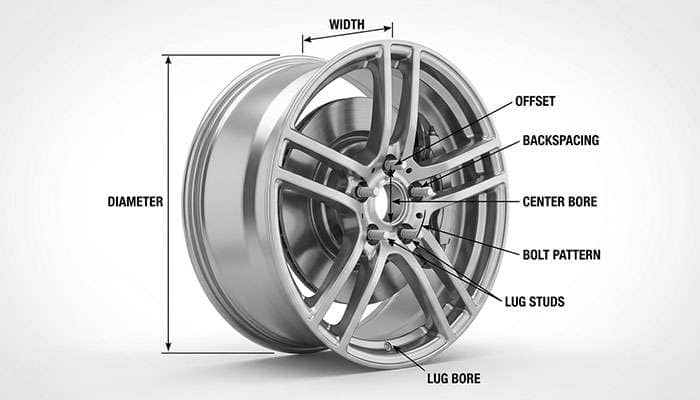

Understanding wheel fitment specifications is essential before selecting custom wheels for your vehicle. Wheel offset represents the distance from the mounting surface to the centerline of the wheel, measured in millimeters. This critical measurement determines exactly how your wheels position themselves on your vehicle and dramatically affects both performance and appearance.

Backspacing works alongside offset to complete the fitment picture. Backspacing measures the distance from the mounting surface to the wheel's back lip in inches. Together, these measurements determine whether your wheels will fit properly within your wheel wells without causing interference issues.

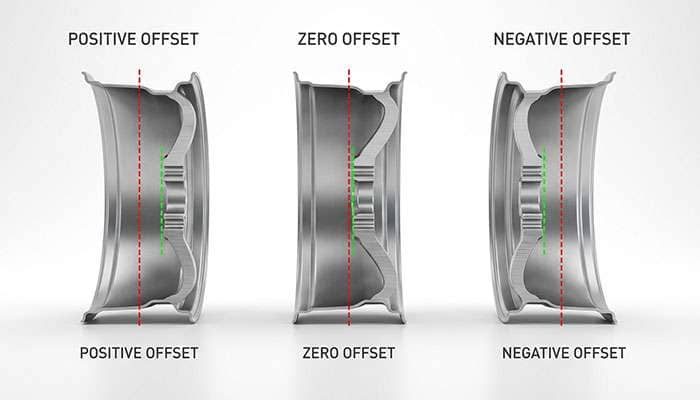

Wheel offset can be positive, zero, or negative. Positive offset wheels have their mounting surface positioned closer to the face of the wheel, while negative offset wheels have the mounting surface positioned toward the back. The lower the offset number, the more your wheel will extend outward from your vehicle.

We believe that mastering these technical specifications prevents costly mistakes and ensures perfect wheel selection. Our comprehensive guide breaks down each concept, explains how they affect your vehicle's stance, and provides the knowledge you need to make confident decisions about your next wheel upgrade.

Wheel offset measures the distance in millimeters between the wheel's mounting surface (where it bolts to the hub) and the centerline of the wheel. This measurement controls how your wheels position themselves relative to your vehicle's body and suspension components. Offset determines whether your wheels tuck inward, sit flush, or extend outward from the fenders.

Picture a wheel split exactly in half through its width. The centerline runs through the middle point between the inner and outer edges of the rim. Manufacturers position the mounting surface at different distances from this centerline, creating the offset measurement.

Consider a wheel with +35mm offset. The mounting surface sits 35mm toward the street side of the wheel's centerline. This pulls the wheel inward, creating a tucked appearance inside the fender. A wheel with -44mm offset positions the mounting surface 44mm toward the brake side, pushing the wheel outward.

Positive offset wheels create a tucked, streamlined appearance beneath your vehicle's body. Most modern vehicles, especially front-wheel drive cars and newer rear-wheel drive models, use positive offset wheels from the factory. This configuration maintains factory handling characteristics and improves aerodynamics.

Negative offset wheels produce that aggressive "deep dish" look where wheels extend outward from the vehicle. The mounting surface sits behind the centerline, pushing the wheel outward and creating a wider stance. Off-road vehicles, custom trucks, and performance enthusiasts often choose this style for its commanding appearance.

Zero offset wheels offer middle ground - the mounting surface aligns perfectly with the centerline, creating a balanced position between tucked and extended.

Offset controls clearance between your tires and suspension components. Too much positive offset can cause rubbing against struts, calipers, or inner fenders. Excessive negative offset risks fender contact, tire protrusion, and accelerated wear on suspension joints.

Offset changes your vehicle's track width - the distance between left and right wheels. More negative offset increases track width, which can improve handling by reducing lateral load transfer during cornering. However, this wider stance stresses ball joints, tie rods, and wheel bearings through increased leverage.

Appearance-wise, offset dramatically transforms your vehicle's stance. Aggressive negative offsets create that planted, wide look enthusiasts love, while positive offsets maintain a factory-like appearance. Whether you want subtle flush fitment or eye-catching width, offset makes it possible.

Even 5mm changes in offset noticeably affect both performance and appearance. When upgrading wheels, staying within 5mm of your factory offset maintains proper handling and prevents premature component wear.

Wheel backspacing uses inches as its standard unit of measurement, unlike offset which relies on millimeters. This measurement determines whether your wheels will clear brake components, suspension parts, and steering systems without interference.

Wheel backspacing represents the distance between the wheel's mounting surface and the inner edge of the wheel. This measurement tells you exactly how much wheel sits inside your wheel well versus how much extends toward the road.

Measuring backspacing requires these steps:

Place your wheel face-down on a soft surface with the inside face up

Lay a straight edge across the wheel's inside rim

Measure the distance from the mounting surface to the straight edge

Record the measurement in inches

Steel wheels with larger center holes can be measured face-up through the center hole from the floor to the backside of the wheel face.

Backspacing measures from the mounting surface to the back edge of the wheel, while offset measures from the mounting surface to the wheel's centerline. Backspacing uses inches while offset uses millimeters.

The relationship is direct but distinct. More negative offset equals less backspacing, while more positive offset correlates to greater backspacing. Backspacing is always expressed as a positive number, whereas offset can be positive, negative, or zero.

Convert between measurements using this formula: Offset = Backspacing - (Total wheel width ÷ 2). An 11-inch wheel with 5 3/16 inches of backspacing equals approximately -0.81 inches offset.

A 7-inch wide wheel with 3.5-inch backspacing equals zero offset because the mounting surface aligns perfectly with the wheel's centerline.

Factory wheels on newer 4x4s typically measure 6-8 inches wide with backspacing between 4-6 inches. These stock configurations position wheels further under the fenders.

Aftermarket off-road wheels usually feature backspacing between 3.5 and 5 inches. This reduced measurement pushes wheels outward for that aggressive stance enthusiasts prefer. Aftermarket 4x4 wheels often exceed 8 inches in width and commonly use backspacing measurements 1-2 inches less than factory specifications.

Finding the right balance is crucial. Too little backspacing (2-3 inches on 10-12 inch wide wheels) creates appealing wide stance but can cause unpredictable steering behavior and handling issues on rough roads. Excessive backspacing risks tire interference with suspension components.

Suspension modifications demand precise backspacing measurements. This is especially critical for vehicles with independent front suspension, where A-arms could contact wheels with excessive backspacing. Always check suspension manufacturer recommendations before selecting new wheels.

Converting between offset and backspacing helps you understand exactly how wheels will fit on your vehicle. Both measurements describe wheel positioning, but they use different reference points and units of measurement.

Converting from offset (millimeters) to backspacing (inches) requires a straightforward formula. Since offset measures from the wheel's centerline while backspacing measures from the rear lip, we need to account for both measurements.

For positive offset wheels:Backspacing = (Wheel Width ÷ 2) + (Offset × 0.03937)

For negative offset wheels:Backspacing = (Wheel Width ÷ 2) - (Offset × 0.03937)

Here's a practical example: For a 9-inch wide wheel with +25mm offset, the calculation would be: 9 ÷ 2 + (25 × 0.03937) = 4.5 + 0.98 = 5.48 inches of backspacing

Many wheel manufacturers and enthusiasts round to the nearest standardized measurement. A calculated 5.48 inches might be manufactured as 5.5 inches of backspacing.

When you know the backspacing and want to calculate the offset, use this formula: Offset (mm) = (Backspacing - (Wheel Width ÷ 2)) × 25.4

Consider a wheel with 5.5 inches of backspacing and a width of 9 inches: (5.5 - (9 ÷ 2)) × 25.4 = (5.5 - 4.5) × 25.4 = 1 × 25.4 = +25.4mm offset

A simpler example would be a 7-inch wide wheel with 3.5-inch backspacing, resulting in zero offset (0mm) since the mounting surface aligns perfectly with the wheel's centerline.

Round the result to the nearest millimeter, as wheel manufacturers typically use standardized offsets. If your calculation yields a negative number, the wheel has negative offset; if positive, then positive offset.

Understanding both measurements is crucial for proper wheel fitment. These values determine whether your wheels will clear suspension arms, brake calipers, and fender wells.

Incorrect offset and backspacing create several problems:

Steering and suspension systems can be negatively affected

Fenders may experience rubbing against tires

Brake components might not have adequate clearance

Frames could sustain damage from tire contact

Correct measurements allow sufficient room for suspension, brake, tire, and steering systems to operate without interference from the wheel. This becomes especially critical for lifted vehicles or those with aftermarket suspension components.

While offset is the automotive industry standard (measured in millimeters), backspacing is widely used in the powersports industry (measured in inches). Understanding both systems helps you make informed decisions regardless of which measurement a manufacturer provides.

Bolt patterns represent the foundation of wheel compatibility. This measurement determines whether your wheels can physically attach to your vehicle's hub - get it wrong, and your wheels simply won't fit.

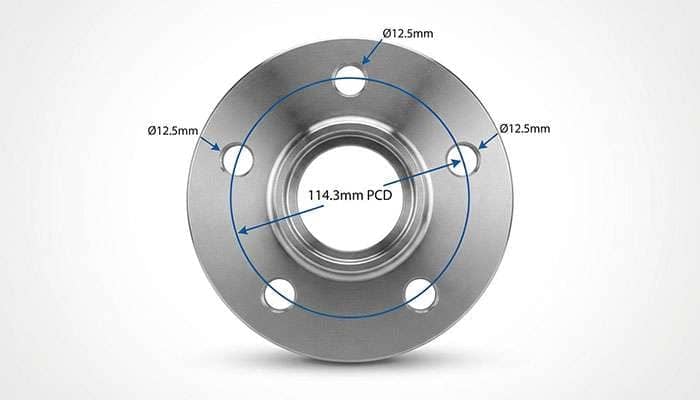

Bolt pattern, also called Pitch Circle Diameter (PCD), refers to the diameter of an imaginary circle passing through the centers of all wheel bolts or studs. This specification uses two numbers: the bolt count and the circle diameter. A "5x114.3" pattern means five bolts arranged in a circle measuring 114.3mm across.

Reading bolt patterns depends on the number of lugs. Wheels with 4, 6, or 8 lugs are straightforward - measure straight across from center to center of opposite lug holes. Five-lug patterns require a different approach. Measure from the center of one lug to the outer edge of the opposite lug, or use a specialized bolt pattern gauge for accuracy.

Vehicle manufacturers choose bolt patterns based on weight capacity and design requirements. Most passenger cars use 4-lug (4x100, 4x114.3) or 5-lug patterns (5x100, 5x114.3). The 5x114.3mm pattern appears across many Japanese vehicles including Honda, Toyota, and Nissan models.

SUVs typically use 5-lug or 6-lug configurations, with the 6x139.7mm pattern being popular for mid-size to full-size models. Pickup trucks commonly feature 6-lug patterns, while heavy-duty trucks require 8-lug patterns (8x165.1mm) for maximum load distribution. The heavier the vehicle, the more lugs needed to safely distribute weight.

Matching your wheel's bolt pattern to your vehicle's hub is non-negotiable for safety. Even minor mismatches prevent proper wheel centering. Wrong bolt patterns create excessive vibrations, unpredictable handling, and serious safety risks.

Using incorrectly matched bolt patterns causes premature wear on tires, suspension components, and steering systems. Worst case scenario: wheel detachment while driving - a potentially catastrophic failure. Dual-drilled wheels offer some flexibility by accommodating multiple bolt patterns, but exact matches remain the safest choice.

Selecting proper wheel specifications ensures both safety and performance for your vehicle. Even small errors in wheel specs can create significant problems that affect both your wallet and your driving experience.

Proper wheel fitment prevents tires from rubbing against brakes, fenders, or suspension components. When upgrading wheel size, verify that the overall diameter maintains adequate clearance around braking components and suspension parts. Vehicles with independent front suspension require special attention, as insufficient clearance can cause tires to contact A-arms. Check both interior clearance (between wheels and suspension) and exterior clearance (between tires and fenders).

Watch for these warning signs of rubbing problems: unusual tire wear patterns, burning rubber smells, and scraping noises during turns. Proper offset selection creates the right wheel positioning within the wheel well to prevent these issues.

OEM wheels are engineered to exact vehicle specifications, ensuring compatibility and seamless fit. Aftermarket wheels offer greater customization options and potentially enhanced off-road performance.

Aftermarket wheels require careful research regarding size and fitment specific to your vehicle. Unlike factory wheels, aftermarket options may require spacers, hub rings, or modifications for proper installation. The extra research pays off when you achieve the exact look and performance you want.

Online wheel fitment calculators help determine whether specific wheels will fit your vehicle. These tools allow you to compare your current wheel specs with potential new setups, showing clearance predictions and fitment outcomes.

Digital tools provide helpful guidance, but consulting with wheel specialists delivers expert recommendations. At Performance Plus Tire, our knowledgeable team provides expert guidance on selecting wheels with proper load capacity and dimensions specific to your vehicle. We help you avoid costly mistakes while achieving the perfect fitment for your build.

Understanding wheel offset, backspacing, and bolt patterns is crucial for anyone upgrading or customizing their vehicle's wheels. These measurements work together to determine how your wheels fit with your vehicle's body, suspension, and braking components. Offset measures the distance from the mounting surface to the centerline in millimeters, while backspacing calculates the distance from the mounting surface to the inner edge in inches. Both measurements directly affect your vehicle's stance, handling characteristics, and component clearance.

Proper wheel fitment requires careful attention to these specifications. Even small changes in offset or backspacing can significantly impact your vehicle's performance and appearance. Matching your bolt pattern to your vehicle's hub remains essential for safety and proper wheel function.

Many enthusiasts modify their wheel specifications for aesthetic or performance reasons. This decision should never compromise safety or functionality. Staying within recommended specifications helps maintain optimal handling while achieving your desired look.

At Performance Plus Tire, our expert team can guide you through the selection process to prevent costly mistakes and ensure proper fitment. You can find specialized wheel fitment tools and professional advice at Performance Plus Tire to help select wheels that perfectly match your vehicle's requirements.

Factory and aftermarket wheels approach these specifications differently. Aftermarket options offer greater customization possibilities but require more research to ensure proper fitment. Understanding wheel offset, backspacing, and bolt patterns allows you to confidently choose wheels that enhance both your vehicle's appearance and performance without compromising safety or reliability.

Understanding wheel offset, backspacing, and bolt patterns is essential for safe and proper wheel fitment that affects both vehicle performance and appearance.

• Wheel offset (measured in millimeters) determines wheel positioning relative to the centerline, affecting stance and clearance with suspension components.

• Backspacing (measured in inches) shows how much wheel sits inside the wheel well versus extending outward toward the road.

• Bolt patterns must match your vehicle's hub exactly - even slight mismatches can cause vibrations, handling issues, and safety hazards.

• Stay within 5mm of factory offset specifications to maintain proper handling characteristics and prevent premature suspension wear.

• Use conversion formulas and fitment calculators to avoid costly mistakes when selecting aftermarket wheels for your vehicle.

Proper wheel fitment requires balancing esthetics with functionality. While aftermarket wheels offer customization opportunities, they demand careful research to ensure compatibility with your vehicle's suspension, braking, and steering systems.

Wheel offset is the distance in millimeters from the wheel's mounting surface to its centerline. It determines how your wheels sit in relation to your vehicle's body and suspension. Positive offset moves the wheel inward, while negative offset pushes it outward, affecting both appearance and handling.

Backspacing is measured in inches from the wheel's mounting surface to its inner edge, while offset is measured in millimeters from the mounting surface to the wheel's centerline. Backspacing tells you how much of the wheel sits inside the wheel well, whereas offset determines the wheel's position relative to the vehicle's centerline.

The bolt pattern must match your vehicle's hub exactly to ensure proper wheel attachment. Even slight mismatches can cause vibrations, handling issues, and safety hazards. Incorrect bolt patterns can lead to premature wear on tires, suspension components, and in severe cases, wheel detachment.

It's generally recommended to stay within 5mm of your factory offset when upgrading wheels. This helps maintain proper handling characteristics and prevents premature wear on suspension components. Larger deviations can significantly affect your vehicle's performance and safety.

Factory wheels are designed to exact vehicle specifications, ensuring compatibility and seamless fit. Aftermarket wheels offer more customization options but require careful research to ensure proper fitment. Consider factors like offset, backspacing, bolt pattern, and clearance with suspension and brake components when selecting aftermarket wheels.