Wheel bolt patterns represent the most critical—yet frequently overlooked—aspect of selecting the right wheels for your vehicle. These patterns consist of two essential numbers: the count of bolt holes and the diameter of the circle they form. Larger vehicles typically feature more lugs, while smaller ones have fewer, with five-lug patterns being the most common on passenger cars, SUVs, and small pickups.

Understanding your vehicle's specific bolt pattern might seem confusing without proper guidance. A wheel with a "5-100mm" bolt pattern, for example, has 5 lug holes equally spaced around a circle with a 100mm diameter. American automobile manufacturers have historically favored five-lug bolt patterns since the late '20s, with each brand developing their own standards.

What does a bolt pattern actually mean? It's simply defined by those two numbers we mentioned earlier. If your wheel has 5 bolt holes forming a circle with a 5-1/2" diameter, you have a "5 on 5-1/2" bolt pattern. We've created this guide to help you understand the complexities of wheel fitment and ensure you select the perfect wheels for your vehicle every time.

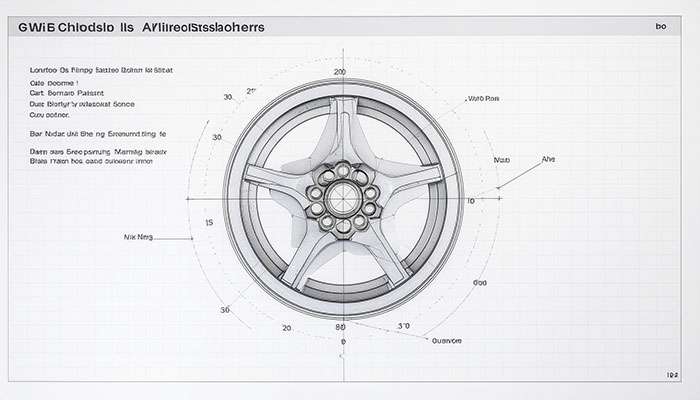

The bolt pattern represents the arrangement of lug holes on your wheel and serves as a fundamental aspect of wheel selection. Unlike what many assume, a bolt pattern isn't the distance between adjacent lugs but rather the diameter of an imaginary circle formed by the centers of each lug hole. This pattern determines which wheels will fit your vehicle.

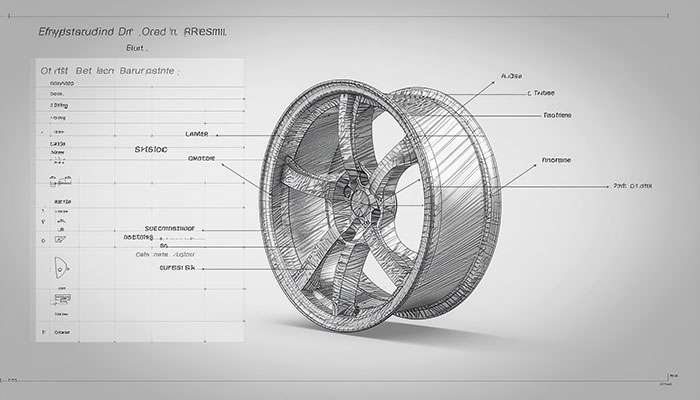

Bolt patterns consist of two crucial numbers: the count of lug holes and the diameter of the circle they form. A "5×100" designation means the wheel has five bolts evenly spaced around a circle with a 100mm diameter. This measurement system is also called the Pitch Circle Diameter (PCD). Manufacturers sometimes produce wheels with dual bolt patterns, allowing a single wheel design to fit multiple vehicle applications.

PCD refers to the diameter of the imaginary circle passing through the center of all studs, wheel bolts, or rim holes. This circle is theoretical and cannot be precisely measured on the wheel itself, but understanding it is crucial for proper wheel fitment. Common PCD measurements on modern vehicles include 100mm, 112mm, and 114.3mm. Over 30 different bolt circle patterns have been used by car manufacturers throughout automotive history, most incompatible with each other.

The number of lugs on a wheel corresponds to vehicle size and weight capacity:

4-lug patterns (4×100mm, 4×114.3mm) commonly appear on smaller vehicles like Honda Civics and some Nissan models

5-lug patterns (5×114.3mm, 5×100mm, 5×120mm) dominate passenger cars, SUVs, and light trucks including Toyota Camrys, BMWs, and Fords

6-lug patterns (6×139.7mm, 6×135mm) generally equip trucks and SUVs from Chevrolet, GMC, and Toyota

8-lug patterns (8×165.1mm, 8×170mm) serve heavy-duty trucks from manufacturers like Chevrolet and Ford

Understanding these differences becomes essential when selecting replacement wheels, especially when considering aftermarket options for your vehicle.

Getting accurate measurements of your wheel bolt pattern is crucial for proper fitment when selecting new wheels. This task requires specific techniques depending on how many lugs your wheel has.

Wheels with 4, 6, or 8 lugs are straightforward to measure. Just measure from the center of one lug hole directly across to the center of the opposite lug hole. This measurement gives you the bolt circle diameter (BCD). If your 4-lug wheel measures 100mm across, your bolt pattern is 4x100. This center-to-center method works because even-numbered patterns have lugs positioned directly opposite each other.

Five-lug patterns create a challenge since no lugs sit directly opposite each other. For these wheels, measure from the center of one lug to the imaginary outboard plane that would bridge the opposite two lugs. You can also measure from the center of one lug to the outer edge of the lug farthest away. These methods give you an approximation, as several 5-bolt patterns have diameters very close to each other.

A bolt pattern gage gives you more precision with 5-lug wheels. Without this specialized tool, your measurement stays an estimate.

Once you have measurements, consult a bolt pattern chart to identify the exact pattern. These charts typically include conversions between inches and millimeters. For example, 5x4.5 inches converts to 5x114.3mm. Charts help confirm your measurements, particularly with 5-lug patterns where small differences matter.

Common errors include measuring from incorrect points on the lug holes instead of their centers. Another mistake is assuming all wheels with the same lug count are interchangeable—the spacing between lugs matters just as much. Using imprecise tools can also lead to inaccurate measurements, potentially resulting in wheels that won't fit properly.

Professional consultation remains valuable for complex fitment situations, particularly with 5-lug patterns where precision is critical.

Each major automaker developed their own wheel bolt pattern standards throughout automotive history, which creates distinct identification systems that affect replacement parts today.

General Motors used two main five-lug patterns that defined their vehicles for decades. The smaller 5x4.75" pattern showed up on most GM passenger cars from 1949 through modern times, including Chevrolet's iconic Tri-Five models, muscle cars, and Corvettes. The larger 5x5" pattern served Cadillac and other luxury vehicles throughout the 1950s, then moved to light GM trucks after 1971. When GM switched to metric hardware, they adopted 5x120mm—just 0.65mm different from the traditional 5x4.75" pattern.

Ford chose the smaller 5x4.5" bolt pattern (sometimes written as 5x4-1/2") for many passenger vehicles starting in the 1950s, including Mustangs and Fairlanes. Ford's larger 5x5.5" pattern first appeared on early passenger cars before becoming the exclusive choice for Ford trucks. Car enthusiasts commonly call these "small Ford" and "large Ford" patterns.

Chrysler Corporation used several different bolt patterns across their vehicle lineup. Their smallest 5x4" pattern appeared on 1960s pony cars. The 5x4.5" pattern—which they shared with Ford—became the go-to choice for many Dodge, Chrysler, and Plymouth models from the 1950s through 1980s. Earlier luxury Chrysler models featured the 5x5.5" pattern.

Trailer manufacturers settled on different standards than passenger vehicles. The industry standard remains 5 lug on 4.5" (545), with 5 lug on 5" (550) as the secondary standard. You'll also find 4 on 4" and 6 on 5.5" patterns commonly used.

Matching bolt patterns is just the beginning of proper wheel fitment. Several additional factors can make the difference between a smooth ride and a problematic installation.

Offset represents the distance from the mounting surface to the wheel's centerline, measured in millimeters. It can be positive (mounting surface closer to the wheel face), zero (mounting surface at centerline), or negative (mounting surface toward the back). Backspacing measures the distance from the mounting surface to the wheel's back lip in inches. These measurements determine how your wheels sit relative to your vehicle's body—positive offset pushes wheels inward while negative offset creates an aggressive stance with wheels extending outward.

The hub bore (center bore) is the machined opening on the wheel that fits over your vehicle's hub. This opening must match or slightly exceed your hub diameter for proper centering. When the wheel's center bore is larger than your vehicle's hub, hub-centric rings can fill this gap. Without proper centering, wheels rely solely on lug nuts to stay centered, potentially causing vibrations, uneven tire wear, and premature component failure.

Proper torque application prevents dangerous under or over-tightening of wheel hardware. Check your owner's manual for vehicle-specific specifications—most passenger vehicles require around 100 ft-lbs. New wheels should be re-torqued after 50-100 miles as wheels settle during initial use. Always use a calibrated torque wrench rather than impact guns, which can damage hardware or apply inconsistent torque.

Getting your wheel bolt pattern right matters more than most people realize when it comes to wheel selection. You now know that bolt patterns aren't just random numbers—they tell the complete story of how wheels attach to your specific vehicle.

Each measurement technique we've covered serves a purpose. Four, six, and eight-lug wheels make measurement simple with their center-to-center approach. Five-lug patterns require a bit more care, but the techniques we've shared will get you the answers you need.

Different manufacturers chose their own paths when developing bolt patterns. GM went with 5x4.75", Ford picked 5x4.5", and Chrysler had their own preferences. This history explains why you can't just swap wheels between different brands without checking the specs first.

Remember that bolt pattern matching is your starting point, not your finish line. Wheel offset, hub bore size, and proper torque specs all matter just as much for a safe, smooth-riding setup. Skip any of these, and you might end up with wheels that bolt on but don't perform the way they should.

You're now equipped with the knowledge to make smart wheel choices. When you're ready to upgrade, you'll know exactly what questions to ask and what numbers to look for. Your vehicle deserves wheels that fit right the first time—and now you know how to make that happen.

Understanding wheel bolt patterns is crucial for safe vehicle operation and proper wheel fitment. Here are the essential insights every vehicle owner should know:

• Bolt patterns consist of two numbers: lug hole count and circle diameter (e.g., 5x114.3mm means 5 lugs on a 114.3mm circle)

• Measurement techniques vary by lug count: Even-numbered patterns use center-to-center measurement, while odd patterns require specialized methods

• Each manufacturer has unique standards: GM uses 5x4.75", Ford prefers 5x4.5", creating compatibility challenges between brands

• Bolt pattern matching is just the beginning: Wheel offset, hub bore size, and proper torque specs are equally critical for safe fitment

• Professional consultation prevents costly mistakes: Complex 5-lug patterns and precision requirements make expert guidance valuable for proper wheel selection

Getting the bolt pattern right ensures your wheels mount safely and perform optimally. Remember that proper fitment goes beyond just matching numbers – it's about understanding the complete system that keeps your wheels securely attached to your vehicle.

A wheel bolt pattern consists of two numbers: the count of lug holes and the diameter of the circle they form. It's crucial for determining which wheels will fit your vehicle and ensuring proper installation.

For even-numbered patterns (4, 6, 8 lugs), measure from the center of one lug hole to the center of the opposite hole. For 5-lug patterns, measure from the center of one lug to the outer edge of the farthest lug. Using a bolt pattern gage provides the most accurate results.

No, not all 5-lug wheels are interchangeable. The spacing between lugs (pitch circle diameter) can vary significantly between manufacturers and vehicle models. Always verify the exact bolt pattern before purchasing new wheels.

Wheel offset, backspacing, hub bore size, and center hole compatibility are crucial factors beyond bolt pattern. These elements determine how the wheel sits in relation to the vehicle's body and ensure proper centering on the hub.

Proper torque application is critical for safe wheel installation. Use a calibrated torque wrench to tighten lug nuts to the manufacturer's specifications, typically around 100 ft-lbs for passenger vehicles. Re-torque after 50-100 miles of driving as wheels may settle during initial use.