When it comes to wheel offset and tire wear, most drivers discover the expensive connection only after replacing tires prematurely. Incorrect wheel offset creates more than just fitment issues — it actively destroys tire tread and forces costly repairs on your vehicle. The problem starts when wheels don't align with their factory position, causing uneven force distribution across the tire surface and creating irregular wear patterns that dramatically shorten tire life.

Wheel offset measures the distance between your wheel's mounting surface and its centerline. This measurement determines exactly how your wheels sit relative to your vehicle's suspension and body. When offset falls outside your vehicle's design specifications, the suspension geometry compensates by altering camber and toe angles, which directly causes accelerated tread wear on the inner or outer tire edges. The issue goes beyond simple appearance problems — wrong offset creates handling instability that becomes dangerous during high-speed driving or aggressive cornering.

Excessive negative offset presents particularly serious problems. This configuration shifts load distribution across wheel bearings and changes how your tire's contact patch meets the road surface, creating uneven sidewall flex every time you turn. Wheels positioned too far from the vehicle body affect suspension geometry and gradually throw your alignment out of specification. The visible wear patterns represent just the beginning — incorrect offset leads to unsafe driving conditions and premature tire replacement costs that add up quickly.

We'll examine the mechanical relationship between wheel offset and tire performance, revealing the critical details that many shops skip when selling aftermarket wheels. Understanding these connections helps you make informed decisions that protect both your tires and your wallet.

Wheel offset represents one of the most critical measurements in custom wheel fitment. This specification determines exactly where your wheels sit relative to your vehicle's suspension components and body panels. Getting offset right prevents the tire wear problems we just discussed.

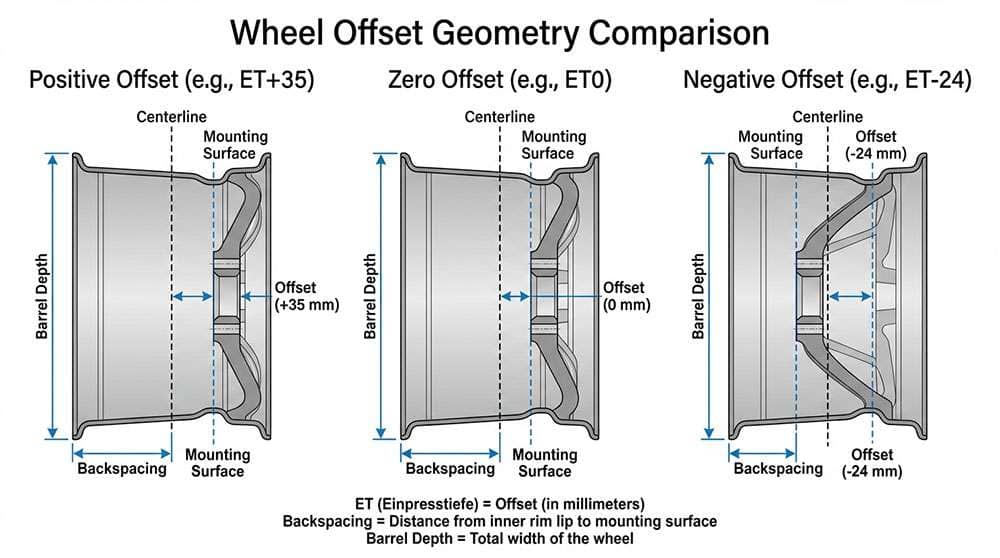

Wheel offset measures the distance between the wheel's mounting surface and the wheel's centerline. Expressed in millimeters, this measurement controls how your wheels position themselves relative to suspension components and fender wells.

Measuring offset requires simple tools:

A straightedge placed across the wheel's back rim

A tape measure to find the distance between mounting surface and centerline

Most quality wheels display their offset stamped directly on the barrel, typically marked with "ET" followed by a number. The "ET" comes from the German term "Einpresstiefe," which means insertion depth. When you see "ET35," you're looking at a positive 35-millimeter offset.

Understanding offset categories helps you select the right wheels for your application:

Positive Offset positions the mounting surface toward the street side of the centerline. Most modern passenger cars and newer rear-drive vehicles use positive offset because it tucks wheels inward toward the suspension, creating better stability and fuel economy.

Zero Offset places the mounting surface exactly at the wheel's centerline. This neutral position creates balanced wheel placement that works well for many applications.

Negative Offset moves the mounting surface behind the centerline, toward the brake side. This creates the aggressive "deep dish" appearance where wheels extend outward from the vehicle body. Off-road trucks and show vehicles commonly use negative offset for both function and style.

Wheel width changes create direct effects on both offset calculations and backspacing measurements. Backspacing measures the distance from the mounting surface to the wheel's back edge, expressed in inches.

Here's how these measurements connect: when you increase wheel width while keeping the same offset, you shift the entire wheel's position. Moving from an 8-inch to a 10-inch wide wheel with identical offset pushes both inner and outer edges outward by 1 inch.

The relationship follows this formula: Offset = Backspacing - (Wheel Width/2). Wider wheels need recalculated offset to maintain proper vehicle positioning. For example, increasing wheel width by just 0.5 inches while keeping the same offset moves the outer edge approximately 6.35mm (¼ inch) further outward. This small change can affect clearance and suspension geometry significantly.

Improper wheel offset creates predictable tire wear patterns that tell the story of your wheel fitment. These patterns develop because forces no longer distribute evenly across the tire tread when wheels sit outside their designed position, leading to accelerated deterioration in specific areas.

Negative offset pushes wheels away from the vehicle, fundamentally changing how weight transfers across the tire surface. The result is typically aggressive inner shoulder wear as the tire's load shifts inward during normal driving. Even minor offset changes make a difference — a 5mm variation can alter tire positioning enough to create noticeable wear acceleration. Vehicles running extreme negative offset develop characteristic inner edge balding, especially pronounced after cornering sessions or spirited driving.

Incorrect offset forces suspension systems to compensate outside their designed range. Your vehicle's engineers calculated specific camber and toe angles based on factory wheel positioning. Moving wheels further from their intended position through offset changes creates dynamic geometry problems that show up in tire wear patterns. Wheels sitting further outward increase negative camber effects during cornering, causing tire edges to bear disproportionate loads. The suspension tries to maintain its alignment specifications, but physics doesn't cooperate when offset moves wheels beyond their designed tolerance.

Scrub radius measures the distance between where your tire contacts the road and where your steering axis would meet the ground. Incorrect offset directly changes scrub radius, which creates excessive tire scrubbing during turns. Think of this as your tire fighting against itself when steering — instead of rolling cleanly through corners, it drags slightly with every turn. This scrubbing effect creates heat, accelerates tread wear, and compounds the wear problems we've already discussed. Over time, scrub radius issues from wrong offset generate distinctive wear marks on outer tread blocks.

Excessive positive offset can create its own problems by forcing tires inward beyond optimal positioning. When wheels sit too far under the vehicle, weight concentrates on center tread blocks rather than distributing evenly across the entire contact patch. This center wear pattern develops gradually but accelerates under heavy loads or aggressive acceleration. Manufacturers design tire compounds to wear uniformly when properly positioned — deviation from correct offset disrupts this engineered balance.

Choosing the right wheel offset requires balancing your desired appearance with tire longevity and vehicle safety. Smart offset selection protects your investment in both wheels and tires while maintaining proper vehicle performance.

We recommend staying within 5mm of your vehicle's original offset specifications for daily driving. Most vehicles can handle aftermarket offsets that vary by 10-15mm without creating serious mechanical problems. Manufacturers design wheel wells with some clearance tolerance, which creates this safe adjustment range. Keep in mind that even a 3mm difference—roughly the thickness of dental floss—produces visible changes in wheel position.

Stock vehicles perform best when you stick close to factory offset values. This maintains the suspension geometry that engineers designed for optimal tire wear and handling. Lifted trucks present different requirements based on modification height:

2-4 inch lifts: Work best with mild negative offsets ranging from -12mm to -24mm

6-inch lifts and above: Can accommodate deeper negative offsets from -24mm to -44mm

Leveling kits: Perform well with offsets between 0mm and -12mm

Offset markings appear either as "ET" followed by a number or as a simple positive/negative measurement. The "ET" comes from the German word "Einpresstiefe," which means insertion depth. When you see "ET35," this indicates a positive 35mm offset, meaning the mounting surface sits 35mm outward from the wheel's centerline.

The difference between -24mm and -44mm offset creates dramatically different results. A -24mm offset provides moderate wheel positioning that works well with 33-35" tires. A -44mm offset creates extreme wheel "poke" beyond your fenders, designed primarily for show builds running 35"+ tires. Beyond appearance, -44mm offset places significantly more stress on wheel bearings and accelerates uneven tire wear patterns.

At Performance Plus Tire, we've seen how proper offset selection can double tire life compared to extreme fitments. Our fitment experts help you find the perfect balance between style and performance for your specific vehicle and driving needs.

Proper wheel offset selection protects both your tire investment and vehicle performance. Small changes in offset create significant mechanical consequences that extend far beyond appearance. Understanding these relationships before selecting aftermarket wheels saves money on premature tire replacements and prevents expensive suspension repairs.

Negative offset delivers the aggressive look many enthusiasts want, but the trade-offs are substantial. Tires wear unevenly when wheels sit outside their designed position, particularly on the inner and outer edges where load distribution concentrates improperly. Suspension components also experience increased stress from leverage effects, leading to accelerated wear on wheel bearings and ball joints.

Our recommendation for daily drivers remains clear: stay within 5mm of factory specifications whenever possible. Aftermarket wheels offer appealing designs, but the hidden costs of incorrect offset compound quickly through tire wear and component failure. Lifted vehicles can accommodate more negative offset, though even these applications require careful consideration of the mechanical impacts.

The right wheel offset balances style with mechanical function. Poor offset choices don't just affect appearance — they actively reduce tire life through uneven contact patch loading and increased scrub radius effects. When selecting new wheels, treat offset as a critical specification that determines how evenly your tires meet the road surface.

We've covered how offset influences scrub radius, bearing loads, and steering response — all factors that directly impact tire longevity. Making informed fitment decisions protects your driving experience while avoiding unnecessary replacement costs. The best wheel setup maintains proper suspension geometry while achieving your desired aesthetic, ensuring both performance and tire life remain optimal.

Understanding wheel offset is crucial for tire longevity and vehicle safety, as improper fitment creates hidden mechanical stresses that accelerate wear and damage components.

• Stay within 5mm of factory offset for daily drivers to prevent premature tire wear and suspension damage • Negative offset increases scrub radius causing tires to drag during turns, accelerating inner/outer edge wear patterns • Offset changes force camber/toe compensation outside design limits, creating uneven load distribution across tire contact patches • Excessive negative offset multiplies bearing stress through leverage, causing premature wheel bearing and ball joint failure • Read offset markings carefully - ET35 means +35mm positive offset; -24mm vs -44mm creates dramatically different tire wear patterns

When selecting aftermarket wheels, remember that offset isn't just esthetic - it's a critical mechanical specification that determines how evenly your tires contact the road and how long they'll last.

Wheel offset significantly affects tire wear patterns. Improper offset can cause uneven load distribution across the tire tread, leading to accelerated wear, especially on the inner or outer edges. Even small deviations from factory specifications can result in premature tire deterioration.

For daily drivers, it's generally recommended to stay within 5mm of the vehicle's original offset specifications. However, some vehicles can tolerate aftermarket offsets that differ by 10-15mm without major issues. Always consult with a professional to determine the safe range for your specific vehicle.

Excessive negative offset increases stress on suspension components. It creates a longer lever arm from bearings to the tire contact patch, which accelerates wear on wheel bearings and ball joints. This can lead to premature failure of these components, especially in lifted trucks or vehicles with extreme offset modifications.

Yes, changes in wheel offset can significantly affect steering and handling. Incorrect offset can increase scrub radius, leading to more effort required for steering and potential torque steer under acceleration. It may also cause excessive feedback through the steering wheel, making precise control more challenging.

Wheel offset markings typically appear as "ET" followed by a number, or simply as a positive or negative number. For example, "ET35" indicates a positive 35mm offset, meaning the mounting surface is 35mm outward from the wheel's centerline. Negative numbers (e.g., -24) indicate the mounting surface is behind the centerline, creating a "deep dish" appearance.