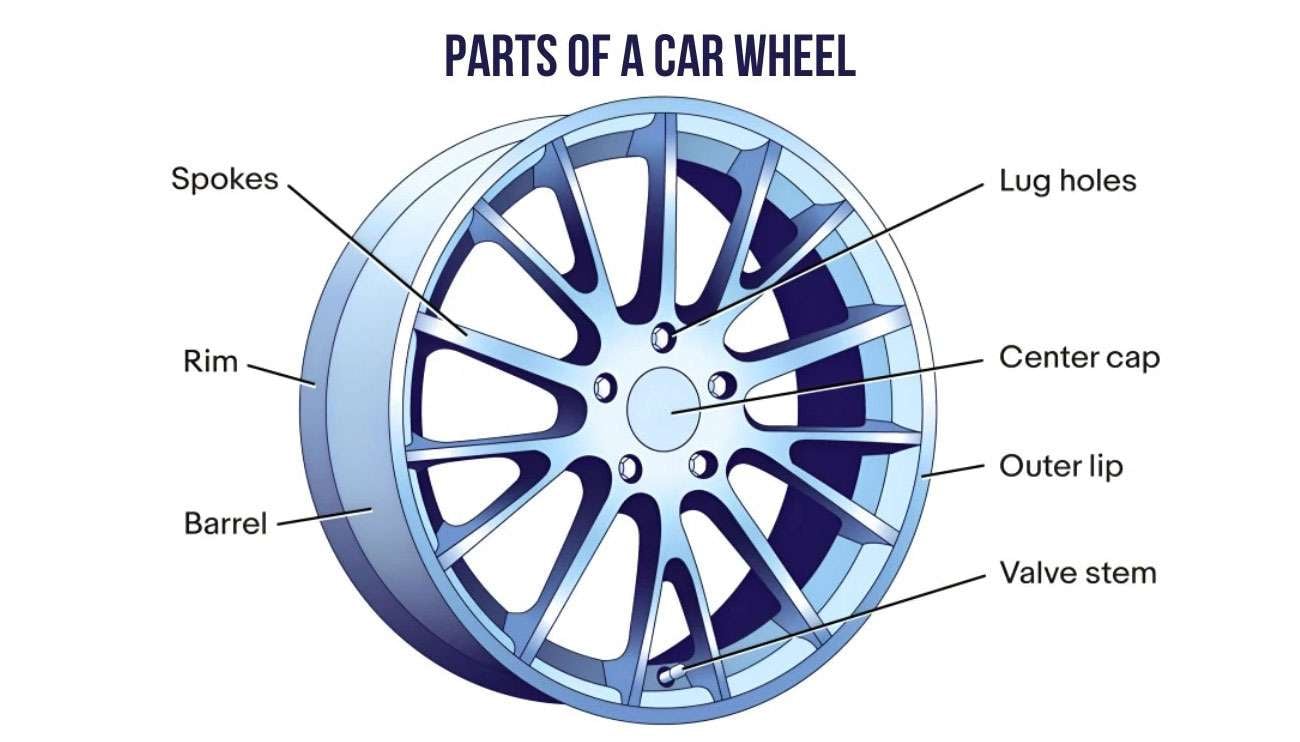

Most car owners use "rims" and "wheels" interchangeably, but understanding the difference is crucial for making smart vehicle decisions. Rims are actually just one component of the complete wheel assembly. This misconception affects more drivers than you might think, especially when over 1 million wheels and tires are purchased annually.

Car wheels function as an integrated system where every component has a specific job. The rim holds your tire in place and maintains its proper shape for optimal fitment. Spokes provide structural support while contributing to your vehicle's overall appearance. The beads create that critical seal between tire and rim, ensuring proper air pressure and tire positioning. When you understand how these wheel components work together, you can make better maintenance and upgrade choices for your vehicle.

We'll break down the essential rim components and explain how each affects your driving experience. You'll learn about rim width, flanges, bolt holes, and offset - key factors that determine whether a wheel fits your vehicle properly. This knowledge helps you maintain your car correctly and makes wheel shopping much easier when the time comes to upgrade.

The structural integrity of every wheel depends on several critical rim components working together. The barrel forms the central cylindrical section that connects the outboard face to the inboard rim edge. This foundation supports everything else.

Flanges extend outward at 90-degree angles along both barrel edges, creating barriers that prevent tires from slipping off the wheel. These raised edges are essential for tire retention during normal driving and emergency situations.

The beads are flat, precisely machined areas inside the flanges where tire edges seat to form an airtight seal. Even minor damage to these surfaces can cause vibrations that travel directly through your suspension system. The bead seat must match tire bead dimensions exactly to ensure proper fitment and prevent air leaks.

The drop center represents one of the most clever engineering solutions in wheel design - a depression in the barrel that allows tire installation. Without this recessed area, mounting a tire with the same inner diameter as the wheel's outer diameter would be impossible. The drop center creates the necessary space for one tire side to slip over the rim edge during installation.

Mounting humps circle both sides of the barrel, acting as safety blocks that keep tires positioned correctly on wheel edges. These features become particularly important when tire pressure drops, helping retain tire beads even under extreme conditions that might otherwise cause tire separation.

Safety components in your rim work behind the scenes to prevent dangerous failures. Rim flanges act as your first line of defense, creating those essential 90-degree curves that keep tires locked in place. Without properly functioning flanges, you'd lose the airtight seal between tire and wheel, leading to sudden pressure loss.

Valve stems might look insignificant, but they're critical for maintaining proper tire pressure. This small tube houses a spring-loaded valve that controls air flow in and out of your tire. A damaged valve stem can cause slow leaks or catastrophic pressure loss, making regular inspection essential.

When you're running aftermarket wheels, hub-centric rings become crucial for safe installation. These rings eliminate the gap between your wheel's center bore and your vehicle's hub, ensuring precise wheel positioning. Without them, you risk dangerous vibrations that can affect your vehicle's handling and wear out suspension components prematurely.

Your bolt pattern determines whether wheels will fit your vehicle safely. This measurement includes both the number of lug bolts and their circular spacing. Get this wrong, and your wheels won't mount securely to your vehicle.

Lug nuts provide the final safety connection between wheel and vehicle. Proper torque specifications create thousands of pounds of clamping force, keeping your wheels attached even during hard cornering or emergency stops. Never guess at torque values - always follow manufacturer specifications for your safety.

Image Source: Chalco Aluminum

Rim design choices directly impact how your vehicle looks and performs on the road. Material selection represents your first major decision when choosing wheels. Steel wheels deliver outstanding durability and value, handling harsh conditions without cracking. However, their weight penalty is significant - steel wheels weigh approximately 2.5-3 times more than comparable aluminum wheels, which hurts acceleration and fuel efficiency.

Aluminum alloy wheels offer a superior alternative with dramatically reduced weight that improves handling, acceleration, and fuel economy. The material's flexibility also allows manufacturers to create intricate spoke patterns and diverse finishes, from brilliant chrome to aggressive matte black.

Wheel width plays a crucial role in vehicle dynamics. The optimal wheel width typically runs about half an inch wider than your tire's tread width. Simply mounting a 225mm tire on a properly sized wider wheel instead of a narrower one can shave a full half-second off lap times.

Offset determines both your vehicle's stance and handling characteristics. The offset measures the distance between the mounting surface and wheel centerline. Positive offset pulls wheels deeper into the fenders for a clean, factory appearance, while negative offset pushes wheels outward for that aggressive, muscular look.

Finish options let you match your personal style - glossy black creates an aggressive appearance, brushed aluminum delivers a premium look, and matte finishes provide a stealthy aesthetic. When you're ready to find wheels that balance performance with style, Performance Plus Tire offers an extensive selection of wheels across all designs and finishes to match your vision.

Understanding wheel rims gives you the knowledge needed to make smart maintenance and upgrade decisions for your vehicle. Rims are just one component of your wheel assembly, but they work with barrels, flanges, and beads to create a complete system that keeps you safe on the road.

Safety components like mounting humps and rim flanges prevent dangerous tire slippage during low-pressure situations. Valve stems and properly torqued lug nuts keep your wheels securely attached under all driving conditions.

Material selection affects both performance and appearance. Aluminum alloy wheels deliver significant weight savings that improve handling and fuel efficiency compared to steel wheels. Wheel width, offset, and finish options let you customize your vehicle to match your driving style and personal preferences.

When you're ready to upgrade your wheels, Performance Plus Tire offers the best selection of rims at the lowest prices. Our extensive inventory includes options that deliver both performance and style. Whether you need custom wheels, off-road rims, or classic designs, we have the perfect match for your vehicle.

Your knowledge of wheel components helps you drive safer, maintain your vehicle better, and enjoy improved performance. At Performance Plus Tire, we're confident we can provide you with the ideal wheels for your ride at prices you can afford.

Understanding rim components helps car owners make informed maintenance and upgrade decisions while ensuring optimal vehicle safety and performance.

• Rims are just one part of the wheel assembly, not the entire wheel - they support tires through integrated components like barrels, flanges, and beads that work together.

• Safety features like mounting humps and rim flanges prevent tire slippage during low-pressure situations, while properly torqued lug nuts secure wheels under extreme driving conditions.

• Material choice significantly impacts performance - aluminum alloy wheels weigh 2.5-3 times less than steel, improving acceleration, handling, and fuel efficiency.

• Wheel width and offset directly affect vehicle dynamics - optimal width is typically half an inch wider than tire tread, while offset determines both esthetics and handling characteristics.

• Proper understanding of components like valve stems, bolt patterns, and hub-centric rings ensures safe installation and prevents dangerous air leaks or vibration issues.

This knowledge empowers you to maintain your vehicle properly, choose appropriate upgrades, and communicate effectively with tire professionals when making wheel-related decisions.

When buying rims, ensure they match your vehicle's bolt pattern and center bore. Prioritize functionality over style, have them professionally inspected if buying used, and always opt for professional installation to ensure safety and proper fitment.

The wheel hub is the central part of the wheel that connects the rim to the vehicle's axle. It plays a crucial role in supporting the wheel's weight and allowing it to rotate smoothly while driving.

Yes, there are free online wheel visualizers that allow you to see how different rim styles, sizes, and colors would look on your specific vehicle model before making a purchase.

The offset number, such as "+35," refers to the distance in millimeters from the wheel's mounting surface to its centerline. A positive offset means the mounting surface is closer to the outside of the wheel, while a negative offset positions it closer to the inside.

Rim width directly impacts vehicle dynamics. The optimal wheel width is typically about half an inch wider than the tire's tread width. A wider wheel can improve handling and potentially enhance lap times in performance driving scenarios.