Replacing your car's rims costs anywhere from $200 to $2,000 for your entire vehicle. This wide price range reflects the significant differences in materials, construction quality, and brand reputation across the custom wheel market.

Budget-conscious drivers can find basic steel rims starting at incredibly affordable prices—as little as $30 per rim or about $120 for a complete set of four. Rim replacement costs jump dramatically when you enter premium territory. High-end custom rims can exceed $1,000 each, while specialized options like carbon fiber wheels might cost $10,000 to $13,500 for a complete set.

Most drivers spend around $725 for a complete wheel replacement. Standard alloy rims generally cost between $100 and $500 per rim, including installation labor and balancing. This middle ground delivers a solid combination of durability, appearance, and performance benefits.

We believe understanding these price ranges is crucial before making any decisions about upgrading your vehicle's appearance or performance. In this expert price guide, we'll break down exactly what you can expect to pay for different types of rims, from budget-friendly steel options to premium custom designs.

Steel rims represent the most durable and straightforward wheel option available today. Made primarily from an alloy of iron and carbon, these wheels deliver exceptional strength that makes them perfect for demanding driving conditions. Steel wheels focus purely on functionality rather than flashy appearance—a trait that appeals to practical drivers who value reliability above all else.

The manufacturing process for steel wheels starts with sheets of steel pressed into shape through a stamping technique. Modern steel wheels use warm-rolled steel with high offset yield strength exceeding 600 MPa. The process involves bending rectangular sheet metal into a cylindrical sleeve, with edges welded together to create the rim structure.

Manufacturers prevent distortion by using sectional welding instead of continuous welding seams. These welding seams are strategically placed in areas that experience minimal driving stress, ensuring the wheel maintains fatigue resistance throughout its lifespan.

The rim and wheel disk fit together under the outer seat and are welded in place, aligning the wheel center perfectly with the hub center. This precise alignment, called "offset" or "ET" (from German "Einpresstiefe"), measures the distance from the disk to the rim's back edge.

Steel wheels excel at resisting scratches, dents, and surface damage. Their simple construction makes them less vulnerable to cosmetic issues, emphasizing durability and strength over appearance.

Pros:

Nearly impossible to crack or bend without tremendous force

Outstanding durability in harsh conditions and rough terrain

Most affordable wheel option available

Simple to repair when damaged

Better traction on snowy or icy roads

Handle heavy loads—some models support up to 1600 lbs

Cons:

Heavier than aluminum options—approximately 2.5-3x more weight

Limited design choices compared to alloy wheels

Less corrosion resistant than aluminum

Reduced acceleration and fuel economy due to extra weight

Fewer size options—most available only in 16-inch diameter

Basic appearance without wheel covers

The weight factor creates both advantages and disadvantages. While it hurts performance, the extra weight provides better stability during winter driving. Modern steel wheels include corrosion-resistant coatings that extend their lifespan significantly, especially in harsh winter climates.

Steel wheels offer the most economical solution when you need rim replacement. These wheels typically cost $50 to $200 per wheel. A complete set of four rims ranges from $200 to $800.

Basic steel wheels for everyday passenger cars start at the lower price range. Specialized steel wheels designed for off-road use or enhanced durability features cost more but still remain affordable.

Performance Plus Tire has the best selection of rims at discount prices when you need quality steel wheels that fit your budget. We offer various styles and specifications to match your vehicle's requirements.

Steel wheels cost less because of their simpler construction and steel's abundance as raw material. Their long-term value often exceeds the initial savings—steel wheels frequently last longer than other types due to their durability and damage resistance.

Steel wheels perform best in specific situations where their characteristics provide clear advantages:

Winter driving - The heavier weight improves traction on snow and ice. Many drivers switch from alloy to steel wheels during winter months. Steel wheels resist damage from road salt, chemicals, and winter hazards.

Off-road adventures - When you drive off the beaten path, steel wheels provide unmatched durability against rocks, ruts, and rough terrain. Their resistance to bending and cracking makes them ideal for off-road enthusiasts.

Heavy-duty applications - Trucks and vehicles that haul heavy loads benefit from steel wheel strength. They support significant weight without compromising structural integrity, making them perfect for work vehicles.

Classic car restoration - Steel wheels remain popular among classic car enthusiasts who want period-correct appearance. Hot rod and muscle car builders choose steel wheels for both vintage looks and strength. Models like the Liquid Metal Atom and Unique 83 deliver authentic styling.

Budget-conscious drivers - When you prioritize function over form, steel wheels offer practical, long-lasting performance at affordable prices. They make excellent replacements for damaged wheels when you need quick, cost-effective solutions.

Steel wheels might not win beauty contests, but they deliver reliable performance in 2025 for strength and durability. Whether you're hauling heavy loads or navigating winter conditions, these practical performers provide consistent results without breaking your budget.

Aluminum rims have become the standard choice for most modern vehicles, striking an excellent balance between performance, appearance, and cost. These lightweight wheels, primarily made from aluminum with additions of nickel, manganese, magnesium, and other elements, offer several advantages over traditional steel options.

The composition of aluminum wheels typically includes aluminum alloy with various elements such as manganese, magnesium, chromium, and titanium. This combination creates a material that's approximately 2.5 times lighter than steel, resulting in significantly reduced wheel weight. Most aluminum rims weigh around 47 pounds—approximately 30 pounds lighter than comparable steel options.

Manufacturing processes for aluminum wheels fall into two main categories:

Casting: The most common method involves pouring molten aluminum into a mold to create the wheel shape. This process allows for complex designs and is more cost-effective.

Forging: This premium manufacturing technique involves shaping aluminum under high pressure. Forged wheels are stronger and lighter than cast wheels but come at a higher price point.

Beyond their construction, aluminum wheels excel at heat dissipation—offering over three times better performance than steel in dissipating brake-generated heat. This characteristic helps maintain brake system stability, enhancing overall safety during intense driving conditions.

Corrosion resistance represents another key advantage. Unlike steel rims, aluminum doesn't rust, making these wheels particularly suitable for harsh weather conditions or coastal environments. They still require proper maintenance to preserve their appearance and structural integrity.

Pros:

Lightweight construction improves fuel economy, handling, and acceleration

Superior heat dissipation extends brake life and improves braking performance

Corrosion resistant with no rusting like steel wheels

Available in numerous designs, styles, and finish options

Can be manufactured in larger sizes (15 to 24 inches and beyond)

Reduces engine load, potentially extending engine lifespan

More precise steering response and better handling

Cons:

More expensive than steel wheels—approximately 2-3 times higher cost

Less dent resistant than steel options

More prone to cracking or bending when hitting potholes or curbs

Requires more careful maintenance to preserve appearance

Susceptible to corrosion over time in areas with salt and moisture

More easily damaged by harsh road conditions

The weight advantage of aluminum wheels creates a cascading effect of benefits. The suspension system can follow terrain more closely, improving ride quality and handling. The reduced unsprung weight contributes to better acceleration when pressing the gas pedal, giving drivers that satisfying rush of speed.

When evaluating rim replacement costs, aluminum wheels represent the mid-range option. Standard aluminum wheels typically cost between $125 and $500 per rim. For a complete set of four wheels, expect to pay approximately $500 to $2,000 depending on size, design complexity, and brand reputation.

The wide price range reflects significant variations in manufacturing quality and processes:

Basic cast aluminum wheels: $125-$200 per rim

Mid-range aluminum wheels: $200-$350 per rim

Premium aluminum wheels: $350-$500+ per rim

For the best selection of rims at cheap prices with options for every budget and performance need. Our inventory includes various aluminum wheel designs to match your vehicle's specifications and your personal style preferences.

The initial investment in aluminum wheels often pays off through improved fuel efficiency. Studies suggest that using aluminum wheels can reduce fuel consumption by up to 3% or more. Over approximately 20,000 kilometers of driving, these fuel savings can offset the higher initial purchase price.

Aluminum wheels shine in specific applications where their unique properties provide maximum benefit:

Daily drivers and commuter vehicles: The improved fuel efficiency and enhanced handling make aluminum wheels ideal for everyday use. Their lighter weight reduces strain on the vehicle's suspension components, potentially lowering maintenance costs over time.

Performance-oriented vehicles: Sports cars and performance vehicles benefit from the reduced rotational mass, which improves acceleration, braking, and cornering abilities. The precise steering response is particularly valuable for drivers who enjoy spirited driving experiences.

Luxury and appearance-focused vehicles: The wide variety of designs and finishes available with aluminum wheels makes them perfect for drivers seeking to enhance their vehicle's appearance. Custom finishes like chrome, polished, matte-black, and even exotic colors allow for personalization.

Fleet vehicles: Commercial fleet operators often choose aluminum wheels to reduce overall vehicle weight, allowing for increased payload capacity without exceeding legal weight limits. This weight reduction is especially beneficial for bulk haul fleets where cargo weight is a primary concern.

Motorsport applications: From Formula 1 to NASCAR and rally racing, aluminum wheels are favored for their ability to enhance performance and handling. The lighter wheels allow for quicker pit stops and better acceleration out of corners.

Aluminum wheels offer an excellent middle-ground solution for most drivers—combining reasonable durability with enhanced performance characteristics and attractive appearance. They've become the standard wheel type across most modern passenger vehicles for good reason, balancing cost considerations with meaningful performance benefits.

Crafted from a precise blend of metals, alloy rims represent the perfect balance between performance and style. These wheels consist primarily of aluminum combined with other metals such as magnesium, nickel, or silicon—creating a wheel that offers superior characteristics compared to single-metal alternatives.

At their core, alloy wheels are manufactured using a carefully engineered combination of aluminum and complementary metals that enhance specific properties. This strategic blending creates wheels with an excellent strength-to-weight ratio that contributes to improved vehicle performance.

Two primary manufacturing methods define alloy wheel production:

Casting: The most common and cost-effective method involves pouring molten metal into a mold. This technique allows for complex and intricate designs while keeping production costs reasonable.

Forging: A premium manufacturing process where high pressure shapes solid metal blocks. Forged alloy wheels offer superior strength and reduced weight, albeit at a higher price point.

What truly distinguishes alloy wheels is their exceptional heat conductivity. This characteristic enables them to dissipate brake-generated heat efficiently, reducing the risk of brake fade during demanding driving conditions. Alloys can prevent brake fade through better cooling, which is especially crucial during intense driving situations.

The structure of alloy wheels makes them notably responsive to driver inputs, resulting in improved braking performance and faster acceleration. The unique composition allows for intricate spoke designs and a wider variety of finishes than what's possible with other wheel types.

Pros:

Enhanced performance through lighter weight improving handling, steering response, and fuel efficiency

Superior heat management with better heat dissipation improving brake performance and reducing failure risk

Weight reduction studies show 10% decrease in wheel weight can increase mileage by up to 2%

Esthetic versatility with wide range of designs, finishes, and colors for personalization

Precision handling with reduced unsprung weight providing more responsive steering and better road contact

Corrosion resistance offering greater resistance to rust and road salt compared to steel wheels

Cons:

Higher investment than steel alternatives, reflecting advanced manufacturing

Vulnerability with more prone to cracking or bending upon impact with potholes or curbs

Maintenance requirements needing regular cleaning to prevent brake dust buildup

Theft concerns as high-end alloys can attract thieves, requiring additional security measures

Susceptibility to damage with the softer aluminum material making them more vulnerable to scratches

Although alloys cost more upfront, their benefits often justify the investment. Independent research indicates a 2-5% improvement in fuel efficiency after switching to alloy wheels. The fuel savings over approximately 20,000 kilometers can offset much of the initial price difference.

Alloy wheels typically range from $100 to $500 per wheel. A complete set of four alloy rims costs between $400 and $2,000 depending on design complexity, size, and brand reputation.

Several factors influence the final rim replacement cost:

Manufacturing Process: Forged alloys command premium prices due to their enhanced strength and reduced weight

Design Complexity: Intricate patterns and specialized finishes add to manufacturing costs

Wheel Size: Larger diameter wheels (18+ inches) generally cost more than smaller options

Brand Reputation: Established manufacturers with proven quality records typically charge more

Find the best selection of rims at discount prices with options that won't break your budget. Our inventory includes various alloy wheel styles to match both your performance needs and esthetic preferences.

When comparing costs between OEM and aftermarket options, brand-name manufacturers typically charge more. Upgrading a new car with alloy wheels directly from the manufacturer typically costs $1,000 and up for a set of four. Aftermarket alloy wheels often provide better value, with quality options available for under $500 per wheel.

Alloy wheels excel in specific situations where their unique characteristics provide maximum benefit:

Performance-oriented driving: The lighter weight significantly improves acceleration, cornering, and braking—making alloys ideal for spirited driving.

Fuel economy optimization: Drivers covering substantial distances benefit from the 2-5% fuel efficiency improvement. The reduced rotational mass requires less energy from the drivetrain, resulting in better mileage.

Esthetically-focused vehicles: With countless design options, alloys allow owners to personalize their vehicles' appearance. From polished to painted finishes, these wheels enhance visual appeal.

Hot climate driving: Superior heat dissipation makes alloys excellent for regions with high temperatures or mountainous terrain where braking generates significant heat.

Daily commuters: The balance of durability, esthetics, and performance makes alloys perfect for daily use, offering improved handling without sacrificing reliability.

Alloy wheels have become standard on most modern vehicles for good reason. Their combination of performance benefits and visual appeal satisfies both practical needs and style preferences. Whether seeking better fuel economy, enhanced handling, or simply a more customized look, alloy wheels offer compelling advantages that continue to make them a popular choice among drivers of all types.

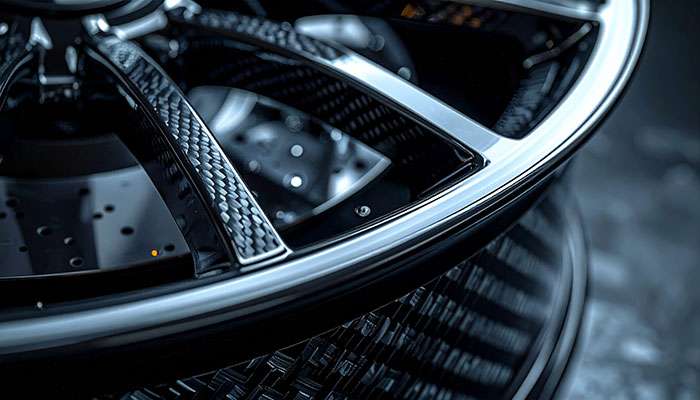

Carbon fiber rims represent the absolute pinnacle of wheel technology, combining extraordinary performance with cutting-edge materials science. These ultralight champions deliver the ultimate expression of automotive engineering for drivers who demand nothing but the best.

Carbon fiber wheels consist of thin carbon filaments woven together and bonded with resin or epoxy to create an incredibly strong yet lightweight composite material. This advanced construction produces wheels that are 40% to 50% lighter than comparable aluminum alternatives while maintaining equivalent strength. The significant weight reduction occurs primarily at the wheel's outer edges, where rotational mass matters most for vehicle dynamics.

The manufacturing process involves carefully layering carbon fiber sheets in strategic patterns to optimize strength in critical areas. Unlike metal wheels that use uniform material throughout, carbon fiber's anisotropic properties allow engineers to "tune" the wheel's performance characteristics by adjusting fiber orientation and density.

Carbon fiber's remarkable strength-to-weight ratio enables designers to create wheels that are both structurally sound and dramatically lighter. A 24-inch carbon fiber wheel can weigh the same as an 18-inch aluminum wheel—representing a 45-50% weight reduction. Across a complete set of four wheels, this can subtract over 100 pounds from a vehicle's unsprung weight.

Carbon fiber wheels also excel at vibration damping. The material's natural ability to absorb vibrations contributes to reduced road noise—an advantage particularly noticeable in electric vehicles where powertrain noise no longer masks road vibration.

Pros:

Dramatic weight reduction improves acceleration, handling, and fuel efficiency

Superior lateral stiffness enhances steering precision and cornering abilities

Excellent vibration dampening properties reduce road noise and driver fatigue

Improved heat dissipation compared to some wheel materials

Can save up to 1.5 seconds per 2-minute lap in racing applications

Potential for 5-10% range increase in electric vehicles

Aerodynamic designs possible without significant weight penalties

Cons:

Extremely high cost compared to all other wheel types

Susceptible to catastrophic failure rather than bending when damaged

Not easily repairable if cracked or severely damaged

May be too stiff for certain driving conditions

Potential concerns about long-term durability in harsh environments

Higher theft risk due to premium status

Unlike aluminum wheels that might dent or bend upon impact, carbon fiber wheels typically either withstand damage completely or fail catastrophically if their structural integrity is compromised. This characteristic makes visual inspection critical, as internal damage may not always be apparent.

Carbon fiber wheels represent the absolute pinnacle of rim pricing. These ultralight performance enhancers typically range from $4,000 to $5,300 per individual wheel. For a complete set of four rims, expect to invest between $16,000 and $20,000.

Several factors influence carbon fiber rim pricing:

Manufacturing complexity and proprietary technologies

Wheel size (larger diameters command higher prices)

Specific performance characteristics

Brand reputation and exclusivity

Find the best selection of rims at discount prices, including more affordable alternatives to carbon fiber if these premium options exceed your budget. Our extensive inventory can help you balance performance goals with cost considerations.

The extreme price difference between carbon fiber and other wheel types reflects both material costs and manufacturing complexity. Pure carbon fiber is expensive to produce, and the layup process is highly specialized, requiring significant skilled labor compared to the more automated production of metal wheels.

Carbon fiber wheels deliver maximum benefits in specific applications where their unique properties justify the premium price:

High-performance sports cars - The substantial weight reduction improves acceleration, braking, and cornering capabilities. Some exotic car manufacturers now offer carbon fiber wheels as factory options to maximize performance metrics.

Track day enthusiasts - Serious drivers seeking every possible performance advantage benefit from carbon wheels' ability to reduce lap times. The weight reduction and increased stiffness provide measurable performance improvements.

Electric vehicles - The significant weight savings can extend range by 5-10%. Since EVs are already heavier due to battery weight, carbon wheels help offset some of this disadvantage while improving efficiency.

Luxury vehicles - Carbon fiber wheels offer exclusive visual appeal and premium status that complement high-end vehicles. Their distinctive look signals technological sophistication.

Racing applications - From professional motorsport to serious amateur competition, carbon fiber's weight advantage translates directly to faster acceleration and improved lap times.

Carbon fiber wheels appeal to drivers seeking absolute maximum performance regardless of cost. These wheels represent the ultimate expression of performance engineering in the automotive wheel market, delivering measurable improvements that justify their premium price for those who demand the very best.

For enthusiasts seeking peak performance, forged and custom rims represent the gold standard in wheel manufacturing. These premium wheels undergo an intensive production process where solid aluminum billets are subjected to extreme heat and pressure, creating a dense material structure with superior strength characteristics.

Forged wheels start with a single piece of aluminum billet that's compressed under tremendous force, aligning the metal's grain structure to eliminate potential weak points. This resource-intensive process yields wheels that maintain exceptional strength while using less material. Unlike cast wheels that are poured into molds, forged wheels have significantly improved structural integrity.

Most forged wheels are custom made-to-order, engineered specifically for each vehicle application. Beyond their strength, forged wheels offer unprecedented customization—available in various diameters (up to 22 inches), virtually any width, and countless finish options. Furthermore, many manufacturers offer three-piece designs with unique color combinations for the center, inner rim, and outer rim.

Pros:

Substantially stronger than cast alternatives

Lighter weight improves acceleration, handling, and fuel efficiency

Enhanced heat dissipation properties

Superior resistance to cracking and impact damage

Extensive customization possibilities

Often repairable when damaged

Cons:

Significantly higher cost than other wheel types

Longer manufacturing and delivery times

Potentially greater theft risk due to premium status

Some ultralight designs may be susceptible to damage on rough roads

When it comes to rim replacement cost, forged wheels command premium prices reflecting their manufacturing complexity. Entry-level forged wheels typically start around $645 per rim, whereas high-end custom forged wheels can exceed $2,500 each, including forged options that balance quality and value.

A complete set of custom forged wheels typically ranges from $2,000 to $10,000—substantially more than cast alternatives that average around $2,000 per set. This significant price gap stems from labor-intensive production processes, higher-quality materials, and extensive customization options.

Forged wheels excel in performance-focused applications where strength-to-weight ratio matters most. High-performance vehicles benefit tremendously from reduced unsprung weight, experiencing improved acceleration, handling, and braking. Racing applications rely on forged wheels' superior structural integrity during extreme driving conditions.

Off-road enthusiasts frequently choose forged wheels for their exceptional durability when traversing rough terrain. Luxury vehicle owners appreciate the exclusivity and customization possibilities that communicate attention to detail and automotive sophistication.

The decision between forged and cast wheels depends on your driving habits and budget. Daily commuters may find the performance benefits negligible compared to the cost difference, whereas drivers of premium vehicles (worth over $70,000) often consider forged wheels a worthwhile investment that complements their vehicle's capabilities.

Rim Type |

Price Range (per rim) |

Weight Characteristics |

Key Benefits |

Main Drawbacks |

Best Use Cases |

Steel Rims |

$50-$200 |

2.5-3x heavier than aluminum |

- Nearly impossible to crack or bend |

- Limited design options |

- Winter driving conditions |

Aluminum Rims |

$125-$500 |

2.5x lighter than steel |

- Superior heat dissipation |

- Higher cost than steel |

- Daily commuter vehicles |

Alloy Rims |

$100-$500 |

Lighter than steel, similar to aluminum |

- Enhanced overall performance |

- Higher initial investment |

- Performance driving |

Carbon Fiber Rims |

$4,000-$5,300 |

40-50% lighter than aluminum |

- Dramatic weight reduction |

- Extremely high cost |

- High-performance sports cars |

Forged & Custom Rims |

$645-$2,500+ |

Lighter than cast alternatives |

- Substantially stronger construction |

- Significantly higher cost |

- Performance vehicles |

Choosing the right rims for your vehicle requires balancing cost against performance needs and style preferences. Throughout this guide, we've shown how rim prices vary dramatically based on materials, manufacturing processes, and design complexity. Steel rims remain the most budget-friendly option at $50-$200 per rim, delivering exceptional durability despite their weight limitations. Aluminum and alloy options occupy the middle ground at $100-$500 per wheel, providing solid performance benefits at reasonable prices for most drivers.

The price jump to premium options becomes clear when considering carbon fiber wheels, which cost $4,000-$5,300 per rim but deliver unmatched weight reduction and performance gains. Forged wheels offer superior strength and customization starting around $645 per wheel, though prices can reach $2,500+ for high-end custom designs. For those ready to upgrade their vehicle's appearance and performance, you can find the best selection of custom rims at discount prices at Performance Plus Tire.

Understanding these price ranges helps you make smart decisions based on your specific driving needs. Daily commuters might find aluminum or alloy wheels provide the best value, while performance enthusiasts can justify the premium for forged or carbon fiber options. Remember that rim quality directly affects your vehicle's performance, safety, and appearance. View your wheel purchase as an investment rather than just an expense. Factor in installation costs and potential long-term benefits like improved fuel efficiency when calculating the true cost of your rim upgrade. The right set of wheels does more than complete your vehicle's look—it enhances your entire driving experience.

Understanding rim pricing helps you make smart decisions that balance performance, esthetics, and budget for your specific driving needs.

• Steel rims ($50-$200 per wheel) offer unbeatable durability and winter performance but sacrifice esthetics and fuel efficiency due to heavy weight.

• Aluminum/alloy rims ($100-$500 per wheel) provide the best value for most drivers, delivering improved handling and fuel economy at reasonable prices.

• Carbon fiber rims ($4,000-$5,300 per wheel) deliver dramatic weight reduction and performance gains but only justify their extreme cost for serious enthusiasts.

• Forged custom rims ($645-$2,500+ per wheel) offer superior strength and unlimited customization for performance vehicles and luxury applications.

• Factor total ownership costs including installation, maintenance, and fuel savings when calculating your rim investment—lighter wheels can improve fuel efficiency by 2-5%.

The right rim choice depends on your driving habits, budget, and performance priorities. Daily commuters benefit most from aluminum options, while performance enthusiasts should consider forged or carbon fiber upgrades that transform the entire driving experience.

The cost of car rims is influenced by factors such as material (steel, aluminum, alloy, carbon fiber), manufacturing process (cast or forged), size, design complexity, brand reputation, and customization options.

The price range for a set of four rims varies widely. Basic steel rims can cost as little as $200-$800, while aluminum or alloy rims typically range from $500-$2,000. Premium options like carbon fiber or custom forged rims can exceed $10,000 for a set.

Expensive rims can be worth it depending on your priorities. High-end rims often offer benefits like reduced weight, improved performance, better heat dissipation, and enhanced esthetics. However, for daily driving, mid-range options usually provide the best balance of cost and benefits.

Steel rims are the heaviest but most durable. Aluminum and alloy rims offer a good balance of weight reduction and performance. Carbon fiber rims provide the most significant weight savings and performance benefits but at a much higher cost. Forged rims offer superior strength and customization options.

Yes, upgrading to lighter rims can improve fuel efficiency. Aluminum and alloy wheels can provide a 2-5% improvement in fuel economy compared to steel wheels. Carbon fiber wheels can potentially increase range by 5-10% in electric vehicles due to their extreme lightness.