Tire-related fatalities have dropped by over 50 percent according to recent government data. This remarkable safety improvement stems directly from advances in tire composition, with manufacturers developing compounds that deliver superior performance across different weather conditions.

Modern tires offer better road grip, extended lifespan, and improved fuel efficiency. The secret lies in understanding that tire compounds behave very differently when temperatures change. Softer rubber formulations provide exceptional traction in colder weather—which explains why winter tires and high-performance summer options work so well in their intended conditions. Winter tires become essential equipment for drivers facing harsh winter conditions, as their specialized rubber compounds stay flexible in cold temperatures for better grip on snow and ice.

Silica technology has changed how tire materials handle wet and snowy surfaces. When you understand how different compounds perform under extreme testing conditions, what goes into tire construction, and how to match the right chemical composition to your climate, you can make better decisions for your vehicle's safety and performance.

We'll break down the testing data that shows exactly how these compounds behave when pushed to their limits.

Tire performance starts with molecular engineering. The chemistry behind tire compounds controls how your vehicle grips the road, handles temperature swings, and performs across different driving conditions.

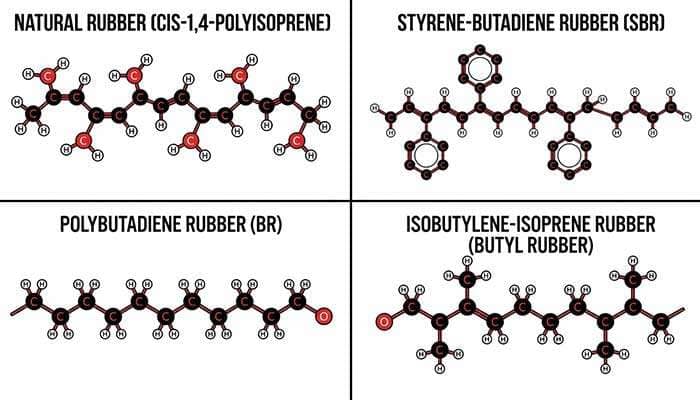

Today's tires blend natural and synthetic rubbers to achieve specific performance targets. Natural rubber comes from Hevea brasiliensis trees and delivers exceptional elasticity plus outstanding resistance to fatigue cracks. Testing shows natural rubber achieves tensile strength between 15-22 MPa with elongation at break reaching 600-900%.

Synthetic rubbers like polybutadiene (BR) and butyl rubber excel in different applications. These engineered materials provide superior resistance to temperature changes, aging, and abrasion. Synthetic rubber tensile strength typically ranges from 10-18 MPa with elongation capabilities of 400-600%.

The ideal blend ratio sits around 60:40 or 70:30 natural-to-synthetic rubber, creating the perfect balance between flexibility and thermal durability. Natural rubber maintains its properties better in sub-zero conditions, while synthetic varieties stay stable above 80°C.

Styrene-butadiene copolymer serves as the primary ingredient in approximately 50% of tires. SBR comes in two main forms: emulsion SBR (created through redox polymerization) and solution SBR (made through living anionic polymerization).

SBR combines the best properties of polybutadiene (highly flexible with excellent wet grip) and polystyrene (rigid structure with low rolling resistance). Recent developments have created SBR with twice the mechanical strength of conventional versions, actually surpassing natural rubber's capabilities. Tires using these advanced formulations show more than 50% better wear resistance while maintaining excellent fuel economy.

Continental Tires breaks down their popular summer models this way: rubber (natural and synthetic) makes up 41%, fillers like carbon black and silica comprise 30%, reinforcing materials account for 15%, plasticizers form 6%, vulcanization chemicals represent 6%, and anti-aging agents make up the remaining 2%.

Carbon black constitutes 25-30% of rubber composition and dramatically boosts wear resistance. Modern passenger tires contain up to 25 different components and 12 distinct rubber compounds, each carefully engineered to deliver specific performance characteristics.

Rubber alone doesn't make a tire perform in extreme weather. The real performance comes from specialized fillers and additives mixed into the compound. These microscopic ingredients determine whether your tires grip the road safely or slide dangerously when conditions turn challenging.

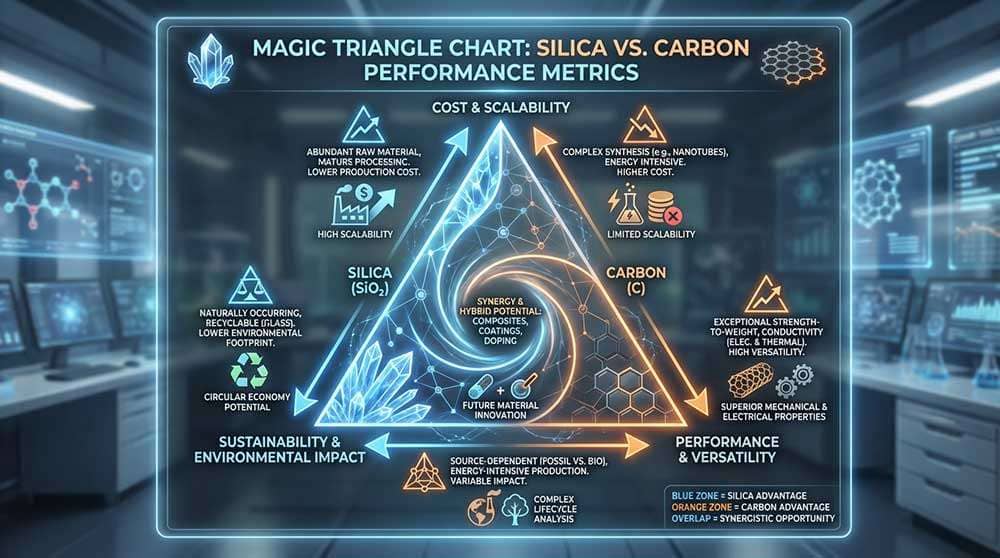

For decades, carbon black served as the standard filler, strengthening tires by filling tiny gaps in the rubber structure. Today, silica-based compounds deliver superior performance when roads get wet or temperatures drop. Laboratory testing proves silica-filled compounds show higher tan delta values at 0°C compared to carbon black alternatives, which means better wet traction. The numbers tell the story—silica compounds maintain flexibility at -23°C while carbon black formulations stiffen up at -28°C.

Silica brings additional advantages that directly benefit your driving experience. These compounds generate about half the heat buildup of carbon black during standard ASTM D623 testing. This translates to real savings at the pump—silica-filled tires can reduce rolling resistance by 20-30%, delivering 3-15% better fuel efficiency compared to traditional carbon black formulations.

Your tires face constant attack from environmental forces. Carbon black acts as the primary shield against UV damage, absorbing harmful ultraviolet radiation and converting it to harmless heat. Meanwhile, phenolic antioxidants work behind the scenes to improve long-term thermal stability, while amine-based variants fight off heat aging and fatigue.

Ozone presents another threat that requires specialized protection. P-phenylenediamine (PPD) antiozonants, including 6PPD and DPPD, migrate to the tire surface where they intercept ozone before it can crack the rubber. Research has detected 6PPD-quinone, a transformation product, at concentrations up to 1562 ng/L in environmental samples.

The vulcanization process creates the durability that makes modern tires possible. Zinc oxide (ZnO) makes up 1-3% of tire weight but plays a crucial role in activating the crosslinks that give rubber its strength. When ZnO reacts with sulfur during vulcanization, it forms powerful vulcanizing agents that enhance mechanical properties across all temperature ranges.

Testing reveals exactly how tire compounds behave when pushed to extreme limits. Real-world performance data becomes clear only when compounds face the harshest temperature conditions drivers encounter.

Advanced testing facilities 300 km beyond the Arctic Circle provide precise evaluation of winter tire performance. These specialized facilities use Skid Trailer technology to measure grip parameters on real snow and ice circuits. Testing shows dramatic differences in coefficient of rolling resistance (Crr) between winter conditions, ranging from 0.010 to 0.056. Road sections treated with anti-icing chemicals and brushing perform significantly better than those with basic plowing and sanding.

Tire compounds start showing serious structural changes as temperatures climb. Laboratory viscosity measurements require 125°C testing because compounds become too thick to measure accurately at 100°C. Desert environments push these limits further—asphalt temperatures can hit 180 degrees, causing substantial weakening in rubber compounds.

Temperature range testing from 40°C to -40°C shows rolling resistance increases dramatically as cold sets in. The best-performing tires showed a 56% increase in rolling resistance between temperature extremes, while poor-performing compounds demonstrated a massive 116% increase. This data explains why fuel economy drops significantly during winter months.

Desert conditions cut tire lifespan from the normal 4-6 years (60,000 miles) down to just 3-4 years (40,000 miles). All-season tires with harder compounds typically last longer in these brutal conditions than softer performance formulations. The extreme heat literally accelerates the breakdown of softer rubber compounds, requiring more frequent replacement for drivers in hot climates.

The right tire compound makes the difference between confident handling and dangerous sliding when weather conditions change. Your climate determines which chemical composition will deliver the best performance, safety, and value for your driving needs.

Winter tires stay flexible when temperatures drop below 45°F (7°C) thanks to specialized rubber formulations designed specifically for cold weather performance. These compounds feature higher silica content that keeps the rubber pliable in freezing conditions. Natural origin resins boost grip on icy surfaces where standard compounds fail.

The performance difference is dramatic—winter tires cut braking distances on ice and snow by up to 30% compared to all-season alternatives. If you drive regularly in snow or experience freezing temperatures for extended periods, these specialized compounds become essential safety equipment.

All-season tires use biphasic polymeric materials linked by silica particles that adapt to changing conditions. These smart compounds soften for cold weather grip yet firm up for stability in hot weather. Continental's "Chili Blend" combines five different compounds from proven summer and winter tire designs. The formulation includes dampening technology for winter traction alongside heat-resistant polymers for summer performance.

This versatility makes all-season tires the practical choice for drivers who face moderate temperature swings without extreme winter conditions.

Summer compounds resist heat breakdown through specialized polymers that maintain their structure on scorching pavement. These formulations prevent tread blocks from deforming when temperatures soar. Heat resistance becomes critical since tire pressure increases one PSI for every 10-degree temperature rise, and soft compounds can lead to dangerous blowouts.

Summer tires maintain optimal grip and longevity above 45°F, while winter or all-season options wear quickly in sustained heat. Choose summer compounds if you live in consistently warm climates or want maximum performance during hot weather driving.

Tire compound technology has advanced significantly, making vehicles safer in all weather conditions. Manufacturers now balance natural and synthetic rubber with precision to create compounds that perform when it matters most. These carefully engineered blends determine how your vehicle handles during temperature extremes.

Silica-based formulations represent a major breakthrough for wet and cold weather driving. These compounds deliver better traction while reducing rolling resistance compared to traditional alternatives. Winter compounds with high silica content can cut braking distances by up to 30% on snow and ice versus standard all-season tires.

Different weather conditions demand specific compound solutions. Winter formulations stay flexible in freezing temperatures, while summer compounds resist breakdown in extreme heat. Knowing your local climate helps you select the right tire chemistry for your driving needs.

Testing data shows dramatic performance variations across temperature ranges. Poor compound formulations can increase rolling resistance by 116% between temperature extremes. This makes tire selection about much more than tread pattern or brand recognition.

When shopping for tires, look beyond price and appearance. The compound formulation determines how your vehicle responds when weather conditions change unexpectedly. Your safety depends on these engineered rubber compositions and how they perform against nature's toughest challenges.

At Performance Plus Tire, we understand that choosing the right compound for your climate is essential for both safety and performance. Our knowledgeable staff can guide you through the selection process to find tires with the proper chemical composition for your specific driving conditions and local weather patterns.

Understanding tire compound chemistry is crucial for safety and performance, as the right formulation can mean the difference between secure handling and dangerous skidding in extreme weather conditions.

The invisible chemistry beneath your tires determines how your vehicle responds during unexpected weather changes—making compound selection as important as tread pattern for your safety.

In extreme cold, tire compounds can become stiffer and less flexible. Winter tires are specifically designed with softer compounds that remain pliable below 45°F (7°C), providing better traction on snow and ice. These specialized formulations can reduce braking distances by up to 30% compared to all-season tires in winter conditions.

Summer tire compounds are formulated to resist softening and deformation in high temperatures, maintaining optimal grip and longevity above 45°F. Winter tire compounds, on the other hand, contain higher silica content and natural resins to enhance flexibility and grip at low temperatures. All-season tires use adaptive polymer blends to perform adequately across a wider temperature range.

Extreme heat can cause significant changes in tire behavior. As temperatures climb above 100°C, tire compounds begin to break down structurally. In desert environments, where asphalt can reach 180 degrees, rubber compounds weaken dramatically. This can lead to accelerated tread wear, reducing tire lifespan from the typical 60,000 miles to around 40,000 miles in these conditions.

Carbon black and silica are crucial fillers that influence tire behavior in various weather conditions. Silica-based compounds demonstrate superior performance in wet and cold conditions, exhibiting better traction and lower rolling resistance compared to carbon black alternatives. Silica-filled tires can reduce rolling resistance by 20-30%, resulting in 3-15% fuel savings compared to pure carbon black formulations.

The lifespan of tire compounds varies depending on usage and environmental factors. Generally, tires last around 6 to 10 years in storage. However, the National Highway Traffic Safety Administration advises against using tires past the 5-year mark due to the breakdown of rubber compounds over time, which can result in cracks and dry rot. Regular use in extreme weather conditions, particularly heat, can significantly shorten a tire's lifespan.