Understanding wheel components starts with the rim - the outer circular edge of a wheel that holds your tire securely in place. This critical component forms the outer perimeter of the wheel assembly where the tire's inside edge mounts on vehicles ranging from automobiles to bicycles. The rim features a distinctive U-shaped cross-section with a deeper center and raised outer edges, specifically engineered to support the tire bead and maintain proper fitment.

Your rim serves several essential functions that directly impact vehicle performance:

Creates a secure seal between tire and wheel assembly

Maintains tire position during acceleration, braking, and cornering

Keeps air pressure stable in tubeless tire systems

Provides structural support for the entire wheel system

Most rims are manufactured from the same materials as the rest of the wheel - typically steel or aluminum alloy. Many feature protective coatings like Teflon that increase durability and resist road damage. Steel and aluminum dominate rim construction because they offer the best balance of strength, weight, and cost-effectiveness for most applications.

The rim's U-shaped profile becomes clearly visible when you examine a wheel without its tire. This design serves a specific purpose: the deeper center section allows easier tire mounting, while the raised edges (called flanges) prevent the tire from sliding off during operation. These flanges work together with the tire bead to create the airtight seal that tubeless tires require for proper performance.

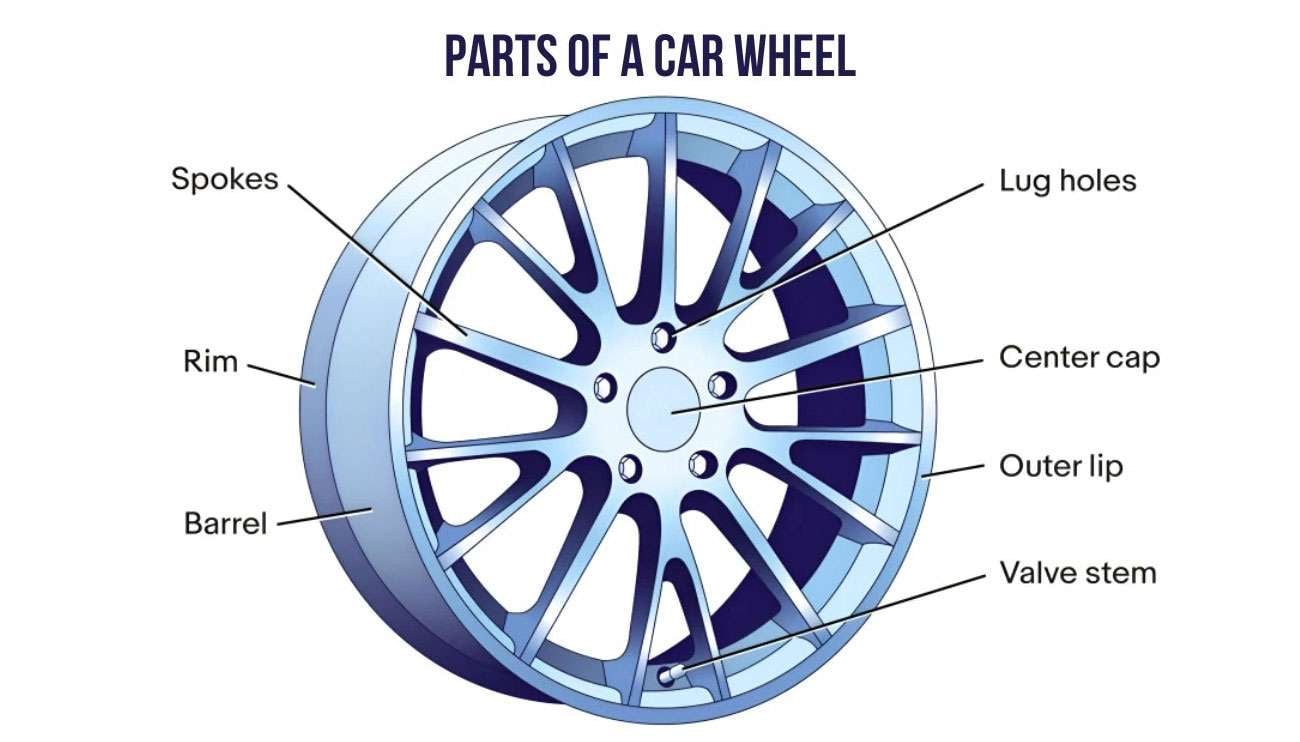

Many people use "wheel" and "rim" interchangeably, but they're not the same component. The rim refers specifically to the outer edge where your tire mounts - think of it like the rim of a coffee cup that refers only to the edge. A complete wheel assembly includes the rim plus the hub (which connects to your vehicle's axle), spokes (linking hub to rim), and the barrel (the main structure extending from mounting surface to rim flange).

The rim's configuration and depth determine which tire sizes and types will fit properly. Beyond appearance, rim design affects crucial performance factors including handling characteristics and load capacity. Truck rims, for example, require stronger construction to handle the heavier loads they must support.

Image Source: Forged Wheels

Understanding the different types of wheel rims is essential for making the right choice for your vehicle. Each type offers distinct advantages depending on your specific needs and driving conditions.

One-piece rims represent the pinnacle of wheel construction, manufactured from a single piece of material, typically aluminum. These monoblock wheels undergo advanced manufacturing processes like flow forming or rotary forging, where a preform is shaped into the final design.

The absence of seams or joints provides superior structural integrity, making them the go-to choice for high-performance applications. One-piece rims deliver an unbeatable strength-to-weight ratio, enhanced durability, and require minimal maintenance. They also weigh significantly less than multi-piece alternatives, which can improve your vehicle's fuel efficiency.

Multi-piece rims consist of separate components bolted together to create the complete wheel. Two-piece wheels feature a center section and outer rim, while three-piece wheels incorporate an inner rim, outer rim, and center piece.

This modular design offers manufacturers incredible flexibility, allowing them to create various widths and offsets from a single wheel design by mixing different components. While heavier than one-piece alternatives, multi-piece rims provide greater customization options and easier repairs. When damage occurs, you can replace individual components rather than replacing the entire wheel.

Beadlock rims feature a bolted outer ring that physically clamps the tire's bead to the rim. This specialized design allows for extremely low tire pressure without the risk of the tire bead separating from the rim.

This capability proves invaluable for off-road performance, where deflated tires provide better traction on loose, slippery terrain. Beadlock rims offer improved off-road performance and stronger rim edges, but they come with important considerations. They're heavier, more expensive, require regular maintenance to re-torque bolts, and most importantly, are generally not legal for street use.

Safety rims come standard on most passenger vehicles and feature distinctive bumps extending inward that hold the tire bead firmly against the rim. These bumps work with tire pressure to prevent the tire from slipping inward off the rim.

Unlike beadlock rims that physically clamp the bead, safety rims rely partially on proper tire inflation to function correctly. They provide a crucial safety feature that allows limited driving on a nearly flat tire for short distances at low speeds—approximately 5 miles at 5 mph—until you can reach service.

The rim serves as the essential foundation for tire performance, providing crucial support mechanisms that directly impact your vehicle's safety and handling capabilities.

The rim creates a secure anchor point for the tire bead—a loop of high-tensile steel cable coated with rubber—against the rim flange. This critical connection forms the foundation of the tire-wheel interface, allowing the rim to transmit forces between tire body plies and wheel. The bead bundle, typically weighing about one pound, consists of large monofilament steel cords wound into a precisely sized loop.

Without this secure connection, your tire would simply slip off the wheel during operation, making proper bead seating absolutely essential for safe driving.

Tubeless tires depend entirely on the rim's design to create an airtight seal. The rim maintains air inside tubeless tires through proper fitting between the tire bead and rim flange. This seal prevents air leakage from the tire/rim interface. Proper inflation depends on this seal's integrity, as inadequate pressure can cause excessive sidewall flexing.

When this seal fails, you'll experience gradual air loss that can lead to dangerous driving conditions and premature tire wear.

Rim configuration directly impacts how your vehicle performs on the road. Sidewall deflection varies based on rim design, influencing how forces transmit from ground to vehicle. The sidewall maintains lateral stability during cornering or braking.

Larger diameter rims with lower profile tires typically provide sharper handling response but may sacrifice some ride comfort on rough surfaces.

During vehicle operation, the rim prevents tire deformation that could compromise performance. Proper rim design ensures the tire maintains optimal contact patch and shape, even under load.

This consistent shape retention helps maintain even tread wear patterns and predictable handling characteristics throughout the tire's lifespan.

Off-road enthusiasts benefit from specialized rim features designed for challenging terrain. Rim locks prevent tire spinning on the rim. Anti-slip knurled beads—small machined grooves on the rim's inner lip—enhance grip between wheel and tire under high-performance conditions.

These features become particularly important when running lower air pressures for improved traction on sand, mud, or rocky terrain.

When it comes to wheel terminology, most people use "rim" and "wheel" interchangeably. While this confusion is understandable, knowing the difference can help you make better decisions when shopping for upgrades or replacement parts.

The rim refers specifically to the outer circular edge of the wheel where your tire mounts. Think of it like the rim of a coffee cup - it's just the edge, not the entire cup. This outer section creates the mounting surface that holds and seals your tire, ensuring proper fitment and maintaining air pressure in tubeless tires.

A wheel includes much more than just the rim. The complete wheel assembly consists of the rim, hub (which connects to your vehicle's axle), spokes (linking the hub to the rim), center disk, lug holes, valve stem, and center cap. The hub houses critical components like brake pads and rotors. If the rim is the edge, then the wheel is the entire structure that makes everything work together.

The mix-up happens because the rim is the most visible part of your wheel. People see those shiny outer edges and naturally call them "rims," even when referring to the complete assembly. Plus, let's be honest - saying "I need new rims" just sounds better than "I need new wheels". This casual usage has become so common that even automotive professionals sometimes use the terms interchangeably.

For casual conversation, using either term rarely causes problems - people understand what you mean. However, when you're shopping for replacement parts or getting repairs done, using the correct terminology becomes important to avoid costly mistakes. When in doubt, "wheel" is the safer choice since it covers the entire assembly.

Understanding this difference helps you communicate more effectively with tire shops and ensures you get exactly what you need for your vehicle.

Understanding wheel rims is essential for any vehicle owner, as these components play a crucial role in tire performance and vehicle safety.

• A rim is the outer circular edge of a wheel that holds the tire bead in place and maintains air pressure in tubeless tires.

• Four main rim types exist: one-piece (strongest, lightest), multi-piece (customizable), beadlock (off-road only), and safety rims (standard on passenger vehicles).

• Rims support tires by anchoring the steel bead, creating airtight seals, and preventing tire slippage during operation.

• While often used interchangeably, "rim" refers only to the outer edge, while "wheel" includes the entire assembly with hub and spokes.

• Proper rim-tire compatibility directly affects ride comfort, handling performance, and overall vehicle safety.

The rim's U-shaped design and precise engineering make it far more than just a mounting surface—it's a critical safety component that ensures your tires stay properly seated and inflated during every drive.

A rim is the outer circular edge of a wheel that holds the tire in place. It forms the outer perimeter of the wheel assembly where the inside edge of the tire is mounted. The rim has a U-shaped design with a deeper center and shallower outer edges, engineered to support the tire bead and maintain proper tire shape.

A rim supports the tire in several ways. It holds the tire bead firmly in place, maintains air pressure in tubeless tires, affects ride comfort and handling, supports the tire's shape during motion, and prevents tire slippage, especially in off-road use. The rim's design is crucial for creating an airtight seal and transmitting forces between the tire and wheel.

There are four main types of wheel rims: one-piece rims (strongest and lightest), multi-piece rims (customizable), beadlock rims (for off-road use), and safety rims (standard on passenger vehicles). Each type is designed for specific applications and performance requirements, offering different advantages in terms of strength, weight, customization, and safety features.

No, it is not safe to drive with a damaged rim. A broken or damaged rim can severely affect the vehicle's stability, steering, and braking, potentially leading to accidents. If you suspect your rim is damaged, it's crucial to have it inspected and repaired or replaced before attempting to drive the vehicle.

While often used interchangeably, "rim" and "wheel" refer to different components. The rim is specifically the outer edge of the wheel where the tire mounts. The wheel, on the other hand, includes the entire assembly - the rim, hub, spokes, and other components. In technical contexts, it's important to use the correct term, especially when dealing with repairs or replacements.