Alloy wheels represent a significant upgrade from traditional steel wheels, combining aluminum or magnesium with other metals to create superior wheel performance. When we talk about "alloy wheels" in the automotive world, we're specifically referring to wheels made from nonferrous metal combinations that deliver enhanced strength, reduced weight, and improved appearance.

The foundation of alloy wheels starts with aluminum as the primary metal, typically making up the largest portion of the composition. Manufacturers then add carefully measured amounts of magnesium, nickel, zinc, iron, copper, or silicon. Each metal serves a specific purpose - some increase strength, others improve workability, and some enhance corrosion resistance. This precise blending allows wheel manufacturers to fine-tune performance characteristics for different applications and driving needs.

Alloy wheel development has a rich history dating back to the 1960s. Magnesium alloys led the way as the first lightweight wheel option, though production remained limited. The real breakthrough came in the mid-to-late 1960s when aluminum casting improvements solved earlier problems with brittle wheels. Before these advances, aluminum wheels were problematic, with only 2-3% elongation capability.

Modern alloy wheels deliver substantial advantages that make them an excellent choice for vehicle upgrades:

Lighter Weight - Dramatically reduces unsprung weight, improving acceleration, braking, and handling performance

Superior Heat Management - Excellent heat conductivity helps brake components stay cooler during demanding driving

Enhanced Durability - Better impact resistance protects against damage from potholes and road hazards

Corrosion Protection - Natural resistance to rust, salt, and environmental damage extends wheel life

Style Options - Advanced manufacturing enables complex designs with thin spokes and premium finishes

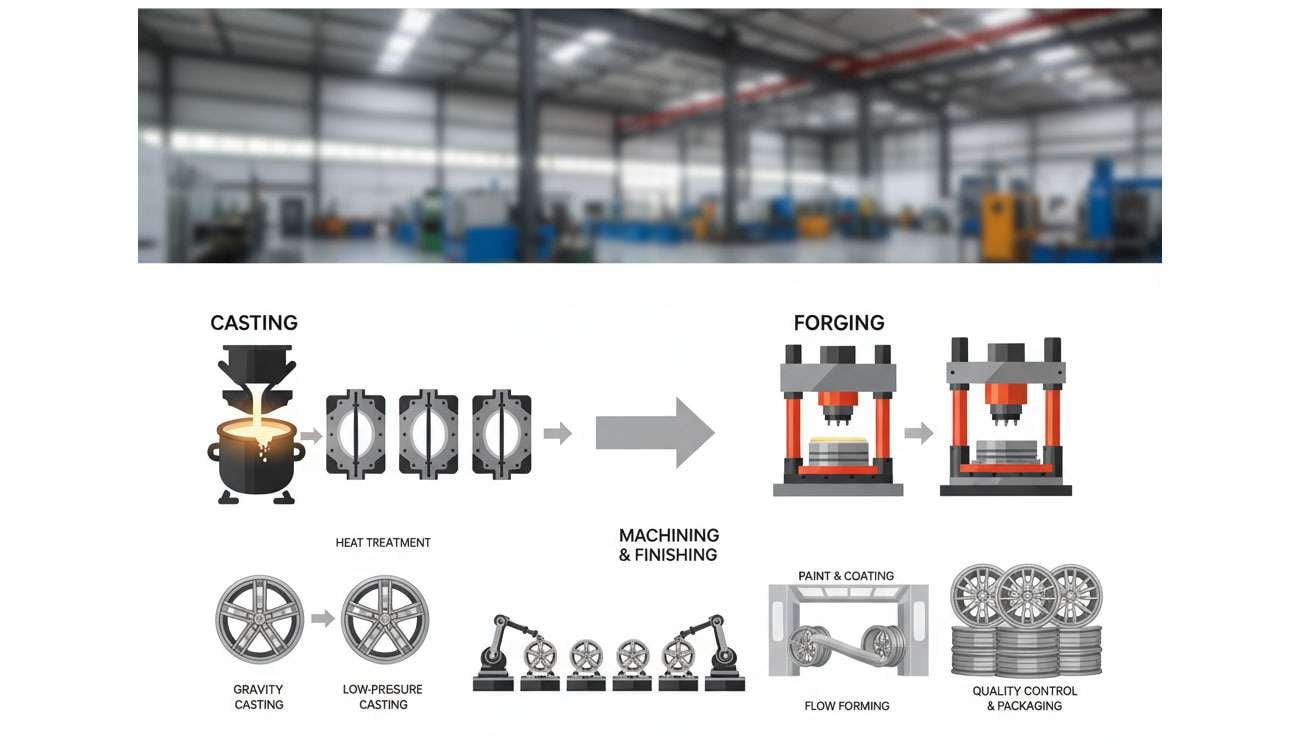

Two main manufacturing processes create alloy wheels: casting and forging. Casting pours molten metal into molds, while forging uses extreme pressure to shape solid metal. The manufacturing method directly impacts the wheel's final strength, weight, and cost, with forged wheels offering superior performance at a premium price.

What started as an exclusive option for luxury vehicles has become widely available. Since 2000, alloy wheels have become standard equipment on many vehicle types, from economy cars to high-performance machines. This shift reflects both improved manufacturing efficiency and growing consumer demand for enhanced vehicle performance and appearance.

Aluminum forms the foundation of modern alloy wheels, typically comprising 90-95% of the total composition. This base metal provides the ideal balance of strength, weight, and workability that makes alloy wheels superior to their steel counterparts.

The remaining 5-10% consists of carefully selected metals that enhance specific performance characteristics:

Magnesium: 2-5% - reduces overall weight while maintaining structural strength

Silicon: 1-3% - improves casting properties and reduces shrinkage during cooling

Additional elements: 1-2% - including copper, nickel, zinc, manganese, and iron

Aluminum's low density - roughly one-third that of steel - explains why alloy wheels can deliver significant weight savings without sacrificing durability. The material also conducts heat efficiently, helping brake systems perform better under demanding conditions.

Most cast alloy wheels use A356 aluminum alloy, where silicon serves as the primary alloying element alongside copper or magnesium. This specific formulation provides excellent casting characteristics and good mechanical properties for everyday driving applications.

Forged wheels require different material approaches. These high-performance options typically use 6-series aluminum alloys, particularly 6061 aluminum (designated EN AW-6061). The magnesium and silicon content in these alloys creates superior strength, flexibility, and corrosion resistance compared to cast alternatives.

Magnesium wheels, despite being the original "mag wheels," have largely disappeared from mainstream applications due to corrosion concerns. However, racing applications still value magnesium alloys for their exceptional light weight and performance benefits.

Some premium manufacturers incorporate exotic elements like scandium or titanium into specialized wheel alloys. These advanced materials provide extraordinary strength-to-weight ratios and thermal resistance, though at substantially higher costs.

The precise blend of these metals determines how your wheels will perform. Surface treatments like anodizing, chromate coatings, or specialized paints add another layer of protection and visual appeal. Each material choice represents a balance between performance, durability, and cost considerations.

When it comes to selecting alloy wheels, understanding the different manufacturing methods helps you make the right choice for your vehicle and budget. There are four main types of alloy wheels, each offering distinct advantages depending on your performance needs and intended use.

Cast alloy wheels represent the most common type you'll find on vehicles today, accounting for approximately 90% of OEM wheels on new vehicles. The manufacturing process involves pouring molten aluminum into molds and allowing it to cool and solidify.

Two primary casting methods exist: gravity casting and low-pressure casting. Gravity casting relies on Earth's gravity to fill molds, resulting in less dense wheels with potential air pockets. Consequently, manufacturers add extra material, making these wheels heavier. Low-pressure casting uses positive pressure to inject molten aluminum, creating more consistent wheels with superior mechanical properties and minimal porosity.

Cast wheels offer several advantages for most drivers. They provide affordability, design versatility, and good shock absorption. The manufacturing process allows for complex designs and various finishes. However, they tend to fracture upon high-impact collisions rather than bend.

Forged wheels start as solid aluminum billets subjected to extreme compression—between 8,000 to 10,000 tons of pressure. This process fundamentally alters the metal's internal structure, creating a directional grain pattern that follows the wheel's shape. The forging process allows alignment of metal fibers along the spokes, resulting in superior mechanical properties.

These wheels deliver exceptional performance benefits. Forged wheels are approximately 3x stronger and 25% lighter than cast alternatives, offering improved acceleration, braking, and handling. They also dissipate heat more efficiently, benefiting brake performance.

The main consideration with forged wheels is their significantly higher cost compared to cast wheels. They're ideal for performance enthusiasts who prioritize weight savings and strength over budget considerations.

Modular wheels feature multi-piece designs (typically two or three separate components) that are bolted or welded together. These wheels are crafted from high-quality forged 6061-T6 aluminum, offering exceptional strength while maintaining relatively light weight.

The primary advantage of modular construction is customization flexibility—allowing for personalized fitment options, widths, offsets, and finishes. Additionally, if a section becomes damaged, it can be replaced individually without replacing the entire wheel. This makes them popular among enthusiasts who want unique specifications or need repair options.

Modular wheels require regular maintenance and come with a premium price tag. They're best suited for custom builds and show vehicles where personalization is a priority.

Magnesium wheels, often called "mag wheels," contain predominantly magnesium alloy. They are manufactured through either casting or forging processes. Magnesium offers three key properties: exceptional lightness (1.5 times less dense than aluminum), high damping capacity, and impressive specific strength.

These characteristics make magnesium wheels particularly valuable in competitive racing applications. Forged magnesium wheels demonstrate superior durability, bending rather than cracking under impact, and offering 100 times better vibration dampening than aluminum.

However, they require special protective coatings to prevent corrosion when exposed to water, salt, or debris. This maintenance requirement limits their practical use to specialized applications where their weight advantage justifies the extra care needed.

When choosing alloy wheels, understanding the manufacturing process helps you select the right combination of strength, weight, and price for your vehicle. Each production method creates wheels with distinctly different characteristics.

Forging creates the strongest alloy wheels available. The process applies extreme pressure between 8,000-10,000 tons to solid aluminum billets. This intense compression fundamentally changes the metal's internal structure, creating a directional grain pattern that follows the wheel's shape. The result is wheels that require less material while delivering superior strength and significantly lighter weight.

The high pressure eliminates weak points like porosity and cavities that can compromise wheel integrity. When you hit a pothole or road hazard, forged wheels bend rather than crack, which means they can often be repaired instead of replaced. This makes forged wheels the top choice for performance vehicles and off-road applications where durability matters most.

High pressure die-casting injects molten aluminum into steel molds under substantial pressure. This technique delivers excellent dimensional accuracy and allows for complex wheel designs that would be difficult to achieve with other methods. The process creates wheels with consistent quality and minimal internal defects.

The rapid production cycles make high pressure die-cast wheels cost-effective for mass manufacturing. This method strikes a good balance between performance and affordability, making it popular for aftermarket wheels that need to meet both quality and price expectations.

Most original equipment manufacturers choose low pressure die-casting for their wheels. The process uses moderate pressure (20-60kPa) to draw molten aluminum upward into molds. This creates wheels with superior mechanical properties compared to gravity casting.

The controlled solidification under pressure creates a dense, compact structure that improves wheel strength. Low pressure die-casting represents the most common OEM manufacturing technique because it provides reliable quality at reasonable production costs.

Gravity casting offers the most straightforward and cost-effective manufacturing method. The process relies solely on Earth's gravity to fill molds with molten aluminum. This simple approach keeps production costs low.

Manufacturers often use gravity casting for wheels where visual appeal takes priority over weight savings. However, because the process depends entirely on gravity for mold filling, the resulting aluminum is less densely packed. Gravity-cast wheels typically require additional material to achieve necessary strength standards, making them heavier than alternatives.

Understanding these manufacturing differences helps you choose wheels that match your driving needs and budget. Forged wheels cost more but deliver maximum performance, while cast options provide good value for everyday driving.

Understanding alloy wheels helps you make informed decisions about vehicle performance, safety, and value when purchasing or upgrading your car's wheels.

Alloy wheels are made primarily from aluminum (90-95%) mixed with metals like magnesium and silicon for enhanced strength and reduced weight compared to steel wheels

Four main types exist: cast wheels (most common and affordable), forged wheels (strongest and lightest), modular wheels (customizable), and magnesium wheels (racing-focused)

Alloy wheels offer superior heat dissipation, corrosion resistance, and design flexibility while being significantly lighter than steel alternatives

Manufacturing method determines performance: forged wheels are 3x stronger and 25% lighter than cast wheels but cost significantly more

Modern alloy wheels have evolved from luxury aftermarket items to standard equipment on many economy vehicles since 2000

The choice between different alloy wheel types ultimately depends on your budget, performance needs, and intended vehicle use—from daily driving to competitive racing applications.

Alloy wheels offer several benefits, including reduced weight for better performance, improved heat dissipation for brake cooling, higher corrosion resistance, and greater design flexibility for esthetic appeal.

While alloy wheels are generally not as strong as steel wheels, they offer a better strength-to-weight ratio. Forged alloy wheels, in particular, can be up to 3 times stronger and 25% lighter than cast alloy wheels.

Alloy wheels are primarily made of aluminum (90-95%) combined with other metals like magnesium, silicon, copper, and nickel. The specific composition varies depending on the desired properties and manufacturing process.

Manufacturing processes like forging, high-pressure die casting, low-pressure die casting, and gravity casting each produce wheels with different characteristics. Forged wheels are typically the strongest and lightest but also the most expensive.

Alloy wheels are now widely used across various vehicle types, from economy cars to high-performance vehicles. While initially popular as aftermarket upgrades or on luxury cars, they have become standard equipment on many vehicles since the early 2000s.