About 75% of roadside flat tires happen because drivers ignore slow air loss. This statistic reveals a simple truth: most tire failures are preventable through proper maintenance.

Your tires naturally lose 1-3 psi every month through osmosis, even without any visible damage. This gradual pressure loss may seem minor, but tires deflated more than 25% from recommended pressure actually triple your crash risk.

Many drivers ask why tires lose air when there's no puncture. The answer lies in basic physics - air molecules continuously seep through tire walls, creating gradual pressure loss. Temperature changes accelerate this process, with tires losing 1-2 psi for every 10-degree Fahrenheit drop.

Tires lose air without holes for several reasons. Temperature fluctuations, slow leaks, valve stem issues, and rim problems commonly cause pressure loss without punctures. Older tires and those made with lower-quality materials lose air even faster.

We'll show you what causes tires to lose air, how to spot slow leaks, and most importantly, how to prevent these issues from becoming dangerous and expensive problems. Understanding tire maintenance helps keep you safe while extending tire life and improving fuel economy.

Properly inflated tires serve as a critical safety system for your vehicle. The National Highway Traffic Safety Administration documents a stark reality: vehicles with significantly underinflated tires face dramatically higher accident risks in tire-related crashes. In 2023 alone, 646 people lost their lives in tire-related crashes.

Low tire pressure creates immediate handling problems that put you at risk. Your steering precision suffers dramatically when pressure drops below recommended levels. Braking distances increase substantially, making emergency stops dangerous situations.

Blowouts represent the most serious threat from underinflated tires. Low pressure forces excessive sidewall flexing, which generates dangerous heat buildup. This heat accumulates because underinflated tires create more surface contact with the road, increasing friction beyond safe levels.

Vehicle responsiveness deteriorates with low pressure. Your car develops a "mushy" feel during turns and braking, reducing your ability to react quickly. Wet conditions make these problems worse - rolling resistance increases with low pressure, causing hydroplaning at speeds that would normally be safe.

Underinflated tires create two major expenses that add up quickly. Poor fuel efficiency tops the list - the U.S. Department of Energy confirms that proper tire pressure improves gas mileage by up to 3%. At $4.00 per gallon, this means saving approximately $2.40 per 20-gallon fill-up, potentially reaching $125 in annual savings for weekly fueling.

Tire replacement costs escalate rapidly with low pressure. Underinflated tires develop uneven wear patterns on both outer edges, aging roughly 32% faster than properly maintained tires. Maintaining correct pressure extends tire life by an impressive 4,700 miles.

The expense extends beyond tires themselves. Low pressure stresses suspension components and chassis parts, creating potential repair bills that far exceed tire costs.

Regular tire pressure checks become essential maintenance when you consider these safety and financial factors. This simple monthly task prevents dangerous situations while protecting your investment in tires and vehicle components.

Tires lose air without visible punctures for several reasons. Understanding these common causes helps you identify problems before they become expensive repairs.

Temperature affects tire pressure more than most drivers realize. Every 10°F temperature drop reduces tire pressure by 1-2 PSI. This explains why your TPMS warning light activates on cold winter mornings.

Seasonal temperature swings create significant pressure changes. The 50°F difference between North American summers and winters can drop tire pressure by 5 PSI. When you start driving, tire temperature rises about 20°F within several miles, increasing pressure by 2 PSI. These constant fluctuations require regular monitoring to maintain proper pressure.

Rubber isn't completely airtight. Tire sidewalls naturally allow microscopic air molecules to escape through permeation. This process happens continuously, even in new tires.

Tires typically lose 1-3 PSI monthly through natural permeation. Higher temperatures speed up this process, while different air molecules escape at different rates. Older tires and those made with cheaper materials lose air faster than premium options.

Valve stems are small but crucial components that deteriorate over time. These rubber or metal tubes typically last 4-6 years before requiring replacement.

Weather conditions, UV rays, and road chemicals cause valve stems to crack, dry out, or become brittle. Metal valve stems corrode in humid areas or where road salt is used. A worn valve stem creates pathways for gradual air escape.

The tire bead forms a critical seal where rubber meets the wheel rim. Dirt, debris, or corrosion interferes with this seal. Improper tire installation prevents correct bead seating.

Road salt and moisture accelerate corrosion at this junction. Without a proper seal, air escapes gradually even without punctures.

Hitting potholes, curbs, or speed bumps hard enough can bend wheel rims. Winter driving exposes wheels to corrosive road salt and moisture, creating uneven surfaces that can't maintain proper seals.

Aluminum wheels are especially vulnerable to corrosion. A bent rim causes air leakage while creating vibrations, uneven tire wear, and handling problems.

Finding a slow leak takes detective work and the right approach. These invisible air losses frustrate drivers but respond well to systematic diagnosis.

The soapy water method gives you the most reliable way to spot tiny leaks at home. Mix dish soap with water using a 1 to 3-4 ratio in a spray bottle. Spray this solution thoroughly on the tire, covering the tread, sidewall, bead area, and valve stem. Look for bubbles forming - even slow leaks create small, persistent bubbles. Wait several minutes for exceptionally slow leaks since bubbles may take time to appear.

Put your ear close to suspected leak areas, especially around the valve stem. Escaping air creates a distinct hissing sound. This technique works particularly well for valve stem leaks, though extremely slow leaks might remain silent.

Regular pressure monitoring helps identify gradual leaks before they become problems. Check tire pressure with a reliable gage on cold tires - those that haven't been driven for at least three hours. Write down the pressure readings and check again after several days. When one tire consistently loses more pressure than others, you've likely found your slow leak.

Remove the tire for thorough inspection when:

Soapy water tests show no bubbles despite ongoing pressure loss

You suspect a bead leak or rim issue

The leak continues after valve replacement

For stubborn leaks, submerge tire sections in water and watch for bubbles. Reducing pressure to just 5 PSI sometimes makes tiny leaks more detectable.

Finding the leak is only half the battle. Fixing it properly prevents future air loss and extends tire life. These proven solutions keep your tires properly inflated and performing at their best.

Valve stems cause about 10% of slow leaks and need replacement every 4-6 years. UV rays and road chemicals naturally deteriorate these components over time. Standard rubber valve stems come off easily with a valve stem tool before installing a new one.

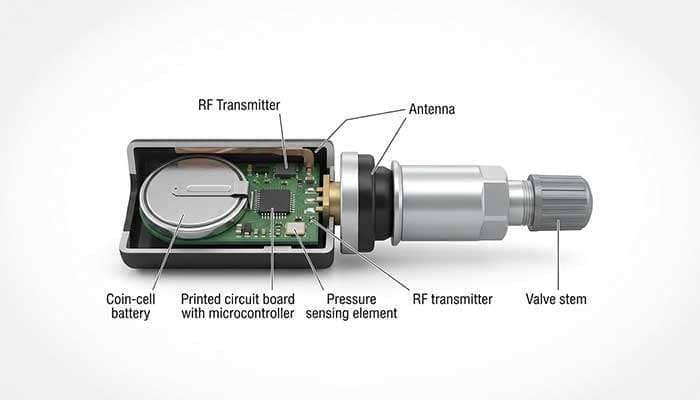

TPMS-equipped vehicles require extra care. The sensor stays in place while you replace only the rubber stem portion. Use a torque wrench for proper installation to avoid damaging the sensor or creating new leaks.

The rim-to-tire interface must seal perfectly to maintain pressure. Dirt, rust, or corrosion at this junction allows air to escape gradually. Remove the tire completely and clean both the rim edge and tire bead thoroughly with a wire brush.

Apply a thin layer of appropriate sealant before remounting. This creates an airtight connection that prevents slow leaks at the bead area.

Tread area punctures (never sidewalls) respond well to plug kit repairs. Remove the penetrating object, ream the hole clean, then insert a sticky rubber plug. This provides an effective temporary fix until professional repair.

Liquid sealants work for holes under 6mm but typically last only 100-500 miles or 3 days. Consider these emergency solutions that get you to a tire shop safely.

Check tire pressure monthly even with TPMS systems. Cold tires give accurate readings - check them before driving or after sitting for three hours. Quality tire gauges provide consistent measurements.

TPMS sensors last 5-10 years and may need recalibration after tire rotations or battery replacement. Don't rely solely on warning lights for pressure monitoring.

Replace tires showing these warning signs regardless of remaining tread:

Bulging or bubbling sidewalls

Cracks or brittleness in rubber compounds

Age over 6 years (never use tires over 10 years old)

Age matters more than appearance. Rubber compounds deteriorate over time, making older tires prone to sudden failure even with good tread depth.

Tire pressure maintenance represents one of the easiest ways to protect your safety and save money. The causes of air loss are well understood, and the solutions are straightforward for any driver to implement.

Monthly pressure checks form the foundation of good tire care. Use a quality gauge when tires are cold to get accurate readings. Watch for warning signs like uneven wear or one tire consistently losing more pressure than others.

Simple repairs handle most air loss issues. Replace valve stems every 4-6 years, keep rim edges clean, and address small punctures promptly. The soapy water test helps you find leaks before they become serious problems.

Your four tires are the only parts of your vehicle touching the road. They deserve attention through basic maintenance that prevents dangerous blowouts while extending tire life. A few minutes each month checking pressure pays dividends in safety and savings.

At Performance Plus Tire, we believe proper tire care shouldn't be complicated. These straightforward practices keep you rolling safely while protecting your investment in quality tires and wheels.

Understanding tire pressure loss and prevention can save your life and money while keeping you safely on the road.

• Check tire pressure monthly when cold - Tires naturally lose 1-3 PSI monthly, and underinflated tires triple crash risk while reducing fuel efficiency by up to 3%.

• Temperature drops cause pressure loss - Every 10°F temperature decrease reduces tire pressure by 1-2 PSI, explaining why TPMS lights activate on cold mornings.

• Use soapy water to detect invisible leaks - Mix soap and water in a spray bottle to find slow leaks through bubble formation, especially around valve stems and bead areas.

• Replace valve stems every 4-6 years - These small components cause 10% of slow leaks and deteriorate from UV exposure and road chemicals over time.

• Address issues before they become dangerous - Properly maintained tires last 32% longer and prevent the 646 annual tire-related fatalities reported by safety authorities.

Proper tire maintenance isn't just about avoiding flats—it's about protecting your safety, extending tire life by thousands of miles, and maintaining optimal vehicle performance through simple monthly checks and timely repairs.

First, locate the leak using soapy water or by listening for a hissing sound. For small punctures in the tread, use a tire plug kit as a temporary fix. Replace faulty valve stems, clean and reseal the rim, or use a tire sealant for slow leaks. If the issue persists, consult a professional for a thorough inspection and repair.

Tires can lose air due to natural permeation through the rubber, temperature changes, valve stem wear, bead leaks, or issues with the rim. Even without a puncture, tires typically lose 1-3 PSI per month. Temperature drops can cause additional pressure loss, with tires losing about 1-2 PSI for every 10-degree Fahrenheit decrease.

Check your tire pressure at least once a month, preferably when the tires are cold (haven't been driven for at least three hours). Regular checks help identify slow leaks early and ensure optimal tire performance. Additionally, inspect your tires more frequently during significant temperature changes, as these can affect pressure.

Underinflated tires pose serious safety risks, including reduced handling, increased braking distances, and a higher chance of blowouts. They also negatively impact fuel efficiency and tire lifespan. Vehicles with tires underinflated by at least 25% are three times more likely to be involved in a tire-related crash.

Replace your tires when they show signs of aging, regardless of tread depth. Look for bulging or bubbling sidewalls, cracks or brittleness in the rubber, or if the tire is over 6 years old. As a general rule, never use tires that are more than 10 years old, even if they appear to be in good condition.