Custom offset wheels represent one of the most critical decisions you'll make when upgrading your vehicle's appearance and performance. Getting the offset wrong can create serious problems - too much positive offset prevents your wheels from clearing suspension or brake components, while excessive negative offset leads to handling issues and puts extra stress on your suspension components.

When it comes to custom offset wheels, the measurement between your wheel's centerline and hub mounting surface determines everything. Offset controls exactly where your wheels sit - positive offset tucks them closer to your suspension, while negative offset pushes them outward for that aggressive stance many enthusiasts want.

Wheels with lower or negative offsets create the coveted concave look that makes your vehicle stand out. The more aggressive the offset, the deeper that lip appearance becomes. This styling comes with responsibility though - choosing the right offset keeps your vehicle safe, performing well, and comfortable for daily driving.

Most drivers should stick within 1 to 2 inches of their factory wheel size and stay close to the manufacturer's recommended offset. This approach gives you the custom look you want without compromising the engineering that makes your vehicle handle properly.

We'll walk you through everything about custom offset wheels - from basic measurements to real-world fitting advice. Our goal is helping you make the right choice for your vehicle's performance, handling, and the exact style you're looking for.

Custom offset wheels give you control over exactly how your wheels sit on your vehicle. These aftermarket wheels are specifically engineered with offset measurements that differ from what came on your car from the factory. We see enthusiasts choose custom offsets to achieve the exact stance, performance, and style that factory wheels simply can't deliver.

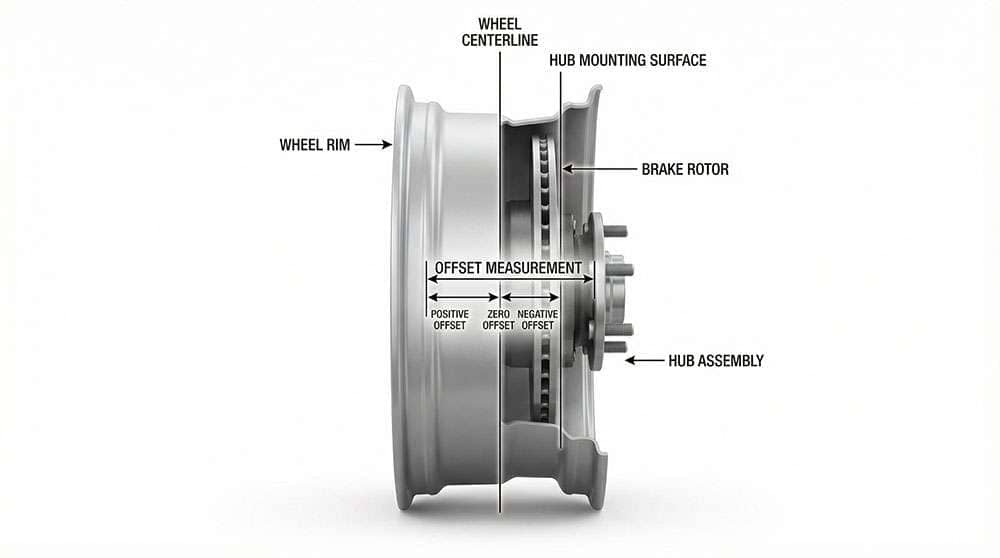

The wheel's hub mounting surface and centerline relationship determines your wheel's offset measurement in millimeters. This measurement controls where your wheels position themselves relative to your suspension components and fenders.

You'll typically find offset marked on your wheels as "ET" followed by a number - this comes from the German term "Einpresstiefe" meaning insertion depth. Custom offset wheels serve three main purposes:

Styling Control - Get that perfect stance with wheels positioned exactly where you want them

Performance Enhancement - Change your vehicle's track width to alter handling characteristics

Modification Compatibility - Make room for bigger brakes, suspension upgrades, or wider tires

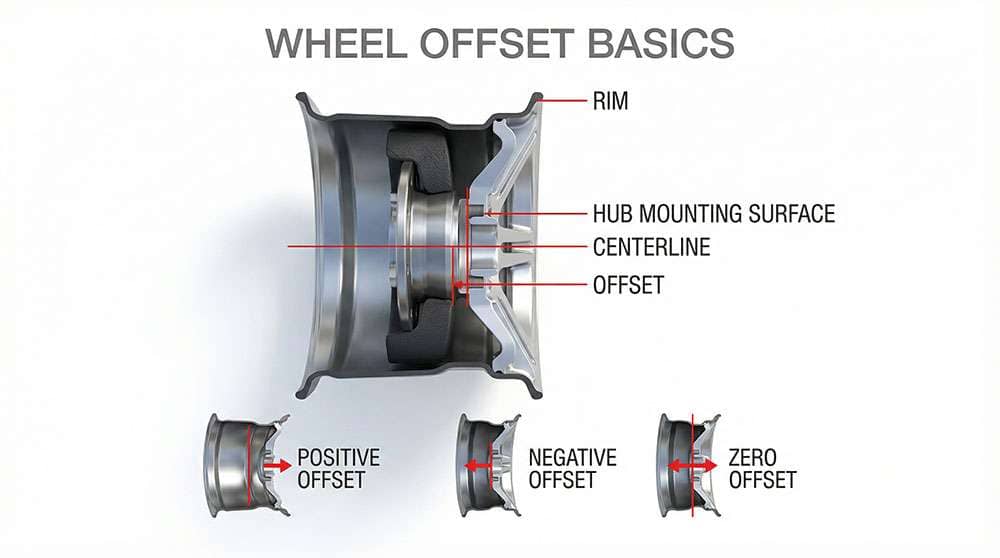

Understanding the three offset types helps you choose the right setup:

Positive offset: Mounting surface sits toward the street side, tucking wheels inward. Most front-wheel drive vehicles and newer cars use positive offsets.

Zero offset: Mounting surface aligns with the wheel centerline for balanced positioning.

Negative offset: Mounting surface sits toward the brake side, pushing wheels outward for that classic deep dish look.

Factory wheels play it safe with high positive offsets like +30mm to +40mm, keeping everything tucked tight against the body. Manufacturers design this way for good reasons:

Water and debris stay off your vehicle and other drivers

Keeps overall width manageable for parking and daily driving

Maintains predictable handling by centering weight properly

Provides plenty of clearance around suspension and brake components

Custom offset wheels open up possibilities that factory wheels restrict. Lower positive offsets or negative offsets create distinctive characteristics:

Aggressive Appearance - Wheels sit flush with fenders or even poke past them

Design Freedom - More space for dramatic styling like deep lips and bold spoke patterns

Wider Track Width - Increased distance between wheels can improve cornering stability

Different Feel - Changes scrub radius, which affects how steering responds

We see customers use custom offsets to accommodate modifications like big brake kits, coilovers, and chassis work that won't fit with standard wheels. Even small offset changes make noticeable differences in how your vehicle steers, handles, and wears suspension components.

The biggest advantage is styling freedom. Factory wheels with their conservative offsets can't achieve the deep dish appearance that many enthusiasts want. Custom offset wheels make those dramatic looks possible while giving you the performance characteristics you're looking for.

Wheel offset determines exactly where your wheels sit relative to your vehicle's body and suspension components. This measurement affects everything from your vehicle's appearance to its handling characteristics and component clearances.

Wheel offset measures the distance in millimeters between your wheel's hub mounting surface (where it bolts to your vehicle) and the wheel's centerline. This measurement controls whether your wheels sit flush with your vehicle's body, tuck inside the fenders, or extend outward. The offset impacts your vehicle's track width, handling dynamics, and overall stance.

Three types of wheel offset create distinct fitment characteristics:

Zero offset: The hub mounting surface aligns perfectly with the wheel's centerline. This balanced position creates a neutral wheel stance.

Positive offset: The mounting surface sits toward the front half of the wheel, closer to the street side. This configuration tucks wheels inward toward your brakes and suspension. Most factory wheels on modern vehicles use positive offsets, especially front-wheel drive cars.

Negative offset: The mounting surface positions toward the back half of the wheel. This setup pushes wheels outward from your suspension, creating the aggressive "deep dish" appearance and wider stance. Off-road trucks and custom builds frequently use negative offsets.

A +40mm offset places the mounting surface 40 millimeters toward the street side from the wheel's centerline. This relatively high positive offset positions the wheel further inward toward your suspension compared to lower or negative offset wheels. Many factory wheels feature +30mm to +40mm offsets, which maintains the vehicle's center of gravity and reduces overall width.

A -12mm offset positions the mounting surface 12mm behind the wheel's centerline toward the brake side. This negative offset pushes the wheel outward, creating an aggressive stance while providing space for larger tires. The -12mm offset offers a popular off-road choice among enthusiasts. It balances aggressive styling with functional performance without severely compromising suspension geometry. However, negative offsets like -12mm can stress suspension components and create potential fender clearance issues if not properly matched to your vehicle.

Understanding wheel offset impacts both the appearance and function of your custom wheel setup. Even small offset changes can dramatically alter your vehicle's stance, handling, and clearance requirements.

Test fitting your custom offset wheels properly prevents expensive mistakes and ensures your investment performs safely. This step-by-step process helps you catch potential problems before they damage your vehicle or wheels.

Start by placing the wheel onto your vehicle to verify the drilled bolt pattern matches your vehicle's studs. The bolt pattern has two key measurements: the number of lug holes and the diameter of the circle they form. A 5x114.3 pattern means five lug holes arranged on a 114.3mm diameter circle.

You'll notice some space between the wheel hub bore and your vehicle's hub - this is normal since aftermarket wheels are typically lug-centric rather than hub-centric. If vibrations occur from this gap, hub rings can center the wheel properly.

Next, visually check clearance around the brake caliper, inner valve stem, and wheel weights. Rotate the wheel by hand slowly and confirm sufficient clearance at every point. Aftermarket brake systems need at least 0.100 inches (approximately 3mm) of clearance around the caliper to accommodate heat expansion.

Place cardboard under the front tires before lowering the vehicle completely. Have someone turn the steering wheel fully left and right while you check for contact points between the tire and suspension components. Pay special attention to areas where the tire might rub during full lock turns.

Secure your wheels using a torque wrench set to your manufacturer's specifications. The star pattern keeps wheels centered and prevents vibrations:

Hand-tighten all lugs first

Use torque wrench in star pattern

Follow manufacturer's torque specifications

Re-torque after 25-50 miles of driving

Perform a complete inspection once the vehicle's full weight rests on the suspension. Check all four wheels for adequate clearance in every area. Remember that suspension compression during driving can change clearance measurements.

For complex fitment situations or if you're unsure about any part of this process, get professional wheel offset help from the Pros at Performance Plus Tire (https://www.performanceplustire.com/). Our expertise can save you time and prevent costly damage to both your vehicle and wheels.

Even with careful planning, custom offset wheels can create unexpected problems after installation. Here's how to identify and solve the most common fitment challenges you might encounter.

Vibrations after installing your new wheels usually point to centering problems. Most aftermarket wheels have a larger center bore than your vehicle's hub, which creates imbalance issues that you'll feel through the steering wheel.

Hub rings (also called hub-centric rings) solve this by filling the gap between your wheel's center bore and the vehicle's hub. These simple rings ensure proper centering and eliminate those annoying vibrations. Make sure your wheels are properly balanced with weights on both the inside and outside surfaces for complete static and dynamic balance.

Different vibration patterns help diagnose the problem. Dynamic imbalance typically causes vibrations between 52-65 MPH, while static imbalance shows up above 70 MPH. If you're experiencing vibrations, check your wheel balance before assuming you need hub rings.

Tire rubbing happens when your tires make contact with the wheel well, fender, or suspension components. This problem usually stems from incorrect wheel offset, oversized tires, or suspension modifications.

Too much positive offset positions your wheels too close to suspension parts, creating inner fender interference. Not enough positive offset (or too much negative offset) causes outer fender rubbing. Watch for warning signs like unusual tire wear patterns, burning rubber smell, or scraping noises when turning.

You can adjust wheel offset using several methods. Wheel spacers create additional space between the hub and rim, effectively pushing your wheels outward. Keep in mind that spacers increase leverage on your wheel bearings without changing the wheel load.

Changing wheel offsets also affects how weight distributes across your tire tread. After making offset adjustments, you'll need a professional alignment because changed offsets affect your suspension geometry. This isn't optional - proper alignment ensures your vehicle handles safely and your tires wear evenly.

Small offset changes can create bigger impacts than you might expect. While 2mm seems minimal, it can represent a 5% difference in some applications. The industry recommends staying within 5mm of your factory offset for optimal performance and safety.

For vehicles with tight clearances around brake calipers or suspension components, even 2mm could determine whether your setup works properly or creates rubbing issues. When you're dealing with small offset differences, get professional wheel offset help from the Pros at Performance Plus Tire for proper assessment. Our expertise can save you from costly mistakes and ensure your setup works perfectly.

Protecting your investment in custom offset wheels means using the right care techniques for your specific wheel finish. Regular maintenance prevents costly damage and keeps your wheels performing at their best for years to come.

Chrome wheels need gentle treatment to maintain that mirror-like shine you paid for. Use pH-neutral cleaners (around pH 7) with a microfiber cloth - harsh detergents will strip the protective coating and leave you with expensive repair bills. Chrome-plated aluminum requires a non-abrasive cream wax after cleaning to prevent surface corrosion.

Alloy wheels demand different approaches depending on their construction. Forged wheels have machined finishes that harsh cleaners will damage permanently. Cast wheels handle stronger cleaners better, but gentle, non-abrasive products still work best for long-term appearance.

Those small crater-like marks called pitting come from road salt, brake dust, and trapped moisture. Clean your wheels every two weeks to remove these corrosive elements, and always clean them immediately after driving near the coast or in rain.

Never clean hot wheels - cold water on extremely hot surfaces creates water spots that will pit chrome permanently. Road grime that sits on your wheels traps moisture against the metal, creating corrosion that turns into permanent damage over time.

Wheel wax creates a barrier between your wheels and moisture - reapply every 3-4 weeks to maintain protection. Ceramic coatings offer superior protection that repels water, brake dust, and road grime for months rather than weeks.

These coatings fill the microscopic imperfections on wheel surfaces, creating a smooth finish that lets contaminants slide off easily. Ceramic-coated wheels require less frequent cleaning while maintaining their appearance much longer than untreated wheels.

Custom offset wheels can dramatically change how your vehicle looks and performs. The right offset choice depends on your specific vehicle requirements, how you drive, and the exact appearance you want to achieve. Positive and negative offsets aren't just numbers - they directly affect how your vehicle handles, what clearances you have, and how comfortable your daily driving experience will be.

Safety comes first when selecting custom offset wheels. Small changes of just 2mm can make noticeable differences in fitment and performance. Staying within 5mm of your factory specifications gives you the best balance between the custom look you want and the reliability you need for everyday driving.

Proper installation makes sure your custom wheels work exactly as intended. Check bolt patterns, verify clearance around brakes and suspension components, and use correct torque specifications to prevent problems before they start. Hub-centric rings can solve vibration issues that might otherwise affect your driving experience.

Maintenance keeps your investment looking great and performing well. Different wheel finishes need specific cleaning methods and protective treatments. Regular cleaning prevents corrosion and pitting that can permanently damage your wheels.

The best custom offset setup balances the look you want with the performance you need. Deep-dish negative offset wheels might create the aggressive appearance you're after, but they still need adequate clearance and proper handling characteristics. Working with knowledgeable professionals saves time, money, and frustration when selecting and installing custom offset wheels.

You now have the knowledge to choose custom offset wheels that enhance your vehicle's appearance while maintaining or improving its performance. Take your time during the selection and testing process - it pays off with years of trouble-free enjoyment of your customized ride.

At Performance Plus Tire, our expert team is ready to help you find the perfect offset wheels for your specific vehicle and goals. We understand that the right wheels make all the difference in both style and performance.

Understanding custom offset wheels is essential for achieving the perfect balance between style, performance, and safety for your vehicle.

• Offset determines wheel position: Positive offset tucks wheels inward, negative offset pushes them outward, affecting both appearance and handling characteristics.

• Stay within 5mm of factory specs: Even 2mm offset changes can impact performance; staying close to manufacturer recommendations ensures optimal safety and drivability.

• Test fit before final installation: Check bolt patterns, brake clearance, and suspension components to prevent expensive damage and ensure proper fitment.

• Proper maintenance preserves investment: Use pH-neutral cleaners for different finishes and apply protective coatings every 3-4 weeks to prevent corrosion and pitting.

• Professional guidance prevents costly mistakes: Complex fitment challenges require expert assessment to avoid vibrations, rubbing, and suspension geometry issues.

Custom offset wheels offer tremendous potential for vehicle customization, but success depends on understanding the technical aspects and maintaining realistic expectations about what works safely with your specific vehicle setup.

Wheel offset is the distance between the wheel's hub mounting surface and its centerline. It determines how your wheels sit in relation to the vehicle's body and suspension, affecting esthetics, handling, and clearance.

Positive offset pushes wheels inward towards the suspension, while negative offset moves them outward. Positive offset is common on modern vehicles, while negative offset creates a wider stance and "deep dish" look popular among enthusiasts.

Wheel offset can be adjusted using spacers or by choosing wheels with different offsets. However, even small changes can impact handling, suspension wear, and clearance. It's recommended to stay within 5mm of factory specifications for optimal performance and safety.

When test fitting, verify the bolt pattern, ensure adequate clearance around brake calipers and suspension components, check for rubbing during full steering lock, and perform a final inspection after lowering the vehicle onto its suspension.

Maintain custom offset wheels by using appropriate cleaning methods for their specific finish, applying protective coatings regularly, and cleaning them frequently to prevent corrosion and pitting. Different finishes may require specialized care to preserve both appearance and structural integrity.