Aftermarket Jeep wheels deliver dramatic performance improvements that go far beyond appearance. Quality aftermarket wheels can reduce weight by 8-10 pounds per wheel compared to stock steel options. This weight reduction directly improves your Jeep's acceleration, braking response, and suspension performance while reducing stress on critical drivetrain components.

Understanding proper wheel selection is essential before making your purchase. The wrong wheel and tire combination creates frustrating fitment problems, including rubbing at full steering lock and contact issues during suspension articulation. Jeep bolt patterns vary significantly across models - CJs use the 5x5.5 pattern, YJ/TJ Wranglers require 5x4.5, and modern JK/JL Wranglers along with Gladiators use the current 5x5 standard.

Quality aftermarket wheels offer exceptional value for Jeep owners seeking enhanced performance, superior off-road capability, or distinctive styling. Most aftermarket wheels feature load ratings between 2,500 and 3,500 pounds, providing ample strength for demanding off-road adventures. Jeep enthusiasts consistently rank wheel upgrades among the most impactful modifications because reduced unsprung weight allows your suspension to perform better on every terrain.

We'll guide you through the complete process of selecting aftermarket Jeep wheels, from basic specifications and fitment requirements to choosing the perfect style for your specific model and driving needs.

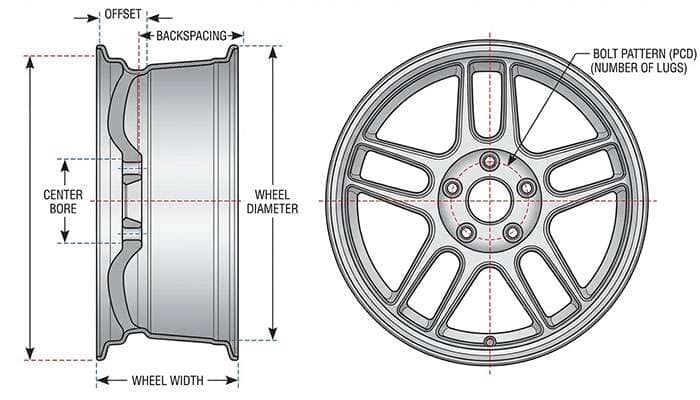

Understanding wheel terminology is important before making a purchase. When it comes to selecting wheels for your Jeep, three critical specifications determine whether they'll fit properly and perform as expected. These measurements affect everything from clearance to ride quality.

Bolt pattern measures the diameter of an imaginary circle drawn through the center of each lug hole on your wheel. This specification is non-negotiable - wheels with the wrong bolt pattern simply won't install on your lug studs.

Most Jeeps use a five-lug design, but the spacing varies by model:

CJs and pre-1986 models: 5-on-5.5 (five lugs with 5.5-inch spacing)

YJ/TJ Wranglers (1987-2006): 5-on-4.5 (five lugs with 4.5-inch spacing)

JK/JL Wranglers (2007-present): 5-on-5 (five lugs with 5-inch spacing)

You can measure bolt pattern yourself by counting the lug holes first. With five lugs, place your ruler at the outer edge of one hole, skip the next hole, and measure to the center of the following hole. This gives you the bolt pattern diameter.

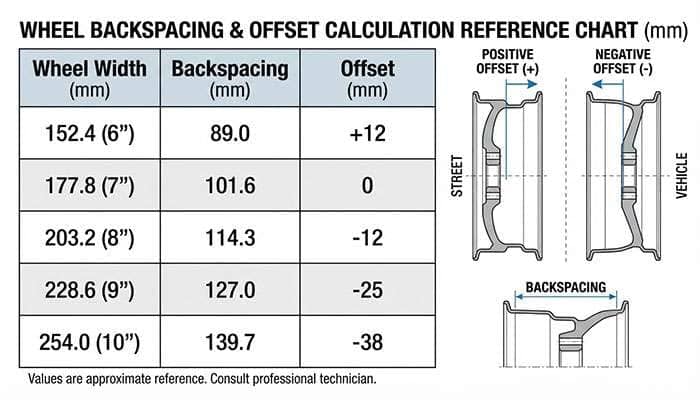

Offset and backspacing control how far your wheels sit from the vehicle's centerline. These measurements directly affect your Jeep's stance and component clearance.

Wheel offset is the distance from the wheel's centerline to its mounting surface. Measured in millimeters, offset comes in three types:

Positive: Mounting surface is forward of centerline, pulling wheels inward

Negative: Mounting surface is behind centerline, pushing wheels outward

Zero: Mounting surface aligns with centerline for neutral positioning

Backspacing measures the distance from the wheel's inner edge to its mounting face. More backspacing reduces inner wheel clearance and can cause suspension component contact.

Factory Jeep wheels typically feature positive offset and higher backspacing. When adding larger tires or lift kits, you'll need wheels with reduced offset and backspacing to prevent component contact during turning or articulation.

The centering method affects both ride quality and wheel performance over time.

Hub-centric wheels feature a center bore that fits precisely over the axle hub. The hub centers the wheel while lug nuts secure it to the mounting surface. This design carries the vehicle's weight through the hub connection. Most factory wheels use this method for optimal ride quality.

Lug-centric wheels center themselves using only the lug nuts. Many aftermarket wheels use this design with oversized center bores to fit multiple vehicle applications. This creates a gap between the wheel and hub when installed.

While some Jeep owners notice no performance difference, others report that lug-centric wheels perform poorly in demanding off-road conditions. Trail impacts can create shear forces on lug studs, potentially causing stud damage and wheel vibration.

Hub-centric wheel spacers offer a solution if you prefer lug-centric wheels. These spacers fit inside the wheel hub and over the axle, converting lug-centric fitment to hub-centric.

Finding wheels that fit your specific Jeep model doesn't require advanced mechanical knowledge. You just need to understand your vehicle's unique specifications and how they relate to available aftermarket options.

Bolt pattern compatibility determines whether wheels will physically mount to your Jeep. Modern Jeep Wranglers (JK/JL 2007-present) and Gladiators (2020-present) use the same 5x5 (5x127mm) bolt pattern, making wheels interchangeable between these models.

Older Jeep models follow different specifications:

YJ/TJ Wranglers (1987-2006): 5x4.5 (5x114.3mm) bolt pattern

CJ Series (1941-1986): 5x5.5 (5x139.7mm) bolt pattern

Cherokee models have varied throughout their production:

Modern Cherokee KL (2014-2019): 5x110mm bolt pattern

Cherokee XJ (1984-2001): 5x4.5 (5x114.3mm) bolt pattern

Grand Cherokee WJ/WK/WK2 (1999-2019): 5x5 (5x127mm) bolt pattern

YJ and TJ Wranglers share complete wheel compatibility, as do JK and JL models. This cross-generation compatibility gives you more options when shopping for aftermarket wheels or even swapping with other Jeep owners.

When consulting compatibility charts, look beyond bolt patterns to four critical specifications: OEM wheel size, stud size, hub center bore, and offset/backspacing measurements.

Hub center bore proves particularly important. Most modern Jeeps use 71.5mm bores, while specialized models like the Cherokee KL require 65.1mm. Mismatched hub bores create vibration problems and accelerated component wear.

Follow this process when using compatibility charts:

Locate your specific Jeep model and year

Verify all specifications match (not just bolt pattern)

Confirm wheel load ratings exceed your vehicle's requirements

Cross-model compatibility requires matching specifications across all categories. A Grand Cherokee WK and Wrangler JK both feature 5x5 bolt patterns, but their offset requirements may differ significantly.

Factory wheels offer guaranteed fitment engineered specifically for your Jeep model. They provide exact offsets, confirmed brake caliper clearance, and precise hub diameters. OEM wheels typically remain available for years after production, ensuring replacement availability if damage occurs.

Aftermarket wheels deliver different advantages. Unlike OEM options designed for single vehicles, aftermarket wheels often accommodate multiple bolt patterns across various models. They typically feature larger hub bores that require hub-centric rings to match factory wheel center bores.

While aftermarket wheels provide greater customization and more aggressive styling options, their availability periods tend to be shorter than OEM alternatives. Finding exact replacements years later can prove challenging if one wheel gets damaged.

Proper Jeep wheel fitment involves much more than matching bolt patterns alone. Browse complete wheel and tire packages designed specifically for your Jeep model at Performance Plus Tire, where compatibility is verified across all critical specifications.

Aftermarket Jeep wheels require careful evaluation beyond visual appeal. The right choice balances your performance requirements, driving style, and terrain preferences with practical considerations like durability and maintenance.

Steel wheels deliver exceptional durability for serious off-road adventures. When damaged on the trail, steel wheels can often be repaired with basic tools—a few hammer strikes typically restore their shape. Steel also provides superior grip in snowy conditions. However, steel's substantial weight penalty—approximately 2.5-3 times heavier than equivalent aluminum options—reduces acceleration, extends braking distances, and decreases fuel efficiency.

Aluminum alloy wheels offer significant performance advantages despite higher initial costs. Reduced unsprung weight improves suspension response over rough terrain, creating a smoother ride quality. Modern alloy construction blends multiple metals for strength that far exceeds earlier aluminum wheel designs. Alloy wheels also provide vastly more style and finish options than steel alternatives.

Consider this key difference for trail use: steel wheels dent when they hit obstacles, while alloy wheels scrape across rocks, creating "rock rash" rather than structural damage.

Wheel diameter directly affects your Jeep's trail capability. Maintain wheel diameter at no more than half your tire's overall height for optimal performance—use 15-16 inch wheels with 33-inch tires, or 17-inch wheels with 35-inch tires. This ratio ensures adequate sidewall flex for absorbing impacts and conforming to terrain.

Wheel width also matters, though not always as expected. Narrower wheels often outperform wider options off-road. A 9-inch wheel paired with a 12.5-inch wide tire creates beneficial tire bulge that protects the rim when crawling over rocks and technical obstacles.

Wheel weight dramatically influences vehicle dynamics. Heavy wheels increase rolling mass, reducing power delivery and requiring longer stopping distances. Quality aftermarket Jeep wheels typically feature load ratings between 2,500-3,500 pounds per wheel, meeting most standard applications.

For heavily modified Jeeps or those carrying maximum payloads regularly, prioritize wheels with higher load ratings. Remember that tire load capacity cannot compensate for inadequate wheel strength—both components must meet your vehicle's demands.

Traditional wheels rely entirely on air pressure to secure tire beads against the rim. This system works perfectly for highway driving but becomes limiting when reducing air pressure for enhanced off-road traction.

Beadlock wheels feature a mechanical locking ring that physically clamps the tire bead to the wheel. This design prevents tire slippage even at extremely low pressures (1-10 psi), dramatically improving traction on challenging terrain. The trade-offs include additional weight, higher cost, and regular maintenance to keep fasteners properly torqued.

For the best combination of performance and style, explore our specialized Jeep wheel and tire packages at Performance Plus Tire, where you'll find options engineered for your specific model and driving requirements.

Proper fitment extends beyond matching bolt patterns. Once you start modifying your Jeep's stance and clearance, new challenges emerge that directly impact your off-road experience and vehicle reliability.

Lift kits create additional clearance for larger tires, but this relationship isn't always straightforward. According to compatibility charts, suspension lift heights directly correlate with possible tire sizes. Many Jeep owners assume a 2-inch lift automatically accommodates 33-inch tires, or that a 4-inch lift guarantees 37-inch tire clearance.

Lifting your Jeep and installing larger wheels places increased stress on the entire drivetrain. The added weight and leverage require your engine, transmission, transfer case, and differentials to work harder. Modest lifts with appropriate tire sizing maintain better reliability than extreme combinations.

Rubbing issues frequently occur at full steering lock or during suspension articulation. Common contact points include:

Sway bar interference during turns

Frame or spring tower contact

Fender well pinch seams during compression

Control arm clearance during articulation

Even properly lifted Jeeps can experience these problems. A Wrangler JK with a 3.5-inch lift encountered severe rubbing after upgrading from 35-inch to 37-inch tires. The solution required wheel spacers to adjust tire position and prevent frame contact.

Adjust control arms to properly position the axles for articulation clearance. Simply adding more lift doesn't solve rubbing if the axles aren't properly centered under the vehicle.

Factory Jeeps come with higher offset and backspacing measurements that keep tires tucked inward. This works perfectly with stock tire sizes but creates clearance problems with larger rubber.

Wheels with reduced backspacing provide greater clearance between tires and suspension components for trail use. This prevents damage during flex and articulation. However, too little backspacing pushes tires outward, potentially increasing leverage on ball joints, hubs, and axles.

Wheels with aggressive negative offset may place additional stress on steering components. They can also push tires beyond legal limits in some jurisdictions, as tires extending past fender lines can violate local regulations.

The visual appeal of your Jeep wheels defines your vehicle's personality and makes a statement about your style. Smart finish selection balances the look you want with the maintenance you're willing to handle.

Each wheel finish offers distinct advantages based on your driving conditions and style preferences:

Chrome plating delivers a classic, mirror-like reflective appearance that protects against corrosion in harsh conditions. This finish works exceptionally well for street-driven Jeeps where maximum visual impact is the goal.

Powder coating provides superior durability against rust, heat, chips, and scratches while offering vibrant color options ideal for off-road applications. This finish stands up to trail abuse better than any other option.

Painted wheels deliver endless color possibilities, from solid colors to eye-catching two-tone designs. Paint finishes allow perfect color matching with your Jeep's body or accent colors.

Polished aluminum creates a smooth metallic sheen without the mirror-like reflection of chrome but requires more maintenance. This finish offers a sophisticated appearance that appeals to many Jeep owners.

Matte and satin finishes hide brake dust and dirt effectively, making them practical for regular trail use. These finishes maintain their appearance with minimal cleaning between adventures.

OEM wheels perfectly match your Jeep's original design with the exact offset, guaranteed brake caliper clearance, and precise hub diameter. They remain available for years after production, ensuring replacement options if damage occurs.

Custom wheels deliver dramatic personalization advantages. Endless style options range from sleek minimalist designs to aggressive tactical looks, with aftermarket wheels enabling unique fitment configurations impossible with factory options. Consider staggered setups with wider rear wheels for a muscular stance.

When shopping for complete jeep wheels and tires packages, look for options specifically designed for your model. Quality packages include properly sized tires mounted on compatible wheels with appropriate load ratings.

Choose packages featuring wheels with finishes matching your intended use—powder-coated for rugged trails or polished for street appeal. Many retailers offer bundled savings compared to purchasing components separately, making packages an excellent value for complete wheel upgrades.

Aftermarket Jeep wheels represent one of the most impactful upgrades you can make to your vehicle. The right wheel selection enhances both performance and appearance while the wrong choice creates costly problems and safety concerns.

Quality aftermarket wheels deliver measurable improvements that go beyond aesthetics. Reduced unsprung weight improves suspension response, while proper fitment prevents drivetrain stress and premature component wear. These benefits make wheel upgrades a smart investment for any Jeep owner.

Your specific Jeep model determines which wheels will work best for your needs. Whether you drive a classic CJ, a reliable YJ/TJ, or a modern JK/JL Wrangler, understanding your vehicle's requirements ensures successful wheel selection. The same principle applies to Gladiator and Cherokee models - specifications matter more than appearance.

Material choice affects long-term satisfaction with your upgrade. Steel wheels offer durability for serious trail use, while alloy wheels provide performance advantages for mixed driving. Both options serve different purposes, and the best choice depends on your typical driving conditions.

Wheel finish selection should match your maintenance preferences and usage patterns. Powder-coated wheels withstand trail abuse better than polished options, while chrome wheels suit vehicles that see more street time. Consider how much maintenance you're willing to perform.

The aftermarket wheel market offers extensive options for every Jeep model and budget. Quality wheels with proper load ratings provide years of reliable service without compromising safety or performance. Focus on fitment and specifications first, then choose the style that matches your preferences.

Double-check all specifications before making your purchase decision. Bolt pattern, offset, backspacing, and load rating must match your Jeep's requirements. This verification prevents fitment problems and ensures optimal performance from your new wheels.

At Performance Plus Tire, we carry the best selection of Jeep wheels at competitive prices. Our fitment experts help ensure you get wheels that work perfectly with your specific model and driving needs. Ready to upgrade your Jeep's performance and style?

Understanding these essential factors will help you make an informed decision when purchasing aftermarket Jeep wheels that enhance both performance and appearance.

Bolt pattern compatibility is non-negotiable - Modern JK/JL Wranglers and Gladiators use 5x5 pattern, while older YJ/TJ models require 5x4.5 pattern for proper fitment.

Wheel weight dramatically impacts performance - Aftermarket wheels can reduce 8-10 pounds per wheel compared to stock, improving acceleration, braking, and suspension response.

Proper offset and backspacing prevent clearance issues - Lower offset wheels provide better clearance for larger tires and lift kits while avoiding rubbing during articulation.

Steel wheels offer durability, alloy wheels provide performance - Steel wheels are repairable on trails but heavy, while alloy wheels reduce unsprung weight for better ride quality.

Wheel diameter should be half your tire height - Use 15-16 inch wheels for 33-inch tires and 17-inch wheels for 35-inch tires to maintain optimal sidewall flex for off-road performance.

When selecting aftermarket Jeep wheels, prioritize technical compatibility over esthetics to ensure safe, reliable performance. Quality wheels with proper load ratings (2,500-3,500 pounds) provide the foundation for enhanced off-road capability and improved on-road dynamics.

The most critical factor is ensuring the bolt pattern matches your specific Jeep model. For example, modern JK/JL Wranglers and Gladiators use a 5x5 pattern, while older YJ/TJ models require a 5x4.5 pattern for proper fitment.

Wheel weight significantly impacts performance. Aftermarket wheels can reduce 8-10 pounds per wheel compared to stock options, improving acceleration, braking, and suspension response while reducing wear on drivetrain components.

Steel wheels offer exceptional durability and are easily repairable on trails but are heavier. Alloy wheels are lighter, reducing unsprung weight for better ride quality and performance, but may be more susceptible to damage from rocks.

A good rule of thumb is to choose a wheel diameter that's about half your tire's overall height. For example, use 15-16 inch wheels for 33-inch tires and 17-inch wheels for 35-inch tires to maintain optimal sidewall flex for off-road performance.

When shopping for a complete package, look for options specifically designed for your Jeep model. Ensure the package includes properly sized tires mounted on compatible wheels with appropriate load ratings (typically between 2,500-3,500 pounds). Also consider wheel finishes that match your intended use – powder-coated for rugged trails or polished for street appeal.