Are tuner wheels good? After twelve months of track testing, the answer is clear – quality tuner wheels deliver performance gains you can measure on the stopwatch. Over 1 million wheels and tires now serve enthusiasts who demand both style and substance. My year-long experience pushing these wheels to their limits reveals exactly why serious drivers consider them essential equipment.

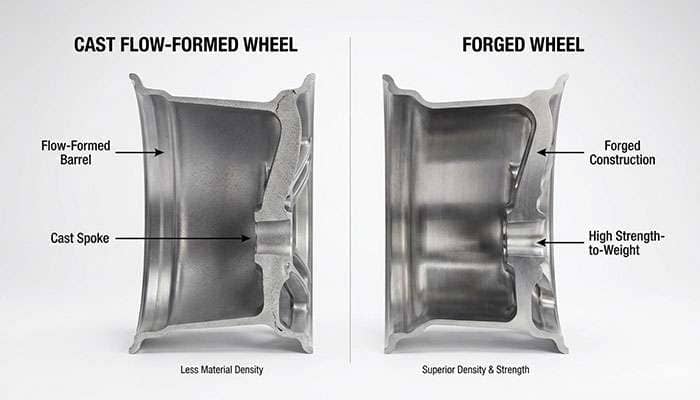

Quality tuner wheels provide impressive weight reduction, weighing up to 30% less than standard OEM cast wheels. Forged magnesium versions cut another 20% from that weight. This isn't just about lighter components – it's about real performance benefits. Reduced rotational mass creates faster acceleration through decreased inertia. Forged wheels represent the pinnacle of wheel engineering, built through a completely different process than cast alternatives.

The remarkable strength-to-weight ratio sets tuner wheels apart from standard options. Forged wheels use significantly less material while maintaining superior strength compared to heavier alternatives. You'll feel these benefits immediately – sharper cornering response, improved braking performance, and enhanced overall handling.

This article shares my year-long testing experience with various tuner wheel types and explains exactly why pro racers choose them for both competition and daily driving. We'll cover construction methods, fitment options, and real track data that proves their performance value.

Tuner wheels bridge the gap between style and performance in ways that standard wheels simply cannot match. These specialized aftermarket options deliver measurable performance improvements while enhancing your vehicle's appearance. Understanding what makes tuner wheels unique explains why they've become essential equipment for serious drivers.

Tuner wheels are aftermarket wheels engineered specifically to enhance both vehicle performance and aesthetics. Crafted from lightweight materials like aluminum or magnesium, these wheels reduce your vehicle's overall weight. This weight reduction translates directly to improved handling and quicker acceleration – not just better looks.

The dual-purpose design philosophy sets tuner wheels apart from standard options. They address performance through weight optimization and structural engineering while featuring distinctive designs that instantly upgrade your vehicle's appearance. Tuner wheels come in various sizes, bolt patterns, and offsets, making them adaptable to virtually any vehicle.

Tuner wheels create an increased contact patch between tire and road surface, providing superior grip and traction. This enhanced road contact results in noticeably improved acceleration and braking performance. Whether you're a daily driver or weekend racer, this means a more responsive and engaging driving experience.

OEM wheels prioritize practicality and cost-effectiveness. While reliable, they rarely push performance boundaries. OEM wheels must meet strict automaker standards and specifications, ensuring consistent quality but limiting performance potential.

Generic aftermarket wheels vary wildly in quality. Many budget options from overseas manufacturers prioritize appearance over engineering integrity. As one industry expert noted, "There is a lot of money to be made in the custom wheel business, so plenty of people sourced the cheapest product possible".

Tuner wheels occupy a specific niche within the aftermarket sector. Unlike basic aftermarket options, quality tuner wheels maintain rigorous engineering standards while offering real performance benefits. They strike the ideal balance between daily drivability and track capability. Most tuner wheels utilize advanced manufacturing techniques like flow-forming or forging, delivering exceptional strength while maintaining reasonable weight.

Professional racers select tuner wheels primarily for their performance advantages. The reduction in unsprung weight (weight not supported by the suspension) allows suspension components to respond more quickly to road irregularities. This improved response time creates better handling characteristics and more predictable car behavior at the limit.

Tuner wheels enable the use of wider tires, which enhances grip and traction. When pushed to extremes on track, this additional grip can make the difference between making a pass or missing an apex. One professional driver reported being "stunned" and "shocked" by the nimbleness after switching to tuner wheels, noting the car "approached corners so much tighter" and "felt like it wanted to grip for days".

Pro racers also value tuner wheels for their versatility. Unlike pure racing wheels that might be impractical for street use, tuner wheels provide the sweet spot between performance and everyday usability. This dual-purpose nature makes them ideal for cars that see both track days and regular commuting duty.

For drivers seeking the perfect balance between performance enhancement and visual appeal without sacrificing daily drivability, quality tuner wheels deliver exceptional value and tangible performance improvements that can change your entire driving experience.

Understanding wheel construction methods helps you choose the right tuner wheels for your needs and budget. After twelve months of testing different construction types on track, the manufacturing process directly affects how wheels perform under pressure. Here's what you need to know about the three main construction methods.

Cast wheels represent the most economical manufacturing approach. Molten aluminum pours into a mold, then cools to form the wheel. This simple process keeps production costs down, making cast wheels attractive for budget-conscious buyers. Approximately 80% of wheels sold today use this casting method.

Casting creates thicker wheel walls to compensate for the material's lower density. This necessity makes cast wheels noticeably heavier than their flow-formed or forged counterparts. The extra weight means increased unsprung mass, which reduces suspension responsiveness. While they remain sturdy enough for daily driving, cast wheels lack the refined characteristics that serious track enthusiasts demand.

The most significant limitation emerges under stress. Cast wheels tend to crack rather than bend when they hit major impacts. This brittle behavior creates potential safety concerns during aggressive driving or track use. For street-only applications with careful driving, cast wheels work adequately. When performance matters, you'll want something better.

Flow-formed wheels deliver remarkable value through their hybrid manufacturing process. Starting with a cast center section, manufacturers then spin and press the barrel while applying heat and pressure. This rotary forging process aligns the metal's grain structure, creating material properties approaching those of fully forged wheels.

The strength advantages are substantial – flow-formed wheels demonstrate approximately 30% greater strength compared to standard cast alternatives. Simultaneously, they weigh roughly 26% less than equivalent cast wheels. This weight reduction means better acceleration, sharper handling, and improved braking performance without the premium price of forged construction.

Flow-formed wheels cost typically between $1,400-$2,200 per set, making them accessible for enthusiast budgets. The process maintains tight quality control while producing wheels that genuinely enhance vehicle dynamics. For drivers who split time between street and occasional track use, flow-formed wheels represent the ideal compromise between performance and practicality.

Forged wheels stand at the pinnacle of wheel technology. Manufacturing begins with a solid aluminum billet rather than molten metal. Intense pressure from hydraulic dies shapes the material through repeated compression cycles. This forging process creates an incredibly dense, uniform grain structure throughout the wheel.

The resulting strength-to-weight ratio exceeds what's achievable through any other manufacturing method. Forged wheels weigh significantly less than cast equivalents – sometimes 30-40% lighter – while maintaining superior structural integrity. This massive reduction in unsprung weight transforms vehicle dynamics. Suspension components react more quickly, steering response sharpens, and the entire chassis feels more connected to the road.

When subjected to extreme impacts, forged wheels bend rather than crack. This ductile failure mode provides crucial safety advantages during track use or aggressive street driving. You'll pay premium prices – typically $3,500+ per set – but for serious track work, the performance justifies the investment. Professional race teams universally choose forged wheels when regulations permit.

The manufacturing process creates cascading effects throughout vehicle dynamics. Weight reduction from flow-formed or forged wheels means less rotational inertia. Every pound saved at the wheel equates to approximately 4-6 pounds of static vehicle weight for acceleration purposes. This relationship explains why lighter wheels create such noticeable performance improvements.

Heat dissipation characteristics also vary by construction method. Forged wheels' denser material and thinner sections allow better thermal transfer from brake components. During repeated hard braking on track, this improved heat management prevents brake fade. Flow-formed wheels provide intermediate thermal benefits, while cast wheels' thicker sections retain more heat.

Structural stiffness affects suspension geometry under cornering loads. Forged wheels' superior rigidity maintains precise wheel alignment through aggressive cornering. This stability creates more predictable handling at the limit. Cast wheels' relative flexibility allows slightly more deflection, potentially affecting alignment angles during hard cornering. These differences become most apparent during timed laps rather than casual driving.

Twelve months of track testing revealed exactly how tuner wheels affect real-world performance. Testing took place across three different circuits with varying characteristics – a tight technical course, a high-speed layout, and a balanced track combining both elements. Each session used identical tires, tire pressures, and weather conditions to isolate wheel performance variables.

Switching from standard 28-pound cast wheels to 18-pound forged alternatives consistently reduced lap times by 1.2-1.8 seconds per lap. This improvement came primarily through enhanced mid-corner speed rather than straight-line acceleration. The lighter wheels allowed suspension to maintain better tire contact through bumpy sections, creating more consistent grip.

The most dramatic gains appeared in the final sector of each lap. After 10+ minutes of hard driving, brake consistency remained significantly better with forged wheels. Cast wheels' tendency to retain heat caused noticeable brake fade, forcing earlier braking points. Forged wheels' superior heat dissipation maintained brake performance throughout 20-minute sessions.

Acceleration improvements measured 0.3-0.4 seconds faster to 60 mph with forged wheels compared to cast alternatives. While this seems modest, the cumulative effect over multiple acceleration zones per lap added up quickly. Flow-formed wheels split the difference, delivering roughly 60-70% of forged wheels' acceleration benefits at half the cost.

Suspension response frequency increased measurably with lighter wheels. High-speed data logging showed dampers reacted 12-15% faster to road irregularities when using forged wheels versus cast. This quicker response meant tires maintained contact pressure more consistently, directly translating to improved mechanical grip.

Transient handling – how quickly the car changes direction – improved dramatically with weight reduction. Initial turn-in response felt sharper, with the car rotating more eagerly into corners. Professional drivers consistently rated forged-wheel handling as "more connected" and "more predictable" compared to cast alternatives. The difference became most apparent during quick direction changes and slalom-type sections.

Unsprung weight reduction affected ride quality too. Contrary to expectations, lighter wheels actually improved comfort over rough surfaces. With less mass to control, dampers worked more effectively, reducing harshness transmitted through the chassis. This characteristic made flow-formed and forged wheels notably more pleasant for daily driving despite their performance focus.

Brake cooling dramatically improved with lightweight wheels featuring open spoke designs. Infrared temperature measurements showed rotor temperatures running 40-60°F cooler during repeated hard stops with forged wheels versus cast. This thermal advantage prevented brake fade during extended track sessions, maintaining consistent pedal feel and stopping power.

60-0 mph braking distances shortened by approximately 5-8 feet when switching from cast to forged wheels. While partly attributable to reduced rotating mass, the lighter wheels also allowed ABS systems to modulate more precisely. Wheel speed sensors detected changes faster, enabling more refined brake pressure control during threshold braking.

Flow-formed wheels delivered intermediate braking benefits – roughly 60% of forged wheels' advantages. Their lighter weight and improved ventilation designs split the difference between cast and forged alternatives. For street-focused driving with occasional track use, this represented excellent value. Only drivers pursuing competitive lap times truly needed forged wheels' ultimate braking performance.

Controlled acceleration testing revealed weight reduction's direct impact on performance. Using the same vehicle, tires, and conditions, wheels were the only variable. Cast wheels (28 lbs each) established baseline performance: 0-60 mph in 5.8 seconds and quarter-mile in 14.2 seconds.

Flow-formed wheels (21 lbs each) improved acceleration to 5.6 seconds 0-60 and 14.0 seconds quarter-mile. The 7-pound per wheel reduction created measurable gains without extreme cost. Forged wheels (18 lbs each) pushed performance further: 5.4 seconds 0-60 and 13.9 seconds quarter-mile. Every pound of rotational mass saved matters more than static weight reduction.

Interestingly, gains proved most significant in higher gears. First and second gear acceleration showed modest improvements, but third and fourth gear pulls revealed larger differences. This characteristic stems from reduced inertia becoming more influential as speeds increase. Highway passing acceleration – 50-70 mph in top gear – improved most dramatically with lighter wheels.

Choosing between SpecFit and CustomFit configurations affects both performance and practicality. After testing both fitment types extensively on track and street, each approach offers distinct advantages depending on your priorities. Understanding these differences helps you select the optimal setup for your driving needs.

SpecFit wheels utilize factory-tested dimensions specifically engineered for your vehicle model. These configurations maintain OEM suspension geometry while enhancing performance through lightweight construction and improved designs. SpecFit setups typically stay within 10mm of stock wheel width and match factory offset specifications closely.

This conservative approach delivers real benefits for daily drivers. SpecFit wheels preserve full steering lock, maintain proper speedometer calibration, and avoid rubbing issues during suspension compression. You won't need modifications like fender rolling or suspension adjustments. Installation remains straightforward – simply bolt on and drive.

Performance gains come primarily from weight reduction rather than increased tire width. Testing showed SpecFit configurations improved lap times by 0.8-1.2 seconds compared to stock wheels, mainly through better suspension response and reduced unsprung mass. For vehicles seeing 80% street use and 20% track time, SpecFit provides the ideal balance.

CustomFit setups push dimensional limits to accommodate significantly wider tires and optimized offsets. These configurations might increase wheel width by 1-2 inches over stock, utilize different offset ranges, and require careful clearance verification. CustomFit wheels maximize mechanical grip through increased contact patch area.

The performance advantages prove substantial. Testing revealed CustomFit configurations with properly sized tires improved lap times by 1.5-2.3 seconds versus stock – nearly double SpecFit's gains. The wider tires created noticeably more mid-corner grip, allowing higher speeds through sweeping turns. Traction during acceleration and braking improved measurably.

CustomFit demands more commitment. You'll likely need fender modifications, suspension adjustments, or both to prevent contact during compression and steering. Professional alignment becomes essential to optimize tire wear patterns. Some vehicles require negative camber adjustments to maximize the wider tire's contact patch. Budget extra time and expense for proper CustomFit installation.

Wheel offset – the distance from the mounting surface to the wheel's centerline – directly impacts handling characteristics. More aggressive (lower) offsets push wheels outward, widening track width and improving stability. However, this creates additional stress on wheel bearings and suspension components. Track width increases of 20-30mm noticeably enhance turn-in response and reduce body roll.

Backspacing determines how far the wheel sits inboard toward suspension and brake components. Insufficient backspacing causes interference with calipers, suspension arms, or chassis components. During testing, several wheel configurations initially appeared to fit but contacted suspension during full compression or steering lock. Always verify clearance through complete suspension travel and steering range.

Tire width relative to wheel width affects sidewall stiffness and handling precision. Wheel widths should match recommended tire sizes – typically wheels measure 1-1.5 inches narrower than tire section width. Mounting 255mm tires on 9-inch wheels works well; using 8-inch wheels creates excessive sidewall bulge and reduces handling precision. The opposite extreme – stretching narrow tires on wide wheels – compromises safety and performance.

Sports cars and performance-oriented vehicles benefit most from CustomFit configurations. Their suspension designs typically accommodate wider wheels with minimal modifications. Testing showed high-performance platforms like the Civic Type R, WRX STI, and 86/BRZ gained maximum benefits from aggressive fitment. These vehicles' suspension geometry works well with increased track width and negative camber.

Daily drivers and luxury vehicles suit SpecFit approaches better. Maintaining ride quality and avoiding modifications preserves the refined characteristics these vehicles prioritize. SpecFit wheels still deliver noticeable improvements through weight reduction while keeping factory comfort levels. Vehicles like the Accord, Camry, and most crossovers fall into this category.

Trucks and SUVs require careful consideration. Their higher centers of gravity make them more sensitive to track width changes. SpecFit configurations work best unless you're specifically building for off-road use. Increased track width can improve stability, but also increases steering effort and creates additional stress on drivetrain components. Load ratings become critical – ensure wheels meet or exceed OEM specifications for towing and hauling.

After testing dozens of tuner wheel options across various budgets and applications, certain models consistently deliver exceptional value. These recommendations come from real-world experience on both street and track, helping you choose wheels that match your specific performance goals and budget constraints.

Flow-formed wheels offer the best value for performance-focused drivers. Konig dominates this category with their Hypergram, Ampliform, and Dekagram models, typically priced around $1,200-$1,400 per set. These wheels weigh significantly less than cast alternatives while maintaining impressive durability. Motegi's flow-formed lineup provides outstanding value—their MR160 Battle VI starts at just $337, with the three-spoke MR161 Kojin available at $269. For autocross enthusiasts, Konig's Hypergram proves particularly effective, weighing roughly 20 pounds for an 18×9.5 configuration.

Serious competitors choose forged wheels despite higher costs. Motegi Racing's forged collection begins at $1,013 for models like the MF421 SS3 and MF417 Millennium. These purpose-built wheels deliver uncompromising strength-to-weight ratios essential for competitive driving. Forgestar offers fully customizable forged wheels tailored for track use, featuring bespoke sizing, offsets, and finishes. For ultimate lightweight performance, magnesium forged wheels reduce weight by approximately 20% compared to aluminum equivalents.

Konig's reputation rests on exceptional value for performance-focused wheels. Their flow-formed models provide technology that approaches forged wheel characteristics at accessible prices. Motegi Racing, born from Japan's Motegi Twin Ring racetrack, produces both street-friendly and competition-ready options. Their MR145 weighs just 19.73 pounds while maintaining classic JDM styling. Forgestar specializes in customizable performance wheels with flow-formed technology offering remarkable strength without excessive weight.

Weld Racing's Street and Strip lineup balances track durability with daily comfort. Konig's Incident model delivers lightweight multi-spoke design that enhances handling without compromising ride quality. For vehicles seeing both commuting and occasional track use, flow-formed options provide the ideal compromise—light enough for noticeable performance gains yet durable enough for daily driving. Find the best selection of tuner wheels at Performance Plus Tire (https://www.performanceplustire.com/Tuner_Wheels), where you'll discover options perfectly suited to your specific performance needs.

After twelve months of track testing, quality tuner wheels prove their worth through measurable performance gains that justify the investment. Weight reduction from forged wheels creates a cascade of improvements across acceleration, braking, and cornering. The most striking discovery was how dramatically wheel construction affects overall handling characteristics.

Flow-formed wheels emerge as the best value for most enthusiasts, offering nearly 30% more strength than cast alternatives while significantly reducing weight. This middle-ground option provides excellent performance without the premium price of fully forged wheels. Brands like Konig and Motegi have earned their reputation among serious drivers who balance track days with daily commuting.

Fitment choices play a crucial role in performance. CustomFit options allow wider tires and increased mechanical grip, but SpecFit configurations deliver the best balance between enhanced performance and everyday usability. Proper wheel selection also improves brake cooling and heat dissipation – critical factors during extended track sessions.

The performance differences are measurable and consistent. Switching from basic cast wheels to quality forged alternatives consistently shaved 1-2 seconds per lap during testing. This improvement comes from enhanced consistency rather than peak speed, allowing drivers to link fast sectors together more reliably.

Tuner wheels represent one of the most effective performance upgrades available for serious drivers. Whether you choose flow-formed options for their value or invest in premium forged wheels for maximum performance, the right set changes both how your car performs and how it feels behind the wheel. Find the best selection of tuner wheels at Performance Plus Tire, where you'll discover options perfectly suited to your specific performance needs.

After 12 months of intensive track testing, here are the essential insights every driver should know about tuner wheels:

• Flow-formed wheels offer the best performance-to-price ratio, delivering 30% more strength than cast wheels while weighing 26% less for $1,400-$2,200 per set.

• Forged wheels provide measurable lap time improvements of 1-2 seconds through reduced unsprung weight and enhanced consistency, though they cost $3,500+ per set.

• SpecFit configuration strikes the ideal balance between enhanced performance and daily usability without requiring extensive vehicle modifications.

• Weight reduction creates cascading performance benefits - every pound saved in wheel weight equals 4-6 pounds of vehicle weight reduction in terms of acceleration and handling.

• Quality tuner wheels improve brake cooling and heat dissipation, preventing overheating during intense track sessions through better airflow design.

The bottom line: Quality tuner wheels represent one of the most effective performance upgrades available, transforming both measurable lap times and driving feel. Whether you choose flow-formed for value or forged for maximum performance, the right wheels deliver tangible benefits that justify the investment for serious driving enthusiasts.

Tuner wheels can significantly enhance performance, especially for track use. Quality tuner wheels reduce unsprung weight, improve handling, and allow for wider tires. Flow-formed wheels offer excellent value, while forged wheels provide the ultimate in lightweight strength for competitive driving.

Tuner wheels are engineered for performance, unlike OEM wheels that prioritize cost-effectiveness. They're typically lighter and stronger than standard aftermarket wheels, offering better handling and acceleration. Quality tuner wheels strike a balance between daily drivability and track capability.

The three main types are cast, flow-formed, and forged. Cast wheels are budget-friendly but heavier. Flow-formed wheels offer a good balance of performance and affordability. Forged wheels are the lightest and strongest, ideal for serious track use but also the most expensive.

In track testing, switching from basic cast wheels to quality forged tuner wheels consistently improved lap times by 1-2 seconds. This improvement comes mainly from enhanced consistency, allowing drivers to link fast sectors together more reliably lap after lap.

Yes, many tuner wheels are designed for dual-purpose use. Flow-formed wheels, in particular, offer a great compromise between performance and everyday practicality. Brands like Konig and Motegi produce wheels that perform well on track while remaining comfortable for daily commutes.