks - Complete deflation before disassembly - Requires specialized training |

| Beadlock Rims | Off-road vehicles, military applications | Mechanical clamping system with 24-32 bolts | - Prevents tire separation at low pressures - Allows extreme off-road use - Maintains seal at pressures as low as 5 PSI |

- Not street legal in most cases - Heavy weight - Higher cost |

- Regular bolt torque checks - Periodic bolt replacement - Meticulous installation |

| Alloy Rims | Performance and luxury vehicles | Aluminum blend with magnesium, nickel, or silicon | - 40% lighter than steel - Better heat dissipation - Enhanced esthetics |

- More expensive - Prone to cracking/bending - Less durable than steel |

- Regular cleaning with pH-neutral cleaners - Protective coating application - Regular damage inspections |

| Steel Rims | Winter driving, heavy vehicles | Pressed sheet metal, welded construction | - High durability - Low cost - Easy to repair |

- Heavy weight - Limited design options - Size restrictions (up to 16 inches) |

Minimal maintenance required, basic rust prevention |

Selecting the right rim type makes a significant difference in how your vehicle looks and performs. We've covered how safety rims keep passenger cars safe during tire emergencies, while split rims handle the tough demands of commercial vehicles despite serious safety risks. Beadlock rims excel for extreme off-road adventures at very low tire pressures, though they're not street-legal and require regular maintenance.

Your rim choice comes down to balancing what you need with what you want. Alloy rims offer that sweet spot of lighter weight for better handling and stunning looks, but they cost more and damage easier. Steel rims may not win beauty contests, but they deliver unbeatable durability and budget-friendly pricing that makes them perfect for winter driving and harsh conditions.

The right rim depends on how you actually drive your vehicle. Think about your daily routes, the weather you face, and how much time you want to spend on maintenance. At Performance Plus Tire, our knowledgeable staff can guide you through the selection process and help you find wheels that match both your driving needs and your budget.

Remember that proper care keeps any rim type working at its best for years. Regular cleaning, checking for damage, and maintaining correct tire pressure will protect your investment and keep you safe on the road. Visit Performance Plus Tire where we carry the best selection of rims at the lowest prices, and our experts will help you make the perfect choice for your ride.

Understanding the five main rim types helps you make informed decisions based on your specific driving needs, budget, and performance requirements.

Safety rims are standard on passenger cars - They feature inward bumps that retain deflated tires at highway speeds, allowing up to 5 miles of emergency driving.

Split rims serve heavy-duty vehicles but pose serious risks - While excellent for quick tire changes on trucks and equipment, they can explosively separate under pressure.

Beadlock rims excel in extreme off-road conditions - They mechanically clamp tire beads for low-pressure driving but aren't street-legal and require regular maintenance.

Alloy rims offer the best performance-esthetics balance - 40% lighter than steel with superior heat dissipation, but cost more and are prone to damage.

Steel rims prioritize durability and affordability - Nearly impossible to crack and ideal for winter driving, though heavier with limited design options.

The right rim choice depends on balancing your driving conditions, budget constraints, and esthetic preferences. Regular maintenance remains crucial regardless of rim type to ensure optimal performance and safety.

The main types of rims include safety rims for passenger vehicles, split rims for heavy-duty applications, beadlock rims for off-road use, alloy rims for performance and esthetics, and steel rims for durability and affordability.

Alloy rims are typically lighter, offer better heat dissipation, and provide more design options. However, they are more expensive and prone to damage. Steel rims are more durable and affordable but heavier and limited in design.

In most cases, beadlock rims with external clamping rings are not street-legal as they fail to meet Federal Motor Vehicle Safety Standards. They are primarily designed for off-road use and extreme low-pressure driving conditions.

Key factors to consider include bolt pattern compatibility, rim width and diameter, offset, center bore size, and your vehicle's specific requirements. It's also important to balance performance needs with budget constraints and esthetic preferences.

Proper maintenance is crucial for all rim types to ensure optimal performance and longevity. This includes regular cleaning, inspections for damage, and maintaining correct tire pressure. Some rim types, like beadlocks, require more frequent checks and specialized care.