What are the components of a tire? Most car tires have a surprisingly complex structure with just two body plies. Large commercial jetliners often have tires with 30 or more plies. This difference shows the specialized engineering behind these vehicle parts.

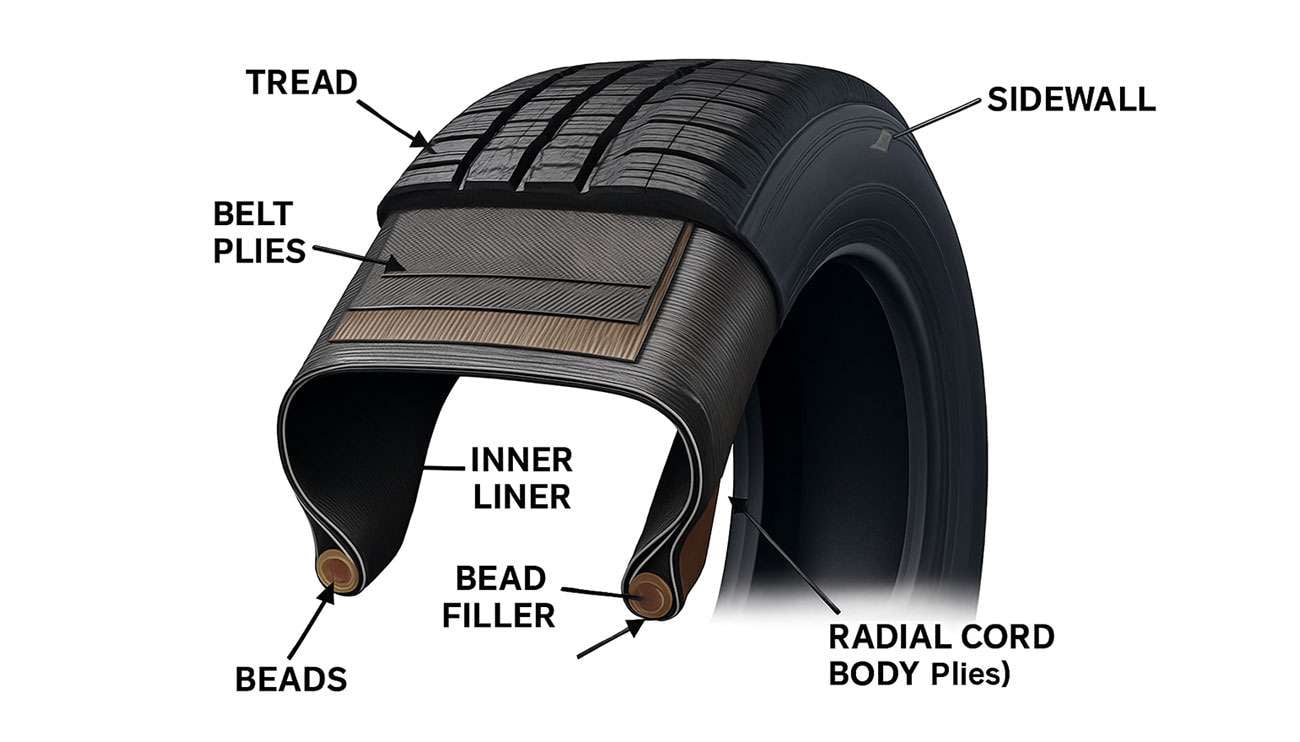

Tire manufacturer Michelin reports over 200 ingredients in a tire that directly impact performance, safety, and efficiency. We understand these various tire parts work together to keep your vehicle safely connected to the road. The tread grips the road surface and delivers traction, especially in wet or slippery conditions, while the sidewall protects internal components and displays important information about your tire. The bead, a reinforced ring made of copper, brass, or bronze-plated high tensile steel wires wound into a rubber band, anchors the tire to the wheel rim ensuring a secure and airtight fit.

Our expert guide breaks down all the tire parts with detailed diagrams. The outermost tread features specialized grooves and patterns that enhance grip while the inner layers consist of a series of belts providing strength and durability. We cover everything you need to know about tire construction.

Modern tires consist of numerous components working together to provide safety, durability, and performance. Understanding these tire parts helps you make informed decisions about maintenance and replacement.

The main components of a tire include several distinct sections, each serving specific functions:

The tread is the outermost rubber portion making direct contact with the road surface. This component provides traction for acceleration, braking, and cornering. The tread features carefully engineered patterns with grooves, sipes, and blocks designed to channel water away from the contact patch, ensuring optimal grip on wet surfaces and preventing hydroplaning.

The sidewall extends from the tread to the bead, forming the vertical portion of the tire. This critical component protects the internal parts while displaying important information such as tire size, load capacity, and speed rating. The sidewall's flexibility allows it to bend as the tire rotates, absorbing road shocks for a smoother ride.

The bead forms an airtight seal with the wheel rim. Constructed from steel wires embedded in rubber, this rigid hoop creates a strong connection that ensures the tire remains securely mounted, even during extreme conditions like high speeds, sharp turns, or heavy loads. The bead's steel core and profile work together to maintain tire seating on the rim, providing safe handling and driving comfort.

The inner liner functions as an airtight layer preventing air from escaping through the tire body. Made from butyl rubber, this impermeable component has replaced traditional inner tubes in modern tires.

When examining a car tire parts diagram, you'll notice the components arranged in specific layers:

Carcass ply (or body ply) - The skeleton of the tire made of artificial fibers such as polyester, rayon, or nylon. This layer provides the tire's strength and flexibility.

Belt package - Located beneath the tread, these steel or aramid fiber layers enhance stability and distribute load evenly across the tire's surface. The belts provide stiffness to the tread and protect the carcass.

Cap plies - Some high-performance tires include additional layers that help hold components in place at high speeds. These can be full cap plies covering the entire width of steel belts or belt edge strips covering just the edges.

Shoulder - The transition area where tread and sidewall meet, designed for cornering stability.

Winding bandage - In some tires, nylon threads embedded in rubber improve driving characteristics at high speeds.

The complex interaction between tire parts creates a system greater than the sum of its individual components.

First, the bead securely attaches the tire to the rim, creating an airtight chamber. The inner liner then retains air pressure within this chamber, functioning like an inner tube though modern tires no longer contain actual tubes.

Next, the body plies provide the structural framework while the belt plies add stability and strength to the tread area. Steel belts particularly help the tire maintain its shape and offer puncture resistance during driving.

Finally, the sidewall protects the internal components from external damage while the tread delivers the essential road contact for traction and handling. The tread pattern's specific design determines how the tire performs in various conditions—from dry pavement to rain, snow, or off-road terrain.

The bead filler—a rubber compound inside the beads—provides stability to the lower sidewall and bead area, with its density and stiffness affecting the tire's overall performance characteristics.

Many components contain specific materials designed for their function. The textile industry supplies materials like rayon, nylon, polyester, and aramid fibers for reinforcement, while the steel industry provides high-strength steel for belts and bead cores.

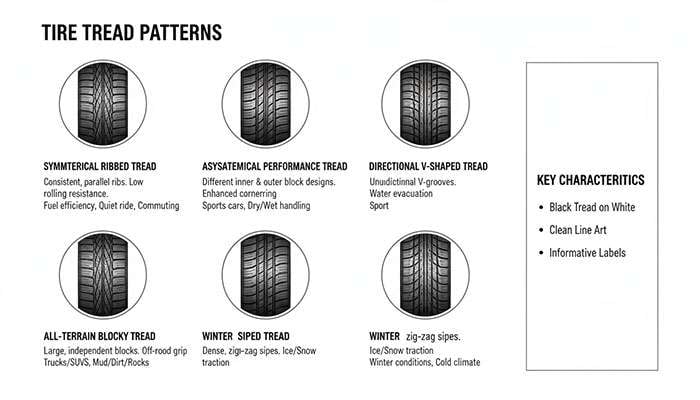

Tire tread patterns create the critical connection between your vehicle and the road surface. These designs directly impact how your tire grips the road, handles water, and performs across different driving conditions.

Tread patterns come in distinct designs, each engineered for specific performance characteristics. The main types include:

Symmetrical tread patterns feature identical designs across the entire tire surface. This uniform configuration creates a continuous rib pattern that repeats around the circumference. The design offers several advantages: even wear, balanced performance, and typically a quieter, more comfortable ride. Most passenger vehicles use symmetrical patterns because they allow for tire rotation in any position on the vehicle.

Asymmetrical tread patterns combine different designs on inner and outer sections. The outer portion typically features larger blocks for improved dry road handling and cornering stability, while the inner section contains smaller grooves optimized for water evacuation and wet performance. This dual-zone design delivers superior handling in both wet and dry conditions.

Directional tread patterns form a V-shaped design that points forward in the direction of rotation. These patterns excel at channeling water away from the contact patch, making them particularly effective in wet conditions and for high-speed driving. The tire must be mounted with the correct rotational direction indicated by an arrow on the sidewall.

Tread depth directly affects your vehicle's safety performance, particularly in wet conditions. New tires typically start with 10/32" to 11/32" of tread depth.

Legal requirements vary by location, but most regions mandate replacement at 2/32" minimum depth. Safety experts recommend replacement at 4/32" for optimal wet weather performance.

You can easily check tread depth using the penny test: insert a penny into the groove with Lincoln's head upside down. If you can see the top of Lincoln's head, your tread has worn to or below 2/32" and requires immediate replacement. For more precise measurements, use a tread depth gauge available at most auto parts stores.

Inadequate tread depth significantly compromises safety. Tests show that tires worn to the legal minimum of 2/32" require 43% more distance to stop on wet pavement compared to new tires. This difference can mean the distinction between avoiding an accident and experiencing a collision.

The tread design consists of three primary elements working together:

Grooves are the wide channels running around and across the tire. These deep cuts serve multiple purposes: they evacuate water from beneath the tire, provide biting edges for traction, and help maintain tire temperature. The groove depth directly correlates with the tire's remaining lifespan.

Sipes are thin slits cut into the tread blocks. While grooves handle bulk water evacuation, sipes create additional biting edges that improve traction on wet, icy, or snowy surfaces. These small cuts also allow tread blocks to flex, improving contact with the road surface.

The contact patch represents the actual area where rubber meets road at any given moment. Typically measuring about the size of your palm (roughly 6 by 8 inches), this relatively small area bears responsibility for all vehicle acceleration, braking, and steering. The contact patch changes size and shape based on tire pressure, load, and vehicle speed.

Proper tire pressure is essential for optimizing the contact patch. Underinflation increases the patch size but creates uneven pressure distribution, causing excessive wear on tire edges. Overinflation reduces the patch size, concentrating pressure in the center and reducing overall traction.

The sidewall serves as both a protective barrier and an information center. This vertical section between tread and bead displays critical specifications while providing structural support and flexibility.

Tire size markings follow a standardized format that appears on every sidewall. A typical marking reads: P225/65R17 102H.

Breaking down this code:

P indicates passenger vehicle (LT for light truck)

225 represents the tire width in millimeters

65 shows the aspect ratio (sidewall height as a percentage of width)

R designates radial construction

17 indicates wheel diameter in inches

102 is the load index (maximum weight capacity)

H represents the speed rating

The load index number corresponds to a specific weight capacity. For instance, a load index of 102 means each tire can safely support 1,874 pounds. Multiplying by four gives your vehicle's maximum load capacity on these tires—7,496 pounds in this example.

The speed rating letter indicates the maximum safe sustained speed for the tire when properly inflated and loaded. Common ratings include:

S = 112 mph

T = 118 mph

H = 130 mph

V = 149 mph

W = 168 mph

Y = 186 mph

The manufacturing date appears as a four-digit DOT code on the sidewall. The first two digits indicate the week of manufacture, while the last two show the year. For example, "2319" means the tire was manufactured in the 23rd week of 2019.

This date matters for safety—tires degrade over time regardless of tread depth. Most manufacturers recommend replacement after six years, with an absolute maximum of ten years from the manufacture date, even if the tread appears adequate.

The sidewall construction differs significantly from the tread area. While the tread contains multiple layers of rigid belts for stability, the sidewall features fewer reinforcing layers to allow necessary flex.

This flexibility serves several purposes. As the tire rotates, the sidewall bends to maintain optimal contact with the road surface over uneven terrain. This flexing also absorbs shock from road impacts, protecting both the wheel and vehicle suspension while providing a more comfortable ride.

The sidewall typically consists of rubber compounds blended for durability and weather resistance rather than road grip. These compounds must withstand exposure to UV radiation, ozone, road chemicals, and physical impacts from curbs or debris.

Damage to the sidewall is often more serious than tread damage. A cut or bulge in this area typically requires tire replacement because repairs cannot restore the structural integrity needed to maintain air pressure and support vehicle weight safely. The sidewall flexes constantly during driving, making any weakness potentially catastrophic at highway speeds.

The bead and inner liner work together to create and maintain the airtight seal essential for tire function. These components, though hidden from view, play critical roles in tire performance and safety.

The bead consists of high-tensile steel wires bundled together and coated in rubber. This construction creates an inflexible ring that must match the wheel rim diameter precisely. Modern passenger car tires typically contain a single steel wire bundle, while heavy-duty truck tires may feature multiple bead bundles for additional strength.

The steel wires used in bead construction are copper, brass, or bronze-plated. This plating serves a dual purpose: it prevents corrosion and provides superior adhesion to the surrounding rubber compound. The tensile strength of these wires typically exceeds 2,800 MPa (approximately 400,000 psi), ensuring the bead maintains its shape under extreme forces.

When mounted on the rim, the bead seats against the wheel's bead seat—a specially designed shelf that creates the airtight seal. The combination of air pressure pushing outward and the bead's rigid construction creates a mechanical lock that holds the tire firmly in place, even during aggressive cornering or emergency maneuvers.

The inner liner functions as a continuous airtight membrane inside the tire. Made from butyl rubber or halobutyl rubber, this layer has replaced the separate inner tubes once used in all tires.

Butyl rubber was specifically chosen for this application due to its exceptional impermeability to air. This synthetic rubber compound prevents air molecules from escaping through the tire body at a rate approximately ten times better than natural rubber. The inner liner typically measures 0.07 to 0.1 inches thick—just thick enough to maintain air retention while keeping the tire weight reasonable.

The inner liner must remain flexible enough to follow the tire's deformation during driving while maintaining its air-tight properties across a wide temperature range. Modern formulations perform effectively from -40°F to over 200°F, ensuring consistent air retention in diverse climates and driving conditions.

The bead filler, also called the apex, is a triangular rubber component positioned above the bead bundle. This often-overlooked part significantly influences tire characteristics and performance.

The filler extends upward from the bead into the lower sidewall, providing a gradual transition between the rigid bead area and the flexible sidewall. This graduated stiffness prevents abrupt stress concentrations that could lead to failure points.

The rubber compound used in bead fillers varies in hardness depending on the tire's intended purpose. High-performance tires typically use harder filler compounds to improve steering response and cornering stability. Comfort-oriented tires employ softer fillers to enhance ride quality and reduce road noise transmission.

The filler's shape and volume directly affect the tire's handling characteristics. Larger, firmer fillers create a stiffer sidewall lower section, improving steering precision but potentially compromising ride comfort. Smaller fillers allow more sidewall flex, prioritizing comfort over ultimate handling precision.

During tire mounting, proper seating of both the bead and its associated components is crucial for safe operation. Incorrect seating can lead to air leaks, uneven wear, or even sudden tire failure. Professional tire technicians use specific procedures and equipment to ensure proper bead seating and verify the airtight seal before releasing the vehicle to customers.

The internal structure of belts and plies forms the tire's skeleton. These layers determine fundamental characteristics including strength, flexibility, and performance across various driving conditions.

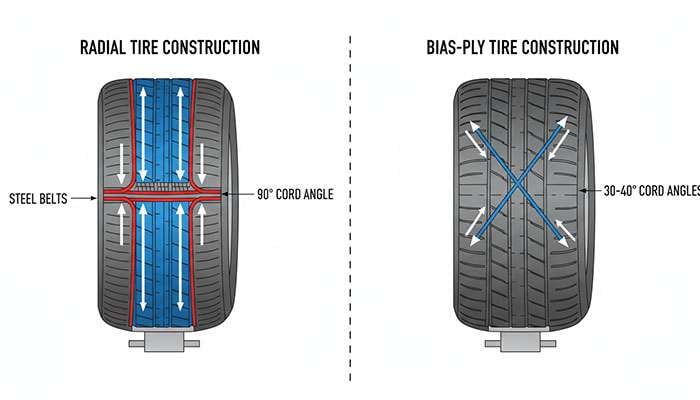

Two distinct construction methods define modern tire architecture: radial and bias-ply design.

Radial construction features cord filaments arranged at 90-degree angles to the direction of travel. This perpendicular orientation runs from bead to bead across the tire. Steel or fabric belts then run circumferentially beneath the tread, typically at angles between 20-30 degrees to the centerline.

This design allows the sidewall and tread to function independently. The sidewall can flex for comfort while the tread remains relatively rigid for stability. Radial tires generate less heat during operation, resulting in approximately 10% better fuel economy compared to bias-ply designs.

Bias-ply construction (also called cross-ply) arranges cord layers diagonally from bead to bead, with each successive layer running in opposite directions. Typically set at 30-40 degree angles, these crisscrossing layers create a rigid, integrated structure.

Bias-ply tires offer superior puncture resistance and sidewall strength, making them preferred for applications like agricultural equipment, trailers, and some off-road vehicles. The construction excels at carrying heavy loads at lower speeds but generates more heat and wears faster than radial designs at highway speeds.

Steel belts revolutionized tire performance when Michelin introduced them in 1946. These layers sit beneath the tread, providing critical functions:

The steel belts consist of thin steel cords, typically 0.15-0.38mm in diameter, embedded in rubber. These cords are brass or bronze-coated to ensure proper adhesion to the rubber matrix. A typical passenger car tire contains 1,100-1,400 individual steel cords in its belt package.

Most radial tires feature two steel belt layers oriented at opposing angles. This configuration creates a stable tread platform that resists deformation during driving. The belts distribute impact forces across a wider area, protecting the carcass and improving puncture resistance.

Steel belts also control tread squirm—the movement of tread elements under load. By minimizing this movement, steel belts reduce rolling resistance and improve fuel efficiency. They also enhance steering response by maintaining a consistent contact patch shape during cornering.

While steel dominates belt construction, textile materials form the foundation of the tire's carcass plies.

Polyester has become the most common material for body plies in passenger car tires. This synthetic fiber offers an excellent balance of strength, flexibility, and moisture resistance. Polyester maintains consistent properties across temperature variations and provides good adhesion to rubber compounds. Its relatively low cost compared to other high-performance fibers makes it economically attractive for mass production.

Nylon (specifically nylon 6 and nylon 6,6) provides superior strength and excellent impact resistance. Often used as a cap ply over steel belts, nylon helps contain the belt package at high speeds. Some tire manufacturers use nylon in the carcass for applications requiring enhanced durability, such as light truck or performance tires.

Aramid fibers (including Kevlar® and Twaron®) represent the premium option in tire reinforcement. These materials offer exceptional strength-to-weight ratios—approximately five times stronger than steel at equivalent weight. Aramid plies appear primarily in high-performance and run-flat tires where their light weight and extreme strength justify the higher material cost.

The number of plies varies by tire type and application. Most passenger car tires feature 1-2 body plies, while light truck tires may have 2-4 plies. Commercial truck tires can contain 6-10 plies or more to support heavy loads.

Cap plies represent an additional reinforcement layer found in many modern high-performance tires. Positioned above the steel belts but below the tread, these plies serve a specific purpose at elevated speeds.

As tire rotation speed increases, centrifugal force attempts to expand the tire's circumference. This expansion can cause the steel belts to lift away from the carcass, potentially leading to tread separation. Cap plies counter this force by creating an additional restraining layer.

Typically made from nylon or aramid cords oriented at near-zero degrees (parallel to the direction of travel), cap plies act like hoops to contain the entire belt package. This containment becomes increasingly critical above 100 mph, where centrifugal forces grow exponentially.

Full cap plies cover the entire belt width, while some tires use belt edge strips covering just the outer edges where stress concentrations are highest. The choice between full cap plies and edge strips represents a trade-off between performance benefits and manufacturing costs.

Cap plies also improve uniformity by helping maintain consistent belt positioning during the curing process. This contributes to better balance and smoother operation throughout the tire's service life.

Tire manufacturing incorporates over 200 raw materials, each selected for specific properties that contribute to performance, safety, and durability. This complex chemistry determines how effectively the various parts of a tire function under diverse driving conditions.

The foundation of any tire begins with rubber—both natural and synthetic varieties working together. Natural rubber, harvested from rubber trees primarily grown in Southeast Asia, provides excellent mechanical resistance and reduces internal heat generation. Synthetic rubber, derived from petroleum-based hydrocarbons, makes up approximately 60% of rubber used in tire manufacturing.

These materials serve different purposes throughout the tire structure. Natural rubber excels in truck and earthmover tire treads, while synthetic elastomers dominate passenger car and motorcycle tires, enhancing grip performance. Most tire formulations achieve optimal results with a natural-to-synthetic rubber ratio around 60:40 or 70:30.

Carbon black, discovered in 1915, dramatically improves wear resistance—increasing it tenfold when added to rubber compounds. Making up 25-30% of rubber composition, it protects against ultraviolet rays that could otherwise cause fissuring.

Since 1992, silica has emerged as a game-changing alternative. Continental first introduced silica in tire tread compounds 30 years ago, reducing rolling resistance and nearly halving braking distances. Today, silica has largely replaced carbon black in tire treads, with average content measuring approximately 23 parts per hundred rubber in modern passenger tires.

Michelin pioneered steel reinforcement in 1934, creating a significant advancement that provides essential rigidity and resistance. Modern tires use recycled steel without compromising safety or performance.

Textile reinforcements, including polyester, nylon, rayon, and aramid, strengthen different tire sections. Continental's ContiRe.Tex technology transforms recycled PET bottles into high-performance polyester yarn for tire carcasses—with a single tire utilizing materials from up to 15 recycled bottles. This innovation reduces CO₂ emissions by approximately 28% compared to fossil-based alternatives.

Antioxidants and antiozonants prevent degradation and cracking caused by exposure to oxygen, ozone, and temperature fluctuations. These compounds effectively counter the deterioration that would otherwise render tires unsuitable for harsh climatic conditions.

The impact is substantial—tires treated with enhanced antioxidant formulations last 20-40% longer than untreated samples. Laboratory tests show antioxidants minimize tensile strength loss after heat aging by 30%, maintaining mechanical properties under stress. These protective compounds extend tire life and reduce environmental impact by minimizing waste.

Understanding modern tires shows why these components play such a critical role in vehicle safety and performance. The intricate design with tread patterns, sidewalls, beads, inner liners, and internal reinforcements work together as an engineering marvel beneath your vehicle.

Tread designs serve as the primary contact point with the road. They provide grip through engineered patterns that channel water away while maintaining traction in various conditions. The sidewall protects internal components while displaying vital information about tire specifications. The bead creates that crucial airtight seal with the wheel rim, ensuring your tire stays firmly attached during challenging driving situations.

The impressive architecture of plies and belts provides structural integrity and distributes forces evenly. Radial construction has largely replaced bias-ply designs in passenger vehicles due to superior performance characteristics. The materials science behind tires represents decades of innovation - from natural and synthetic rubber blends to carbon black, silica, steel, and textile reinforcements working together.

We believe this breakdown helps you understand what lies beneath the surface of these vehicle components. Armed with this knowledge, you can make more informed decisions about tire maintenance and replacement, enhancing both safety and performance on the road.

These components represent one of the most important safety features on any vehicle. Their complex construction reflects continuous advancements in materials science and design principles aimed at balancing durability, performance, and efficiency.

Understanding tire construction helps you make informed decisions about maintenance, replacement, and safety for optimal vehicle performance.

• Modern tires contain over 200 materials working together, including natural/synthetic rubber, steel belts, and textile reinforcements for durability and performance.

• Tread patterns directly impact safety - symmetrical designs offer even wear and quiet rides, while asymmetrical patterns provide superior wet/dry handling.

• Monitor tread depth regularly using the penny test; replace tires when depth reaches 4/32" for optimal wet weather performance.

• Steel belts and radial construction provide 90% better fuel efficiency and longer life compared to older bias-ply designs.

• The bead, inner liner, and sidewall work as a system to maintain air pressure and secure tire-to-rim connection under all driving conditions.

Proper tire knowledge empowers you to maximize safety, performance, and value from these complex engineering marvels that keep your vehicle connected to the road.

The main components of a modern tire include the tread, sidewall, bead, inner liner, and internal structure consisting of plies and belts. Each part serves a specific function, from providing road grip to maintaining air pressure and securing the tire to the wheel rim.

Tire tread design significantly impacts performance. Symmetrical patterns offer even wear and quieter rides, while asymmetrical patterns provide better handling in both wet and dry conditions. The tread depth and pattern also affect water dispersion, traction, and braking efficiency.

Radial tires have cord filaments arranged at 90-degree angles to the direction of travel, allowing sidewalls and tread to function independently. This results in better fuel efficiency and longer tread life. Bias-ply tires have diagonal layers that create a rigid structure, offering superior puncture resistance for heavy-duty applications.

You should regularly check your tire tread depth. Use the penny test - if you can see the top of Lincoln's head when inserted into the tread groove, your tread is below 2/32" and needs replacement. For optimal performance, especially in wet conditions, consider replacing tires when the tread reaches 4/32".

Modern tires incorporate over 200 materials, including natural and synthetic rubber, carbon black, silica, steel, polyester, and nylon. These materials serve different purposes throughout the tire structure, from providing strength and durability to enhancing grip and reducing rolling resistance.