The price difference between 2 piece vs 3 piece wheels and standard single-piece options can be substantial - multi-piece wheels typically cost upwards of 3 times more than conventional designs. This significant investment might seem daunting at first glance, but there's a compelling reason why performance and show car enthusiasts continue to choose these premium options despite the higher price point.

What makes 3-piece wheels so special? These custom wheels consist of three separate components - the center section, outer rim, and inner barrel - all precisely bolted together to create an airtight connection. This modular construction is what gives 3-piece wheels their legendary reputation for customization potential. The modular design allows manufacturers to create different offsets and widths that are easier to produce and interchange with existing setups.

2-piece wheels offer a middle ground approach, combining two of these elements into a single component while still providing enhanced customization options compared to standard one-piece designs.

Understanding multi-piece wheels is important before making a purchase decision. These wheels provide greater design flexibility but require more complex assembly procedures. The assembly process involves precisely aligning and bolting together the separate components - a detailed process that demands attention to precision but results in a wheel built exactly to your specifications.

We'll guide you through the key differences between these custom wheel options to help you determine which might be the perfect fit for your vehicle and goals.

Understanding the construction differences between 2 piece vs 3 piece wheels is essential for making an informed purchasing decision. The structural design of these multi-piece wheels showcases advanced automotive engineering principles that directly impact performance, customization potential, and long-term ownership experience.

2-piece wheels use a modular approach to wheel design, consisting of two primary components that work together to create a complete wheel assembly. Unlike standard single-piece wheels manufactured as one unit, 2-piece wheels feature separate parts joined during final production stages.

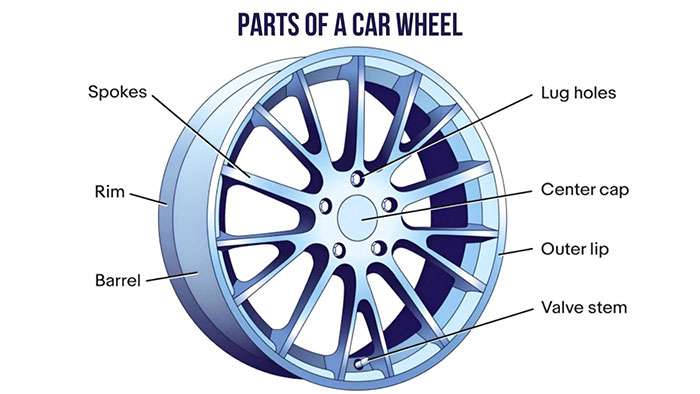

The center section (also called the center disk or face) houses the hub mounting surface, spokes, and design elements that give the wheel its distinctive appearance. This center section bolts directly to your vehicle and transfers torque from the axle to the wheel assembly.

The barrel (or rim) forms the outer circumference where the tire mounts. This barrel creates the critical interface between your vehicle and the road, providing structural support needed to maintain tire pressure and proper positioning.

2-piece wheels come together through one of two primary methods:

Welded Construction: The center section and barrel are permanently joined through welding processes, creating a seamless, unified structure. This method produces a strong bond that eliminates potential weak points but makes repairs challenging if damage occurs.

Bolted Construction: Some manufacturers use bolts to join the center section to the barrel. This approach makes repairs easier but introduces additional complexity to the design.

The manufacturing process begins with separate production of each component. The center might be cast or forged from aluminum, then precision-machined to achieve desired design and fitment specifications. The barrel is often created through a spinning process where aluminum is formed into a cylindrical shape.

2-piece wheels offer a middle ground between one-piece and three-piece designs, balancing customization options with manufacturing simplicity. They provide greater design flexibility than one-piece wheels while maintaining more straightforward construction than their three-piece counterparts.

For those seeking to explore quality 2 piece wheels, various manufacturers offer options that balance esthetics, performance, and cost considerations.

3-piece wheels take modular design to its logical conclusion by separating the wheel into three distinct components. This construction offers unprecedented customization potential along with unique performance characteristics.

The three components include:

Center Section: Similar to 2-piece wheels, this component houses the mounting hub and spokes. It's the structural heart of the wheel and often the most visually distinctive element. The center can be manufactured through various processes including casting or forging, depending on the desired strength-to-weight ratio.

Inner Barrel: This component forms the inside portion of the rim where the tire mounts. It connects directly to the center section and helps establish the wheel's overall width and offset characteristics.

Outer Barrel (or Lip): The outer portion of the rim completes the wheel assembly, creating the outer edge that's most visible when mounted. The depth and profile of this outer lip significantly impact both esthetics and performance.

This three-component construction originated in the early 1970s for racing applications and has since become popular in high-performance and show car communities. The modularity inherent in 3-piece wheels allows manufacturers and owners to create custom widths, offsets, and visual appearances that would be impossible with single-piece designs.

The assembly process for 3-piece wheels is more complex than their 2-piece counterparts. The components are joined using high-strength bolts arranged around the perimeter of the wheel. During assembly, manufacturers apply high-temperature silicone RTV between the inner and outer barrels to create an airtight seal. This sealant is crucial for maintaining tire pressure, though it requires careful handling during tire installation and replacement to avoid damage.

For enthusiasts interested in exploring 3 piece wheels, the customization possibilities are virtually limitless, from different finishes on each component to precise specifications for width and offset.

The method used to join wheel components affects performance, repairability, and cost. Understanding these differences is important when comparing 2 piece vs 3 piece wheels.

Welded Construction

Welded wheels create a permanent bond between components, essentially fusing them into a single unit. This process involves:

Precise alignment of the center section and barrel(s)

Application of welding techniques to join the components

Post-weld machining and finishing to ensure structural integrity

The primary advantages of welded construction include:

Structural Strength: Welding creates a robust connection that minimizes potential failure points

Reduced Weight: Eliminates the need for heavy bolts and assembly hardware

Leak Prevention: Forms a permanent seal that prevents air loss

Lower Cost: Generally less expensive than comparable bolted designs

Welded wheels present significant limitations:

Limited Repairability: If a section becomes damaged, repair often requires cutting apart the wheel and rewelding, which is complex and expensive

Finishing Constraints: The welding process makes it difficult to apply different finishes to different wheel sections

Permanent Specifications: Once manufactured, the wheel's width and offset cannot be modified

Bolted Construction

Bolted construction, predominantly used in 3-piece wheels and some 2-piece designs, takes a different approach:

Components are manufactured separately with precisely machined mating surfaces

High-strength bolts (typically 30-45 depending on wheel size) connect the pieces

Sealing compounds are applied between components to prevent air leakage

The advantages of bolted construction are substantial:

Superior Repairability: Damaged components can be individually replaced without scrapping the entire wheel

Customization Flexibility: Width and offset can be adjusted by changing barrels

Finish Options: Different components can receive different finishes (polished lips with painted centers, for example)

Field Serviceability: Repairs can often be performed without specialized equipment

Bolted construction has drawbacks:

Potential Leak Points: Each bolt hole and seam represents a potential failure point for air retention

Increased Maintenance: Bolts may require periodic checking and tightening

Added Weight: Assembly hardware adds unsprung weight to the wheel

Higher Cost: More complex manufacturing and assembly processes increase overall expense

The manufacturing process and materials used significantly impact a wheel's strength, weight, and cost. Both 2-piece and 3-piece wheels can utilize different materials and production methods for their components.

Cast Aluminum

Casting involves pouring molten aluminum into a mold, allowing it to cool and solidify into the desired shape. There are several casting methods:

Gravity Casting: The simplest method, using gravity to fill the mold. This produces affordable wheels, though they tend to be denser and heavier to achieve adequate strength

Low-Pressure Casting: Uses moderate air pressure to force aluminum into the mold, creating a denser product with fewer imperfections compared to gravity casting

High-Pressure Casting: Employs greater air pressure for even denser results, though the strength-to-weight improvements over low-pressure casting may not justify the increased cost

Cast components offer several advantages:

Design Flexibility: Complex shapes and intricate designs are possible

Cost Efficiency: Lower manufacturing costs translate to more affordable wheels

Wide Availability: Most commonly available wheel construction type

The limitations of cast components include:

Porosity Issues: The cooling process can create tiny air pockets that weaken the structure

Weight Concerns: Requires more material to achieve strength targets

Brittle Failure Mode: Cast wheels tend to crack rather than bend when damaged

Forged Aluminum

Forging starts with a solid billet (block) of aluminum that's shaped under extreme heat and pressure. This process:

Aligns the metal's grain structure to enhance strength

Increases material density

Creates a stronger component that requires less material

The advantages of forged components are significant:

Superior Strength-to-Weight Ratio: Forged parts can be up to 30-35% lighter than cast equivalents while maintaining strength

Enhanced Durability: The aligned grain structure resists fatigue and impact damage

Ductile Failure Mode: Forged wheels tend to bend rather than catastrophically crack when damaged

Higher Load Ratings: Can support greater weights and stresses

Forging's disadvantages center primarily around cost:

Higher Manufacturing Expense: The forging process requires specialized equipment and precision machining

Material Waste: Creating a forged wheel often starts with a 100-pound aluminum blank that's machined down to approximately 19.5 pounds for an 18-inch wheel

Design Limitations: Some intricate designs possible with casting are challenging to achieve through forging

Hybrid Approaches

Many multi-piece wheels use different manufacturing methods for different components. Common combinations include:

Cast aluminum centers welded to forged barrels

Forged centers bolted to spun aluminum barrels

Flow-formed barrels (a hybrid process) combined with forged centers

These hybrid approaches aim to balance strength, weight, appearance, and cost considerations. A wheel might use a stronger forged center section where structural integrity is most critical, combined with less expensive barrels.

The choice between cast and forged components represents a fundamental tradeoff in custom wheels. Cast parts offer affordability and design flexibility but sacrifice some strength and weight advantages. Forged components provide superior performance characteristics but at a significantly higher price point.

Material Considerations in 2 Piece vs 3 Piece Wheels

When comparing 2 piece vs 3 piece wheels, material choices often follow certain patterns:

Entry-level forged 2-piece wheels typically feature forged 6061-T6 aluminum centers welded to spun forged aluminum barrels

Some manufacturers offer cast aluminum centers in 2-piece designs to reduce costs, though this sacrifices some quality and weight advantages

High-end 2-piece wheels may feature both forged centers and forged barrels, though these command premium prices

3-piece wheels typically use forged aluminum centers with spun aluminum barrel sections, offering the best balance of strength, weight, and customization

The material and construction decisions ultimately depend on the intended use case. Track-focused applications generally prioritize strength and weight reduction, often justifying the premium for forged components. Show cars might emphasize appearance and customization potential, sometimes accepting the additional weight of cast components to achieve specific esthetic goals.

Performance characteristics of multi-piece wheels directly impact your driving experience, customization potential, and long-term ownership costs. When comparing 2 piece vs 3 piece wheels in real-world applications, several key factors emerge that can help you make the right choice for your specific needs.

Performance enthusiasts frequently debate weight differences between wheel types, and for good reason - rotational mass significantly affects vehicle dynamics. Surprisingly, 3 piece wheels can potentially be lighter than 2 piece wheels in some configurations due to the ability to select optimal materials for each component. This customized approach allows manufacturers to use thinner, lighter materials where structural demands permit.

However, most sources indicate that 3 piece wheels are typically heavier than one-piece alternatives. Similarly, 2 piece wheels generally weigh more than their one-piece counterparts. This additional weight comes from several factors:

Assembly hardware including bolts and fasteners

Reinforced mating surfaces between components

Overlapping material at connection points

Sealants and gaskets required to ensure airtight assembly

Despite these weight penalties, the advantages in repairability and customization often outweigh the drawbacks for many owners. For ultimate weight savings, forged monoblock wheels still reign supreme, but multi-piece designs offer an unmatched blend of strength, flexibility, and serviceability.

The chief selling point of multi-piece wheels is their ability to accommodate unique customization requirements. 2 piece wheels allow for a degree of custom width and offset by selecting different barrel and center combinations. However, 3 piece wheels represent the ultimate in flexibility.

With 3 piece construction, manufacturers can produce custom widths and offsets to suit nearly any application - from aggressive stance setups to track-oriented fitments. Owners can even modify their wheels after purchase, swapping barrels or lips to adapt to new vehicles or aesthetic preferences.

Finishing options expand dramatically with 3 piece wheels. The separate center, inner barrel, and outer lip can all be finished in different colors, materials, or textures. This level of personalization is not possible with single-piece wheels and limited in 2-piece designs.

Serviceability is one of the most important considerations when comparing 2 piece vs 3 piece wheels.

With 2 piece welded wheels, damage to either component often necessitates replacement of the entire wheel. Bolted 2-piece wheels allow for more straightforward repairs, but still lag behind the flexibility of 3 piece options.

3 piece wheels offer the greatest serviceability. Damaged components - whether the outer lip is curb-rashed or the inner barrel suffers a pothole impact - can be individually replaced. This reduces long-term costs and makes 3 piece wheels an attractive option for both performance drivers and show car owners who want to maintain their investment.

The modular nature of 3 piece wheels also allows owners to change wheel specs (width/offset) if they modify their vehicle, simply by swapping out components.

There’s no denying the premium pricing associated with multi-piece wheels. Entry-level 2 piece wheels often start around $800-$1200 each, while 3 piece wheels routinely cost $1500 or more per wheel for reputable brands. This significant up-front cost reflects the precision manufacturing, premium materials, and enhanced flexibility of these wheel types.

However, 3 piece wheels can save money in the long run. The ability to repair and reconfigure the wheel reduces replacement costs after damage or if vehicle modifications are made. For owners who change vehicles frequently or pursue competitive driving, the investment can pay off over time.

For those prioritizing initial budget, one-piece and 2 piece wheels may provide a more affordable alternative with many of the same esthetic and performance benefits.

The answer ultimately depends on your priorities. 2 piece wheels strike a balance between cost, performance, and modest customization. 3 piece wheels maximize flexibility, serviceability, and finishing options, though they come with higher up-front costs and slightly more maintenance.

For daily drivers and moderate enthusiasts, 2 piece wheels deliver an appealing mix of style and value. For car builders, show car owners, and track day regulars, 3 piece wheels offer a level of customization and future-proofing that is hard to match. Regardless of which path you choose, investing in quality wheels from a trusted retailer ensures you’ll enjoy the experience and protect your vehicle investment.

Strength depends on the materials and manufacturing methods used, but 3 piece wheels are not inherently stronger than 2 piece wheels. Both designs can be made extremely strong, especially if forged components are used.

3 piece wheels are easier to repair since individual components can be replaced. Welded 2 piece wheels are more difficult to repair, but bolted versions can have individual sections replaced like 3 piece wheels.

Multi-piece wheels require precision engineering, premium materials, and complex assembly processes. Their cost also reflects their customization potential and serviceability, which single-piece wheels cannot match.

For daily driving, 2 piece wheels may provide the best balance of cost and customization. 3 piece wheels are typically chosen by enthusiasts who want maximum flexibility, show car quality, or plan frequent modifications.