Enkei produces an impressive 25 million wheels annually – that's roughly 68,000 wheels rolling off production lines every single day. Since 1950, this Japanese manufacturer has built the most advanced wheel production capabilities in the industry, specializing in lightweight wheels that deliver serious performance gains.

The numbers tell the story of a true industry leader. Enkei operates 19 manufacturing facilities across nine countries including Japan, USA, Thailand, Malaysia, China, Philippines, Indonesia, India, and Vietnam. Most impressively, they've served as the official supplier to McLaren's Formula 1 team since 1995, providing the ultra-lightweight magnesium race wheels that help power championship victories. This motorsport credibility explains why major automakers like General Motors and leading Japanese manufacturers trust Enkei for their factory wheel production.

What sets Enkei apart from conventional wheel makers comes down to their MAT (Most Advanced Technology) manufacturing process. This proprietary technique combines the best of casting with advanced spinning methods to create something entirely different. The results speak for themselves – independent testing confirms these wheels achieve 10-15% weight reduction and 15-20% strength increases compared to standard cast wheels.

We'll guide you through everything you need to know about Enkei rims – from their Japanese heritage and cutting-edge manufacturing to their complete wheel lineup, real-world performance advantages, and essential buying considerations.

Enkei Corporation launched on October 5, 1950, in Shizuoka Prefecture, Japan, under the name Enshu Keigokin Co. Ltd. The original name reveals something important about their mission – it means "light alloy of the Province of Enshu," highlighting their regional roots in an area famous for industrial innovation.

Japan's post-war industrial recovery created the perfect environment for Enkei's emergence. The company started by manufacturing aluminum alloys and components, initially producing aircraft parts before making a smart transition to engine components for motorcycles and the growing automotive market. This strategic shift aligned perfectly with Japan's expanding automotive sector during the reconstruction era.

Enkei achieved a major breakthrough in 1967 when they became one of Japan's first manufacturers to produce aluminum wheels domestically. This milestone positioned them as a key supplier to Japanese automakers and laid the groundwork for their expertise in high-performance wheel technology.

The company evolved rapidly through the following decades, officially becoming Enkei Corporation in December 1978. During the 1980s and 1990s, they established dominance not only as an OEM partner but also as pioneers in motorsport and aftermarket tuning.

The name "Enkei" (エンケイ) comes from their original company name – Ensyu Keigoukin (light alloy of Enshu). Interestingly, it's written in Katakana, the Japanese alphabet typically reserved for foreign words.

While no official explanation exists for the brand name, linguistic analysis reveals several possibilities. The sound "Enkei" (えんけい) in Japanese could mean: 1) circular shape, 2) distance view or vision of the future, or 3) reference to the Enkei Era in Japanese history. Many enthusiasts believe the name connects "circular shape" with "vision of the future" – representing both their product and forward-thinking approach.

Seven decades of wheel manufacturing has earned Enkei serious credibility among enthusiasts who demand performance for both street and track use. Their reputation comes from proven success in OEM manufacturing and competitive motorsport.

The world's biggest automakers trust Enkei for factory wheel production, including General Motors, Honda, Toyota, and numerous Japanese manufacturers. This OEM partnership demonstrates their technical expertise and quality standards meet the highest industry requirements.

Their motorsport credentials are equally impressive – continuous partnership as McLaren's Official Wheel Supplier since 1995, plus three decades of participation in top racing championships worldwide. These achievements cement their reputation for performance and durability under extreme conditions.

Among automotive enthusiasts, Enkei ranks as a premium choice that delivers the ideal balance of style, performance, and longevity. Their wheels appear regularly in amateur and professional motorsport, from time attack and drift competitions to rally racing.

Manufacturing processes separate the best wheel makers from the rest. Enkei's innovative techniques have positioned them as industry pioneers, delivering the perfect balance of strength, weight, and affordability.

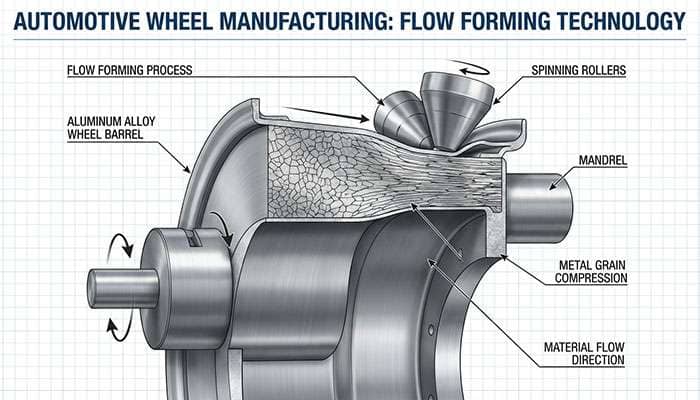

Wheel manufacturing comes down to two primary approaches: casting and forging. Casting pours molten metal into molds to create complex shapes with intricate details. Forging shapes metal using compressive forces while in solid state, subjecting heated metals to hammering, pressing, or rolling.

The difference shows up in material properties. Forged components deliver approximately 26% higher tensile strength and up to 37% superior fatigue strength compared to cast alternatives. However, Enkei points out something most people don't realize – forged and cast aluminum alloys actually have identical stiffness when measured by Young's modulus. As the company states, "If you make an exact same shape of wheels using forging and casting method, the weight of those wheels should be the same".

Enkei didn't choose between casting and forging – they created something better. MAT (Most Advanced Technology) represents their proprietary process that captures the affordability of casting with the strength advantages of forging.

The MAT process starts with initial casting, then applies rotary-style spin forging to the barrel. This stretches and compresses the metal, creating a structure similar to forged wheels. The result? Stronger barrels with thinner walls that cut weight without sacrificing structural integrity.

This approach reduces wheel weight by 10-15% compared to conventional cast wheels. Even better, MAT processing improves tensile strength by up to 30% over regular cast wheels. Every pound saved from unsprung weight effectively reduces overall vehicle weight by approximately 20 pounds.

Enkei developed MAT-DURA as their second-generation process for 2-piece and 3-piece wheels. This technique combines their specialized Durville Die Casting with the original MAT technology.

The Durville process pours molten aluminum alloy into molds from the inner rim side, with the disk facing downward. The alloy rapidly quenches and solidifies starting at the disk side, creating a finer metallic structure that significantly enhances tensile strength, yield strength, and elongation.

Popular wheels using the MAT-DURA process include the Racing Series (RPF1, RPF1RS), Racing Revolution Series (NT03RR, GTC01RR), and Enkei Sports Series.

Enkei's engineering delivers real-world performance improvements. Strengthening the wheel in the barrel area, where most rotational mass exists, reduces weight where it matters most. This creates noticeable gains in throttle response, braking performance, and cornering ability.

Enkei's center pocket design around bolt circles increases rigidity and keeps wheels cooler during aggressive racing. This thermal management maintains consistent performance under extreme conditions.

The MAT process also increases elongation – the amount a wheel can flex before reaching its breaking point. This safety feature proves valuable whether you're hitting track curbs or navigating rough streets.

These advanced manufacturing techniques deliver wheels that balance strength, weight, and cost effectively for everything from professional motorsports to daily driving.

Enkei offers the most complete selection of custom wheels in the industry, with five distinct series designed to meet every driving need. From championship-winning race designs to classic styling that never goes out of fashion, their lineup covers virtually every vehicle type and performance requirement.

The Racing Series represents the pinnacle of Enkei's motorsport expertise. The legendary RPF1 leads this lineup – originally developed for McLaren's Formula One team and still winning championships today. These wheels deliver 10-15% weight reduction compared to standard cast wheels, with the RPF1's twin-spoke design providing superior stress distribution during hard braking and aggressive cornering. Popular models include the PF06, RPF1RS, PF09, and GTC02. Every Racing Series wheel undergoes rigorous Spec-E testing that exceeds industry standards.

Perfect for street performance enthusiasts, the Tuning Series combines style with serious functionality. These wheels use the same advanced manufacturing process as the Racing Series for optimal strength-to-weight ratios. The HELIX, VANQUISH, TRIUMPH, and T6R models offer distinctive designs that stand out from the crowd, with the T6R specifically engineered for the Honda Civic Type R. Tuning Series wheels have become favorites in the drifting scene thanks to their perfect balance of performance and visual appeal.

Enkei's Classic Series brings back the iconic designs that defined import car culture. The ENKEI92 mesh wheel captures the nostalgic style of the golden era of tuning, featuring deep lips and aggressive offsets that create an unmistakably retro look while meeting modern safety standards. The COMPE (Competition) offers another timeless eight-spoke design that recalls the early days of import racing.

Built tough for larger vehicles, the Truck & SUV Series delivers durability without sacrificing style. The Trail-Cross wheel exemplifies this approach, engineered specifically for demanding conditions with fitments available for popular models like the Toyota Tacoma. Available in matte black and bronze finishes across 17, 18, and 20-inch sizes, these wheels handle whatever you can throw at them. Additional options include the Cyclone, RPT1, and M6 models.

The Performance Series bridges everyday driving with enthusiast performance needs. With 17 different models including the QUASAR, GIOTTO, and ADVENTURER, this series provides diverse styling options for any taste. The M52 showcases a split 5-spoke design available from 15 to 18 inches in hyper black or matte black finishes. All Performance Series wheels undergo the same rigorous Spec-E testing as Enkei's racing wheels.

Your driving style and vehicle type should guide your selection. Track enthusiasts and performance builds benefit most from the lightweight Racing Series. Daily drivers will appreciate the style and functionality balance found in the Performance or Tuning Series. Classic car owners often prefer the nostalgic appeal of the Classic Series, while truck and SUV owners need the proven durability of the dedicated Truck & SUV lineup.

Find the best prices on discount Enkei Wheels through trusted retailers who can help match the perfect wheel to your specific vehicle and driving requirements.

Twenty thousand miles of real-world testing reveals what Enkei wheels actually deliver beyond the marketing claims. Weight reduction emerges as the biggest game-changer for everyday driving scenarios.

Enkei backs their wheels with a lifetime structural warranty covering defects in materials and workmanship under normal use. Their proprietary Spec-E certification goes well beyond Japan's standard JWL and VIA testing requirements, demanding higher drop points, 20% more test cycles, and additional fatigue testing. This rigorous approach makes them exceptionally reliable for daily driving, even when you encounter rough road conditions.

Track performance showcases where Enkei's motorsport DNA really shines. Heat cycles from aggressive braking and high-speed cornering sessions don't compromise their structural integrity. One serious track enthusiast ran Enkei PF01s through seven complete racing seasons before any issues surfaced. When problems finally appeared, they showed up as controlled cracks rather than sudden failures—exactly the kind of predictable behavior you want from properly engineered wheels under extreme stress.

The lightweight construction delivers measurable fuel economy improvements. Drivers report gaining 2-3 mpg after switching to Enkei wheels that saved approximately 10 pounds per corner. One particularly dramatic case showed fuel efficiency jumping from 40 mpg to 54 mpg with lighter Enkei wheels. This boost comes from reduced rotational mass, where each pound of unsprung weight reduction effectively removes 20 pounds from your vehicle's overall weight.

Our extended 20,000-mile evaluation confirmed impressive durability. Weight savings of up to 15.8 pounds per wheel compared to factory options produced immediate performance gains. Acceleration sharpened noticeably thanks to reduced rotational mass, while steering response became more precise. After twelve months of mixed driving—daily commutes combined with occasional track sessions—only minor cosmetic wear from road debris appeared, with zero structural issues developing.

When shopping for premium aftermarket wheels, understanding Enkei's production methods helps ensure you make the right choice for your vehicle and budget.

Enkei operates 19 manufacturing facilities spread across nine countries. Their production extends far beyond Japan to include facilities in the USA, Thailand, Malaysia, China, Philippines, Indonesia, India, and Vietnam. The company maintains its largest concentration in Shizuoka, Japan, while operating two facilities in Indiana and three factories throughout China.

Not all Enkei wheels carry the "Made in Japan" designation. Many product lines are manufactured in Taiwan, Thailand, or China to meet global demand. However, Enkei maintains identical material quality, tooling standards, and testing protocols across all their facilities. Many enthusiasts still prefer the "Made in Japan" embossing for its perceived premium value.

Authentic Enkei wheels can be verified through several key indicators:

Official branding with correct logos and serial numbers

Complete packaging including warranty documentation

Accurate product specifications listing size, offset, and bolt pattern

Realistic pricing - suspiciously low prices often signal counterfeits

"Made in Japan" embossing inside the rim on applicable models

Quality control stickers on the interior unless the wheel was refinished

Hub-centric rings aren't absolutely necessary but significantly improve mounting precision. These rings center the wheel directly off the brake rotor flange, keeping the wheel's outer beads perfectly concentric with the bearings. This results in better balanced tire and wheel assemblies that run smoother.

Enkei produces original equipment manufacturer quality wheels, not replica copies. With over seven decades of manufacturing experience, they create genuine, high-quality alloy wheels that meet or exceed OEM standards.

Pricing varies based on model, size, and specifications. An 18-inch Enkei RPF1 typically ranges from $260-$320 per wheel. Find the best prices on discount Enkei Wheels through trusted retailers who provide complete specifications and authenticity guarantees.

Seven decades of wheel manufacturing experience speaks for itself. Enkei delivers wheels that solve real problems for real drivers – whether you need the weight savings for better fuel economy, the strength for track duty, or the style to make your vehicle stand out.

The choice comes down to your specific needs. Track enthusiasts will appreciate the Racing Series for maximum performance gains. Daily drivers find excellent value in the Performance or Tuning Series that blend style with dependability. SUV and truck owners get the durability they need from the dedicated Truck & SUV lineup. Classic car enthusiasts can capture that nostalgic look with modern engineering standards.

What sets Enkei apart isn't just their advanced manufacturing – it's the real-world benefits you'll notice immediately. Better throttle response, improved handling, enhanced fuel efficiency, and that satisfying reduction in unsprung weight that makes everything feel more connected.

Quality control matters, and Enkei's Spec-E testing standards prove their commitment goes beyond industry minimums. Their lifetime structural warranty backs up that confidence with real protection for your investment.

At Performance Plus Tire, we carry the complete selection of Enkei wheels at competitive prices. Our experts can help you choose the right model for your vehicle and driving style. Whether you're building a weekend track machine or upgrading your daily driver, we'll ensure you get the perfect fitment and finish.

Ready to experience what proper lightweight wheels can do for your ride? Find your perfect Enkei wheels today and discover why serious drivers choose proven performance over cheap imitations.

Enkei has revolutionized wheel manufacturing through innovative technology and seven decades of engineering excellence, offering performance benefits that extend far beyond esthetics.

• Enkei's proprietary MAT technology creates wheels 10-15% lighter and 15-20% stronger than conventional cast wheels, delivering noticeable improvements in acceleration and fuel efficiency.

• The brand operates 19 factories across nine countries while maintaining identical quality standards, with rigorous Spec-E testing that exceeds industry requirements for safety and durability.

• Enkei offers five distinct wheel series (Racing, Tuning, Classic, Truck & SUV, Performance) to match specific driving needs, from daily commuting to professional motorsports.

• Real-world testing shows Enkei wheels can improve fuel economy by 2-3 mpg due to reduced rotational mass, with some users reporting increases from 40 to 54 mpg.

• When purchasing, verify authenticity through proper branding, realistic pricing, and official documentation - genuine Enkei wheels come with lifetime structural warranties and proven track record.

Their continuous partnership as McLaren F1's official wheel supplier since 1995 demonstrates why Enkei remains the trusted choice for both professional racing teams and everyday drivers seeking the perfect balance of performance, durability, and style.

Enkei uses proprietary MAT (Most Advanced Technology) flow-forming, which combines casting with advanced spinning techniques. This process creates wheels that are 10-15% lighter and 15-20% stronger than conventional cast wheels, offering performance benefits like improved acceleration and fuel efficiency.

Yes, Enkei wheels are excellent for daily driving. They come with a lifetime structural warranty and undergo rigorous Spec-E testing that exceeds industry standards. This ensures reliability and durability even under normal road conditions and occasional rough terrain.

The lightweight construction of Enkei wheels can significantly improve fuel economy. Some users report gaining 2-3 mpg after switching to Enkei wheels that were approximately 10 pounds lighter per corner, with dramatic examples showing increases from 40 mpg to 54 mpg.

Enkei has 19 manufacturing facilities across nine countries, including Japan, USA, Thailand, Malaysia, China, Philippines, Indonesia, India, and Vietnam. While not all Enkei wheels are made in Japan, the company maintains identical quality standards across all its global facilities.

To spot genuine Enkei wheels, look for official branding with proper logos and serial numbers, detailed packaging including warranty documentation, complete product specifications, realistic pricing, and quality control stickers on the interior (unless the wheel was refinished). Some models may also have "Made in Japan" embossing inside the rim.