KMC or Method wheels – which brand delivers superior off-road performance for your trail adventures? Both manufacturers dominate the aluminum alloy wheels market for serious off-road enthusiasts, yet each brings distinct advantages to challenging terrain.

KMC Wheels brings over four decades of expertise to the table, crafting innovative wheel designs since 1982 with manufacturing that meets rigorous international quality standards. Method Wheels entered the scene more recently in 2020, but they've quickly established a reputation for high-performance wheels that serious off-road enthusiasts trust.

Each brand excels in different areas that matter for trail performance. KMC wheels feature lightweight construction specifically engineered for maximum performance, durability, and strength when tackling demanding off-road conditions. Method Wheels takes a different approach, constructing their off-road offerings from solid A356 aluminum with T6 heat treatment – perfect for rock crawlers, buggies, SUVs, Jeeps, and UTVs.

Both options deliver significant benefits over stock wheels. Aluminum wheels weigh considerably less than steel alternatives, which improves your vehicle's drivability while reducing wear on suspension components and tires. For serious off-road applications, both brands engineer wheels with load ratings between 2,500 and 3,500 pounds – more than adequate for most off-road vehicles.

We'll break down the key differences in design philosophy, real-world trail performance, and overall value to help you choose the right brand for your rig. The differences become clear when the pavement ends and your adventure begins.

Understanding each manufacturer's background reveals important differences that directly impact wheel performance and selection options.

KMC Wheels started as a modest family operation in 1982 and has grown into a globally recognized manufacturer over four decades. This Colorado-based American brand designs wheels domestically while utilizing international manufacturing facilities that meet stringent global industry standards. Rather than chasing every market trend, KMC built their reputation by focusing consistently on creating "well-made wheels".

The company targets "barrier-breaking, game-changing individuals who defy conventional thinking in motorsports". This philosophy attracts diverse customers, from weekend trail riders to professional off-road racers and celebrities. Their wheels have demonstrated exceptional durability in grueling competitions like the 2022 King of the Hammers challenge.

KMC offers an extensive catalog featuring approximately 60 different wheel styles across various diameters (15" to 26") and widths (7" to 10"). Their product range includes:

Cast and forged aluminum options for different strength requirements

Beadlock and non-beadlock designs for various terrains

Specialty models like the Bully OL and Canyon series

Method Race Wheels launched in 2010, founded by professional racers and engineers who brought a competition-focused philosophy to wheel design. Despite their shorter history compared to KMC, Method quickly earned recognition through advanced manufacturing techniques and meticulous attention to detail.

Racing DNA runs deep through Method's product development, most evident in their "Heritage Series" that honors iconic off-road racing vehicles. The company partners with elite drivers like Justin Lofton, Dan McMillin, and AJ Jones. These collaborations produce custom paint schemes that replicate vintage liveries from off-road legends while competing in the world's most demanding races.

Method's engineering philosophy remains unwavering: "We always prefer stronger over lighter. When a weight-reduction decision must be made, we keep the integrity of the structure". This commitment to durability over conventional weight-saving trends has made them the go-to choice among serious off-road enthusiasts who prioritize strength above all else.

Method Race Wheels currently operates under FOX Factory ownership, a premium manufacturer of specialty vehicle components. This strategic partnership combines Method's wheel engineering expertise with FOX's suspension technology, creating complete solutions for off-road applications.

KMC maintains its American brand identity with Colorado-based design teams, though production occurs in international facilities that meet rigorous quality standards. Both companies employ comprehensive testing protocols—KMC emphasizes innovative wheel technology across diverse applications, while Method focuses on real-world validation through professional racing teams who push equipment to absolute limits.

The engineering philosophies behind KMC and Method wheels create distinct performance characteristics that matter when you're pushing your vehicle through challenging terrain.

KMC wheels are built from cast aluminum alloy that delivers lightweight yet strong construction ideal for off-road conditions. Method wheels take a different approach, using solid A356 aluminum with T6 heat treatment. This premium A356-T6 aluminum provides superior yield strength, tensile strength, and fatigue resistance.

The T6 heat treatment process strengthens the aluminum's molecular structure through controlled heating and rapid cooling, creating wheels that maintain structural integrity even under extreme stress. Method specifically chose this material specification because it outperforms standard aluminum alloys for demanding off-road applications.

KMC's engineering approach emphasizes creating lightweight structures without compromising strength. Their cast aluminum construction reduces rotational mass while maintaining adequate durability for most off-road scenarios. This design philosophy results in wheels that enhance vehicle performance through weight reduction.

Method takes the opposite approach – their mantra of "stronger over lighter" means they add material where needed for maximum strength. While this increases weight slightly compared to competitors, Method wheels deliver exceptional durability when facing the most punishing terrain. Their thick spoke walls and reinforced mounting surfaces exemplify this commitment to structural integrity over aggressive weight reduction.

Load capacity reveals significant differences between these manufacturers. KMC wheels typically feature load ratings around 2,500 lbs per wheel, which proves adequate for most trucks, SUVs, and Jeeps used in recreational off-roading.

Method wheels offer considerably higher load capacities. Their standard offerings handle 2,650-3,640 lbs per wheel, with some HD (heavy-duty) models reaching up to 4,500 lbs. This substantial advantage matters most for overlanding rigs carrying heavy gear, armored vehicles, or any application where you're pushing maximum GVWR (gross vehicle weight rating).

Both manufacturers developed proprietary technologies for keeping tires secured during low-pressure off-road situations.

KMC offers traditional beadlock wheels that mechanically clamp the tire's outer bead with a removable ring and 16-24 bolts. This proven design allows extremely low tire pressures (sometimes under 5 psi) for maximum traction on rocks, sand, and mud. However, most beadlock wheels aren't street-legal in many jurisdictions.

Method's patented Bead Grip technology takes a different approach. Their wheels feature integrated grooves on both the inner and outer bead seats. These machined grooves increase the friction coefficient between tire and wheel, providing stronger bead retention without mechanical clamping devices. Bead Grip wheels remain fully DOT-compliant and street-legal while delivering near-beadlock performance down to approximately 10-15 psi.

KMC wheels come in multiple finish options including powder coated, painted, and polished variants. Their finish durability meets industry standards, though exposed finishes require regular maintenance to prevent corrosion from trail debris, moisture, and road chemicals.

Method wheels feature several finish options including satin black, matte bronze, and titanium. The company applies advanced coating techniques that provide exceptional corrosion resistance. Method backs their finish quality with a five-year warranty – significantly longer than most competitors. This confidence in their coating durability reflects the premium materials and application processes they employ.

Real-world testing reveals how these wheels perform when the trail gets demanding and conditions test both equipment and driver.

KMC wheels deliver predictable performance across diverse trail conditions. Their lightweight construction provides noticeable benefits in acceleration and maneuverability on technical sections. The reduced rotational mass helps suspension components react more quickly to terrain changes, improving wheel travel and maintaining better tire contact.

Method wheels trade some of that lightweight responsiveness for rock-solid durability. Their heavier construction absorbs impacts exceptionally well – a critical advantage when mistakes happen at speed. Multiple testers report that Method wheels simply refuse to bend or crack in situations that would damage lighter wheels. This confidence factor matters tremendously when you're miles from civilization on challenging terrain.

Both manufacturers subject their wheels to rigorous testing, but their approaches differ substantially.

KMC validates designs through extensive laboratory testing and real-world applications. Their wheels have proven themselves in professional competitions like King of the Hammers, where catastrophic wheel failure means race-ending consequences. These punishing events provide brutal validation that KMC's designs meet professional standards.

Method's testing philosophy emphasizes abuse beyond normal limits. They partner with professional racing teams who treat wheels as expendable test subjects, pushing them until failure occurs. This destructive testing reveals exactly where breaking points exist, allowing Method engineers to reinforce weak areas before production. The company also maintains an active presence in ultra-competitive racing series, gathering performance data from events that destroy lesser equipment.

Wheel weight directly impacts vehicle dynamics, fuel economy, and suspension performance. KMC's lightweight approach delivers approximately 2-4 lbs of weight savings per wheel compared to Method's equivalent sizes. Over four wheels, that's 8-16 lbs of unsprung weight reduction.

This weight difference produces measurable effects. Lighter wheels improve acceleration, reduce brake fade, and allow suspension to respond more precisely. Your vehicle will feel more agile with KMC wheels, especially noticeable in tight switchbacks or technical rock gardens requiring constant speed adjustments.

Method's additional weight provides benefits too. That extra mass helps maintain momentum through challenging sections, reducing the likelihood of getting stuck. The heavier construction also dampens high-frequency vibrations from rough terrain, potentially improving ride comfort on washboard roads.

Running low tire pressures (15-20 psi or lower) dramatically improves traction on rocks, sand, and mud by increasing the tire's contact patch. However, low pressures risk tire beads separating from wheel rims during aggressive cornering or side impacts.

KMC's beadlock wheels provide maximum bead security through mechanical clamping. Racers routinely run single-digit pressures with true beadlocks, knowing the tire physically cannot separate from the wheel regardless of side loads or impacts. The trade-off involves installation complexity (mounting requires careful torque sequencing of 16-24 bolts) and street-legal restrictions in many areas.

Method's Bead Grip technology offers an elegant compromise. The machined grooves create enough additional friction to prevent bead separation down to approximately 10-15 psi – adequate for most recreational off-roading while maintaining full DOT compliance. Serious rock crawlers who need single-digit pressures will still require traditional beadlocks, but the majority of trail riders find Bead Grip provides sufficient security with zero installation hassle.

Field reports consistently show Method wheels surviving impacts that damage competitive wheels. Their thick spoke sections and reinforced mounting areas distribute impact forces across larger surface areas, preventing stress concentrations that cause cracks.

KMC wheels demonstrate good durability for their weight class. They withstand typical trail hazards like embedded rocks, logs, and ruts without issue. However, their optimized weight means less material in critical areas – when you hit something truly substantial at speed, KMC wheels show damage more readily than Method's overbuilt construction.

Both manufacturers warranty their wheels against defects, but neither covers damage from impacts – that's considered normal wear in off-road applications. Your driving style matters tremendously here. Conservative drivers who avoid major impacts will find either brand perfectly adequate. Aggressive drivers who frequently test limits will appreciate Method's extra margin of safety.

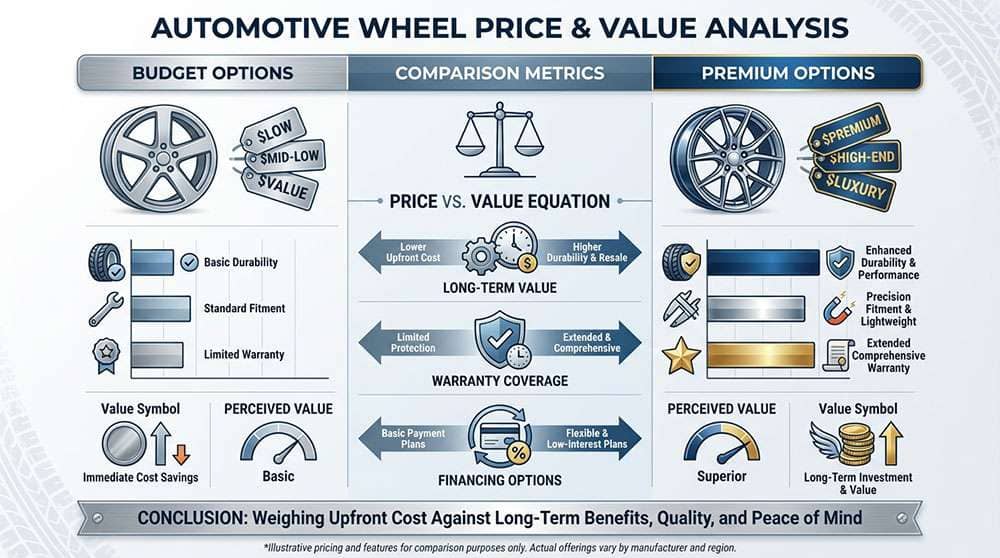

Understanding the financial commitment helps you balance your budget against performance requirements and long-term ownership costs.

KMC wheels position themselves in the mid-to-upper pricing tier for aftermarket off-road wheels. Their extensive catalog spans from affordable entry-level models to premium forged designs, giving buyers flexibility to match budget with requirements. Financing options typically start around $6.76 per week for a complete set, making premium wheels accessible through manageable payments.

Method wheels command premium pricing that reflects their advanced materials and construction methods. Financing generally begins around $8.85 per week, though some models can be found starting as low as $6.58 weekly depending on size and finish options. The higher price point positions Method as a premium choice for enthusiasts who prioritize maximum durability over cost considerations.

KMC's pricing delivers excellent value through extensive selection. With approximately 60 different wheel styles available, you'll find designs matching virtually any aesthetic preference. This variety extends beyond appearances – KMC offers cast wheels for budget-conscious buyers and forged options when weight reduction justifies additional investment.

Method's premium pricing includes benefits that justify the expense for serious users. Their A356-T6 aluminum construction costs more to produce but delivers measurably superior strength. The five-year finish warranty substantially exceeds industry standards, protecting your investment against corrosion and coating degradation. For overlanders or professional users who depend on equipment reliability, Method's higher upfront cost provides long-term value through reduced replacement frequency.

Both brands maintain strong resale values compared to budget wheel manufacturers. KMC's established reputation and widespread availability mean used wheels sell readily in secondary markets. Method wheels often command particularly strong resale prices because buyers recognize their durability advantages.

Consider total ownership costs beyond initial purchase price. Wheels damaged through trail use represent significant replacement expenses. Method's extra durability may prevent costly replacements that offset their higher purchase price. Conversely, KMC's lower initial investment leaves more budget for other vehicle modifications or trail equipment.

KMC provides lifetime structural warranties for original purchasers under normal use conditions. Their finish protection covers one year for chrome and painted aluminum wheels, extending to two years for PVD finishes. Method offers more extensive finish protection – five years from the purchase date. Both manufacturers exclude coverage for racing environments, improper maintenance, or installation with unauthorized adapters.

For current pricing and availability, check out https://www.performanceplustire.com/KMC_Wheels or https://www.performanceplustire.com/Method_Wheels to compare your options and find the best deals on the wheels you want.

Understanding the key specifications helps you make an informed choice between these two off-road wheel manufacturers. Here's a direct comparison of essential features:

| Feature | KMC Wheels | Method Wheels |

|---|---|---|

| Founded | 1982 | 2010 |

| Material Construction | Cast aluminum alloy | A356 aluminum with T6 heat treatment |

| Standard Load Rating | ~2,500 lbs per wheel | 2,650-3,640 lbs per wheel |

| Bead Technology | Bead Retention System with machined grooves | Patented Bead Grip technology with integrated grooves |

| Design Philosophy | Lightweight structure focus | "Stronger over lighter" approach |

| Available Sizes | 15" to 26" diameter, 7" to 10" width | Not specifically mentioned |

| Finish Options | Powder coated, painted, polished | Multiple finishes including bronze and titanium |

| Structural Warranty | Lifetime (original purchaser) | Not specifically mentioned |

| Finish Warranty | 1 year (chrome/painted), 2 years (PVD) | 5 years |

| Weekly Financing Starting At | $6.76/week | $8.85/week |

| Manufacturing Location | International facilities | Under FOX Factory ownership |

| Number of Wheel Styles | ~60 different styles | Not specifically mentioned |

The numbers tell a clear story. KMC offers more style variety and lower entry pricing, while Method delivers higher load ratings and longer finish warranties. Your choice depends on whether you prioritize selection and value or maximum strength and premium construction.

KMC and Method wheels both deliver exceptional off-road performance, but your choice depends on what matters most for your specific trail adventures. KMC wheels offer outstanding value with their lightweight construction and extensive style selection – perfect for enthusiasts who want proven performance at accessible prices. Method wheels command a premium for their superior material strength and load capacity – ideal when you need maximum durability for extreme terrain.

Consider KMC wheels if you prioritize variety and affordability. With 60+ different designs and financing starting around $6.76/week, they provide excellent performance for most off-road applications while giving you more options to customize your vehicle's appearance.

Choose Method wheels when durability and load capacity are non-negotiable. Their A356-T6 aluminum construction and higher load ratings make them the smart choice for heavy-duty applications, rock crawling, and serious trail punishment where wheel failure isn't an option.

Both manufacturers deliver the strength, performance, and style that serious off-roaders demand. We recommend examining both KMC Wheels and Method Wheels collections to see which better matches your vehicle and riding style.

At Performance Plus Tire, we understand that choosing the right wheels can transform your off-road experience. Whether you're building a weekend warrior or a trail-conquering machine, both KMC and Method wheels will serve you well when the adventure begins beyond the pavement.

When choosing between KMC and Method wheels for off-road adventures, understanding their core differences helps you make the right decision for your specific needs and budget.

• Material matters for durability: Method uses premium A356-T6 aluminum for superior strength, while KMC focuses on lightweight cast aluminum for balanced performance and affordability.

• Load capacity varies significantly: Method wheels handle 2,650-4,500 lbs per wheel compared to KMC's ~2,500 lbs, making Method better for heavy-duty applications.

• Budget-friendly vs premium positioning: KMC offers more accessible pricing starting at $6.76/week with 60+ style options, while Method commands $8.85/week for enhanced durability.

• Different approaches to tire retention: Method's patented Bead Grip technology provides near-beadlock performance while staying DOT-compliant, versus KMC's traditional beadlock systems.

• Warranty protection differs substantially: Method provides 5-year finish warranties compared to KMC's 1-2 year coverage, though KMC offers lifetime structural warranties.

Both brands deliver proven trail performance, so your choice should align with whether you prioritize maximum strength and premium features (Method) or lightweight versatility and value (KMC).

KMC wheels are made of cast aluminum alloy, while Method wheels use A356 aluminum with T6 heat treatment. Method's construction offers superior strength, while KMC focuses on a lightweight structure balancing performance and affordability.

KMC wheels typically have load ratings around 2500 lbs per wheel. Method wheels offer slightly higher capacities, with standard sizes handling 2650 lbs and some models reaching up to 3640 lbs or even 4500 lbs for heavy-duty versions.

KMC offers beadlock wheels with an outer ring that mechanically clamps the tire bead. Method uses patented Bead Grip technology, featuring integrated grooves on both inner and outer bead seats for stronger hold under extreme side loads.

KMC wheels are generally more affordable, with financing options starting around $6.76 per week for a set. Method wheels typically command higher prices, with financing beginning around $8.85 per week, though some models can be found for as low as $6.58 weekly.

KMC provides lifetime structural warranties for original purchasers under normal use, with 1-2 year finish protection. Method offers more generous finish protection, covering up to five years from the purchase date.