Ford F150 Raptor aftermarket wheels have evolved significantly across three generations of this high-performance truck. The first-generation Raptor (2009-2014) came equipped with 17-inch wheels and 315/70R17 tires, while today's third-generation Raptor can accommodate massive 37-inch all-terrain tires on the same 17-inch wheel diameter.

Upgrading your Raptor's wheels delivers both enhanced performance and improved appearance when you maintain proper fitment. All Ford F150 models, including the Raptor, feature a specific 6x135mm bolt pattern that serves as the foundation for wheel selection. The hub bore size of approximately 87.1mm for Gen 3 models ensures your aftermarket wheels perform optimally whether you're tackling city streets or challenging terrain.

Aftermarket wheels offer clear advantages over stock options. Quality aftermarket wheels often weigh less than factory wheels, improving acceleration and handling response. When you select the correct ford f150 raptor offset, you'll maintain proper clearance while potentially accommodating larger tires for superior off-road capability.

We'll guide you through selecting the best Ford F150 Raptor aftermarket wheels step-by-step. Our expert knowledge helps ensure you make an informed decision that enhances both the style and function of your high-performance truck.

Understanding your Raptor's factory wheel configuration is essential before selecting ford f150 raptor aftermarket wheels. The stock setup provides baseline measurements that determine compatibility for any upgrade. Getting these specifications right prevents costly fitment issues and ensures optimal performance both on paved roads and off-road terrain.

Your Ford F150 Raptor comes equipped with 17x8.5 inches wheels. This measurement breaks down to a 17-inch diameter with an 8.5-inch width. These dimensions remain consistent across Raptor generations, though styling varies between model years.

Stock Raptor wheels feature a +34mm offset with approximately 6.08 inches of backspacing. This specific offset configuration serves several critical functions:

Positions the wheel correctly relative to suspension components

Maintains proper clearance during full suspension compression

Ensures the wheel sits properly within the fender well

When measuring wheel width, the 8.5-inch specification refers to the inside edge-to-edge measurement where the tire mounts. The full section width edge-to-edge measures approximately 9.5 inches. This distinction becomes important when calculating clearance for aftermarket options.

Your Raptor uses a 6x135mm bolt pattern. This specification means:

Six lug holes arranged in a precise pattern

Holes positioned on a 135mm diameter circle

This bolt pattern has remained consistent across all Raptor generations, making compatible wheel selection straightforward. The bolt pattern is non-negotiable—wheels with different patterns won't fit unless you use adapters, which we don't recommend for performance applications.

Ford F-150 models from 2004 to present share this same 6×135 bolt pattern. However, older Ford trucks may use different patterns, so wheels from pre-2004 models won't be compatible.

Your Raptor's wheels feature hub-centric design with a center bore of 87.1mm. This design approach means:

The hub bore supports the wheel's weight

Lug nuts primarily secure the wheel to the hub

Proper centering is crucial for balance and vibration prevention

For lug nuts, the Raptor uses M14 x 2.0 threaded studs:

M14: 14mm diameter thread

2.0: Thread pitch measured in millimeters between threads

These precise measurements are critical when selecting aftermarket wheels. Quality aftermarket wheels for the Raptor accommodate these specifications, often featuring larger center bores that work with centering rings.

The spare tire rim features flat black coloring to distinguish it from standard wheels and typically lacks a TPMS (Tire Pressure Monitoring System) sensor.

These specifications form the foundation for any wheel upgrade decision. Any deviation from these specs could create fitment problems, affect performance, or compromise safety.

Wheel size represents your first major decision when selecting ford f150 raptor aftermarket wheels. This choice impacts everything from your truck's appearance to its performance capabilities, making it essential to understand the tradeoffs between different wheel diameters.

Ford engineers didn't choose 17-inch wheels for the Raptor by accident. All three generations, from the original (2009-2014) through today's third-generation models, feature this diameter for specific performance reasons that become clear when you examine the benefits.

17-inch wheels deliver:

Superior off-road performance with better impact absorption

Larger tire sidewalls that flex over obstacles

Protection against rim damage on rocky terrain

More affordable tire replacements

Greater tire selection in specialized off-road compounds

The larger sidewall offered by 17-inch wheels provides critical cushioning when navigating rough trails. This extra rubber between the wheel and ground absorbs impacts that would otherwise transfer to the rim, reducing the risk of costly damage during hard off-road use.

Larger wheels (18-22 inches) offer different advantages:

More aggressive, modern styling

Sharper handling response due to reduced sidewall flex

Improved braking feel from less tire sidewall deflection

Greater visual impact with larger brake caliper visibility

Wheels in the 18-22 inch range reduce the tire sidewall height proportionally. While this creates a firmer, more responsive feel on pavement, it compromises off-road capability by reducing the tire's ability to absorb impacts from rocks and obstacles.

The wheel diameter you choose should align with your primary use case. If you regularly take your Raptor off-road, particularly on technical trails with rocks and obstacles, the 17-inch diameter remains the optimal choice. This size maximizes tire sidewall, which serves as natural suspension that complements your truck's advanced Fox Racing shocks.

For predominantly street-driven Raptors where appearance takes priority, larger wheels deliver the visual impact you're seeking. 20x9 inch wheels represent a popular upgrade that maintains reasonable proportions while creating a more aggressive stance.

Consider these additional factors:

Tire availability: 17-inch wheels offer the widest selection of off-road tire options

Replacement costs: Larger wheels require more expensive tires

Weight considerations: Larger wheels typically weigh more, affecting acceleration and fuel economy

Speedometer accuracy: Larger wheels may require recalibration to maintain accurate readings

The third-generation Raptor's capability to accommodate 37-inch tires on 17-inch wheels demonstrates why this diameter remains the performance standard. This combination delivers maximum ground clearance and off-road capability while maintaining the sidewall height needed for serious trail use.

Your decision ultimately depends on whether you prioritize appearance or capability. Many Raptor owners maintain two sets of wheels—one set with 17-inch wheels and aggressive off-road tires for trail use, and another set with larger diameter wheels for daily driving and shows.

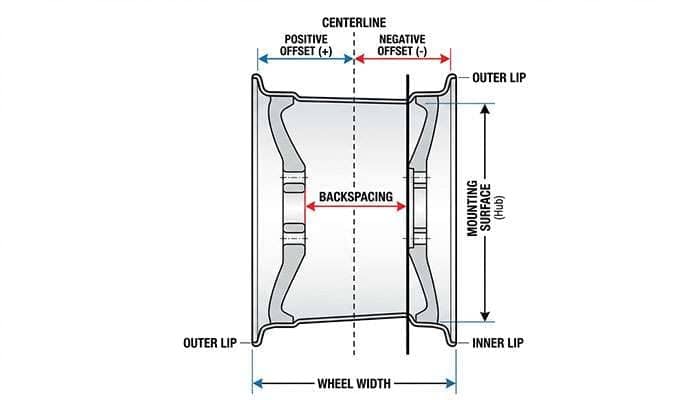

Wheel offset and backspacing determine how your aftermarket wheels sit relative to your Raptor's suspension and body. These measurements directly affect handling characteristics, clearance, and your truck's stance. Getting these specifications right prevents rubbing issues while maintaining optimal suspension geometry.

Wheel offset measures the distance between the wheel's mounting surface and its centerline. Positive offset means the mounting surface sits closer to the street side of the wheel, while negative offset positions it closer to the brake side.

For stock height Raptors:

Factory offset: +34mm

Recommended range: +0mm to +20mm

Optimal stance: +10mm to +18mm

Moving to a less positive offset (closer to 0mm) pushes the wheels outward, creating a wider, more aggressive stance. However, reducing offset too much can cause the tire to contact the fender during full suspension compression or steering lock.

For leveled Raptors (1.5-2.5 inch front lift):

Recommended range: +0mm to +12mm

Popular choice: +6mm with 9-inch wheel width

Leveling kits provide additional clearance in the front, allowing more aggressive offset choices without rubbing. The extra clearance accommodates the outward wheel position while maintaining full steering and suspension travel.

For fully lifted Raptors (3+ inches):

Recommended range: -12mm to +6mm

Common setup: 0mm offset with 9-inch width

Full lift kits create significant additional clearance, allowing even more aggressive negative offset options. However, extremely negative offsets stress suspension components and can accelerate wear on ball joints and wheel bearings.

Backspacing measures from the wheel's mounting surface to its inner edge (the side facing the vehicle). While offset and backspacing are related, backspacing provides a more intuitive measurement for clearance verification.

Stock Raptor backspacing: approximately 6.08 inches

The relationship between offset and backspacing depends on wheel width. For the same offset, a wider wheel requires more backspacing to maintain proper positioning. This is why you can't simply copy offset specifications without considering wheel width.

Calculating backspacing from offset:

For a 9-inch wheel with +12mm offset:

Convert offset to inches: 12mm ≈ 0.47 inches

Half the wheel width: 9 ÷ 2 = 4.5 inches

Add offset: 4.5 + 0.47 = 4.97 inches backspacing

This calculation helps you visualize how the wheel will sit relative to suspension components and fenders. Less backspacing pushes the wheel outward, while more backspacing tucks it inward toward the vehicle.

Key backspacing considerations:

Suspension clearance: Adequate backspacing prevents tire contact with control arms and other suspension components

Fender clearance: Less backspacing can cause the tire to contact fender liners during compression or turning

Ball joint stress: Extreme backspacing changes place additional load on steering and suspension components

The correct offset and backspacing combination depends on your wheel width, tire size, and suspension setup. A 17x9 inch wheel requires different specifications than a 17x8.5 inch wheel to achieve the same stance.

Many Raptor owners successfully run 17x9 wheels with +0mm to +18mm offset on stock suspension. This range provides an aggressive appearance while maintaining clearance during full suspension travel. However, individual results vary based on specific tire size and wheel design.

Testing fitment before permanent installation is essential. When possible, test-fit wheels with your desired tire size before committing to a purchase. This verification prevents expensive mistakes and ensures proper clearance under all driving conditions.

Your Ford F150 Raptor's bolt pattern and hub specifications are non-negotiable requirements for wheel compatibility. These measurements ensure proper wheel mounting and load distribution, directly affecting safety and performance. Understanding these specifications helps you avoid costly mistakes and ensures your aftermarket wheels function exactly as intended.

The Raptor uses a hub-centric wheel design where the center bore supports the wheel's weight. This design offers several advantages over lug-centric systems:

Better load distribution across the hub surface

Reduced vibration at highway speeds

More precise wheel centering for optimal balance

Your Raptor's hub diameter measures 87.1mm. Aftermarket wheels must accommodate this specification through either:

Exact hub bore matching: Wheels manufactured with 87.1mm center bores fit directly onto your Raptor's hubs with no additional components needed. This represents the ideal scenario for perfect fitment.

Larger bore with hub rings: Many quality aftermarket wheels feature larger center bores designed to fit multiple vehicle applications. These wheels require hub-centric rings (also called hub rings or centering rings) that adapt the larger wheel bore to your truck's specific hub diameter.

Hub-centric rings fill the gap between your hub and the wheel's center bore. These rings are typically made from:

Aluminum: Durable and corrosion-resistant, though more expensive

Polycarbonate plastic: Affordable and effective for most applications

Quality hub rings ensure the wheel centers properly on the hub before you torque the lug nuts. This centering is critical for preventing vibration and ensuring balanced wheel rotation at all speeds.

Never run wheels with larger center bores without proper hub rings. The gap allows the wheel to sit off-center, creating vibration that can damage wheel bearings and compromise handling. While lug nuts will secure the wheel, they can't provide the precise centering that hub-centric design requires.

Your Raptor's lug nuts secure the wheels to the hub and must match specific thread and seat specifications. The factory specification is M14 x 2.0:

M14: 14mm thread diameter

2.0: 2.0mm thread pitch (distance between threads)

Aftermarket wheels may require different lug nut styles based on their design:

Conical/Tapered seat: The most common design, featuring a 60-degree cone that centers in the wheel's lug hole. Factory Ford wheels use this style, and most aftermarket wheels require it.

Flat/Mag seat: Features a flat washer that contacts a flat surface in the wheel. Some aftermarket wheels, particularly those with exposed lug nuts, use this design.

Tuner/Spline drive: Specialized lug nuts with a unique drive pattern requiring a matching key. These provide theft deterrence while working with aftermarket wheels that have smaller lug holes.

Using incorrect lug nuts compromises wheel security and can damage both the wheel and hub. The lug nut seat must match your wheel's design exactly—using conical lug nuts on flat-seat wheels or vice versa creates an insecure connection that can loosen during driving.

Proper torque specifications matter:

Ford specification: 150 lb-ft (203 Nm)

Use a calibrated torque wrench for accuracy

Tighten in a star pattern for even pressure distribution

Re-torque after 50-100 miles of driving

Over-tightening damages threads and can warp brake rotors, while under-tightening allows wheels to loosen—both situations create serious safety hazards. A quality torque wrench is essential for proper wheel installation.

When purchasing aftermarket wheels, verify what's included with your purchase:

Hub-centric rings: Often included but not always—confirm before ordering

Lug nuts: Usually sold separately unless specifically noted

Center caps: May be included with the wheels or available as separate accessories

Quality wheel manufacturers provide detailed specifications for required hardware. Before completing your purchase, ensure you have all necessary components for safe installation. This includes not just the wheels themselves, but also appropriate lug nuts, hub rings if needed, and TPMS sensors compatible with your Raptor's monitoring system.

The 6x135mm bolt pattern remains consistent across Ford F-150 models from 2004 onward, giving you access to a wide selection of compatible aftermarket wheels. However, never assume compatibility based on bolt pattern alone—always verify center bore, offset, and width specifications match your specific application and suspension setup.

Your choice of aftermarket wheels directly influences tire size options, and tire size determines what suspension modifications you'll need. Understanding this relationship helps you plan a complete upgrade that maintains proper clearance and functionality across all driving conditions.

Wheel diameter limits your tire size choices, with each diameter offering distinct advantages for different applications.

17-inch wheels accommodate:

34-35 inch tires (stock height and leveled trucks)

37 inch tires (lifted trucks only)

Maximum sidewall height for off-road capability

Popular tire sizes for 17-inch Raptor wheels include 315/70R17 (approximately 34.4 inches) and 37x12.50R17. The larger sidewall provided by 17-inch wheels maximizes off-road performance by allowing the tire to flex and absorb impacts from rocks and obstacles.

20-inch wheels accommodate:

33-35 inch overall tire diameter

Reduced sidewall height compared to 17-inch options

Sharper handling response on pavement

Common sizes include 305/55R20 (approximately 33.2 inches) and 35x12.50R20. These combinations deliver aggressive styling while maintaining reasonable sidewall height for occasional off-road use.

22-inch wheels accommodate:

33-34 inch overall diameter typically

Minimal sidewall height

Maximum visual impact for show trucks

Sizes like 305/45R22 (approximately 33.8 inches) work with 22-inch wheels, though the reduced sidewall significantly compromises off-road capability. These setups work best for street-focused Raptors where appearance takes priority over trail performance.

Stock Ford F150 Raptors accommodate up to 34-inch tires without modifications. Beyond this size, suspension changes become necessary to prevent rubbing during full steering lock or suspension compression.

For 35-inch tires:

Leveling kit: 1.5-2.5 inch front lift

Maintains stock rake while adding front clearance

Cost-effective solution for moderate size increase

Preserves factory ride quality

A leveling kit raises the front of your truck to match the rear height, creating additional clearance in the wheel wells. This modification typically doesn't require recalibration of suspension systems and maintains the stock shock absorbers.

For 37-inch tires (maximum Raptor capability):

Full lift kit: 3+ inches recommended

Complete suspension overhaul for proper clearance

May require additional modifications:

Aftermarket upper control arms for alignment

Extended brake lines for increased travel

Differential drop brackets or relocation

Possible trimming of front bumper and fender liner

The third-generation Raptor can run 37-inch tires on factory suspension with the available 37-inch package from Ford. However, aftermarket 37-inch tire setups on earlier generation Raptors require comprehensive modifications for proper clearance.

Additional considerations for larger tires:

Speedometer calibration: Larger tires rotate fewer times per mile, making your speedometer read slower than actual speed. Recalibration through your dealer or aftermarket programmer corrects this discrepancy.

Gear ratio changes: Larger, heavier tires reduce effective gearing, potentially affecting acceleration and towing capability. Some owners install lower gear ratios to compensate for the larger rolling diameter.

Brake performance: Heavier wheel and tire combinations increase rotational mass, potentially affecting brake performance. Stock brakes typically handle moderate size increases, but extreme setups may benefit from upgraded brake components.

Fuel economy impact: Larger, heavier tires and wheels increase rolling resistance and rotational mass, reducing fuel efficiency. The impact varies based on tire size and weight but typically results in 1-3 mpg reduction.

Load rating: Ensure your chosen tires maintain adequate load rating for your truck's GVWR (Gross Vehicle Weight Rating). This becomes especially important if you tow or carry heavy loads regularly.

The relationship between wheel size, tire size, and suspension modifications requires careful planning. Stock suspension works well with modest increases (up to 34 inches), leveling kits handle 35-inch tires effectively, and full lift kits enable 37-inch tire fitment. Each step up requires progressively more modification and investment, so consider your actual needs versus desires when planning upgrades.

Many Raptor owners find that 35-inch tires on 17-inch wheels with a quality leveling kit provide the optimal balance of capability, appearance, and reasonable modification requirements. This combination delivers substantial visual impact and improved off-road performance without the extensive modifications required for 37-inch tires.

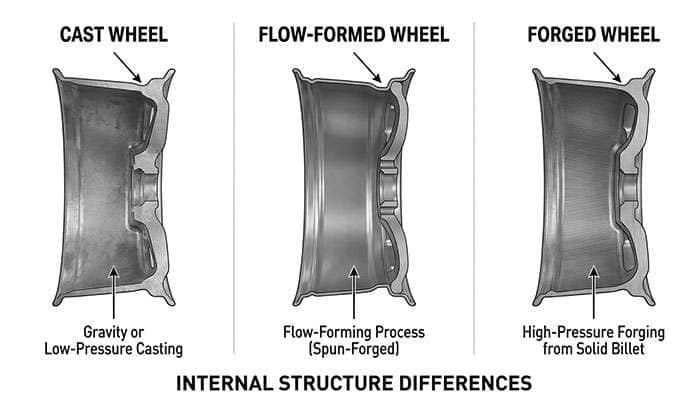

Wheel construction method and materials directly affect performance, durability, and cost. Understanding the differences between manufacturing processes helps you select wheels that match your Raptor's intended use and your budget. Each construction method offers distinct advantages that become important when you push your truck's capabilities.

Cast wheels represent the most common and affordable manufacturing method. Molten aluminum is poured into a mold and allowed to cool into the final wheel shape. This process creates wheels that work well for daily driving and light off-road use. Cast wheels offer:

Lower cost compared to other construction methods

Wide variety of designs and finishes

Adequate strength for street and moderate off-road use

Heavier weight compared to flow-formed or forged alternatives

Quality cast wheels from reputable manufacturers provide reliable performance for most Raptor owners who primarily drive on streets with occasional off-road adventures.

Flow-formed wheels (also called flow-forged or rotary-forged) start as cast wheels but undergo additional processing. After initial casting, the wheel barrel is spun at high speed while rollers apply pressure, stretching and compressing the aluminum to create a stronger, lighter structure. This process delivers:

Significantly lighter weight than comparable cast wheels

Greater strength in the barrel section

Better impact resistance for off-road use

Moderate price increase over cast wheels

Flow-formed construction represents an excellent middle ground between cast and forged wheels. The process creates wheels that approach forged wheel performance at a fraction of the cost, making them popular among serious off-road enthusiasts who want performance without the premium price of fully forged wheels.

Forged wheels represent the premium choice, created by compressing solid aluminum blocks under extreme pressure. This results in exceptionally strong, lightweight wheels that excel in demanding off-road conditions. Forged wheels offer:

Maximum strength-to-weight ratio

Superior impact resistance

Better load-bearing capability

Optimal heat dissipation properties

Highest cost among wheel types

The forging process aligns the aluminum's grain structure, creating a wheel that can withstand severe impacts without cracking. This makes forged wheels ideal for aggressive off-road use, rock crawling, and high-speed desert running where wheel failure could have serious consequences.

Serious off-road adventures benefit from beadlock capabilities that enhance traction and control.

Ford offers factory beadlock-capable wheels that can be converted with the Ford Performance Functional Beadlock Ring Kit (approximately $865). True beadlock wheels physically clamp the tire bead to the wheel, preventing it from dislodging at very low tire pressures—essential for maximum off-road traction.

Benefits of functional beadlock wheels:

Allows extremely low tire pressures (5-8 psi) for maximum traction

Prevents tire de-beading on obstacles and during aggressive driving

Essential for rock crawling and technical terrain

Provides peace of mind during extreme off-road use

Considerations for beadlock wheels:

Regular maintenance required (checking and re-torquing beadlock bolts)

Not DOT-approved for street use (though widely used)

Higher initial cost and ongoing maintenance time

Heavier than non-beadlock equivalents

Most street-driven Raptors use standard non-beadlock wheels, as functional beadlocks are designed primarily for off-road use. Many manufacturers offer simulated beadlock appearances that provide the aggressive look without the mechanical complexity.

Simulated beadlock wheels feature styling that mimics functional beadlocks but don't actually clamp the tire. These wheels offer:

Aggressive, off-road appearance

No maintenance requirements

Lighter weight than functional beadlocks

Lower cost

Full DOT approval for street use

For most Raptor owners who occasionally venture off-road but primarily drive on streets, simulated beadlock wheels provide the desired appearance without the maintenance requirements of functional beadlocks.

Certain brands consistently deliver superior performance for Raptor applications:

Fuel Off Road wheels, especially their Maverick D538 and Anza D583 models, deliver distinctive styling with proven off-road durability. These wheels combine aggressive appearance with the strength needed for demanding terrain. Fuel wheels typically feature:

Bold, distinctive designs

Quality construction (cast and flow-formed options)

Wide range of finishes and styles

Proven durability in off-road conditions

Method Race Wheels offers excellent 17×8.5" options that are ideal for heavily off-road focused builds. Method wheels are engineered specifically for off-road performance and punishment. Their designs emphasize:

Function over form with practical designs

Beadlock and beadlock-ready options

Lightweight construction

Racing-derived engineering

Pro Comp's 69 Series polished alloy wheels provide classic styling with trail-ready performance. These wheels offer a timeless look while delivering the durability you need for off-road adventures. Pro Comp wheels feature:

Traditional off-road styling

Proven reliability

Competitive pricing

Wide range of sizes and offsets

For the most extensive selection of quality ford f150 raptor aftermarket wheels, we recommend checking Performance Plus Tire's F-150 Raptor collection, where you'll find wheels matched precisely to your truck's specifications. Our expert team can help you select the perfect wheels that combine the style and performance your Raptor deserves.

Choosing the right aftermarket wheels for your Ford F150 Raptor comes down to matching the correct specifications with your specific driving needs. We've covered the essential factors that determine successful wheel upgrades, from understanding your stock setup to selecting the optimal wheel construction for your intended use.

The key specifications remain non-negotiable - your Raptor's 6x135mm bolt pattern and proper offset requirements ensure safe, functional fitment. Whether you choose 17-inch wheels for maximum off-road capability or larger diameters for aggressive styling, the right specifications matter more than appearance alone.

Your suspension setup directly influences which wheel and tire combinations will work best. Stock height Raptors accommodate different options than lifted trucks, and understanding these relationships helps you avoid costly fitment mistakes.

Cast wheels work well for daily driving, while forged construction delivers superior performance for serious off-road use. Beadlock capabilities add another level of functionality for extreme terrain adventures.

At Performance Plus Tire, we carry the best selection of Ford F150 Raptor aftermarket wheels matched precisely to your truck's specifications. Our extensive inventory includes trusted brands like Fuel Off Road, Method Race Wheels, and Pro Comp - all designed to enhance both the appearance and performance of your high-performance truck.

The right wheels transform your Raptor's capabilities while maintaining the reliability you demand. Whether you're conquering challenging trails or commanding attention on city streets, quality aftermarket wheels deliver the performance and style your Raptor deserves.

Ready to upgrade your ride? Browse our F-150 Raptor wheel collection to find the perfect wheels that combine proper fitment with exceptional performance.

Choosing the right aftermarket wheels for your Ford F150 Raptor requires understanding critical specifications and matching them to your driving needs. Here are the essential insights every Raptor owner should know:

• Know your stock specs first: All Raptors use 6x135mm bolt pattern, +34mm offset, and 87.1mm center bore - these are non-negotiable for proper fitment.

• Choose wheel size based on use: 17-inch wheels excel off-road with better impact absorption, while 20-inch wheels provide sharper handling and aggressive styling.

• Match offset to your suspension: Stock height works with +0mm to +20mm offset, while lifted trucks need more conservative offsets to prevent rubbing.

• Consider suspension modifications early: Leveling kits accommodate 35-inch tires, but 37-inch tires require full lift kits for proper clearance.

• Select construction for your needs: Cast wheels suit daily driving, flow-formed offer strength-to-cost balance, and forged wheels excel in extreme off-road conditions.

The key to successful wheel selection is balancing esthetics with functionality while ensuring all specifications align with your Raptor's capabilities and your intended use.

Wheel offset is the distance from the wheel's hub mounting surface to its centerline. It's crucial because it affects how the wheels sit in relation to the truck's body and suspension. The right offset ensures proper handling, prevents rubbing, and maintains ideal suspension geometry.

Stock Ford F150 Raptors can accommodate 34-inch tires without modifications. For 35-inch tires, a leveling kit (1.5-2.5 inches) is typically sufficient. However, 37-inch tires usually require a full lift kit of 3 inches or more to ensure proper clearance and suspension travel.

Forged wheels offer superior strength and lighter weight compared to cast wheels. They're created by compressing solid aluminum blocks under extreme pressure, resulting in a wheel that excels in demanding off-road conditions. While more expensive, forged wheels provide better performance and durability for serious off-road use.

Wheel size directly impacts ride quality. Smaller wheels (17-18 inches) provide more sidewall flex, offering better shock absorption but slightly less precise handling. Larger wheels (20-22 inches) reduce sidewall height, creating firmer ride quality yet improved cornering response. The choice depends on your preference for comfort versus handling precision.

For off-road use, consider wheels with proper strength (forged or flow-formed), appropriate size (typically 17-inch for better tire options), and correct offset for your suspension setup. Beadlock or beadlock-capable wheels are beneficial for extreme off-roading. Brands like Fuel Off Road, Method Race Wheels, and Pro Comp offer popular options designed for off-road performance.