Wheel weights are small metallic or composite devices that attach to your vehicle's wheel rims to counterbalance irregularities in the tire-wheel assembly. These components correct imbalances caused by manufacturing variations in both tires and wheels, ensuring smooth rotation by offsetting centrifugal force.

You'll typically see wheel weights as small rectangular or curved metallic pieces positioned on either the inner or outer surface of a wheel's rim. Most feature protective coatings like zinc or lead-free plastic to resist corrosion from environmental elements. The weight ranges from 0.25 to 2.1 ounces, with the exact amount determined by the specific imbalance detected during the balancing process.

Manufacturers use several materials for wheel weights, including steel, lead, and zinc alloys. Some specialized versions incorporate aluminum in their composition. According to U.S. Patent US20040007912A1, certain zinc weights can contain up to 27% aluminum as part of a specialized zinc alloy. Pure zinc weights are rare, with most utilizing specially formulated zinc alloys instead.

The science behind wheel weights involves basic physics principles. Since tires and hubs can't achieve perfectly uniform mass distribution during manufacturing, uneven mass creates centrifugal force when wheels rotate. This force follows a formula where mass, rotation radius, and angular velocity determine the resulting vibration. Wheel weights counteract this force by adding precisely calculated mass at specific wheel positions.

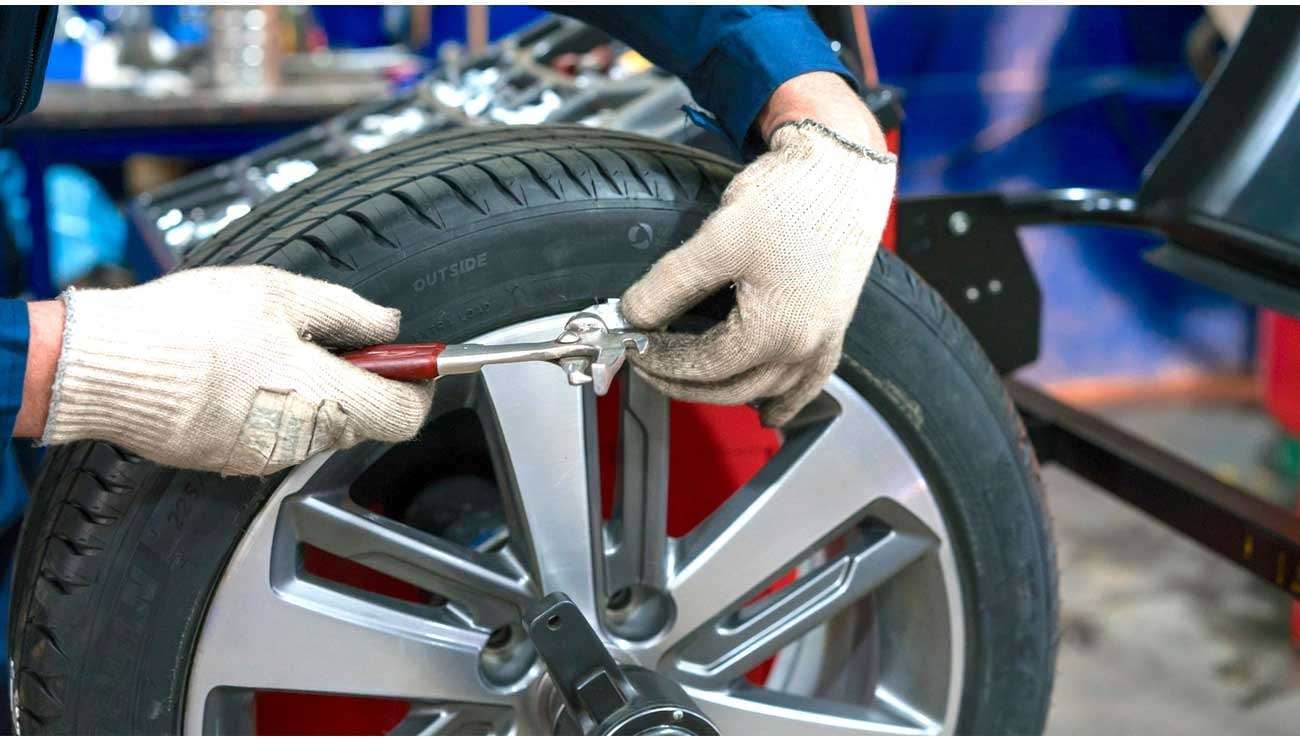

Two primary types dominate the market. Clip-on weights (also called hammer-on weights) use a clamp-like design that securely attaches to the rim. These work best on steel wheels and can be installed or removed without damaging the wheel finish. Adhesive wheel weights feature strong adhesive backing and are designed for aluminum alloy or composite wheels. These adhesive variants typically use lead or steel construction and come in both standard and low-profile designs.

Wheel weight technology has evolved over nearly a century, with the original clip-on weight first patented in the early 1930s. Adhesive wheel weights appeared in the early 1970s, providing a new balancing method for aluminum rims. This innovation particularly helped vehicles where appearance mattered, allowing weights to be hidden behind wheel spokes.

Despite their small size, wheel weights significantly impact vehicle performance, safety, and component longevity. Without proper wheel balancing from these weights, vehicles experience disturbing vibrations that compromise comfort, create safety risks, and dramatically reduce the lifespan of various vehicle components.

Wheel weights serve a crucial function by counterbalancing irregularities in tire-wheel assemblies, eliminating the vibrations and wobbling that would otherwise make your vehicle uncomfortable and unsafe to drive. These small components add precisely calculated mass at specific wheel positions to offset centrifugal force generated by uneven mass distribution during tire and wheel manufacturing. The physics behind this process involves counteracting force based on mass, rotation radius, and angular velocity that determine resulting vibrations.

Properly balanced wheels deliver immediate performance improvements. You'll notice reduced steering wheel vibration, less road noise, and prevention of premature suspension and tire wear. More importantly, wheel weights enhance driving stability by eliminating wobbling, which dramatically improves traction at higher speeds. This stability makes your vehicle safer and reduces accident risk from imbalanced wheels.

The rotational mass principle creates the most significant impact on vehicle performance. A single pound of rotating wheel weight affects acceleration equivalent to 5-10 pounds of static vehicle weight. Wheel weights optimize this rotational inertia by ensuring balanced weight distribution throughout the wheel assembly.

Real-world testing demonstrates impressive results from proper wheel balancing. Reducing wheel weight by just 12 pounds per wheel improved a vehicle's 0-60 time by 0.29 seconds. Additionally, fuel efficiency can improve by up to 8% with properly balanced wheels - testing showed stock wheels averaged 22.8 mpg compared to 21.1 mpg with heavyweight wheels.

Balanced wheels also improve suspension response. The suspension system can react more effectively to bumps and road imperfections, maintaining consistent tire contact with the road surface. This leads to better handling and maneuverability, particularly when cornering or driving at high speeds.

For daily driving, the benefits include:

Smoother ride comfort with eliminated vibrations

Extended tire lifespan through even wear patterns

Better fuel efficiency from reduced resistance

Less stress on suspension components

Enhanced vehicle control and safety

Whether you drive a passenger car, heavy-duty truck, or high-performance sports car, the right wheel weights improve vehicle performance, safety, and component longevity. The specific weight requirements depend on wheel type (alloy versus steel), tire type (low-profile or standard), and your driving conditions.

Wheel weights become particularly critical at high speeds. At 150 mph, wheels revolve approximately 33 times per second, amplifying any imbalance effects. Professional racing teams invest heavily in minimizing wheel weight while maintaining structural integrity because performance advantages become increasingly significant as speed increases.

When it comes to selecting wheel weights, understanding the different types available is essential for achieving the perfect balance on your vehicle. We offer a comprehensive selection of wheel weights designed for specific applications, with each type engineered to meet particular performance requirements.

The wheel weight market breaks down into two primary categories based on attachment method, with various materials available to suit different vehicle needs and preferences.

Clip-on weights (also called hammer-on weights) remain the traditional choice for steel wheels. These weights feature a spring steel clip that grips the rim flange securely. The design allows for quick installation and removal without special tools - just position the weight and tap it into place with a hammer. Clip-on weights come in different profiles to match various rim flange configurations, including standard, reverse flange, and import styles.

Adhesive wheel weights have become increasingly popular, particularly for aluminum alloy wheels where clip-on weights could damage the finish. These stick-on weights feature industrial-strength adhesive backing that bonds directly to the rim's inner surface. The adhesive formulation maintains grip across temperature extremes from -40°F to 250°F. Low-profile designs help adhesive weights remain hidden behind wheel spokes, preserving your vehicle's appearance.

Steel weights have largely replaced lead in many applications due to environmental regulations. Coated steel weights resist corrosion while providing reliable balancing performance. Zinc alloy weights offer another lead-free alternative with excellent corrosion resistance and recyclability. Some premium applications still use lead weights where regulations permit, as lead's density allows for smaller weight sizes. Chrome-plated options are available for visible installations where appearance matters.

Proper installation of wheel weights is crucial for achieving optimal balance and ensuring they remain securely attached throughout your vehicle's operation. Here's what you need to know about installing both types of wheel weights effectively.

Installing clip-on weights begins with using a wheel balancer to determine imbalance in both planes. Position the weight on the rim lip, ensuring it sits securely against the edge. Use a hammer to tap the weight's central section several times, crushing the center slightly to create a tight grip on the wheel. This secure attachment prevents loosening during vehicle operation. Position weights at the 12 o'clock mark unless your balancing machine indicates otherwise.

Adhesive weights need careful application for long-term durability. Begin by rotating the tire to determine imbalance in both planes. Once the balancer identifies the exact position needed, clean the application area thoroughly. Remove the protective backing without touching the adhesive surface. Apply the weight to the rim, pressing firmly from center outward toward the edges. Maintain consistent pressure for about 20 seconds—extend this time in cooler conditions. The adhesive develops 80-90% of its force within 24 hours, reaching full adhesion after 72 hours.

Clean surfaces are essential for adhesive weight performance. Start with a water-based cleaner like Formula 409 to remove grease and dirt. Follow up with isopropyl alcohol to ensure complete surface cleanliness. Avoid petroleum-based cleaners such as brake cleaner or engine degreasers, as they leave residue that prevents proper adhesion. For stubborn contaminants, use specialized tools like 3M Scotch-Brite pads to loosen difficult dirt. After cleaning, wipe the surface with a clean, soft cloth before applying the weight.

Temperature plays a crucial role in adhesive weight performance. Install weights within the optimal range of 50°F to 125°F (10°C to 52°C). Keep weight, rim, and ambient temperature at 60°F (15°C) minimum for best adhesive performance. Allow extra time for cleaning solvents to evaporate completely in colder conditions. Higher temperatures improve adhesion, while lower temperatures reduce it. Understanding temperature effects ensures wheel weights maintain their position throughout their service life.

When wheel weights fall off, your vehicle immediately starts telling you there's a problem. Missing these small but crucial components creates a cascade of issues that affect everything from your daily comfort to your wallet.

Missing wheel weights cause unmistakable vibrations that you'll feel right away. At speeds between 50-70 mph, steering wheel shaking typically signals front wheel imbalance. Rear wheel problems show up differently - you'll feel vibrations through the seat and floor. Your wheel literally bounces down the road instead of spinning smoothly, making every drive uncomfortable. These vibrations get worse as speed increases, with effects intensifying above 100 km/h.

Imbalanced wheels create irregular wear patterns including bald spots and cupped edges. This happens because your tire can't maintain even contact with the road. The result? Dramatically shortened tread life that can cost hundreds of dollars in premature tire replacements. We see this problem frequently - customers who ignore wheel balance issues often need new tires months earlier than necessary.

Missing wheel weights increase rolling resistance as your tires struggle to rotate evenly. This forces your engine to work harder, burning more fuel with every mile. Testing consistently shows that properly balanced wheels deliver better fuel economy compared to imbalanced setups. With today's fuel prices, this added cost adds up quickly.

Extended driving without proper wheel weights sends constant shockwaves through your suspension system. This stress loosens tie rods, wears out shocks and struts, and causes premature failure of ball joints and bearings. Wheel hub bearings deteriorate faster, and shock absorbers may develop oil leaks. What starts as a simple wheel weight replacement can turn into expensive suspension repairs.

Get your wheels rebalanced immediately after:

Installing new tires or repairing existing ones

Experiencing steering wheel vibrations

Noticing uneven tire wear patterns

Every 5,000-7,500 miles as preventative maintenance

Following impacts with potholes or curbs

When switching between seasonal tires

At Performance Plus Tire, we recommend addressing wheel balance issues promptly. The cost of professional rebalancing is minimal compared to the expensive problems that develop when you wait. Our experienced technicians can quickly identify imbalance issues and restore smooth operation to your vehicle.

Understanding wheel weights is essential for vehicle safety, performance, and cost savings. These small but critical components prevent major problems and optimize your driving experience.

Wheel weights counterbalance tire-wheel irregularities, eliminating vibrations and ensuring smooth rotation at all speeds

Two main types exist: clip-on weights for steel wheels and adhesive weights for aluminum rims, each requiring specific installation techniques

Missing wheel weights cause steering vibrations, uneven tire wear, reduced fuel efficiency, and expensive suspension damage

Proper installation requires clean surfaces and correct temperature (50-125°F) for adhesive weights to maintain long-term performance

Regular rebalancing every 5,000-7,500 miles prevents costly repairs and can improve fuel economy by up to 8%

When wheel weights fall off, the consequences extend far beyond simple discomfort. The resulting imbalance creates a cascade of problems that can cost hundreds in premature tire replacement and suspension repairs. Investing in proper wheel balancing and maintenance saves money while ensuring optimal vehicle performance and safety.

If you experience vibrations in the steering wheel, seat, or floorboard, especially at speeds between 50-70 mph, it's likely that your wheels need balancing. Uneven tire wear patterns can also indicate a need for wheel balancing.

Driving without proper wheel weights can lead to excessive vibrations, increased noise, uneven tire wear, reduced fuel efficiency, and potential damage to suspension components over time. It can also affect your vehicle's overall performance and handling.

It's recommended to have your wheels balanced every 5,000-7,500 miles as part of regular maintenance. You should also consider rebalancing after installing new tires, repairing existing ones, or experiencing impacts with potholes or curbs.

There are two main types of wheel weights: clip-on weights, which are typically used for steel wheels, and adhesive weights, which are commonly used for aluminum alloy wheels. The choice depends on the wheel type and specific balancing needs.

Yes, proper wheel balancing can improve fuel efficiency. Tests have shown that vehicles with balanced wheels can achieve up to 8% better fuel economy compared to those with imbalanced wheels, as balanced wheels reduce rolling resistance and allow the engine to work more efficiently.