When it comes to selecting custom wheels, understanding the right specifications can make the difference between a perfect upgrade and a costly mistake. Your vehicle requires specific measurements that must be matched exactly for proper fitment and safety.

Understanding wheel dimensions becomes essential when shopping for new wheels. The bolt pattern - whether your vehicle uses 4, 5, 6, or 8 lugs - must match precisely. Get this wrong, and your new wheels simply won't fit.

Wheel diameter affects more than just appearance. Most passenger cars use 16-19 inch wheels, while trucks and SUVs typically run 17-20 inch wheels. The size you choose directly impacts how your vehicle handles on the road.

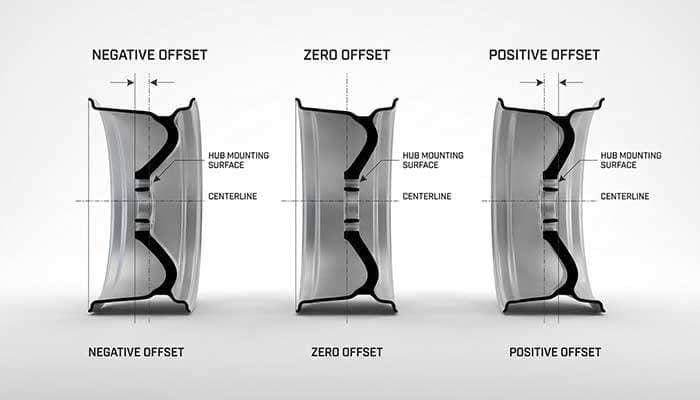

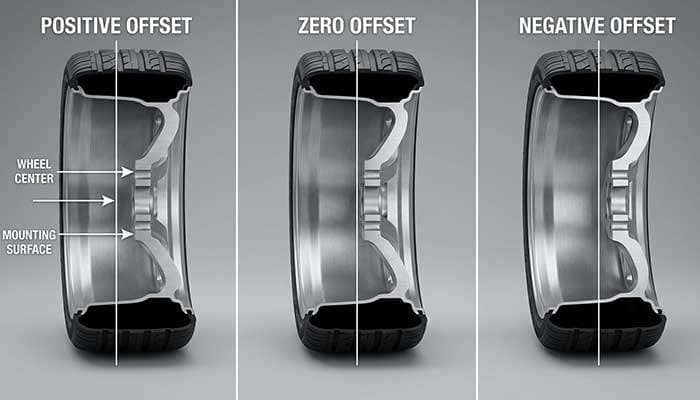

Wheel offset determines how your wheels sit in relation to your vehicle's fenders. This measurement controls whether wheels tuck under the fender or extend outward. Incorrect offset can cause wheels to stick out up to 3 inches beyond your fender line, creating safety concerns and potential legal issues.

Larger wheels can improve handling and give your vehicle more aggressive styling. They allow for bigger tires with better road contact, which means improved grip and maneuverability. However, bigger isn't always better - larger wheels typically cost more to replace and can affect ride comfort.

At Performance Plus Tire, we help customers choose wheels that deliver both the look they want and the performance they need. The key specifications we'll cover - from bolt patterns to offset measurements - ensure your new wheels fit properly and perform safely. Getting these measurements right the first time saves you money and gives you confidence in your wheel selection.

Wheel specifications aren't just numbers on paper - they determine how your vehicle performs, handles, and even how safe you'll be on the road. Performance engineers spend years developing the exact wheel specifications for each vehicle because these measurements directly control your driving experience.

Larger wheels allow for bigger brake systems, which can improve stopping power and response time. The size and weight of your wheels affect everything from acceleration to fuel consumption. When you increase wheel diameter, you raise the vehicle's center of gravity, which increases body roll during cornering. However, properly sized larger wheels can actually improve stability and reduce braking distances.

Weight makes a significant difference in performance. Lightweight wheels reduce unsprung mass, allowing for quicker acceleration and more responsive handling while improving fuel economy and reducing wear on suspension parts.

Get the specifications wrong, and you're looking at potentially expensive damage. Tires that are too wide can rub against struts, springs, and other components, causing suspension damage and making your vehicle difficult to drive. Mismatched wheel widths create tire profile problems - wheels too narrow for the tire can cause bead separation during hard cornering, while wheels too wide cause premature tire wear.

Incorrect offset creates uneven tire wear and changes your suspension geometry. This puts extra strain on steering components and accelerates wear on wheel bearings, leading to costly repairs.

Larger wheels give your vehicle an aggressive, commanding appearance, but style must be balanced with practicality. Bigger wheels typically mean thinner tire sidewalls, which are more vulnerable to damage from potholes and rough roads.

Ride comfort is another consideration. Larger wheels with low-profile tires create a harsher ride because there's less sidewall cushioning. Smaller wheels with higher-profile tires provide better comfort and cushioning for daily driving.

Understanding these trade-offs helps you choose wheels that deliver both the performance and appearance you want.

Understanding wheel dimensions is essential for proper wheel selection. These measurements determine whether your new wheels will fit correctly and perform safely on your vehicle.

Rim diameter measures the distance across the wheel from bead seat to bead seat, where the tire makes contact. This measurement is expressed in inches - 16", 17", 18", and so on. The diameter must match your tire size exactly. You cannot mount a 17" tire on a 16" wheel.

Rim width measures the distance between the inner bead seats, not the outer edges of the wheel. Most custom wheels range from 6" to 14" in width. The width you choose affects your tire's contact patch with the road. Wider wheels allow for wider tires, which can improve handling and give your vehicle a more aggressive stance.

Wheel offset measures the distance between the wheel's mounting surface and its centerline, expressed in millimeters. This measurement can be positive, negative, or zero. Positive offset means the mounting surface is closer to the outside of the wheel. Negative offset places the mounting surface toward the inside.

Backspacing measures from the mounting surface to the inner edge of the wheel, typically in inches. Correct offset prevents wheels from rubbing against brake calipers, fenders, or suspension components. It also determines your wheel stance - whether wheels tuck under the fenders or extend outward.

The bolt pattern uses two numbers: the number of bolt holes and the diameter of the circle they form. A "5x114.3" pattern means five lugs arranged on a 114.3mm diameter circle. For wheels with 4, 6, or 8 lugs, measure from the center of one hole straight across to the center of the opposite hole.

The center bore is the large hole in the wheel's center that fits over your vehicle's hub. This measurement is critical because different manufacturers use different center bores even with identical bolt patterns. If the center bore is too small, the wheel won't fit. If it's too large, you'll need hub-centric rings for proper centering.

The load index appears as a number in your tire's service description and indicates maximum weight capacity. Load index 94 means each tire can carry 1,477 pounds at maximum air pressure. Never choose wheels with a lower load rating than your original equipment.

The speed rating uses letters to show maximum safe speed capability. A "Y" rating indicates the tire can safely maintain speeds up to 186 mph. When selecting new wheels, always match or exceed your original load index and speed rating to maintain safety standards.

Checking wheel compatibility starts with knowing what's currently on your vehicle. Getting this step right prevents costly mistakes and ensures your new wheels perform safely.

Your tire sidewall contains all the information you need. Look for a code like "P215/65R15" - the "P" means passenger vehicle tires, "215" is the width in millimeters, "65" represents the aspect ratio (sidewall height as percentage of width), and "15" is your wheel diameter in inches. Truck tires show "LT" while trailer tires display "ST".

The load index and speed rating appear at the end of this code. These numbers and letters tell you the maximum weight each tire can carry and the highest safe speed. When upgrading wheels, you must match or exceed these ratings to maintain safety standards.

At Performance Plus Tire, we have the most advanced and comprehensive custom wheel fitment search engine in the world. Online calculators take the guesswork out of wheel upgrades by showing exactly how changes will affect your vehicle.

These tools let you input your current specs and desired measurements to spot potential problems before you buy. Many retailers offer visualizers that show how specific wheels will look on your exact vehicle. The best calculators also check clearance measurements to prevent rubbing issues.

Even experienced enthusiasts make these critical errors:

Forgetting about brake caliper clearance, especially on performance vehicles

Skipping wheel alignment after installation

Choosing wheels with insufficient load ratings for your vehicle's weight

Overlooking hub-centric fitment requirements

Selecting wrong backspacing or offset that causes rubbing against fenders or suspension components

We help customers avoid these problems by providing accurate fitment information and expert guidance. Our team ensures your new wheels fit perfectly and perform safely on your specific vehicle.

Selecting the right wheels depends on how you actually drive your vehicle. Your choice of material and size affects both performance and your wallet.

For daily commuting, lightweight alloy wheels offer better heat dissipation and improved braking performance. They provide the best balance of performance and comfort for regular street driving.

Off-road enthusiasts need different priorities. Steel wheels resist damage and bending better than alloy wheels, making them excellent for rough terrain adventures. When you're hitting rocks and uneven surfaces, durability beats looks every time.

Performance drivers should consider forged wheels for their superior strength-to-weight ratio, which enhances speed and handling. The investment pays off in better acceleration and cornering response.

For off-road applications, 17-inch wheels represent the ideal size, striking the perfect balance between clearance and tire compatibility. This size allows for larger tire sidewalls that absorb impacts from rocks and uneven surfaces.

Wheel prices vary significantly by material and construction. Steel wheels typically cost $50-$200 per wheel ($200-$800 per set). Standard aluminum wheels range from $125-$500 each ($500-$2000 for a set). Premium forged wheels start around $645 each but can exceed $2,500 per wheel for custom designs.

We believe in helping customers find wheels that fit their budget without sacrificing quality or safety. Higher-priced wheels often provide better performance and durability, but you can find excellent options at every price point.

Plus-sizing (increasing wheel diameter) provides better cornering grip but may sacrifice ride comfort. Plus-one sizing offers the greatest overall performance benefit. Staggered setups (wider rear wheels) improve rear traction and reduce understeer, particularly beneficial for rear-wheel drive vehicles.

These modifications work best for performance-oriented driving where handling improvement outweighs comfort considerations.

Ready to Find your next set of wheels that perfectly match your driving style and budget?

Getting wheel specifications right protects your vehicle and your investment. The measurements we've covered - bolt pattern, offset, diameter, and load ratings - determine whether your new wheels fit safely and perform properly. Skip these details, and you risk expensive damage to suspension components, uneven tire wear, and poor handling.

We believe in helping customers make smart wheel choices. The right specifications deliver better braking performance, improved handling, and the aggressive styling you want. Wrong specifications create problems that cost far more than taking time to measure correctly from the start.

Steel wheels offer durability for off-road adventures. Alloy wheels provide the best balance of weight and strength for daily driving. Forged wheels deliver maximum performance for enthusiasts who demand the best. Each material serves different needs and budgets.

Before you buy, check your current setup and use online fitment tools to verify compatibility. Match your vehicle's bolt pattern exactly. Choose wheels with proper load ratings. Verify offset measurements to prevent rubbing or clearance issues.

At Performance Plus Tire, we have the expertise to guide you through wheel selection. Our fitment guarantee ensures the wheels you choose will work perfectly with your vehicle. Whether you're upgrading for style, performance, or off-road capability, we help you find wheels that deliver exactly what you need.

Ready to upgrade your ride? Visit Performance Plus Tire today for expert guidance and the best selection of custom wheels at unbeatable prices.

Understanding wheel specifications is crucial for vehicle safety, performance, and avoiding costly damage to your suspension and steering components.

• Match critical dimensions exactly: Bolt pattern, center bore, and load index must match your vehicle's specifications to prevent damage and ensure safety.

• Offset determines wheel positioning: Incorrect offset causes rubbing, uneven tire wear, and altered suspension geometry that strains steering components.

• Balance size with practicality: Larger wheels improve handling but reduce ride comfort, increase replacement costs, and make tires more vulnerable to damage.

• Use fitment tools before buying: Online calculators and visualizers help identify clearance issues and prevent expensive compatibility mistakes.

• Choose wheels based on driving needs: Daily drivers need comfort-focused alloys, off-roaders benefit from durable steel wheels, and performance enthusiasts should consider lightweight forged options.

Getting wheel specifications right the first time saves money, protects your vehicle, and ensures optimal performance for your specific driving style and needs.

The most critical specifications are bolt pattern, rim width and diameter, offset, center bore, and load index. These must match or be compatible with your vehicle to ensure proper fitment, safety, and performance.

Wheel offset determines how far in or out the wheel sits from the suspension. Incorrect offset can cause rubbing, uneven tire wear, and altered suspension geometry. It's best to stay close to the factory offset to maintain proper handling and steering characteristics.

If the wheel's center bore is larger than your vehicle's hub, you can use hub-centric rings to ensure proper centering. However, if it's smaller, the wheel won't fit unless professionally machined, which is often not cost-effective.

Start by checking your vehicle's current wheel and tire specifications. Generally, you can safely go up or down one inch in wheel diameter. Consider your driving needs, desired tire profile, and ensure the new size doesn't interfere with brakes or suspension components.

Quality aftermarket wheels from reputable manufacturers can offer benefits like reduced weight, increased strength, and improved esthetics. However, they may be more expensive than OEM wheels. The best choice depends on your specific needs, budget, and vehicle application.