Off-road wheels come in several distinct types, each engineered to handle specific terrain challenges and driving demands. Most off-road wheels range from 15 to 20 inches in diameter, with widths varying from 7 to 12 inches, giving you plenty of options to match your vehicle's requirements and your adventure plans.

Understanding the construction and materials is essential when selecting the right wheels for your off-road setup. Steel wheels provide exceptional strength and durability, making them the go-to choice for rock crawling and heavy-duty applications. Aluminum wheels offer improved handling and better fuel efficiency due to their reduced weight. When performance matters most, forged wheels deliver superior strength compared to cast alternatives in demanding conditions. Beadlock wheels have gained tremendous popularity among serious off-roaders because they use a mechanical locking ring to secure tires at extremely low pressures, while also providing an aggressive appearance with their distinctive mounting hardware. Popular models like the Fuel Rebel demonstrate impressive load capacities, handling anywhere from 2300 lbs on 6-lug configurations to 3700 lbs for 8-lug setups, with some specialized wheels rated up to 4500 pounds per wheel.

We've put countless off-road wheels through their paces on everything from technical rock sections to deep sand washes. Our hands-on experience across diverse terrains gives us the insights you need to choose the right wheel type for your specific off-road adventures.

Image Source: TREAD Magazine

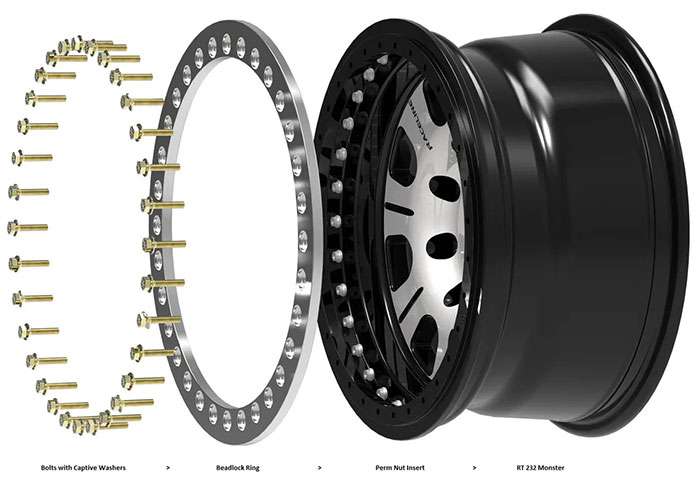

Beadlock wheels represent a specialized category of off-road wheels designed with a unique mechanical clamping system. The name tells the story - these wheels literally "lock" the tire's bead to the rim using a metal ring and multiple bolts. This design originated from military applications where they were known as "combat wheels," but serious off-road enthusiasts have adopted them for extreme terrain challenges.

The fundamental difference between beadlock wheels and standard wheels lies in how they secure the tire. While conventional wheels rely entirely on air pressure to hold the tire in place, beadlock wheels add a mechanical element that physically clamps the tire bead to the wheel. This mechanical advantage becomes crucial when running extremely low tire pressures for maximum traction on challenging surfaces.

The mechanical clamping system sets beadlock wheels apart from every other wheel type. Standard wheels depend entirely on air pressure to keep your tire in place, but beadlocks take a different approach. They use a metal ring bolted directly to the wheel's outer edge, creating a physical lock that holds the tire bead securely. This system creates a layered assembly with five essential components:

Inner Wheel Ring - The main body that mounts to the vehicle

Outer Beadlock Ring - A separate ring that bolts to the wheel

Mounting Bolts - Typically 24-32 bolts that secure the outer ring

Tire Bead - The edge of the tire that sits between the rings

Mounting Surface - The precision-machined area where the rings meet

Installation requires mounting the tire's inner bead like a standard wheel, then positioning the outer bead against the wheel's mounting surface. The beadlock ring goes over the tire's outer bead, followed by installing the bolts in a specific pattern with exact torque specifications. This mechanical clamp prevents tire separation regardless of air pressure - a crucial advantage when you're running extremely low pressures for maximum traction.

Beadlock wheels come in various materials including cast aluminum, forged aluminum, and steel. The Raceline Monster stands out as one of the first and most recognizable beadlock wheels, dominating off-road racing for almost 20 years. This proven track record demonstrates the reliability these wheels offer when you're pushing your vehicle to its limits.

Pros:

Superior Tire Security: You can drop tire pressure as low as 5-7 PSI without risking the tire coming off the rim - compared to 12-20 PSI minimum for standard wheels.

Enhanced Traction: The ability to run extremely low tire pressures increases the tire's contact patch on challenging surfaces.

Rock-Solid Performance: These wheels excel in severe off-road conditions where tire slippage would otherwise occur.

Durability: Generally stronger and more robust for facing trail beatings.

DIY-Friendly: Easier tire changes without special tire shop equipment - helpful when out on remote trails.

Esthetic Appeal: The visible bolts and extra ring deliver that hardcore off-road style many enthusiasts desire.

Cons:

Weight Penalty: Beadlocks add significant heft to each corner of your vehicle due to the additional hardware, affecting handling, fuel economy, and putting extra stress on suspension components.

Maintenance Demands: These wheels require regular attention including bolt torque checks before and after off-road use, cleaning of mounting surfaces, and inspection for damage or wear.

Cost Considerations: Expect higher initial purchase prices and ongoing maintenance expenses.

Legal Restrictions: Most beadlock wheels are not DOT (Department of Transportation) approved for street use. If bolts come loose during driving, the tire could experience rapid deflation, creating a safety hazard.

Specialist Installation: Many tire shops won't touch beadlock wheels for legal reasons, meaning you might need to mount them yourself.

Beadlock wheels excel in specific situations where their unique advantages outweigh the added complexity and cost:

Extreme Off-Roading: Rock crawling, deep sand runs, and mud bogging benefit significantly from ultra-low tire pressures (5-8 PSI) that provide maximum traction. Standard wheels simply can't handle these pressures without risking tire separation from the rim.

High-Power Applications: Vehicles with serious horsepower, typically 800+ HP, need beadlocks to prevent tire slippage during hard launches on sticky surfaces. Those pushing 1200-1300 horsepower often require double beadlock setups for ultimate tire security.

Desert Racing: High-speed runs across rough desert terrain demand the tire stability that only beadlocks can provide. The mechanical clamping system keeps tires positioned correctly even under extreme stress.

Professional Competition: Championship-winning performance across multiple off-road racing categories proves these wheels deliver when competition matters most.

Occasional Off-Roaders: "Beadlock-capable" wheels offer a smart compromise for those splitting time between streets and trails - they provide the aggressive appearance and can be converted to true beadlocks later without immediate legal concerns.

Here's the reality: beadlock wheels aren't necessary for everyone. Unless you regularly tackle seriously challenging terrain or run very high horsepower, standard off-road wheels will likely serve your needs with fewer complications. Many manufacturers offer wheels with beadlock styling that remain street-legal while skipping the mechanical clamping function of true beadlocks.

Beadlock wheels represent a specialized tool in your off-road arsenal. They're invaluable for specific applications but potentially unnecessary for casual trail riders who rarely push their vehicles to extreme limits.

Image Source: J.D. Power

Forged aluminum wheels represent the top tier of off-road wheel construction, delivering exceptional strength-to-weight performance that serious enthusiasts demand. These premium components start as solid blocks of 6061-T6 aerospace-grade aluminum that undergo an intense manufacturing process unlike anything used for cast wheels.

The manufacturing process sets forged aluminum wheels apart from every other wheel type. Manufacturers begin with solid aluminum billets that are heated and compressed under 8,000-10,000 tons of pressure. This extreme force fundamentally changes the metal's internal structure, aligning grain patterns to follow the wheel's contours.

After the initial forging, these wheels receive precision CNC machining to achieve their final design, with craftsmen adding hand-finished details. This careful process eliminates the internal porosity and weak spots that plague cast wheels.

Forged aluminum wheels use high-quality 6061-T6 aluminum alloy with T6 heat treatment, resulting in wheels that weigh 25-30% less than comparable cast options. To put this in perspective, a forged aluminum wheel designed for a 7,400-pound load rating weighs just 39 pounds compared to a steel wheel's 70 pounds for the same capacity.

Beyond weight reduction, forged wheels deliver:

Superior strength-to-weight ratio: The compressed aluminum structure lets manufacturers use less material while maintaining or exceeding the strength of heavier alternatives

Higher load capacities: Specialized forged aluminum wheels can handle up to 13,000 pounds per wheel

Enhanced heat dissipation: Aluminum dissipates heat three times more effectively than steel, extending tire, brake, and suspension component life

Customization options: The forging process enables multiple fitment configurations, including SureFit, SpecFit, CustomFit, and CustomFitEXT options for various vehicle modifications

Pros:

Exceptional strength: The compression-aligned grain structure creates wheels that resist cracking, denting, and breaking under extreme stress

Significant weight reduction: Lighter unsprung weight improves acceleration, braking, and suspension response

Enhanced performance: Reduced rotational mass allows quicker directional changes and better handling

Superior heat management: Tests in Phoenix demonstrated forged aluminum wheels running significantly cooler than steel wheels, even after vehicles sat parked at day's end

Corrosion resistance: Aluminum naturally resists corrosion without additional coatings, unlike steel wheels that require paint protection

Extended service life: The structural integrity and material properties contribute to extended durability in demanding conditions

Value retention: Despite high initial costs, forged wheels typically hold their value well and resell without significant depreciation

Cons:

Premium pricing: The labor-intensive manufacturing process, expensive materials, and specialized equipment make forged wheels significantly more costly than cast alternatives

Extended production time: Custom forged wheels typically require 4-5 weeks lead time for production

Limited availability: Finding specific sizes or designs can be challenging compared to more common wheel types

Repair challenges: While durable, damaged forged wheels can be difficult and expensive to repair

Forged aluminum wheels excel in applications where their benefits justify the premium investment:

High-performance off-roading: The superior strength-to-weight ratio makes these wheels perfect for desert racing, rock crawling, and technical trail riding where every pound affects vehicle dynamics. The Method Race Wheels 202 offers an impressive 4,000-pound load rating specifically designed for rock crawling and desert racing applications.

Heavy-duty applications: Refuse collection, logging, mining, and other demanding vocational uses benefit from forged aluminum's combination of strength and reduced weight. Many manufacturers offer specialized heavy-load forged wheels with significantly higher load ratings than standard options.

Performance-focused builds: Vehicles where handling precision and acceleration matter benefit substantially from reduced unsprung and rotational mass. The weight reduction at each corner improves responsiveness, braking, and overall driving dynamics.

Modified vehicles with aggressive fitments: The CustomFit and CustomFitEXT options available with some forged wheels accommodate lifted trucks and SUVs with wheels extending up to and beyond 3 inches outside the fender. These aggressive fitments often require specialized wheel construction that forged aluminum provides.

Competitive motorsports: Professional racing teams across various disciplines choose forged wheels for their combination of strength, weight savings, and performance benefits. The extreme demands of competition make the premium price worthwhile for serious competitors.

Extreme terrain exploration: For adventurers tackling challenging environments like desert dunes, rocky trails, or mud bogs, the superior durability of forged wheels provides reliability in remote locations where wheel failures could prove catastrophic.

Many serious off-roaders consider forged aluminum wheels the ultimate choice, especially options like the Method Race Wheels 202 with its iconic 12-window design. For vehicles regularly pushed to their limits in demanding conditions, the initial investment in forged wheels typically pays dividends through improved performance, reduced maintenance, and greater reliability over time.

Image Source: RBP Tires

Steel wheels stand as the workhorses of the off-road world, delivering unmatched durability at prices that won't strain your budget. These robust components have earned their reputation among serious off-road enthusiasts who need reliable performance when the trail gets tough.

Steel wheels are built from robust carbon steel, providing exceptional strength and durability for demanding off-road conditions. The manufacturing process is straightforward - sheets of steel are stamped into the desired wheel shape. This simple production method keeps costs down while ensuring widespread availability.

The structural integrity of steel wheels sets them apart from other options. Steel offers tremendous resistance to bending and cracking when you encounter rocks, stumps, and other trail obstacles. This resilient nature makes steel wheels practically indestructible under normal off-road use, withstanding impacts that would damage or destroy other wheel types.

Steel wheels feature utilitarian designs with fewer styling options compared to alloy alternatives. Most come in simple spoke patterns with painted or silver finishes. This basic appearance serves a practical purpose - when trail damage inevitably occurs, you can easily repaint steel wheels rather than replacing them entirely.

The field-repairability of steel wheels proves invaluable during remote adventures. The malleability of steel means that if a wheel gets damaged on the trail, you can often hammer it back into usable shape with basic tools. This capability can mean the difference between continuing your adventure and being stranded miles from help.

Pros:

Exceptional durability: Steel wheels are nearly impossible to crack or bend without tremendous force, making them ideal for challenging off-road conditions.

Field repairability: Damaged steel wheels can often be hammered back into shape without specialized equipment – a significant advantage during remote adventures.

Cost-effectiveness: Steel wheels are substantially more affordable than aluminum alternatives, with prices starting as low as $55 per wheel compared to $100+ for alloy options.

Winter performance: The heavier weight of steel provides better traction on snowy and icy roads.

Impact resistance: Steel wheels absorb impacts from rocks, potholes, and trail obstacles without sustaining permanent damage.

Simplicity: Their straightforward design means fewer components that could potentially fail under stress.

Cons:

Weight penalty: Steel wheels weigh approximately 2.5-3 times more than aluminum wheels of equivalent size. This excess weight negatively impacts acceleration, braking performance, and overall fuel economy.

Limited design options: Steel wheels offer fewer styling choices, typically coming in simple spoke patterns with basic finishes.

Corrosion vulnerability: Steel wheels require protective paint to prevent rusting, unlike aluminum which naturally resists corrosion.

Reduced fuel efficiency: The increased rotational mass requires more energy to accelerate and maintain speed.

Suspension stress: The additional unsprung weight puts greater strain on suspension components.

Size limitations: Many steel wheels are only available in smaller diameters (typically up to 16 inches), limiting options for vehicles designed for larger wheels.

Steel wheels excel in specific off-road scenarios where their unique attributes provide meaningful advantages:

Extreme off-road environments: For rock crawling, mud bogging, or technical terrain, steel wheels provide confidence-inspiring durability. Their resistance to damage means one less worry when tackling challenging obstacles.

Budget-conscious builds: Entry-level off-roaders or those building rigs on tight budgets benefit from steel wheels' affordability without sacrificing essential performance. The cost savings can be redirected toward other critical components like tires or suspension upgrades.

Winter wheeling: The heavier weight of steel provides superior traction in snowy and icy conditions, making them excellent seasonal options even for vehicles that normally run alloy wheels.

Heavy-duty work applications: For vehicles that serve dual purposes as both off-road adventurers and work trucks, steel wheels handle heavy loads with ease. Their durability under repeated stress makes them ideal for vehicles facing both recreational and vocational demands.

Remote expedition vehicles: For overland travelers venturing far from civilization, the field-repairability of steel wheels provides crucial peace of mind. The ability to repair rather than replace a damaged wheel can mean the difference between continuing an adventure and being stranded.

Historical or period-correct builds: For vintage off-road vehicle restorations or period-correct builds, steel wheels often provide the authentic appearance sought by enthusiasts.

Steel wheels represent the no-nonsense choice for off-roaders who prioritize function over form. While they lack the flash and performance advantages of lighter alternatives, their bulletproof durability and budget-friendly price point ensure they remain relevant. For many serious off-road enthusiasts facing brutal trail conditions, steel wheels continue to provide the reliability and strength needed to reach the most remote destinations.

Image Source: Relations Race Wheels

Flow form wheels offer an attractive compromise for off-road enthusiasts who want better performance than cast wheels without the premium price of forged options. This innovative manufacturing approach delivers enhanced strength and reduced weight at a more accessible cost point.

The flow form manufacturing process sets these wheels apart from standard cast alternatives. Also known as flow forging or spin forging, this technique starts with a conventional cast aluminum wheel blank that gets a performance upgrade through secondary processing. The cast wheel spins at high speed while hydraulic rollers apply intense pressure to the barrel area under controlled heat. This process stretches and compresses the aluminum, changing its internal structure for improved strength.

This manufacturing method creates a denser, more uniform grain structure in the barrel section. The compression process significantly strengthens the aluminum without the extensive tooling costs required for fully forged wheels. Flow formed wheels typically deliver 30% greater strength compared to cast wheels.

Most flow formed wheels use A356 aluminum alloy, which differs from the 6061 aluminum found in forged wheels. The manufacturing technique allows for thinner walls without sacrificing durability, resulting in wheels that are approximately 15-25% lighter than traditional cast options.

Pricing for flow formed off-road wheels sits between cast and forged alternatives, with models starting around $248 for UTV applications and reaching $352 for full-size truck applications. This middle-ground pricing makes performance upgrades more attainable for budget-conscious enthusiasts.

Pros:

Notable weight savings – Flow formed wheels average 26% lighter than comparable cast wheels, reducing unsprung weight for better acceleration, braking, and handling

Improved strength – The spin forging process increases tensile strength and impact resistance, delivering 30% more strength than cast alternatives

Better heat management – The refined structure dissipates heat more effectively, helping prevent brake fade during demanding conditions

Smart value – These wheels provide many forged wheel benefits at a more reasonable price point

Enhanced fatigue resistance – The tighter grain structure distributes stress more evenly, reducing the localized cracking issues common with cast wheels

Design flexibility – The manufacturing process supports aggressive styling with thinner spokes and deeper concavity while maintaining structural integrity

Cons:

Hub section limitations – The center remains cast with inherent porosity, creating a potential weakness under extreme stress

Higher cost than cast – While less expensive than forged options, flow formed wheels still cost more than basic cast alternatives

Fewer customization options – Limited size, finish, and offset choices compared to fully forged wheels

Weight trade-off – Despite improvements over cast wheels, they're still heavier than forged alternatives

Strength limitations – Though substantially stronger than cast wheels, they don't achieve the ultimate strength of forged wheels

Flow formed wheels work well for several specific applications where their balanced characteristics provide real advantages:

Weekend trail riders – For enthusiasts who occasionally tackle challenging terrain without regularly pushing extreme limits, flow formed wheels offer adequate strength without forged wheel costs. Their enhanced durability over cast wheels provides confidence on rough surfaces.

Mixed-use vehicles – The reduced unsprung weight improves vehicle dynamics, making these wheels ideal for drivers seeking better handling, acceleration, and braking response. They're popular among those who split time between street and trail driving.

Expedition builds – For overland vehicles requiring reliability without excess weight, flow formed wheels strike a practical balance. Their strength-to-weight ratio helps maintain fuel efficiency during long journeys across varied terrain.

Electric vehicle applications – The weight savings particularly benefit electric vehicles where rotational mass significantly affects range and performance. Reduced unsprung weight helps suspension systems work more effectively while improving energy efficiency.

Performance on a budget – For enthusiasts seeking upgrades without premium forged wheel pricing, flow formed options deliver meaningful benefits at accessible price points. This value proposition makes them increasingly popular for daily drivers that see occasional off-road use.

Flow formed wheels represent a practical middle path for many off-road enthusiasts, providing enhanced performance characteristics without the premium investment required for fully forged alternatives.

Cast alloy wheels make up approximately 90% of originally equipped wheels on most vehicles today, making them the most common type you'll encounter in the off-road wheel market. Their widespread popularity comes from an effective balance of reasonable cost, attractive styling options, and solid performance for most off-road applications.

Cast alloy wheels start as molten aluminum (or aluminum alloys) that gets poured into molds, taking the wheel's shape as the metal cools. This production happens through two primary methods:

Gravity casting uses natural gravitational force to fill the molds with liquid aluminum. This budget-friendly approach allows for quick production of identical wheels, though it often creates less dense material. The cooling process can form small air pockets, requiring manufacturers to add extra material for structural strength.

Low-pressure casting has become the dominant manufacturing method, using positive pressure to force molten aluminum into the molds. This creates denser wheels with better mechanical properties than gravity-cast options. However, manufacturers still add extra material to strengthen the spokes and barrel sections, increasing the overall weight.

Cast alloy wheels offer impressive design flexibility. Product catalogs show numerous styling options, from the Black Rhino GUARD with its bold military-inspired appearance to the refined DIAMONDBACK model that comes in three different finishes and multiple diameters.

Pros:

Affordable manufacturing makes them much less expensive than forged or flow-formed alternatives

Design variety allows for detailed styling and numerous appearance options

Comfortable ride helps reduce road harshness and improves overall comfort

Sufficient strength for most daily driving and light to moderate off-road use

Corrosion resistance outperforms steel wheels, especially valuable in coastal areas or winter conditions

Easy availability in many designs, sizes, and bolt patterns

Cons:

Extra weight – typically heavier than forged or flow-formed wheels due to additional material requirements

Structural constraints – internal air pockets make them more likely to crack under extreme stress

Failure characteristics – tend to crack rather than bend when damaged, which can leave you stranded

Heat handling issues – don't dissipate heat as effectively as forged options

Fewer customization choices compared to forged wheels

Cast alloy wheels work well for everyday driving situations and moderate off-road adventures. Their performance characteristics make them suitable for:

Daily drivers with weekend trail time – Vehicles that primarily see pavement duty but occasionally hit dirt roads or mild trails get adequate durability without excess cost.

Budget-focused builds – Starting around $344 for 17-inch wheels from established manufacturers like Black Rhino, cast alloy wheels provide an affordable entry into off-road wheel upgrades.

Style-focused upgrades – The extensive design selection makes cast alloy wheels perfect when you want visual improvements without extreme performance requirements.

Light to moderate trail use – These wheels handle forest roads, gravel paths, and occasional rough terrain well when matched with proper tires.

Salt exposure environments – The natural corrosion resistance makes cast alloy wheels especially good for vehicles exposed to ocean spray or winter road salt.

Cast alloy wheels dominate the off-road market not because they excel in any single area, but because they provide a workable balance of performance, appearance, and cost that satisfies most drivers' needs without stretching budgets.

When selecting the right off-road wheels for your vehicle, this comparison breaks down the key differences between each type to help you make an informed decision:

| Attribute | Beadlock Wheels | Forged Aluminum Wheels | Steel Wheels | Flow Form Wheels | Cast Alloy Wheels |

|---|---|---|---|---|---|

| Manufacturing Process | Mechanical clamping system with bolted outer ring | Compressed from solid aluminum billet under 8,000-10,000 tons pressure | Stamped from steel sheets | Cast blank with secondary spin-forging process | Poured molten aluminum into molds |

| Material | Available in aluminum and steel | 6061-T6 aerospace-grade aluminum | Carbon steel | A356 aluminum alloy | Aluminum alloy |

| Weight Characteristics | Heavier due to additional hardware | 25-30% lighter than cast wheels | 2.5-3x heavier than aluminum wheels | 15-25% lighter than cast wheels | Heavier than forged/flow formed due to extra material |

| Strength/Durability | High durability for extreme conditions | Exceptional strength-to-weight ratio | Nearly indestructible, highly impact resistant | 30% stronger than cast wheels | Adequate for moderate use, prone to cracking |

| Cost Consideration | High initial and maintenance costs | Premium pricing, highest cost | Most affordable option | Mid-range pricing | Most cost-effective alloy option |

| Best Use Cases | Extreme off-roading, rock crawling, desert racing | High-performance off-roading, competitive motorsports | Extreme terrain, remote expeditions, heavy-duty work | Moderate off-road use, overland vehicles | Daily drivers, light to moderate off-roading |

| Key Advantages | Can run extremely low tire pressures (5-7 PSI) | Superior heat dissipation, highest strength | Field-repairable, excellent impact resistance | Good balance of performance and cost | Design versatility, wide availability |

| Main Disadvantages | Not DOT approved for street use, high maintenance | Extended production time, limited availability | Heavy weight impacts performance, prone to rust | Limited customization options | Internal porosity, less heat dissipation |

Our experience testing these wheel types across demanding terrain shows that the right choice depends heavily on your specific off-road needs and budget. For most weekend trail riders, cast alloy or flow form wheels provide excellent value. Serious rock crawlers and desert racers benefit from the specialized capabilities of beadlock or forged options, while steel wheels remain the smart choice for remote expeditions where field repairability matters most.

Selecting the right off-road wheels comes down to matching your actual driving needs with the right construction type and features. Beadlock wheels remain the top choice for extreme terrain where ultra-low tire pressures make the difference between success and failure. Forged aluminum wheels deliver unmatched strength-to-weight performance for serious enthusiasts who demand the best. Steel wheels continue to be the most reliable choice for remote expeditions where durability and field repairability matter most.

Flow form wheels offer the sweet spot between performance and value for moderate trail use and overlanding adventures. Cast alloy wheels provide sufficient capability for casual off-roaders while keeping costs manageable.

Our extensive testing across challenging terrains has shown us that the right wheel type depends entirely on your specific use case. Weekend trail riders can achieve their goals with cast alloy wheels, while dedicated rock crawlers need the security of beadlocks or the strength of forged options.

The key is being honest about your off-road activities rather than buying more wheel than you need. Find the best selection of off-road wheels that match your vehicle and budget requirements. Whether you prioritize lightweight performance, maximum durability, or cost-effective reliability, choosing the right wheel type ensures years of successful off-road adventures.

At Performance Plus Tire, we have the expertise to help you select the perfect wheels for your specific off-road needs and vehicle requirements.

Understanding the five main types of off-road wheels helps you choose the right option for your specific terrain and driving style.

• Beadlock wheels enable ultra-low tire pressures (5-7 PSI) for extreme traction but aren't street-legal and require high maintenance

• Forged aluminum wheels offer the best strength-to-weight ratio, being 25-30% lighter than cast wheels with superior durability

• Steel wheels provide unmatched impact resistance and field repairability at the lowest cost, ideal for remote adventures

• Flow form wheels deliver 30% more strength than cast wheels at mid-range pricing, perfect for moderate off-road use

• Cast alloy wheels offer the most design options and adequate performance for casual trail riding at budget-friendly prices

The key is matching wheel type to your actual off-road needs rather than simply choosing the most expensive option. Weekend warriors hitting light trails can succeed with cast alloy wheels, while serious rock crawlers benefit from beadlocks or forged aluminum. Consider your typical terrain, performance requirements, and budget to find the optimal balance of durability, weight, and cost for your adventures.

The five main types of off-road wheels are beadlock wheels, forged aluminum wheels, steel wheels, flow form wheels, and cast alloy wheels. Each type has unique characteristics suited for different off-road applications and driving styles.

Forged aluminum wheels provide the best strength-to-weight ratio, being 25-30% lighter than cast wheels while offering superior durability. They're ideal for high-performance off-roading and competitive motorsports.

Beadlock wheels allow for extremely low tire pressures (5-7 PSI) without risking tire separation from the rim. This provides superior traction in extreme off-road conditions like rock crawling and desert racing.

Yes, steel wheels remain an excellent choice for off-roading, especially in remote areas. They offer unmatched durability, impact resistance, and field repairability at the lowest cost, making them ideal for extreme terrain and heavy-duty applications.

Flow form wheels offer a middle ground between cast alloy and forged wheels. They're about 15-25% lighter than cast wheels and 30% stronger, making them suitable for moderate off-road use and overland vehicles. They provide better performance than cast alloy wheels at a more accessible price point than forged options.