Car rims are more than just the circular metal that holds your tires. They directly influence how your vehicle handles, accelerates, and stops. Every driver should understand these critical components, whether you're building a show car or simply want reliable transportation that looks great.

The two main materials dominate today's rim market: steel and alloy. Alloy rims weigh significantly less than steel, giving performance vehicles a clear advantage in acceleration and handling. Steel rims offer superior durability at budget-friendly prices, typically $50 to $150 each. The right rim choice transforms your vehicle's appearance while delivering measurable performance improvements.

Your factory wheels weren't chosen randomly. Manufacturers carefully matched them to your vehicle's suspension geometry, gear ratios, and body clearances. These engineering decisions directly affect ride quality and overall performance. Wider rims provide increased contact patch and superior grip, particularly beneficial for sports car applications.

Selecting rims involves much more than personal preference. Weight affects fuel economy. Size influences ride comfort. Material determines durability. Offset impacts handling characteristics. We'll guide you through every consideration that matters, from understanding different materials and construction methods to proper fitment and long-term maintenance strategies.

At Performance Plus Tire, we've helped thousands of customers find the perfect rims for their specific needs and driving style. This guide covers everything you need to make an informed decision for your vehicle.

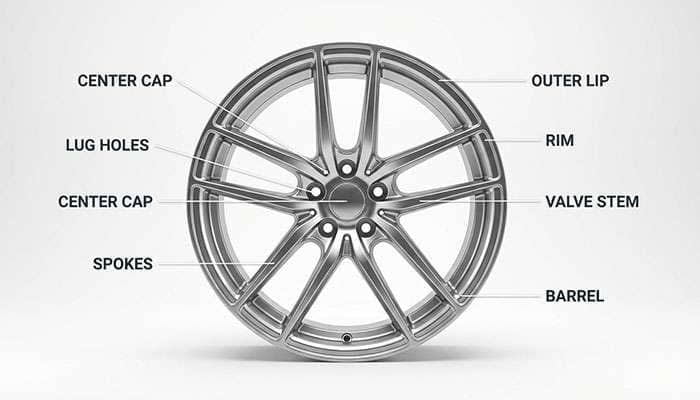

Most people use "rims" and "wheels" as if they mean the same thing. They don't. The rim is specifically the outer edge where your tire mounts. The wheel includes everything: rim, spokes, hub, and all connecting components. Think of the rim as the U-shaped channel that grips your tire and maintains the seal.

Car enthusiasts might say "nice rims" when admiring someone's wheels, but the rim technically refers only to those outer edges. This distinction affects how you shop, what you pay for, and what you're actually getting. The rim's job is creating an airtight seal with your tire while supporting the weight and forces of driving. The rest of the wheel connects to your vehicle through the hub and transfers all those driving forces to your suspension system.

Four main materials dominate the rim market today:

Steel: Most durable option, nearly impossible to crack, costs $50 to $150 each

Aluminum alloy: Lighter weight improves performance, ranges from $125 to $500 per wheel

Carbon fiber: Stronger than steel yet lighter than aluminum, found on high-performance vehicles

Titanium: Half the weight of steel with equal strength, prices reach thousands per wheel

Some manufacturers add Teflon coatings during production for extra protection against corrosion.

Rim size and weight directly change how your car behaves. Lighter rims mean your engine works less to spin the wheels, improving both acceleration and fuel economy. Heavy rims create more rotational inertia, slowing acceleration and making the car less responsive in corners.

Larger wheel diameter raises your vehicle's center of gravity, which can increase body roll and affect stability. However, bigger wheels also provide better braking performance and can improve overall stability when properly matched to your vehicle. Wider rims increase the tire's contact patch for better grip, but this comes with higher rolling resistance.

Damaged rims create serious safety hazards. Cracks or bends can cause vibrations, handling problems, tire failure, or complete loss of control.

Steel and aluminum alloy dominate today's rim market. Each material serves different purposes, from daily driving to high-performance applications. Understanding these differences helps you choose the right option for your specific needs and budget.

Steel rims earn their reputation through straightforward construction and exceptional toughness. Manufacturers stamp and weld steel sheets into wheel shapes, creating rims that resist cracking and handle serious impacts. When steel rims do get damaged, they typically bend rather than shatter, and many dents can be hammered back into acceptable shape.

These rims excel in harsh conditions. Winter driving with salt exposure, off-road adventures, and work truck applications all favor steel's durability. Heavy-duty vehicles benefit from steel's ability to handle substantial loads without failure.

The trade-offs are significant. Steel rims weigh 2.5 to 3 times more than aluminum alternatives, directly impacting acceleration and fuel economy. Design options remain limited, and sizes rarely exceed 16 inches in diameter. For drivers prioritizing function over form, steel delivers unmatched value.

Aluminum alloy rims blend aluminum with metals like nickel, magnesium, or silicon, creating wheels that transform vehicle dynamics. The weight savings provide immediate benefits: sharper steering response, improved acceleration, better fuel efficiency, and reduced suspension wear.

Heat dissipation represents another crucial advantage. Alloy rims transfer brake heat more effectively than steel, reducing brake fade during aggressive driving. The manufacturing flexibility allows intricate spoke patterns, multiple finish options, and sizes up to 24 inches or larger.

Expect to invest $125 to $500 per wheel for quality alloy options. Impact resistance trails steel significantly, and repair costs exceed steel rim maintenance. For performance-oriented drivers and those seeking distinctive appearance, alloy rims justify the premium.

Chrome wheels feature steel or alloy bases with multi-layer chrome plating. The mirror finish creates stunning visual impact but demands consistent maintenance to prevent oxidation.

Forged wheels represent the pinnacle of strength-to-weight engineering. Manufacturers compress solid aluminum under 8,000 to 10,000 tons of pressure, creating rims 10-20% lighter than cast equivalents with superior structural integrity. Cast wheels use molten metal poured into molds, offering lower costs but higher porosity that can lead to cracking.

Multi-piece construction allows ultimate customization. Two-piece wheels separate the center from the rim, while three-piece designs split the rim into two halves. This modularity enables custom width, offset, and finish combinations.

Magnesium wheels ("mags") achieve the lightest possible weight but require careful maintenance to prevent corrosion. Carbon fiber wheels weigh 40% less than comparable aluminum, making them ideal for track applications despite premium pricing around $5,000 each.

When selecting rim materials, consider your driving priorities, maintenance preferences, and budget constraints. For drivers seeking performance upgrades without breaking the bank, explore options to discover discount car rims that match your vehicle's requirements and driving style.

Choosing custom rims requires understanding key fitment specifications that determine whether your wheels will work safely with your vehicle. Get these measurements wrong, and you risk rubbing, handling problems, or even safety issues.

Offset determines where your rim sits in the wheel well—measured from the hub mounting surface to the rim's centerline. Three offset types exist: zero offset places the mounting surface at the centerline, positive offset moves it toward the street side, and negative offset positions it behind the centerline. Proper offset prevents your rims from hitting suspension components, brake calipers, or body panels.

We recommend staying within 5 millimeters of your original offset when selecting new rims. Backspacing matters too—this measurement accounts for both offset and rim width, becoming critical when you're installing wider rims than your factory setup.

Before purchasing, verify these essential specifications:

Size compatibility: Diameter, width, and offset must match your vehicle's requirements

Bolt pattern: Must align perfectly with your vehicle's hub

Hub size and center bore: Ensures secure mounting without vibration

Load rating: Must handle your vehicle's weight safely

Professional installation: Proper balancing and alignment prevent problems

Double-check every specification before ordering. Wrong fitment creates handling issues, safety risks, and comfort problems.

Bolt patterns use two numbers: lug count and bolt circle diameter. Most vehicles use 4, 5, 6, or 8-lug configurations. Measuring varies by lug count—for 4, 6, and 8-lug patterns, measure center to center across opposite holes. For 5-lug patterns, measure from one lug center to the outer edge of the opposite lug.

OEM wheels guarantee perfect fitment and quality since manufacturers design them specifically for your vehicle. Aftermarket options provide more variety in designs, potentially lighter weight for better performance, and flexible pricing from budget to premium forged options.

When you're ready to explore your options, discover discount car rims that combine your style preferences with proper fitment specifications.

Maintaining your rims properly keeps them performing at their best and protects your investment. We see too many customers who could have avoided expensive replacements with simple preventive care.

Watch for these problems that indicate rim damage:

Visible cracks or chips that penetrate below the paint surface

Bent or dented rims that affect tire seating

Rust or corrosion, especially after exposure to road salt

Unusual vibrations felt in the steering wheel or seats

Recurring tire pressure loss despite refilling

Noticeable decline in fuel efficiency or EV range

Uneven tire wear patterns

Don't ignore these symptoms. They lead to poor handling, extended braking distances, and premature wear on suspension components.

Steel wheels can often be straightened after minor damage, but aluminum wheels present different challenges. Here's what you need to know:

Repairable aluminum wheel damage:

Minor bends on the back side of the wheel

Certain cracks in the barrel area

Surface scratches and cosmetic issues

Replace immediately for these problems:

Cracks on the front face or spokes

Severe structural damage

Compromised lug nut holes

Never let anyone hammer aluminum wheels back into shape. This almost always results in cracking or complete failure.

Start with cool wheels and gentle soap using a microfiber cloth or soft brush. Different finishes require specific care:

Chrome rims need special chrome polish to prevent pitting. Regular car wax won't provide adequate protection.

Matte and satin finishes should never be polished or waxed. Simple soap and water maintains their appearance.

Polished aluminum requires regular polishing to prevent oxidation. Skip this step and you'll see permanent discoloration.

After cleaning, apply wheel-specific protective products. Ceramic coatings shield against brake dust and contaminants for 1-2 years with proper maintenance.

Your finish choice should match how often you want to clean your wheels:

High-maintenance finishes:

Gloss creates a clean, shiny appearance but shows every scratch

Polished provides dramatic contrast but requires frequent upkeep

Low-maintenance options:

Matte hides minor imperfections better

Satin offers subtle shine with easier maintenance

For daily drivers, we recommend satin or gunmetal finishes that hide brake dust between cleanings. Show cars benefit from high-gloss or polished finishes if you don't mind the extra maintenance.

Car rims directly impact every aspect of your driving experience. The right choice improves handling, fuel efficiency, and vehicle appearance while the wrong choice compromises safety and performance.

We've covered the essential factors that matter most. Steel rims offer unbeatable durability at budget-friendly prices. Alloy rims provide performance advantages through weight reduction and better heat dissipation. Specialty materials like carbon fiber and titanium deliver premium performance for those who demand the best.

Proper fitment remains critical regardless of material choice. Incorrect bolt patterns, offset, or load ratings create safety hazards and handling problems. Always verify compatibility before purchase and ensure professional installation for optimal results.

Regular maintenance protects your investment and maintains performance. Clean your rims appropriately for their specific finish. Address damage promptly to prevent bigger problems. Watch for warning signs like vibrations, pressure loss, or unusual wear patterns.

At Performance Plus Tire, we help customers find the perfect rim solution for their specific needs and budget. Whether you need reliable steel rims for winter driving or lightweight alloy rims for performance applications, we carry the best selection at the lowest prices. Our fitment experts ensure compatibility with your vehicle while our financing options make upgrades affordable.

Ready to upgrade your ride? Our knowledgeable team stands ready to guide you through the selection process and help you find rims that deliver both style and performance for your vehicle.

Understanding car rims goes beyond esthetics—these components directly impact your vehicle's safety, performance, and fuel efficiency. Here are the essential insights every driver should know:

• Material choice matters for performance: Steel rims offer durability and affordability ($50-150 each), while alloy rims provide better handling and fuel efficiency ($125-500 each) due to their lighter weight.

• Proper fitment is critical for safety: Always verify bolt pattern, offset, and size specifications before purchasing—incorrect fitment can cause handling issues, tire damage, or complete loss of vehicle control.

• Regular maintenance prevents costly replacements: Watch for cracks, vibrations, or pressure loss as warning signs, and clean rims with appropriate products based on their finish type to extend lifespan.

• Larger wheels improve handling but affect ride quality: While bigger rims enhance stability and braking, they also increase weight, reduce acceleration, and can make the ride less comfortable.

• OEM vs aftermarket involves trade-offs: Original equipment ensures perfect fit and quality, while aftermarket options offer more design variety and potential performance benefits at various price points.

The right rim selection balances your style preferences with practical considerations like driving conditions, vehicle type, and budget—making informed choices ensures both safety and satisfaction on the road.

While often used interchangeably, rims are actually just one part of the wheel. The rim is the outer edge where the tire mounts, while the wheel includes the entire metal assembly - rim, spokes, hub, and other components.

Steel rims are durable and affordable but heavier, while alloy rims are lighter, improving handling and fuel efficiency. Carbon fiber and titanium offer the best strength-to-weight ratios but at a premium price. The material choice impacts acceleration, cornering, and overall driving dynamics.

Key considerations include size compatibility (diameter, width, offset), bolt pattern matching, hub size, load rating, and professional installation. Always verify specifications to ensure proper fitment, as incorrect sizing can compromise safety and handling.

Minor damage like surface scratches or small bends on the back of alloy wheels can often be repaired. However, cracks on the front face or spokes, severe structural damage, or compromised lug nut holes typically require replacement for safety reasons.

Clean rims regularly with appropriate products based on their finish (e.g., specific chrome polish for chrome rims). Apply protective coatings to guard against brake dust and contaminants. Watch for signs of damage like cracks, vibrations, or recurring tire pressure loss, and address issues promptly to extend rim lifespan.