Understanding the rim is essential when selecting wheels for your vehicle. A rim is the outer circular edge of a wheel that holds the tire securely in place. Many vehicle owners mistakenly believe the rim represents the entire wheel assembly, but it actually forms just one critical component of the complete system. The rim creates the mounting surface where your tire attaches to the vehicle.

When examining a rim's cross-section, you'll notice its distinctive U-shaped design with a deeper center than the edges. This specific structure supports the tire bead and ensures proper fitment for optimal performance. The rim establishes precise mounting points that keep your tire firmly positioned during operation while forming a secure seal with the tire bead to prevent air leakage.

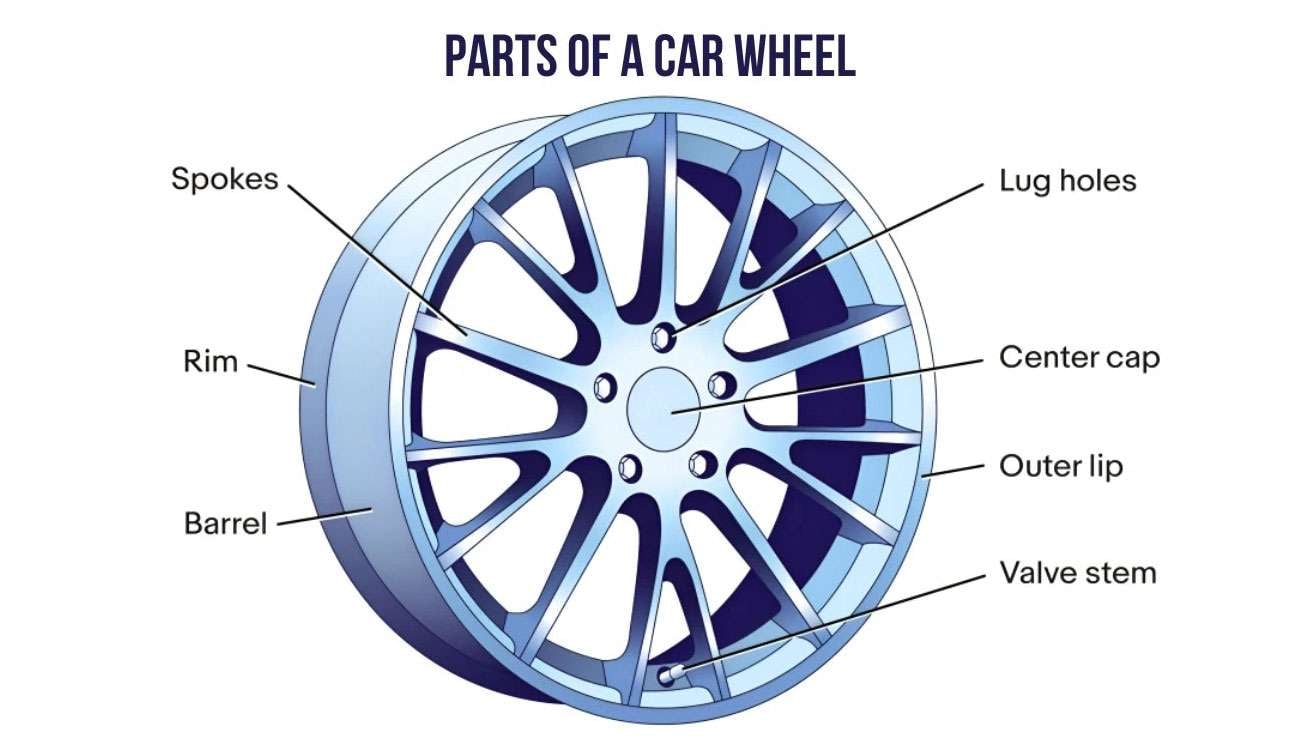

Every rim includes several essential components that work together for safe operation:

Flanges - Flared edges along both sides that prevent the tire from slipping off during driving

Bead Rests - Designated areas where the tire's beads sit securely on the wheel

Mounting Humps - Small ridges that prevent tire beads from slipping and maintain proper position

Drop Center - The narrowest section of the barrel that allows tire mounting without overstretching

Valve Stem Hole - Opening that houses the valve for inflation and pressure monitoring

Rim construction typically uses metal materials that match the wheel's composition. Steel and aluminum represent the most common choices, with premium rims featuring Teflon coverings for enhanced protection against road debris and corrosion. Standard automotive steel rims begin production with rectangular sheet metal bent into a cylindrical sleeve, followed by welding and precise shaping to meet strict safety standards.

Car enthusiasts and professionals frequently use "rim" and "wheel" interchangeably, though this creates technical confusion. The rim specifically describes the outer portion where the tire mounts, similar to how a coffee cup's rim refers only to its edge rather than the entire container. This terminology mix-up persists because modern manufacturing often casts or stamps the rim and wheel as a single metal piece instead of separate components found in traditional wire wheels.

The rim's primary job is supporting and sealing the tire to the wheel assembly, maintaining air pressure inside tubeless tires through proper fitment. Beyond this critical function, the rim contributes significantly to your wheel's structural integrity and overall vehicle performance.

Image Source: https://pixabay.com/

Understanding rim anatomy helps you make better decisions when selecting wheels for your vehicle. Each component serves a specific purpose in supporting tire performance and vehicle safety.

The cylindrical exterior structure, known as the barrel, gives the wheel its characteristic shape and provides the foundation for tire mounting. This barrel houses several critical components that work together to secure your tires.

The outer lip measures from the wheel face to the outboard edge. A deeper outer lip creates a more aggressive appearance but increases vulnerability to curb damage since the spokes provide less protection from impacts. Three-piece wheels feature separate outer lips, allowing for custom width configurations.

Flanges create flared edges along both sides of the rim that prevent tire slippage during operation. These raised edges work with bead rests to create secure mounting areas where tire beads sit firmly against the wheel. Mechanics recommend cleaning bead rest surfaces before tire installation to ensure proper sealing.

Mounting humps form small ridges inside each bead rest area. These ridges prevent tire beads from slipping inward and maintain proper positioning against the wheel. The drop center creates the narrowest section of the barrel, allowing easier tire installation without overstretching the bead wires.

The valve stem hole accommodates the air valve for inflation and pressure monitoring. Spokes connect the outer rim to the center disk (also called the plate), which contains lug holes for axle mounting. The center bore represents the wheel's center opening, typically covered by a decorative cap featuring the manufacturer's logo.

The wheel safety bead creates a raised lip approximately one inch inside the rim's outer edge. Combined with proper air pressure, this feature prevents tire beads from slipping inward during operation. Safety bead designs vary across wheel models, with some offering superior protection against bead separation.

Rim width significantly impacts vehicle handling characteristics. Wider rims provide greater stability through increased track width and better flotation in soft terrain. Narrower rims offer advantages for off-road applications by providing better tire bead protection when running lower air pressures.

Rim materials directly affect performance and durability. Steel construction offers maximum durability at lower cost, making it popular for work trucks and winter wheels. Aluminum provides lightweight benefits that improve acceleration and fuel economy while offering better heat dissipation.

Specialized applications utilize magnesium alloys for racing applications where weight reduction is critical. Carbon fiber options exist but remain limited due to brittleness concerns despite excellent strength-to-weight characteristics. Some premium rims incorporate protective coatings that resist road debris and corrosion damage.

Material selection impacts more than just appearance. Lighter rim materials reduce rotational mass, improving vehicle responsiveness and reducing strain on suspension components. Proper material choice ensures your wheels perform reliably under your specific driving conditions.

Rim dimensions and materials create significant impacts on how your vehicle handles, rides, and performs. When selecting aftermarket rims, understanding these performance trade-offs helps you make the right choice for your driving needs.

Rim size fundamentally changes your vehicle's personality on the road. Larger diameter rims with low-profile tires deliver sharper handling by reducing sidewall flex during cornering. This setup increases road contact and provides more responsive steering inputs. Performance drivers often choose larger rims specifically for the improved high-speed stability and precise cornering they provide.

The trade-off comes in ride comfort. Larger rims with thinner tires transmit more road vibration directly to the cabin, creating a harsher, noisier driving experience. Less rubber means less cushioning - you'll feel every bump and road imperfection. Smaller wheels with taller sidewalls offer the opposite: superior bump absorption and quieter operation.

Proper rim selection directly impacts your safety on the road. Correctly sized rims accommodate larger brake systems, potentially improving your stopping power and brake responsiveness. Wider rims increase the tire's contact patch with the road, enhancing both traction and load-bearing capacity.

Incorrect rim sizing creates serious safety risks. Changing the wheel offset affects how far your tires extend from the vehicle, which can disrupt steering geometry and cause irregular tire wear that may lead to dangerous blowouts. Any rim modifications must maintain proper clearance within the wheel wells to prevent rubbing against fenders or suspension components.

Rim weight significantly affects your fuel costs. Heavier rims increase rotational mass, forcing your engine to work harder during acceleration and maintaining speed. Research shows that larger, heavier wheels can reduce fuel economy by 4-10% compared to stock wheels. This efficiency loss occurs because wider tires create more rolling resistance while heavier wheels increase the engine's workload.

Lightweight alloy rims offer the opposite benefit. Independent studies indicate alloy rims can improve fuel efficiency by 2-5%. This improvement comes from reduced rotational mass, decreasing the energy needed for acceleration. Alloy materials also dissipate heat more efficiently than steel, potentially enhancing brake performance while maintaining fuel economy benefits.

The key is finding the right balance between performance gains and efficiency losses based on your driving priorities and budget.

Rim development stretches back thousands of years, long before the first automobile rolled off a production line. Ancient civilizations discovered that strengthening primitive wheels required better edge construction, laying the groundwork for every custom wheel we see today.

Celtic metalworkers around 1000 B.C. pioneered iron rim technology by wrapping metal bands around wooden wheels, dramatically improving durability on rough terrain. This fundamental innovation—metal reinforcing wood—influenced wheel design for millennia. Blacksmiths heated iron strips, wrapped them around wooden wheels, then cooled them to create tight fits that prevented warping and splitting.

Early automobiles borrowed directly from carriage and bicycle technology. The first motor vehicles featured wooden-spoked wheels with steel rims mounted to central axles. Ford's Model T exemplified this approach, using wooden artillery wheels until 1926-1927, when the company switched to welded steel spoke wheels. These early vehicles needed constant maintenance. Period photographs show cars in shallow rivers not for cleaning, but because drivers had to soak wooden wheels that had shrunk in dry weather.

Bicycle manufacturer Thomas B. Jeffery created a pivotal advancement with his 1882 patent that changed rim design forever. Jeffery developed a tire with wire embedded in the rubber that could be tightened onto the rim, becoming the foundation for all modern clincher tires. This innovation provided much more secure tire mounting than previous designs.

The evolution accelerated with 1934's introduction of drop-center steel rims, featuring a middle section lower than the edges. This design made tire mounting significantly easier and became the industry standard. Modern clincher tires use wires embedded in both beads that fit inside rim edges, creating the secure seal we rely on today.

Lightweight alloy wheels appeared much earlier than most enthusiasts realize. The legendary Bugatti Type 35 featured aluminum wheels in 1924, taking advantage of aluminum's superior heat dissipation properties. Hybrid designs emerged between 1955-1958, with Cadillac offering wheels featuring aluminum spokes riveted to steel rims.

Racing applications drove rapid rim technology advancement throughout the 1950s-1960s. Magnesium-aluminum alloy wheels became racing staples before transitioning to high-performance road cars. Ford introduced cast aluminum wheels with chromed rims for the Mustang GT350 in 1965, followed by one-piece cast-aluminum ten-spoke wheels in 1966. Today's modern rims combine advanced materials and manufacturing techniques that deliver both durability and style for every type of vehicle.

Car enthusiasts and industry professionals frequently mix up "rims" and "wheels" in everyday conversation. While this confusion is understandable, understanding the technical difference helps when shopping for aftermarket options or discussing modifications with mechanics.

The rim is specifically the outer circular edge of the wheel where the tire mounts. This U-shaped component forms the mounting surface that secures the tire to the wheel assembly. The rim creates the airtight seal necessary for tubeless tire operation while providing the structural support needed during vehicle operation.

Most rims feature protective coatings like Teflon to resist road debris and corrosion. The rim's primary job is maintaining proper tire fitment and preventing air leakage from the tire-wheel interface.

A wheel encompasses the complete metal assembly that bolts to your vehicle's axle. This includes the rim plus several other components: the center disk (or hub), spokes, lug holes, valve stem opening, and often a center cap bearing the manufacturer's logo.

The wheel serves as the foundation that connects your tire to the vehicle. Spokes transfer loads between the rim and the central mounting area, while lug holes provide the secure attachment points to the axle hub.

The terminology confusion stems largely from automotive culture. Car enthusiasts commonly say "I need new rims" when referring to complete wheel replacements. This usage became popular through marketing, music, and media coverage of custom wheels.

Modern manufacturing also contributes to the confusion. Today's wheels are typically cast or forged as single units, making the rim and other components inseparable. This contrasts with older wire wheels where the rim was a distinct piece attached to separate spokes.

Regional preferences add another layer of complexity. Some areas favor "rims" while others prefer "wheels" for the same aftermarket products. At Performance Plus Tire, we understand both terms refer to the complete wheel assembly in most customer conversations, even though technically the rim is just one component of the whole wheel.

Understanding rim terminology and functionality helps car enthusiasts make informed decisions about wheel modifications and maintenance.

• Rims are just the outer edge: The rim is only the circular outer portion where tires mount, not the entire wheel assembly that includes spokes, hub, and center disk.

• Performance trade-offs matter: Larger rims improve handling and cornering but reduce ride comfort and fuel efficiency by 4-10% due to increased weight and road vibration.

• Safety depends on proper sizing: Incorrect rim dimensions can disrupt steering geometry, cause tire wear, and create dangerous clearance issues with suspension components.

• Material choice affects efficiency: Lightweight alloy rims can improve fuel economy by 2-5% compared to heavier steel options while providing better heat dissipation.

• Terminology confusion is common: Car enthusiasts often use "rims" and "wheels" interchangeably, though technically incorrect, this cultural usage has become widely accepted in automotive circles.

The distinction between rims and wheels may seem technical, but understanding these components helps drivers make better choices for their vehicle's performance, safety, and efficiency needs.

While often used interchangeably, rims are technically just the outer edge of the wheel where the tire mounts. The wheel refers to the entire metal structure, including the rim, spokes, and center disk.

The term "rims" has become popular in car culture, especially when referring to aftermarket or custom wheels. This usage has spread through media, music, and marketing, though it's not technically correct.

Rim size and material can significantly impact handling, ride comfort, and fuel efficiency. Larger rims generally improve cornering but may reduce ride comfort, while lighter materials like alloys can enhance fuel economy and acceleration.

It's possible to change rim sizes, but it's crucial to maintain the overall wheel diameter by adjusting tire size accordingly. Improper sizing can affect speedometer accuracy, handling, and clearance.

Common rim materials include steel, aluminum alloy, and in high-performance applications, magnesium alloy. Each material offers different benefits in terms of weight, strength, and cost.