Torsional rigidity has come a long way since the muscle car era. Today's vehicles deliver up to four times the structural resistance to twisting compared to their predecessors. Consider this: a 1966 Ford Mustang managed approximately 5,000 Nm per degree of torsional rigidity, while the 2015 Mustang exceeds 20,000 Nm/degree. High-performance vehicles like the Bugatti Veyron push values over 60,000 Nm/deg. This engineering parameter determines exactly how your vehicle responds to every input you make.

What does torsional rigidity actually mean? The concept is straightforward - it measures a structure's ability to resist twisting under torque. Higher torsional rigidity means less twisting when force is applied. When it comes to wheel design, this property becomes critical for vehicle performance. Stiffer wheels deliver more direct power transfer and precise handling. Less stiff wheels offer greater comfort and compliance over rough surfaces.

Torsional stiffness ensures your power transfers effectively into forward momentum, especially during acceleration and climbs. Wheels with higher stiffness guarantee that power input immediately translates into acceleration, maximizing performance when it matters most. Vehicles with superior torsional rigidity handle better, ride better, and respond more effectively to driver inputs because the suspension can work more efficiently.

At Performance Plus Tire, we understand how these engineering principles affect your driving experience. The hidden factor behind superior vehicle handling lies in understanding how torsional rigidity influences everything from cornering response to ride comfort. We'll examine the engineering considerations that balance performance with comfort in modern wheel design, helping you make informed decisions about your vehicle's performance potential.

"Torsional stiffness or torsional rigidity is a measure of the amount of torque required to twist one unit length of an object by one unit radian." — Fictiv Engineering Team, Product design and engineering experts

Torsional rigidity serves as the foundation for vehicle performance on the road. When it comes to wheel design, this engineering principle becomes even more critical as it directly affects power transfer, handling characteristics, and overall driving experience.

Torsional rigidity describes a structure's ability to resist twisting when subjected to a torque or rotational force. For automotive applications, it specifically measures how well a car's chassis or wheels can withstand twisting forces during driving maneuvers. The concept measures the resistance to angular deformation that a material or structure possesses.

Cars rely on torsional rigidity primarily in the chassis and wheels. A vehicle with high torsional rigidity requires more torque to produce the same degree of twist, resulting in more predictable handling and better overall performance. When you increase a car's torsional rigidity, the suspension can work more efficiently and predictably.

The evolution of this engineering parameter tells an impressive story. A 1966 Ford Mustang had torsional rigidity around 5,000 Nm per degree, while modern performance vehicles like the Bugatti Veyron claim values exceeding 60,000 Nm/degree. This dramatic improvement shows the importance manufacturers place on this property.

Wheels specifically use torsional rigidity to describe their resistance to twisting under torque. A torsionally stiff wheel ensures power efficiently transfers into forward momentum, particularly during acceleration and climbs where power transfer is critical.

Engineers typically express torsional rigidity in Newton-meters squared (Nm²) in SI units or pound-feet in FPS units. For vehicles, engineers often use Newton-meters per degree (Nm/degree) to indicate how much torque is required to twist the structure by one degree.

The formula for calculating torsional rigidity is:

Torsional Rigidity = (Applied Torque × Length) ÷ Angle of Twist (in radians)

Alternatively, it can be expressed as:

Torsional Rigidity = Shear Modulus × Polar Moment of Inertia

Laboratory measurements typically involve:

Applying a controlled load to the wheel

Using laser or dial gages to track deformation

Recording results in N/mm for lateral stiffness or Nm/degree for torsional stiffness

Automotive chassis standards suggest torsional rigidity should be at least 4,000 Nm per degree over the wheelbase, unless the vehicle has been professionally designed to operate at lower stiffness levels.

Torsional rigidity and torsional stiffness were used interchangeably in older engineering literature. Modern engineering makes important distinctions between related concepts.

Torsional rigidity refers to the overall ability of an entire structure to resist twisting, while torsional stiffness can refer to the rigidity of one unit length of the component. Two shafts with identical torsional stiffness but different lengths will have different torsional rigidity values - the longer shaft having lower rigidity despite identical stiffness per unit length.

Compliance represents the inverse of stiffness. It measures how much a structure deforms under a given load. High compliance means a structure will deform more easily under load, while low compliance indicates resistance to deformation. For automotive applications, vertical compliance contributes to ride comfort by enabling the wheel to absorb bumps and road irregularities.

Torsional flexibility serves as the inverse of torsional rigidity. A structure with high torsional flexibility will twist more readily under torque application, potentially compromising power transfer but possibly offering benefits in terms of compliance over rough surfaces.

The balance between torsional rigidity and compliance is crucial for vehicle handling and performance. Excessive rigidity may transmit too much road feedback and create an uncomfortable ride, despite offering precise handling. Insufficient rigidity results in unpredictable handling and energy loss during power transfer.

Automotive wheels exhibit distinct types of rigidity, each affecting different aspects of vehicle performance and comfort. Understanding these properties explains why certain wheels feel responsive in corners while others excel in power delivery.

Lateral stiffness and torsional rigidity represent fundamentally different mechanical properties that affect wheel performance in unique ways. Lateral stiffness refers to a wheel's resistance to side-to-side bending forces—think of cornering or hitting a pothole. A wheel with superior lateral stiffness flexes minimally under these forces, maintaining alignment and improving handling precision.

Torsional rigidity, in contrast, describes a wheel's resistance to twisting forces around its axle. This property becomes crucial during acceleration and braking when torque is applied through the hub. Unlike lateral stiffness which primarily affects cornering and stability, torsional rigidity directly impacts power transfer efficiency.

The direction of force differs significantly between these properties:

Lateral stiffness: Side-to-side (left/right) bending

Torsional rigidity: Twisting (rotational torque)

For high-performance driving, torsional stiffness often matters more than lateral stiffness, as it ensures immediate power response during explosive acceleration.

Vertical compliance—though technically not a form of stiffness—plays a vital role in ride quality. It refers to a wheel's ability to absorb vibrations and impacts from road surfaces. Wheels with appropriate vertical compliance reduce driver fatigue by dampening road chatter.

Modern wheel designers often reduce vertical stiffness intentionally to improve comfort without sacrificing performance. Some manufacturers have decreased vertical stiffness by up to 77% in their latest wheel generations.

The tire provides approximately 100 times more vertical compliance than the wheel itself. This explains why changes in tire pressure, volume, and casing often have greater effects on comfort than wheel design modifications.

Torsional rigidity dictates how effectively driving force translates into forward motion. During high-power efforts like acceleration, wheels with poor torsional stiffness twist slightly before transferring torque, creating a subtle lag between input and acceleration.

When power can exceed 1,500 watts, this momentary energy loss becomes particularly significant. Wheels with superior torsional rigidity reduce uneven stress on spokes during high-torque efforts, extending spoke and hub durability.

Several design factors enhance torsional performance:

Wider flange spacing in the hub

Larger flange diameters

Straight-pull spokes

Carbon rims with high hoop strength

Compliance in vehicle systems isn't inherently negative. As noted in racing engineering, "developing compliance is not a case of eliminating issues and can be used to our advantage". The key lies in optimizing each type of rigidity for its intended application—whether for racing, comfort, or a balance of both.

Several engineering elements work together to determine a wheel's torsional rigidity. Each component—from rim dimensions to hub architecture—plays a crucial role in how effectively power transfers to forward motion.

Rim geometry significantly influences wheel stiffness, and the numbers tell the story. According to Mavic's research, rim depth has a greater impact on radial stiffness, while rim width more strongly affects lateral stiffness. Deeper rims respond more quickly to acceleration forces, making them more efficient since less power disperses as the wheels flex.

The rim profile itself creates structural differences you can feel. A deeper rim profile results in a more aerodynamic wheel but may be more susceptible to crosswind forces. We see many manufacturers offering varying rim depths to balance these factors—ranging from shallow 16mm designs to deep 88mm profiles.

Spoke arrangement markedly affects torsional performance. Here's something interesting: increasing the number of crossings significantly enhances torsional stiffness, although it slightly decreases lateral and radial stiffness. For optimal power transfer, the general rule suggests using 2x lacing with 20-24 spokes, 3x lacing with 32-36 spokes, and 4x lacing with 40 spokes.

Spoke tension balance between drive and non-drive sides impacts longevity as much as performance. Wheels with the lowest tension range typically offer the longest fatigue life. Quality builds maintain higher tension—approximately 100 kg-f on the drive side and 60 kg-f on the non-drive side—to ensure optimal stiffness.

Material choice fundamentally alters wheel characteristics. Generally, carbon rims are both radially and laterally stiffer than aluminum equivalents. This translates to a more positive driving sensation in smooth conditions.

Carbon's advantages include:

Higher torsional stiffness for better power transfer

Weight savings (typically 100g per wheel compared to aluminum equivalents)

Superior strength-to-weight ratio

Aluminum often provides a more forgiving ride quality, offering better grip in challenging conditions and reducing driver fatigue on rough terrain. For drivers seeking long-term reliability or maximum comfort, Performance Plus Tire offers extensive wheel options in both materials to match specific driving preferences.

Hub construction fundamentally influences power transfer efficiency. Larger flange diameters allow for wider spoke angles, increasing lateral stiffness and improving power transmission during acceleration. The spacing between flanges affects wheel dish and balances spoke tension—optimized offset minimizes uneven tension.

Bearing placement within the hub shell equally affects performance. The farther apart the bearings are positioned, the better they resist torsional forces. This explains why high-performance hubs often place bearings closer to the flanges, despite requiring more precise manufacturing tolerances.

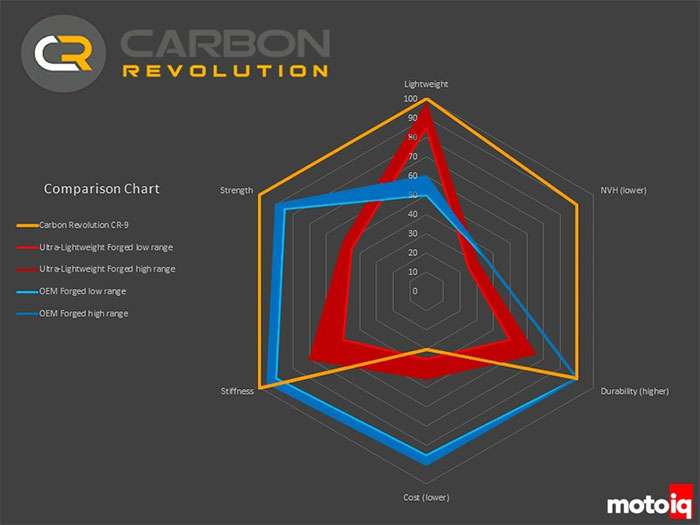

Image Source: MotoIQ

The perfect wheel stiffness and ride comfort balance represents one of the biggest challenges in wheel engineering. Neither maximum rigidity nor complete flexibility delivers optimal results for all driving conditions.

Excessively stiff wheels transmit more road vibrations to the driver, potentially causing fatigue on long drives. This explains why manufacturers balance stiffness with compliance, creating wheels that transfer power efficiently yet remain comfortable. After reaching a certain threshold of rigidity, gains become less noticeable. Most modern wheels already offer stiffness beyond what average drivers can utilize.

The diminishing returns principle applies here—ultra-stiff wheels may provide negligible performance benefits while substantially decreasing comfort. On rough or uneven roads, some wheel flex actually helps absorb bumps, improving grip and control rather than hindering it.

Different driving scenarios demand unique rigidity profiles. Performance-oriented road driving requires wheels like those from Performance Plus Tire that prioritize torsional stiffness for responsive handling and direct power transfer. Race applications require maximum stiffness to eliminate power loss during acceleration.

Gravel applications demand a different approach entirely. Gravel wheels must handle rugged terrain without sacrificing comfort, ensuring drivers stay fresh even after hours off-road. The impedance breakpoint—the optimal tire pressure maintaining constant ground contact—becomes crucial for gravel scenarios.

The FLO 64 AS demonstrates road-optimized design with its deeper rim and reinforced carbon layup enhancing lateral and torsional stiffness. This wheel delivers noticeable efficiency gains during acceleration and sprinting while maintaining acceptable comfort through carbon fiber orientation.

The FLO G700 takes a different approach, featuring a super-wide 25mm internal rim profile optimized for 32-48mm tires. Its carbon layup acts as a leaf spring to reduce vibration. The wider profile creates artificial casing tension, allowing lower tire pressures without the typical spongy feeling.

Their performance differences highlight how proper wheel selection depends on usage rather than pursuing maximum stiffness universally. At Performance Plus Tire, we help you choose wheels that match your specific driving needs and performance goals.

"Torsional rigidity has a major impact on how a vehicle acts and handles. A stiffer chassis means the vehicle handles more predictably." — ChansMachining.com Editorial Team, Engineering content specialists

The best wheels don't just look good on paper - they deliver noticeable performance gains you can feel behind the wheel. High torsional rigidity creates measurable improvements across diverse driving conditions, from tight corners to challenging terrain.

Superior torsional rigidity makes a dramatic difference when you turn the wheel. A chassis that resists twisting motion during cornering maintains optimal geometry for suspension and steering components. This resistance to flex improves steering precision while providing better feedback to the driver. Vehicles with high torsional rigidity deliver sharper handling by allowing suspension components to control a larger percentage of the vehicle's kinematics.

Chassis torsional stiffness directly influences vertical wheel travel while turning, subtly affecting wheel camber and toe angles – critical factors in cornering performance. The result? Your vehicle responds exactly how you expect it to, corner after corner.

When you need maximum acceleration, torsional stiffness becomes even more important. Wheels that effectively resist twisting under torque ensure immediate power transfer and reduce energy loss. This becomes particularly significant during all-out acceleration where power spikes can exceed 1,500 watts.

Poor torsional stiffness creates a noticeable problem - wheels momentarily twist before fully transferring torque, creating lag between your input and vehicle response. Strong torsional stiffness reduces uneven stress on spokes during high-torque efforts, extending component durability.

Every bit of power matters on steep climbs. Torsional stiffness essentially dictates how efficiently your power translates into forward motion. Lightweight yet rigid wheels from specialists like Performance Plus Tire provide immediate response under power while remaining comfortable enough for extended climbs. This means less energy wasted flexing components and more directed toward upward momentum.

Here's something that might surprise you - increased rigidity often contributes to improved comfort. A flex-free chassis transmits fewer vibrations and resonances into the cabin, resulting in a quieter and more refined driving experience.

Properly designed wheels emphasize compliance without sacrificing essential lateral stiffness, reducing fatigue and maintaining power output even on rugged terrain. This balance becomes particularly important for off-road vehicles where torsional loads fluctuate dramatically across changing surfaces. The right wheel selection can make the difference between a punishing ride and an enjoyable adventure.

Torsional rigidity stands as a fundamental aspect of wheel design that directly impacts your vehicle's performance. The engineering behind this property influences everything from cornering response to power transfer efficiency, making it a critical factor in wheel selection.

The numbers tell the story clearly. We've seen torsional rigidity values jump from 5,000 Nm/degree in a 1966 Mustang to over 60,000 Nm/degree in today's high-performance vehicles. This dramatic improvement shows how seriously manufacturers take this property and its effect on driving dynamics.

Different types of rigidity work together to create optimal wheel performance. Torsional rigidity ensures efficient power transfer during acceleration and climbing. Lateral stiffness provides cornering stability. Vertical compliance delivers necessary comfort over rough surfaces. The perfect wheel design balances these competing priorities rather than maximizing stiffness alone.

Material selection, spoke patterns, rim dimensions, and hub design all contribute to achieving the desired balance between rigidity and compliance. Carbon fiber generally provides superior torsional stiffness compared to aluminum, though at higher cost and sometimes with less forgiveness on rough terrain.

At Performance Plus Tire, we offer wheels with application-specific tuning because we recognize that road, gravel, and race scenarios demand distinct rigidity profiles. Our extensive selection helps you find the right balance for your driving style and conditions.

When your vehicle responds precisely to your inputs during a tight corner or accelerates efficiently during a steep climb, you're experiencing the benefits of proper torsional rigidity engineering. This hidden factor transforms ordinary driving into an engaging, responsive experience that connects you to the road.

Understanding torsional rigidity in wheel design reveals the engineering principles that separate ordinary vehicles from exceptional performers, directly impacting how your car handles, accelerates, and responds to your driving inputs.

• Torsional rigidity measures a wheel's resistance to twisting under torque - higher values mean more direct power transfer and precise handling, with modern performance vehicles achieving over 60,000 Nm/degree compared to 5,000 Nm/degree in older cars.

• Different types of rigidity serve distinct purposes - torsional rigidity affects power transfer during acceleration, lateral stiffness improves cornering stability, while vertical compliance enhances ride comfort over rough surfaces.

• Material and design choices dramatically impact performance - carbon fiber wheels typically offer superior torsional stiffness compared to aluminum, while factors like rim depth, spoke patterns, and hub design all influence rigidity characteristics.

• Optimal wheel design balances stiffness with comfort - excessive rigidity provides diminishing returns while compromising ride quality, making application-specific tuning essential for road, gravel, or race scenarios.

• Real-world benefits include improved acceleration response and cornering precision - wheels with proper torsional rigidity eliminate power loss during high-torque efforts and maintain suspension geometry for predictable handling.

Torsional rigidity significantly improves a vehicle's handling by resisting twisting forces during cornering and acceleration. This results in more precise steering, better power transfer, and overall improved responsiveness to driver inputs.

Torsional rigidity refers to a wheel's resistance to twisting forces around its axle, affecting power transfer efficiency. Lateral stiffness, on the other hand, is the wheel's resistance to side-to-side bending, which impacts cornering stability and handling precision.

While carbon fiber wheels generally offer higher torsional stiffness and are lighter, they're not always better. Aluminum wheels can provide a more forgiving ride quality and better grip in challenging conditions. The choice depends on specific riding preferences and conditions.

Wheel design balances rigidity and compliance to optimize both performance and comfort. Factors like rim depth, spoke patterns, and material choice all contribute to this balance. A well-designed wheel efficiently transfers power while also absorbing road vibrations for a comfortable ride.

Extremely stiff wheels can transmit more road vibrations to the driver, potentially causing fatigue on long drives. After a certain threshold, increased stiffness offers diminishing returns in performance while significantly decreasing comfort. The goal is to find an optimal balance for the intended use.