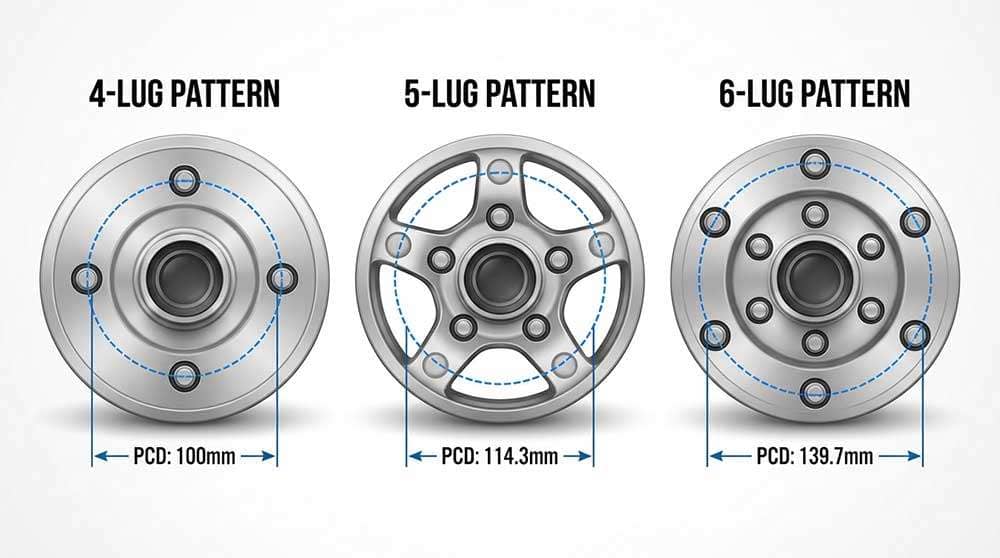

Your wheel's bolt pattern, also called PCD (pitch circle diameter), is one of the most critical measurements for wheel fitment. It describes two things: how many lug holes a wheel has and the diameter of the imaginary circle that passes through the center of each lug hole. Getting this measurement right is essential—a wheel with the wrong bolt pattern simply won't mount to your vehicle.

The bolt pattern ensures that your wheel aligns precisely with the wheel studs or bolts on your vehicle's hub. When the pattern matches, each lug hole lines up perfectly, allowing you to secure the wheel safely. When it doesn't match, the wheel cannot be installed—there's no "close enough" with bolt patterns.

Bolt patterns are expressed as two numbers separated by an "x" symbol. The first number indicates the lug count (how many bolt holes the wheel has), and the second number indicates the PCD (the diameter of the bolt circle in millimeters or inches).

For example, 5x114.3 means the wheel has 5 lug holes arranged on a circle with a 114.3mm diameter. You may also see this written as 5x4.5 (the same measurement in inches, since 114.3mm equals 4.5 inches). Both notations describe the identical bolt pattern—the difference is simply metric versus imperial units.

Here are some real-world examples:

Bolt Pattern |

Meaning |

Common Vehicles |

|---|---|---|

4x100 |

4 lugs, 100mm circle |

Honda Civic, Mazda Miata, VW Golf |

5x114.3 (5x4.5) |

5 lugs, 114.3mm circle |

Honda Accord, Toyota Camry, Ford Mustang |

5x120 |

5 lugs, 120mm circle |

BMW 3-Series, Chevy Camaro, Tesla Model 3 |

6x139.7 (6x5.5) |

6 lugs, 139.7mm circle |

Toyota Tacoma, Chevy Silverado 1500, Ford F-150 |

8x170 |

8 lugs, 170mm circle |

Ford Super Duty (1999-present) |

For more conversions between metric and imperial measurements, use our Bolt Pattern Conversion Chart.

Passenger vehicles typically use 4-lug, 5-lug, 6-lug, or 8-lug patterns, with the configuration depending on the vehicle's size, weight, and intended use.

Four-lug patterns are common on compact cars, economy vehicles, and some sports cars. Popular 4-lug patterns include 4x100, 4x108, and 4x114.3. These patterns offer sufficient strength for lighter vehicles while keeping wheel and hub designs simple.

Five-lug patterns are the most common configuration for sedans, coupes, crossovers, and mid-size trucks. The extra lug provides increased load capacity and a more balanced distribution of clamping force. Common 5-lug patterns include 5x100, 5x112, 5x114.3, 5x120, and 5x127.

Six-lug patterns are standard on full-size trucks and SUVs. They provide the additional strength needed for heavier vehicles and towing applications. The most common 6-lug patterns are 6x135 (Ford trucks) and 6x139.7 (GM and Toyota trucks).

Eight-lug patterns appear on heavy-duty trucks and commercial vehicles. They provide maximum load-carrying capacity for work trucks, dually configurations, and vehicles that regularly haul or tow heavy loads. Common patterns include 8x165.1 (Chevy/GMC HD) and 8x170 (Ford Super Duty).

For comprehensive bolt pattern information by vehicle, see our Wheel Bolt Patterns Guide.

Measuring your bolt pattern requires knowing both the number of lugs and the PCD. Counting the lugs is straightforward—the tricky part is measuring the circle diameter accurately, and the technique varies depending on whether you have an even or odd number of lugs.

For even-numbered lug patterns, measure from the center of one lug hole straight across to the center of the hole directly opposite. This direct center-to-center measurement gives you the PCD. Use a tape measure or calipers for accuracy.

Five-lug patterns require a different approach because no two holes are directly opposite each other. Measure from the center of one lug hole to the outer edge of the hole that is farthest away (two holes over). This measurement equals the PCD. Alternatively, measure from the back of one hole to the center of the hole two positions away.

You can also measure the bolt pattern on your current wheel rather than the hub. The technique is the same—just measure the lug holes on the wheel instead of the studs on the vehicle. This is often easier and gives you the same result.

For step-by-step instructions with photos, visit our Measuring Your Bolt Pattern guide.

Some aftermarket wheels feature dual-drilled or multi-pattern configurations—they have two sets of bolt holes to fit multiple bolt patterns. For example, a wheel might be drilled for both 5x100 and 5x114.3, making it compatible with a wider range of vehicles.

Dual-drilled wheels can be a practical solution if you're upgrading from a vehicle with one pattern to another, or if you want wheels that might transfer to a future vehicle. However, you'll only use one set of holes at a time—the unused holes remain visible behind the lug nuts.

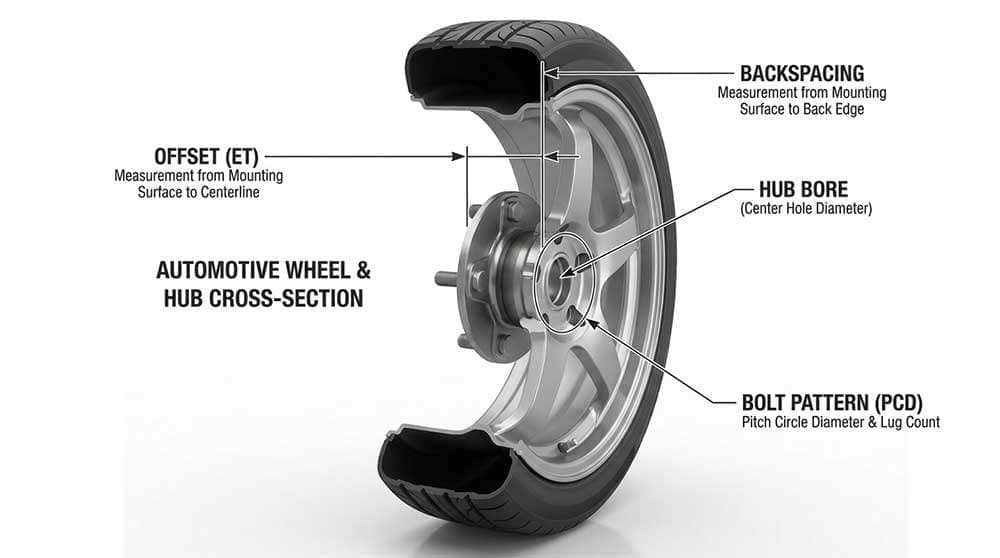

While bolt pattern is essential, it's only one piece of the wheel fitment puzzle. A wheel can have the correct bolt pattern but still not fit your vehicle properly. Here are the other critical measurements to verify:

Offset measures the distance from the wheel's mounting surface to its centerline, expressed in millimeters. Positive offset means the mounting surface is toward the street side; negative offset means it's toward the brake side. Incorrect offset causes the wheel to sit too far in or out, potentially causing tire rubbing, fender contact, or handling issues. Learn more: Wheel Offset Explained.

Backspacing measures from the wheel's mounting surface to the back edge of the wheel (the side facing the brakes). This measurement, combined with wheel width, determines how much clearance you'll have for brake calipers and suspension components. See our Custom Wheel Backspacing guide.

The hub bore is the large center hole in the wheel that fits over your vehicle's hub. It must be equal to or larger than your vehicle's hub diameter. If the wheel's center bore is larger than needed, hub-centric rings can fill the gap for a vibration-free fit. If it's smaller, the wheel won't mount. Details: Custom Wheel Hub Bore.

Larger brake calipers may require wheels with specific spoke designs or diameters to clear without contact. Always verify that your new wheels provide adequate clearance for your brake setup, especially if you've upgraded to performance brakes.

When changing wheel or tire sizes, use these tools to ensure everything fits and your speedometer remains accurate:

Even with the correct bolt pattern, you need the right hardware to mount your wheels safely. Lug nuts and bolts come in different seat types, thread pitches, and lengths—and using the wrong hardware can result in improper seating, loose wheels, or damaged threads.

Conical (tapered) seats have a 60-degree angled surface and are the most common type on domestic and Asian vehicles. Ball (radius) seats have a rounded surface and are standard on European vehicles like BMW, Mercedes, and VW/Audi. Mag (flat) seats have a flat washer-style surface and are used on some mag-style wheels. Using the wrong seat type prevents proper contact between the lug nut and wheel, which can lead to wheel loosening.

Thread pitch must match your vehicle's wheel studs or bolts. Common thread pitches include 12x1.25, 12x1.5, 14x1.5, and 14x2.0. Installing lug nuts with the wrong thread pitch will damage the threads and compromise wheel security.

Always torque lug nuts to the manufacturer's specification using a calibrated torque wrench. Under-torquing can cause wheels to loosen; over-torquing can warp brake rotors, stretch studs, or crack wheels. Typical passenger vehicle specs range from 80-100 ft-lbs, while trucks may require 120-140 ft-lbs or more.

Wheels and tires must meet or exceed your vehicle's original load capacity and speed rating requirements. Underrated components can fail catastrophically under heavy loads or at high speeds.

Check your tire's load index and speed rating to ensure they match or exceed OE specifications. Our Load Index Chart and Load & Speed Ratings guides explain how to decode these ratings.

If your vehicle is equipped with a Tire Pressure Monitoring System (TPMS), new wheels may require TPMS sensor transfer, reprogramming, or new sensors entirely. See TPMS Service for details.

Shopping by bolt pattern is a great starting point, but proper wheel fitment involves verifying offset, hub bore, brake clearance, and load ratings. Our fitment specialists confirm every measurement before your order ships, ensuring your new wheels and tires fit perfectly.

Prefer turnkey convenience? Our Wheel & Tire Packages arrive mounted, balanced, and ready to bolt on—with TPMS sensors installed if needed. We take the guesswork out of wheel and tire shopping.

Can't find your bolt pattern or need a specific drilling? Some wheels are supplied blank and can be professionally drilled to a specified pattern within design limits—ask us for availability.

Contact Us to speak with a fitment specialist, or start browsing: Shop Wheels and Shop Tires.

Reviewed by the Performance Plus Tire Fitment Team.

It's a 5-lug wheel with lugs spaced on a 114.3mm (4.5") circle. Both the lug count and the circle diameter must match your vehicle for the wheel to fit.

Measure from the center of one lug hole to the outer edge of the hole directly across (two holes over). This distance equals the PCD. You can convert between millimeters and inches using our Bolt Pattern Conversion Chart.

No. You must also confirm offset, backspacing, hub bore, brake caliper clearance, hardware seat type, and thread pitch for proper fitment.

Often yes, within the wheel's design limits. Some wheels are manufactured blank and can be custom drilled to your specifications. Contact us to verify if custom drilling is available for your application.

Use our Plus/Minus Sizing Calculator, Tire Size Comparison Calculator, and Wheel & Tire Size Calculator to find compatible sizes. Our Bolt Pattern Conversion Chart helps translate between metric and imperial measurements.

They're the same bolt pattern expressed in different units. 5x114.3 uses millimeters while 5x4.5 uses inches (114.3mm = 4.5 inches). Both describe a 5-lug wheel with the same bolt circle diameter.

No. Wheels must have the exact bolt pattern that matches your vehicle. Adapters that change bolt patterns exist but add complexity, may affect handling, and aren't recommended for most applications.

Dual-drilled wheels have two sets of bolt holes to fit multiple bolt patterns. For example, a wheel might fit both 5x100 and 5x114.3 vehicles. Only one pattern is used at a time; the unused holes remain visible.