The custom wheel world is changing fast, and 2026 promises to be the most exciting year yet. Art meets engineering meets pure performance, and the results are nothing short of impressive. What started as simple wheel upgrades has evolved into something much bigger—a complete rethink of how wheels can transform your vehicle.

The trend momentum really picked up steam during 2025, with luxury brands like Ferrari, McLaren, and Porsche setting the pace for wheel styles worldwide. Larger wheels have taken over the aftermarket, and 22-inch and 23-inch options are now the standard choice for SUVs, performance cars, and luxury sedans. Advanced manufacturing has stepped up too, with 3D-forged wheels using precise CNC machining to create intricate, high-strength designs that drop weight while boosting visual appeal.

Here's where it gets interesting: hybrid car sales are jumping over 23% in 2025, and EV markets are pushing past 10% of new sales. Wheel technology is adapting to match these shifts. Carbon fiber wheels are gaining serious traction thanks to their ultra-lightweight properties and impressive durability. Forged carbon fiber has become the go-to choice for supercar and hypercar owners who want to shed weight without giving up strength.

Performance Plus Tire is excited to walk you through the seven most significant custom wheel trends that will shape 2026. We're here to help you stay ahead of what's coming next in the automotive world, making sure you get the perfect wheels for your ride and your style.

Image Source: Wheelshome

Single-piece construction is taking the wheel world by storm, and for good reason. Clean lines and bold sculptures are defining what we're seeing for 2026, with monoblock minimalism becoming one of the biggest trends to watch. These wheels bring understated elegance that works beautifully with matte metallic finishes, creating a look that's both sophisticated and built for performance.

Monoblock wheels come from a single piece of metal, which represents some serious engineering precision. Unlike multi-piece options, these wheels get manufactured from one solid block of aluminum alloy through intense shaping processes. The seamless construction eliminates joints, welds, and bolts, giving you a wheel that's structurally superior while keeping that clean look. Leading brands like Vossen's HF series, BBS CI-R, and HRE's FlowForm lineup are showing us exactly how beautiful minimalist design can be when it's paired with maximum performance.

The performance advantages here are substantial and measurable. Single-piece construction delivers superior strength compared to multi-piece wheels, making them exceptionally durable when things get demanding. This matters a lot for spirited driving and track days.

Monoblock forged wheels really shine with their remarkable strength-to-weight ratio. They're considered the gold standard in wheel engineering, and here's what they bring to the table:

Reduced unsprung weight, improving vehicle responsiveness

Enhanced acceleration and braking efficiency

Superior load-bearing capabilities for high-performance situations

Fewer potential failure points without bolts or welds

The lightweight nature of these wheels directly improves handling, fuel efficiency, and overall driving dynamics. When you reduce vehicle weight, especially in rotating components, the performance impact is immediately noticeable.

The look for 2026 leans heavily into clean, bold, and sculptured designs. Matte finishes are dominating the scene, with three particular finishes leading the trend:

Matte bronze

Satin titanium

Brushed aluminum

These subdued yet sophisticated finishes provide depth and character without being flashy. The minimalist spoke designs complement modern vehicles perfectly, creating a cohesive look that enhances your vehicle's overall appearance. Plus, the absence of visible bolts or seams gives monoblock wheels a cleaner and more refined appearance compared to multi-piece alternatives.

Despite being minimalist by definition, these wheels offer extensive customization possibilities. Manufacturers provide various finishes ranging from high-gloss to matte, with some brands offering three distinct finish categories:

Standard finishes

Transparent coatings

Brushed transparent effects

Customization also extends to colors with options for gloss, matte, satin, or textured finishes. The minimalist design approach doesn't limit personalization; instead, it creates a perfect canvas for individual expression while maintaining structural integrity.

Quality comes at a cost, and monoblock wheels represent a premium segment in the wheel market. Prices vary significantly based on size, manufacturing process, and brand. Black Rhino's monoblock wheels range from approximately $350 to $500 depending on size and finish.

Forged monoblock wheels command higher prices compared to cast alternatives due to their superior manufacturing process. However, this investment offers long-term value through:

Reduced maintenance requirements

Enhanced durability under demanding conditions

Improved vehicle performance

Potential fuel savings through weight reduction

These wheels excel in specific applications where their benefits are most pronounced. For 2026, expect to see monoblock minimalist wheels predominantly on:

Luxury sedans seeking refined looks

Track-focused builds requiring maximum performance

Daily drivers in demanding environments

High-performance vehicles where weight reduction is critical

Sports cars that benefit from improved handling characteristics

For drag racing and track racing, forged monoblock wheels are particularly valuable due to their light weight, strength, and consistent performance. Their reduced maintenance requirements also make them ideal for daily driving in demanding conditions.

Monoblock minimalism with matte finishes stands as a perfect blend of form and function—a trend that satisfies both visual desires and performance demands in the custom wheel landscape.

"SiC is well attuned to the needs of EV powertrains, offering higher levels of thermal conductivity, switching efficiency, and electric current density than traditional silicon-based alternatives." — Supplyframe Intelligence Editorial Team, Industry analysis and market intelligence publication

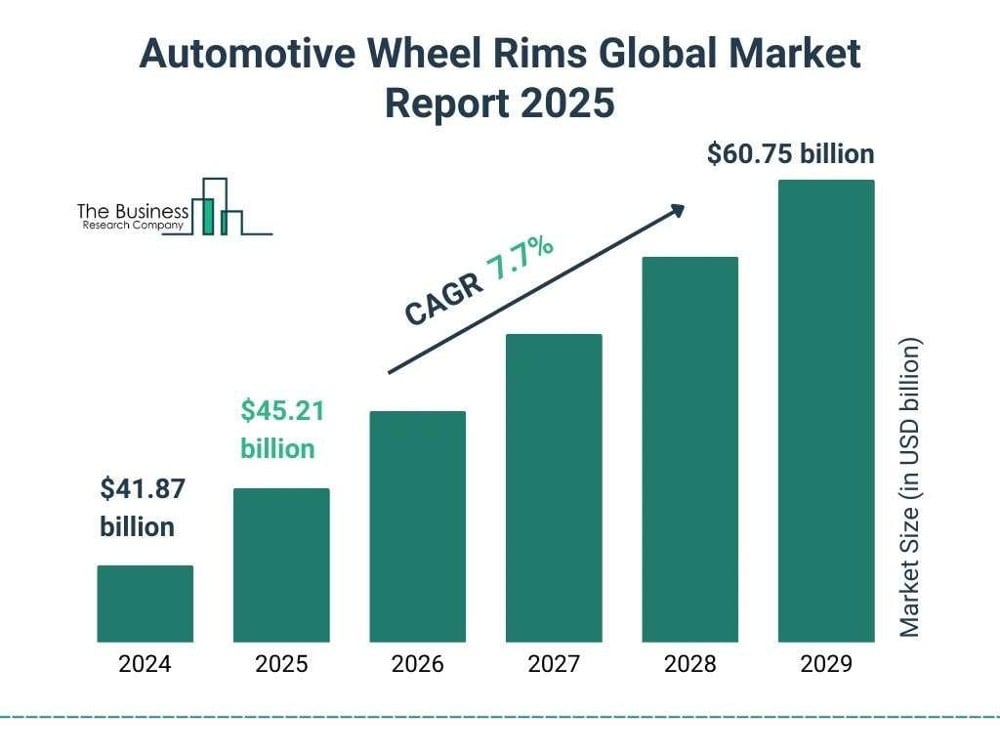

Image Source: The Business Research Company

Precision engineering meets artistic expression in the 3D-forged wheel technology that's quickly becoming a favorite in the custom wheel market. This manufacturing approach stands out as one of 2026's biggest trends, bringing together strength, lightweight properties, and design possibilities that simply weren't available before.

3D-forged wheels start with a solid block of aerospace-grade 6061-T6 aluminum alloy. The process is different from traditional forging—these wheels go through a complex series of operations that include high-pressure forming and precision CNC machining. The manufacturing process aligns the aluminum's grain structure, creating wheels that are virtually free of porosity and structural weaknesses.

Two technologies make this innovation possible: Electron Beam Melting (EBM) and Direct Metal Laser Melting (DMLM). EBM uses an electron beam to melt and fuse fine layers of titanium powder, building up the design in a bed of titanium powder with minimal waste. DMLM employs lasers to melt layers of fine metal powder, creating complex 3D geometries with remarkable precision directly from CAD files.

The performance gains from 3D-forged wheels are impressive:

Weight savings that matter – Some 3D-forged wheels can save approximately one pound in the front and two pounds in the rear compared to conventional high-end wheels of the same size

Strength where you need it – The forging process creates a highly aligned grain structure that significantly increases structural integrity

Better handling and braking – Reduced unsprung mass directly improves vehicle handling, acceleration, and braking efficiency

Solid construction – 3D-forging achieves nearly 100% material density, eliminating the porosity issues common in cast wheels

The reduction in unsprung mass has an outsized effect on vehicle performance, even though wheels make up only about 10% of a vehicle's weight.

What really sets 3D-forged wheels apart is their visual versatility. CNC machining precision enables intricate designs that were previously impossible. Laser detailing allows for remarkably fine detail work, creating complex spoke patterns and surface textures that catch and play with light.

Wheel styling has moved from flatter surfaces toward more three-dimensional effects, with manufacturers now achieving tolerances below 0.02 mm. This precision enables deep concavity, bold spokes, and detailed machining that creates dramatic visual impact.

Customization takes a big step forward with 3D-forged wheels. Manufacturers use cutting-edge 3D design software to create detailed models of custom designs. This gives you the chance to review your concepts in fine detail before production begins.

Your customization options include:

Directionally vented flanges for both form and function

Titanium assembly hardware for additional weight reduction

Custom offsets tailored to specific vehicles

Various spoke designs from traditional to avant-garde patterns

The complex manufacturing process means 3D-forged wheels command premium prices. The extensive machining time—often 8-10 hours per wheel—contributes significantly to cost. During production, forged wheels lose 70-80% of their mass through precision milling, which explains why premium finishing touches like a brushed finish can add another 8 hours of labor per wheel.

These factors place 3D-forged wheels with laser detailing in the high-end market segment, with prices reflecting their performance benefits and exclusivity.

3D-forged wheels work exceptionally well in several situations:

High-performance sports cars and supercars see real benefits from the weight reduction. Their reduced rotational inertia improves acceleration and shortens braking distances.

Racing applications benefit from their exceptional strength-to-weight ratio and reliability under extreme conditions.

Prestige vehicles benefit from their unique visual qualities and customization possibilities, making them popular among enthusiasts seeking to set their vehicles apart.

The technology is particularly valuable for electric vehicles, where reducing unsprung weight enhances range and efficiency—a crucial consideration as EV adoption keeps growing.

Image Source: GM Authority

Carbon fiber technology has shaken up the custom wheel market, and hybrid-tech wheels are quickly becoming one of the hottest trends for 2026. These smart wheels bring together carbon fiber's lightweight advantages with the proven strength of metal alloys. The result? A perfect balance of performance and style that's hard to beat.

Hybrid-tech wheels work with a clever two-piece setup: you get a carbon fiber outer rim (the barrel) matched with a precision-machined forged metal centerpiece, usually aluminum or magnesium. Lightweight titanium fasteners hold everything together, creating a wheel that grabs the best qualities from both materials. Dymag has been leading this charge since 2004, creating proprietary designs like the BOXSTROM™ barrel with features that earned them international patents.

Sure, the multipiece, multimaterial approach brings some engineering challenges compared to traditional one-piece wheels. But quality manufacturers like Carbo Tech and Geric have figured out how to build hybrid wheels that match or beat standard alloy wheel specs for stiffness, durability, and toughness.

The performance gains with hybrid-tech wheels are impressive:

Serious weight drops: Up to 40% lighter than cast aluminum and 20% lighter than forged aluminum wheels

Less unsprung mass: Dymag's 21-inch hybrid wheel tips the scales under 10kg—that's about 7kg less than traditional cast alloy versions

Better heat management: The aluminum centerpiece works like a heat sink, soaking up and releasing brake heat more effectively than full carbon wheels

Stronger and more durable: Carbon-fiber construction delivers superior stiffness and fights fatigue better

Easier rolling: Less energy needed for acceleration and braking

Here's the practical side: lighter wheels make your vehicle handle better by improving suspension response, keeping tires in better contact with the road, and boosting overall driving feel.

These wheels really catch the eye. The high-tech carbon fiber look pairs beautifully with customizable metal centerpieces. That distinctive carbon weave pattern screams performance, while the forged centers can show off different spoke designs.

Take Hyundai's N Performance parts—they feature a 21-inch wheel with a carbon fiber outer rim paired with a precision-machined, five-spoke forged centerpiece in Satin Black. This combo creates a wheel that looks both performance-focused and exclusive.

Two-piece designs open up lots of customization doors:

Forged aluminum or magnesium centerpieces give you more design options than one-piece carbon wheels

You can swap centers without expensive retooling costs

Sizes run from 18-25 inches, with fresh 24-inch and 25-inch options now available

Finish choices include gloss black, silver polished, matte gunmetal, and satin bronze

Plus, if one part gets damaged, you can often replace just that piece instead of buying a whole new wheel—a real advantage over one-piece designs.

Hybrid-tech wheels sit in the premium market segment. Vossen's Hybrid Forged Series starts at $599 for 19-inch wheels and goes up to $1049 for 26-inch versions. These prices make sense when you consider the advanced manufacturing and materials involved.

Performance-focused carbon hybrid wheels cost even more due to their specialized construction and weight benefits. Standard carbon road disk wheels for bicycles start around $900, but automotive applications run substantially higher.

Hybrid-tech wheels really shine in specific situations:

Electric vehicles love them because weight reduction directly affects range and efficiency. The weight savings can mean smaller batteries, lighter suspension, and less sound deadening—creating a positive cycle of efficiency improvements.

High-performance vehicles like the BMW M4 GTS offer hybrid wheels as a factory option. The reduced unsprung mass and gyroscopic effects make the car feel more nimble during cornering and quick direction changes.

Track vehicles benefit from both the weight reduction and enhanced heat dissipation, which helps manage brake temperatures during demanding sessions.

SUVs and trucks see big gains from the reduced rotating mass. RYET's carbon MTB wheelsets show how hybrid technology can improve both e-Mountain and traditional mountain biking experiences.

Gone are the days when wheels only came in black or silver. The wheel world has opened up to a whole new spectrum of colors, and 2026 is bringing some seriously eye-catching options. Chameleon finishes that shift colors as you move around the vehicle? They're here. Electric lime that makes heads turn? Absolutely. This isn't just about looking different—it's about making your vehicle truly yours.

Wheel manufacturers are getting creative with color like never before. Ice blue, burnt copper, electric lime, and those amazing chameleon gradients that shift hues when sunlight hits them just right. Premium brands like Rotiform and Artisa ArtFormed are pushing the envelope with limited-edition colorways that were basically made for Instagram. This goes way beyond simple aesthetics—we're talking about real vehicle personalization here.

These aren't just pretty colors that'll fade after a few months. Modern wheel coloring uses premium paints that match OEM finishes perfectly, so you get durability along with the bold look. Most manufacturers use powder coating for these colors, which actually makes the finish tougher against chips, scratches, and corrosion compared to regular paint. You can get virtually any color you want while keeping the wheel's structural strength intact.

The visual impact is incredible, especially with chameleon finishes that create this shifting color effect based on the angle and lighting. Take the Gloss Blue-Purple Chameleon finish—it goes from deep blue to rich purple as you walk around the car. Even when your vehicle is parked, these finishes add movement and depth that catches the eye from across the parking lot.

The options available now are pretty impressive:

Color Range: Some shops offer over 70 vibrant colors mixed from 20 base toners

Finish Types: High-gloss, satin, matte, chrome effect, and hyper silver

Special Effects: Chameleon finishes that change color with viewing angle

Texture Options: Everything from mirror-like reflective to completely matte

Wheeltone does excellent work with precise color matching, whether you want to match your OEM colors exactly or create something completely custom. You can perfectly complement your vehicle's paint or go for deliberate contrast that makes a statement.

Expect to pay more for these special finishes. Candy-colored finishes typically add about $434 to your base wheel price. Chameleon wheels like the Gianelle CHAMELEON run $594 for 22"x9.5" size, jumping to $813 for 24"x10" versions. Here's how the pricing breaks down:

Size | Finish Type | Price Range |

|---|---|---|

22" | Gray/Black | $594 |

24" | Gray/Black | $813 |

Various | Candy Finish Add-on | +$434 |

The premium reflects both the specialized materials and extra labor these complex finishes require.

These finishes really shine on certain types of vehicles. Supercars and custom builds that want social media attention get the most benefit from these eye-catching colors. Show cars and vehicles hitting automotive events gain serious visual impact with chameleon or candy-colored wheels. If making a statement is your goal, these are perfect.

Daily drivers can still join the fun with more subtle options like metallic blue or bronze that add personality without going overboard. The trend toward colored wheels is spreading from specialty builds to regular vehicle personalization, showing how wheel customization keeps expanding in 2026.

"Environmental concerns and technological innovations are advancing faster than many anticipated. From electrification to IoT connectivity, these shifts are changing the way cars are manufactured, sold, repaired, and driven." — Josh Howarth, Co-Founder and CTO of Exploding Topics

Sustainability isn't just a buzzword anymore—it's driving real change in the wheel industry. Eco-conscious wheels made from recycled materials are quickly becoming one of the hottest trends for 2026. Manufacturers are getting creative with planet-friendly approaches that don't sacrifice performance or style.

These wheels use recycled materials in three main ways. Recycled aluminum is leading the charge, cutting down on mining needs while keeping wheels strong and reliable. Carbon fiber composites are now using renewable or recycled fibers. Some manufacturers are even testing biodegradable natural fibers like hemp or flax mixed with eco-friendly resins .

Maxion is really pushing boundaries here, launching their first ultra-low carbon wheel options with green energy and green aluminum in 2024 . They've also rolled out wheels made primarily from secondary (recycled) aluminum, which takes about 90% less energy to produce than starting from scratch .

Don't worry—going green doesn't mean giving up performance. These recycled materials actually deliver some impressive benefits:

Lighter weight means better fuel efficiency and sharper handling

Reduced rotational mass helps your car accelerate faster

Less unsprung weight translates to shorter stopping distances

Recycled aluminum wheels are just as strong as traditional ones

Today's eco-conscious wheels look great too. They feature clean, modern designs that fit perfectly with current automotive trends. The recycled components often create unique textures and finishes you won't find anywhere else. Many also incorporate aerodynamic elements that boost efficiency while creating that sleek, contemporary look .

You've got plenty of options to choose from:

Recycled aluminum alloys (the most popular choice)

Carbon fiber with eco-friendly resins

Biodegradable plastics (still being tested)

Natural fiber components

Finish options range from brushed metal to various eco-friendly coatings, so you can personalize your wheels without compromising your environmental values.

Pricing varies depending on the recycled material:

Material Type | Price Per Pound |

|---|---|

Clean Aluminum Wheels | USD 0.75 |

Dirty Aluminum Wheels | USD 0.70 |

Chrome Wheels | USD 0.57 |

Aluminum Truck Wheels 6061 | USD 0.66 |

The good news is that eco-conscious wheels are becoming more affordable as production scales up. Plus, their durability often means lower long-term costs, even if you pay a bit more upfront .

These wheels work particularly well for:

Electric vehicles, where every pound matters for range

City commuters who value sustainability

Performance builds that need weight savings

Luxury vehicles where environmental responsibility matches the premium image

Industry experts predict the global market for recycled materials in automotive applications will hit USD 5.60 billion by 2030, with growth rates between 8% and 10.6% annually .

Customization takes center stage with modular multi-piece wheels, and they're becoming a major trend for 2026. These wheels give you flexibility that single-piece designs simply can't match, opening up style possibilities that keep custom wheel enthusiasts coming back for more.

Modular wheels work by bolting multiple components together to create your complete wheel. You'll typically see two-piece designs (center and barrel) or three-piece designs (center, inner barrel, and outer lip) . Each piece gets precision-crafted from high-grade 6061-T6 aluminum, then joined with stainless steel or titanium hardware . The modular setup creates an air-tight seal while giving you customization options that just aren't possible otherwise . Brands like BC Forged, VIP Modular, and 3SDM are really pushing this technology forward right now .

Performance-wise, modular wheels bring some unique advantages to the table:

Better repairability – damage one section, replace just that part instead of buying a whole new wheel

Easy width and offset adjustments to get the perfect fit

Titanium hardware options that can save about 1 pound per wheel

Sure, these wheels tend to weigh more than monoblock versions, but the customization potential makes up for it if you're looking for something truly unique .

The visual impact here is something special. Those exposed bolts and assembly hardware create a look that screams custom work and attention to detail. What really sets modular wheels apart is the ability to get fully polished lips—something you absolutely cannot do with one-piece wheels . Whether you want classic mesh patterns or directional styles that grab attention at shows, modular wheels deliver the goods .

The customization possibilities are pretty much endless:

Hardware choices: stainless steel, black, gold, or titanium

Hardware visibility: fully exposed, 50% exposed, or completely hidden

Face profiles: deep concave or flat

Lip styles: step lip or reverse flat lip

Finishes: gloss, matte, translucent powdercoat, diamond cut, or fully polished

Quality modular wheels require a bigger investment. Expect to pay $345 to $490 per set of four wheels, depending on the diameter :

Size | Price (USD) |

|---|---|

17" | 345.00 |

19" | 405.00 |

21" | 470.00 |

22" | 490.00 |

These prices reflect the complex construction and all those customization options, running about 3 times more than standard single-piece wheels .

Modular wheels really shine in stance builds and show cars where making a visual statement matters most . They're perfect if you need exact fitment specifications or want visual styles that one-piece wheels just can't deliver. They're also great for anyone planning to modify their setup gradually, since you can upgrade individual components as you go .

Sometimes the best way forward is to look back. Vintage wheel designs are staging a major comeback in 2026, bringing classic styling from the 80s and 90s into the modern era. These retro-futuristic mesh and deep dish wheels blend the best of both worlds—timeless looks with today's manufacturing excellence.

Classic five-spoke and mesh designs are getting a fresh makeover with modern finishes like gloss graphite and ghost chrome. Brands like Enkei and Fifteen52 are leading this nostalgic revival, while HRE's Vintage Series specifically targets supercar owners who want classic aesthetics with modern performance. You'll find distinctive styles like the 454 "Italian style five-window" design that pays homage to the iconic Lamborghini Diablo wheels.

Don't let the vintage look fool you—these wheels pack serious performance advantages. Deep dish designs give you a wider footprint, which means better traction and stability when you're pushing the limits. The extra clearance also makes room for larger brake calipers, perfect for high-performance braking systems. Truck and off-road enthusiasts appreciate the wider width for improved traction on challenging terrain.

These wheels make a statement that's hard to ignore. The pronounced lip between the wheel face and tire creates a bold, aggressive profile. Five-spoke star patterns bring back memories of the Ferrari F40, while tight mesh designs recall classic racing Porsches. It's a look that instantly tells people you appreciate both automotive heritage and modern performance.

You've got plenty of options to make these wheels your own. Classic mesh patterns and deep dish profiles come with various lip depths to suit your style. HRE offers these designs in 18 to 20-inch diameters, with widths from seven to 14 inches. They work surprisingly well on modern vehicles, creating an interesting contrast between vintage wheels and contemporary styling.

Quality retro styling comes with a premium price tag. Custom forged two-piece deep dish wheels typically start around $999 per wheel. Here's what you can expect:

Wheel Type | Starting Price |

|---|---|

Forged 2-Piece Deep Dish | $999 |

Forged 3-Piece Mesh | $1,100+ |

These wheels shine on muscle cars and vintage-inspired builds, but they're also gaining popularity on EVs looking for a throwback aesthetic. They're perfect for restomod projects and heritage-inspired models. Custom builders love them for creating that timeless look while still getting modern performance benefits.

Here's a quick side-by-side look at all seven trends we've covered. This table makes it easy to compare what matters most to you—whether that's performance, looks, price, or specific applications. We've broken down the key details so you can quickly see which wheel type fits your needs and budget.

Trend | Key Materials/Construction | Main Performance Benefits | Notable Esthetic Features | Price Range | Best Use Cases |

|---|---|---|---|---|---|

Monoblock Minimalism | Single-piece aluminum alloy | Superior strength, reduced unsprung weight, fewer failure points | Clean lines, matte finishes (bronze, titanium, brushed aluminum) | $350-500 | Luxury sedans, track-focused builds, daily drivers |

3D-Forged Wheels | 6061-T6 aluminum alloy, laser detailing | Exceptional weight reduction, nearly 100% material density | Intricate spoke patterns, deep concavity, fine surface textures | Premium segment (8-10 hrs machining time) | High-performance sports cars, racing applications, EVs |

Hybrid-Tech Wheels | Carbon fiber barrel + metal centerpiece | Up to 40% lighter than cast aluminum, enhanced thermal properties | Carbon weave pattern, customizable center designs | $599-1049+ | EVs, high-performance vehicles, track cars |

Bold Colorways | Premium paints, powder coating | Durable finishes, corrosion resistance | Chameleon effects, vibrant colors, shifting hues | Base + $434 for candy colors | Show cars, social media-focused builds, custom vehicles |

Eco-Conscious Wheels | Recycled aluminum, eco-friendly composites | Weight reduction, improved acceleration, comparable strength | Clean contemporary designs, unique textures | Varies by material type | EVs, urban commuters, luxury vehicles |

Modular Multi-Piece | 6061-T6 aluminum components | Enhanced repairability, adjustable widths | Exposed hardware, polished lips, multiple finish options | $345-490 per set | Stance builds, show cars, custom fitments |

Retro-Futuristic Mesh | Modern alloys with classic designs | Improved traction, better brake clearance | Deep dish profiles, mesh patterns, vintage-inspired looks | $999+ per wheel | Muscle cars, restomods, heritage-inspired builds |

The 2026 custom wheel scene delivers an exciting mix of innovation, style, and serious performance upgrades. These seven major trends show how wheels have moved way beyond basic vehicle accessories—they're now key components that shape both how your car performs and how it expresses your personality.

Monoblock minimalism brings together strength and clean elegance, while 3D-forged wheels push manufacturing limits to create designs that were impossible before. Hybrid-tech wheels show how smart material choices can cut weight without sacrificing durability.

Bold colorways and chameleon finishes open up personalization like never before, and eco-conscious wheels prove you don't have to choose between being green and getting great performance. Modular multi-piece wheels give you incredible customization flexibility, while retro-futuristic mesh designs perfectly blend classic looks with modern engineering.

These trends match bigger changes happening across the automotive world. Weight reduction stays important, especially as electric vehicles become more popular and efficiency matters more than ever. Manufacturing improvements have made visual possibilities real that seemed impossible just a few years back.

Performance Plus Tire stays on top of these industry changes because that's what we do. We go beyond just selling wheels—we help you work through these trends to find options that boost your vehicle's performance and visual appeal. Looking for the clean elegance of monoblock designs or the eye-catching impact of chameleon finishes? Our inventory covers different preferences and needs.

When you're thinking about upgrading your wheels next time, remember these trends aren't just temporary fads. They represent real advances in materials, manufacturing, and design thinking that will shape automotive styling and performance for years ahead. Quality wheels that align with these trends keep your vehicle current and visually distinctive.

Check out our selection and see how these wheel technologies can change your driving experience. The right set of wheels does more than finish your vehicle's look—it changes how your vehicle performs, feels, and shows off your personal style.

Q1. What are the key trends in custom wheels for 2026? The major trends include monoblock minimalist designs, 3D-forged wheels with laser detailing, hybrid-tech wheels with carbon inserts, bold colorways and chameleon finishes, eco-conscious wheels made from recycled materials, modular multi-piece wheels, and retro-futuristic mesh and deep dish designs.

Q2. How are eco-friendly materials being incorporated into wheel manufacturing? Manufacturers are using recycled aluminum, carbon fiber composites with renewable sources or recycled fibers, and experimenting with biodegradable natural fibers like hemp or flax mixed with eco-friendly resins. Some companies are also utilizing green energy in production processes.

Q3. What are the performance benefits of 3D-forged wheels? 3D-forged wheels offer exceptional weight reduction, superior strength-to-weight ratio, reduced unsprung mass, and enhanced material density. These properties improve vehicle handling, acceleration, and braking efficiency.

Q4. How do hybrid-tech wheels differ from traditional wheels? Hybrid-tech wheels feature a two-piece construction with a carbon fiber outer rim paired with a precision-machined forged metallic centerpiece. This combination offers significant weight reduction, improved thermal properties, and enhanced strength compared to traditional wheels.

Q5. What customization options are available for modular multi-piece wheels? Modular wheels offer extensive customization possibilities including various hardware options (stainless steel, black, gold, or titanium), different face profiles, lip options, and a wide range of finishes from gloss to matte, translucent powdercoat, diamond cut, or fully polished.