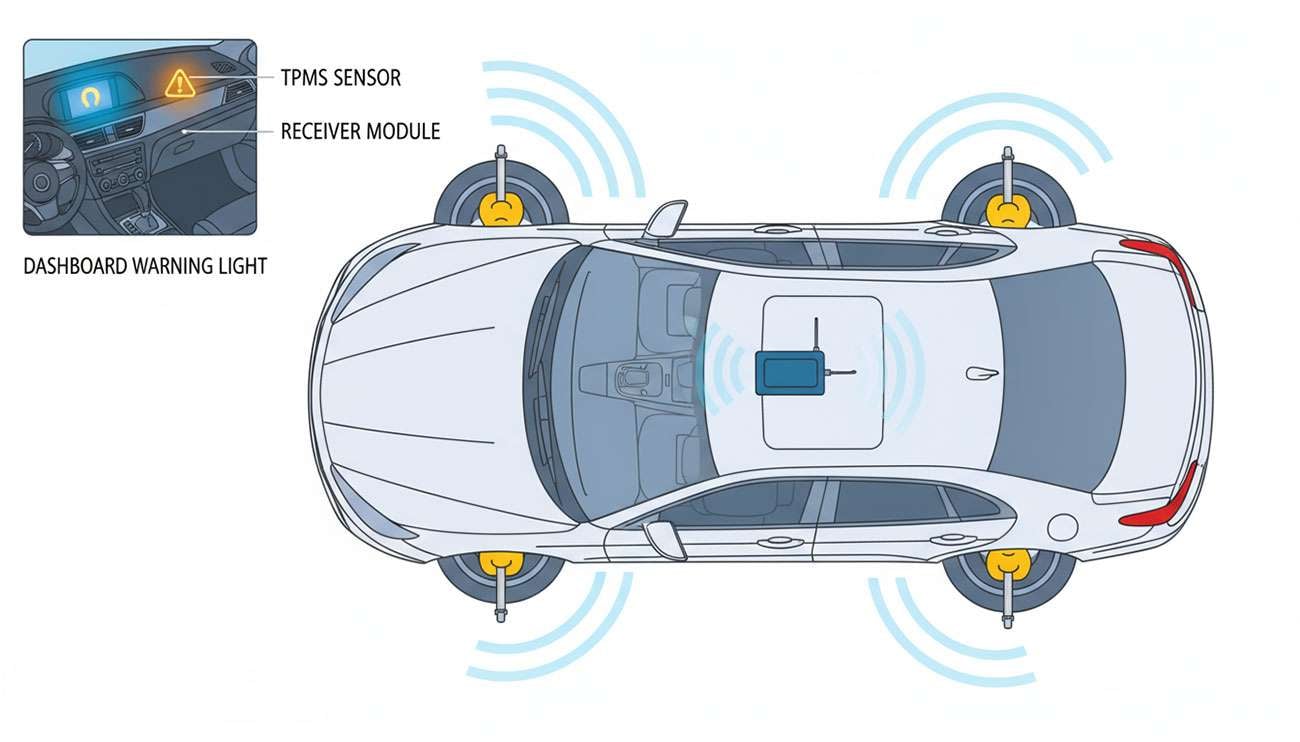

Tire Pressure Monitoring System (TPMS) technology monitors air pressure inside your vehicle's tires and alerts you when dangerous under-inflation occurs. The system uses small electric sensors mounted on each wheel that continuously track tire pressure and send this information to your vehicle's central computer.

When tire pressure drops to unsafe levels, TPMS displays warnings through your dashboard—either as gauge readings, pictogram displays, or most commonly, a warning light that looks like a horseshoe-shaped tire with an exclamation point.

TPMS serves a critical safety function by detecting pressure problems before they become dangerous. Under-inflated tires create serious hazards including reduced vehicle control, compromised braking performance, and increased risk of tire failure or blowouts. Proper tire inflation also directly impacts fuel efficiency, tire longevity, and overall vehicle performance.

The technology first appeared in luxury European vehicles during the 1980s. Widespread adoption followed after the United States enacted the Transportation Recall Enhancement, Accountability, and Documentation (TREAD) Act in response to the Firestone and Ford tire controversy. Most vehicles sold in the United States since 2007 include TPMS as standard equipment. The European Union mandated TPMS for all new vehicles starting November 2014.

TPMS operates through two distinct methods:

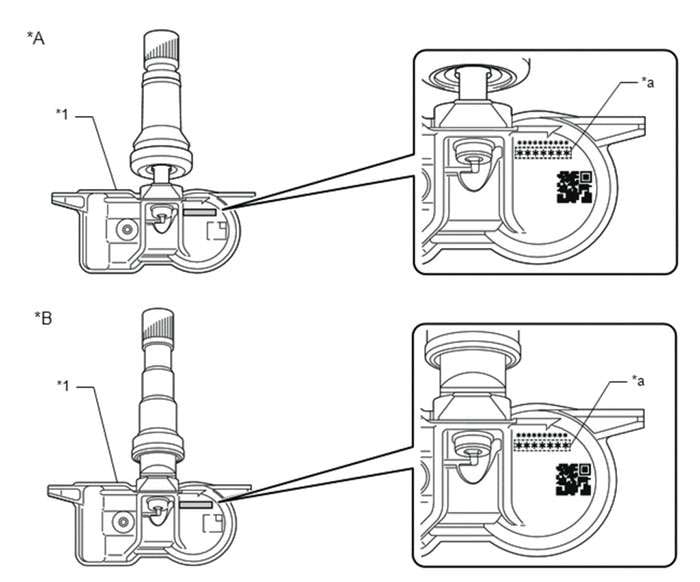

Direct TPMS (dTPMS): Physical pressure sensors mounted inside each tire, typically at the valve stem, directly measure air pressure. These sensors wirelessly transmit accurate real-time readings to your vehicle's computer and immediately alert you when pressure drops below safe levels.

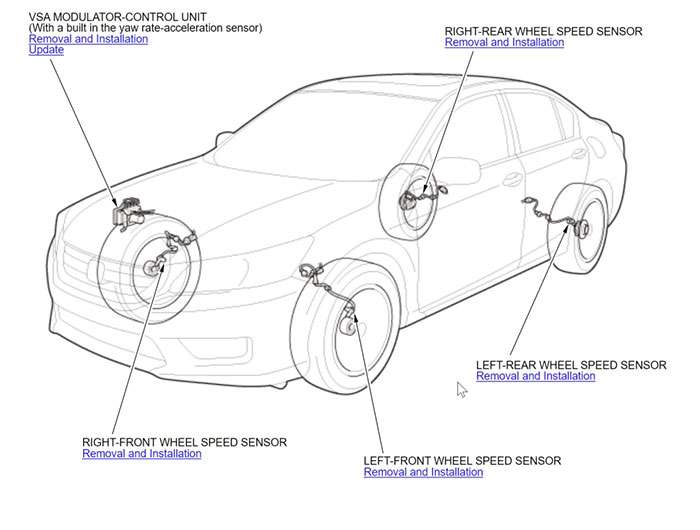

Indirect TPMS (iTPMS): Uses your vehicle's Antilock Braking System (ABS) wheel speed sensors to detect pressure changes. The system compares wheel revolution rates—under-inflated tires have smaller diameters and rotate faster than properly inflated ones.

Key advantages of TPMS include:

Safety enhancement through real-time pressure warnings

Early detection reduces tire failure risk

Maintains optimal pressure for better vehicle handling

Prevents excessive tire wear from incorrect pressure

Improves fuel economy by up to 3% according to the U.S. Department of Energy

Extends tire life through even tread wear promotion

TPMS complements but never replaces regular tire maintenance. The system provides additional safety protection rather than eliminating the need for manual pressure checks. Vehicles with faulty or non-functioning TPMS will fail MOT testing, emphasizing its importance in vehicle safety regulations.

Tire pressure monitoring systems operate through two distinctly different approaches to track tire inflation levels. Each method uses specialized equipment to detect when your tires need attention, but they work through completely different mechanisms.

Direct TPMS uses actual pressure sensors mounted inside each tire. These sensors attach to the valve stem or secure to the rim with a steel band. Each sensor contains pressure transducers that measure the exact air pressure within that specific tire. Modern direct sensors also capture temperature readings, acceleration data, and rotation direction. The sensors broadcast this information wirelessly using ultra-high frequency radio signals - typically 433 MHz in Europe and 315 MHz in other regions.

These battery-powered sensors transmit about 250μW of power, sending unique identification codes along with pressure and temperature data to your vehicle's central control module. The system processes this information and triggers warning indicators when pressure drops approximately 25% below the recommended level. Some advanced vehicles display real-time pressure readings for each individual tire right on the dashboard.

Indirect TPMS takes a completely different approach. This system doesn't use physical pressure sensors inside the tires at all. Instead, it works through your vehicle's existing anti-lock brake system wheel speed sensors. The basic principle is simple: underinflated tires have a smaller diameter than properly inflated ones, causing them to complete more revolutions over the same distance. The system's computer analyzes these wheel revolution rates, comparing them with expected values based on your vehicle's speed and other operational data. When a wheel spins faster than expected, the system recognizes this as underinflation.

Both systems activate dashboard warning lights when tire pressure problems are detected, though they use different detection methods. Direct TPMS provides specific pressure values for each tire, while indirect TPMS compares relative wheel speeds without measuring actual pressure. A major limitation of basic indirect systems is their inability to detect when all four tires lose pressure simultaneously, since they primarily identify pressure differences between tires.

Direct TPMS sensors require movement to function properly. Most contain accelerometers that trigger transmission when motion is detected. Once activated, they transmit at predetermined intervals and immediately send signals if sudden pressure loss occurs. These sensor batteries typically last five to twelve years or approximately 100,000 miles.

Three main types of tire pressure monitoring systems are available in today's vehicles, each offering distinct advantages depending on your priorities for accuracy, cost, and installation complexity.

Direct TPMS represents the most accurate and reliable monitoring method. Physical sensors mounted inside each tire measure actual air pressure and transmit this data wirelessly to your vehicle's computer. Each sensor contains a battery, pressure transducer, accelerometer, and radio frequency transmitter working together to deliver real-time pressure readings. The system alerts you immediately when any tire drops below safe levels, specifying which tire needs attention and providing exact pressure values.

This precision comes with higher costs—sensors typically range from $50-$100 each, creating a $200-$400 replacement expense for a complete set. Battery life limits sensor longevity to approximately 5-12 years. Additionally, direct TPMS requires specialized programming equipment and training, making DIY installation impractical for most vehicle owners.

Indirect TPMS takes a different approach by leveraging your vehicle's existing ABS wheel speed sensors. This system monitors tire rotation speeds to detect underinflation, eliminating the need for additional hardware inside tires. The cost advantage is substantial—no sensors to purchase, replace, or maintain. Installation and tire changes become simpler without sensor considerations.

However, indirect systems sacrifice accuracy and functionality. They cannot provide actual pressure readings or pinpoint which specific tire is underinflated. The system only detects pressure loss after significant drops occur, potentially missing gradual deflation. Most critically, indirect TPMS fails to recognize simultaneous pressure loss across all four tires. Temperature changes and road conditions can trigger false warnings, while certain driving patterns may prevent accurate calibration.

Hybrid TPMS combines both technologies to balance accuracy with cost efficiency. These systems typically use direct sensors on two wheels—usually the rear tires—while monitoring the front tires through ABS sensors. Some configurations place sensors on all four positions but incorporate indirect monitoring as a backup system. This approach reduces sensor replacement costs while maintaining reasonable accuracy for critical tire positions.

When choosing between systems, consider these factors:

Direct TPMS excels when:

You need precise, real-time pressure readings

Individual tire monitoring is important

You're willing to invest in sensor replacements

Your vehicle regularly experiences temperature extremes

Indirect TPMS works best when:

Budget constraints are primary concerns

You perform regular manual pressure checks

Basic warning capability meets your needs

Simplified tire maintenance is preferred

Regulatory requirements also influence system selection. The United States mandates TPMS on all vehicles manufactured after 2007, with most manufacturers choosing direct systems for compliance. European regulations similarly require TPMS, though both direct and indirect systems meet legal standards.

Understanding these differences helps you make informed decisions about sensor replacement, maintenance costs, and system expectations. At Performance Plus Tire, we service all TPMS types and can guide you through options that best match your vehicle's needs and your budget considerations.

Your TPMS warning light serves as your first line of defense against dangerous tire pressure problems. This horseshoe-shaped icon with an exclamation point activates when the system detects issues requiring your immediate attention. Understanding what triggers these warnings and how to respond properly protects both your safety and your vehicle's performance.

The most common trigger is straightforward low tire pressure. When any tire drops approximately 25% below its recommended PSI, the warning light illuminates. This threshold represents the point where tire performance begins deteriorating noticeably, affecting handling, braking distance, and fuel efficiency. Cold weather frequently causes these alerts since tire pressure decreases about 1 PSI for every 10°F temperature drop. Your tires might have been properly inflated during summer, but winter temperatures can push them into the warning zone.

Temperature-related warnings don't always indicate actual problems—just that current conditions have reduced your tire pressure below the safety threshold. You'll still need to add air, but the underlying cause is environmental rather than a leak or puncture. After correcting the pressure and driving for a few miles, the warning light should extinguish automatically once the system confirms proper inflation.

A more concerning scenario involves faulty TPMS sensors. These electronic components can fail due to dead batteries, physical damage from road impacts, or exposure to corrosive road chemicals. When sensors malfunction, they may transmit incorrect pressure data or stop communicating entirely. This creates a dangerous situation where you're driving blind—your tires might be severely underinflated, but you receive no warning because the monitoring system itself has failed.

Sensor problems manifest in various ways. Malfunctioning sensors may display inconsistent pressure readings or fail to communicate with the vehicle's computer entirely.

Other potential causes include damaged wiring, receiver unit problems, or electrical interference disrupting signal transmission. When you encounter persistent warning lights despite correct tire pressure, professional diagnosis becomes necessary.

The distinction between flashing versus solid illumination is crucial for proper response. A solid light exclusively indicates low tire pressure that requires inflation to the recommended PSI. This is straightforward - check your tire pressures and inflate as needed.

A flashing light (blinking for 60-90 seconds before staying solid) signals a system malfunction. This pattern specifically indicates that one or more sensors are not communicating with the vehicle's central computer. Approximately 10% of drivers admit to completely ignoring this critical safety warning. Don't be part of this statistic - address flashing lights promptly to maintain your vehicle's safety systems.

Keeping your TPMS functioning properly requires the right maintenance approach and occasional system resets. Most TPMS systems deliver reliable performance for 70,000 to 100,000 miles when properly maintained. The key is understanding when and how to reset the system, plus following proven maintenance practices that extend sensor life and ensure accurate readings.

Several situations require TPMS recalibration to maintain accurate pressure monitoring. Tire pressure adjustments, tire rotations, sensor replacements, and new tire installations all trigger the need for system resets. Seasonal temperature changes also create challenges, as cold weather can drop tire pressure significantly and cause false warnings. We recommend resetting after these events to ensure your system provides reliable alerts and eliminates unnecessary warning lights.

Your vehicle's make and model determines which reset method works best. Here are the most effective approaches:

Reset Button Method: Turn your ignition to ON without starting the engine. Find the TPMS reset button—typically located under the dashboard or in the glove compartment—and hold it until the warning light blinks three times. Release the button and start your vehicle.

Driving Reset Method: After correcting tire pressure to recommended levels, drive at 50 mph for 10-15 minutes. This driving period allows the sensors to recalibrate automatically and clear any warning lights.

Battery Disconnect Method: With the vehicle off, disconnect the positive battery cable. Turn the ignition to ON and press the horn for 3-5 seconds to discharge remaining electrical power. Reconnect the battery to complete the reset.

Many modern vehicles include auto-relearn features that reset the system automatically after driving for a period following pressure adjustments. However, some vehicles still require manual resets using buttons, vehicle control centers, or specialized diagnostic tools. Check your owner's manual to determine your vehicle's specific requirements.

Regular sensor checks help identify potential problems before they cause system failures:

Use a TPMS diagnostic tool to trigger sensors and verify data transmission

Monitor battery status, as sensors typically last 5-10 years

Inspect sensors and valve stems for physical damage

Watch for inconsistent pressure readings between tires

Maximizing TPMS reliability comes down to consistent care and proper service procedures. Replace all sealing components whenever sensors are removed from rims. Never exceed manufacturer-specified torque values during sensor installation, as overtightening damages both seals and sensors.

Check tire pressure monthly since tires naturally lose approximately 1.5 psi each month. When adjusting pressures, work with outdoor temperatures rather than heated service bay conditions. Every 10°F temperature change affects pressure by roughly 1 psi, so account for seasonal variations in your maintenance routine.

At Performance Plus Tire, we understand that proper TPMS maintenance protects both your investment and your safety. Our experienced technicians can service your TPMS sensors, perform system resets, and ensure optimal functionality for years of reliable monitoring.

Understanding TPMS functionality and maintenance is crucial for vehicle safety, fuel efficiency, and tire longevity. Here are the essential insights every driver should know:

• TPMS prevents dangerous blowouts by alerting drivers when tire pressure drops 25% below recommended levels, significantly reducing accident risk.

• Two main types exist: Direct TPMS uses sensors inside tires for accurate readings, while indirect TPMS monitors wheel speed differences through ABS sensors.

• Flashing vs solid lights matter: A solid TPMS light indicates low pressure needing inflation, while a flashing light signals sensor malfunction requiring professional service.

• Manual resets are often required after tire rotations, pressure adjustments, or seasonal changes - don't expect automatic recalibration in all vehicles.

• Regular maintenance extends sensor life to 5-12 years; check monthly pressure and replace sealing components when sensors are removed to prevent costly failures.

Proper TPMS care combines technology with traditional tire maintenance - the system enhances safety but never replaces regular pressure checks and visual inspections.

While you can drive with the TPMS light on, it's not recommended. The light indicates either low tire pressure or a system fault, both of which can compromise safety and fuel efficiency. It's best to check your tire pressures and address the issue promptly.

You can reset your TPMS manually in several ways. One common method is to locate the TPMS reset button (often under the dashboard), turn the ignition to ON without starting the engine, and hold the button until the warning light blinks three times. Alternatively, some vehicles reset automatically after driving for 10-15 minutes at 50 mph following pressure adjustments.

Modern TPMS, especially direct systems, use unique ID codes for each sensor. These codes allow the vehicle's computer to identify and locate each tire's position, enabling accurate pressure monitoring for individual tires.

TPMS sensor batteries typically last between 5 to 12 years, or approximately 100,000 miles. However, this can vary based on driving conditions and frequency. Regular system checks can help monitor battery health and prevent unexpected failures.

You should reset your TPMS after certain events such as tire pressure adjustments, tire rotations, sensor replacements, or installation of new tires. Additionally, significant temperature changes, especially during seasonal transitions, may necessitate a reset to ensure accurate pressure readings and prevent false alarms.