The trailer tire vs car tire question goes beyond simple labeling – it's a critical safety decision that could prevent dangerous roadside emergencies. Car tires deliver impressive service life of 60,000-80,000 miles across various road conditions, but using them on your trailer creates serious safety risks. Trailer tires are specifically engineered to handle the unique stresses of towing heavy loads over different terrains, while passenger tires are built for completely different driving demands.

Trailer tires differ from car tires in fundamental ways that directly impact your safety. Most trailer tires feature L speed ratings (approximately 75 mph), compared to passenger vehicles that use tires rated for much higher speeds. Trailer tires maintain higher air pressure, dramatically reducing sidewall flex and incorporate heat-resistant compounds that prevent dangerous blowouts. Load ratings tell the real story – passenger car tires carry load indices below 100, while trailer tires are designed with significantly higher capacity.

Speeds above 65 mph (the maximum recommended for trailers) make inappropriate tire selection extremely dangerous. This is why understanding the differences between trailer tires and car tires matters for anyone who tows regularly. Trailer tires need replacement earlier – typically after 3-4 years regardless of tread wear – but this shorter lifespan is a small investment for the specialized protection they provide.

This guide breaks down the essential differences between these tire types, helping you choose the right option for your specific towing needs. Whether you're hauling a boat, camper, or cargo trailer, selecting the correct tire type could mean the difference between a safe journey and a dangerous roadside disaster.

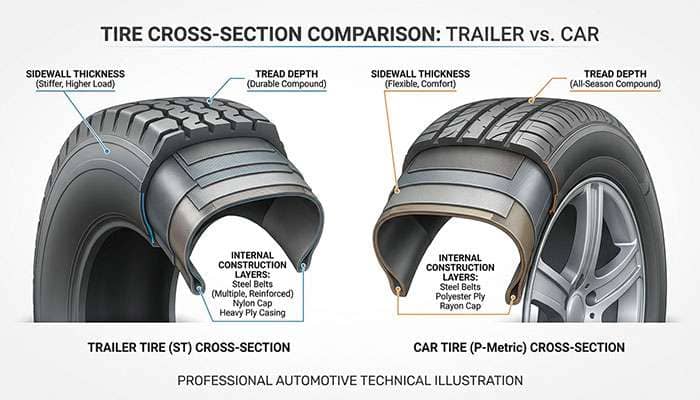

Understanding trailer tire construction reveals why these specialized tires perform differently than passenger vehicle tires. Trailer tires feature distinctly thicker sidewalls and narrower tread width compared to their passenger counterparts. These construction differences serve specific purposes that directly impact safety and performance when towing.

Trailer tires are manufactured with substantially thicker sidewalls because their primary job is load hauling and towing. This rigid construction prevents swaying and buckling under heavy loads. Car tires need flexible sidewalls to maintain maximum tread contact during turns and cornering maneuvers. The stiffer construction of trailer tires maintains optimal shape under heavy loads and reduces deflection—the amount the tire compresses—which improves load-carrying capability.

Trailer tires start with significantly less tread depth than passenger tires. Most trailer tires begin with approximately 8/32" of tread depth compared to the much deeper 17/32" or 18/32" found on light truck tires. This reduced depth minimizes "tread squirm," which occurs when the tire flexes in the contact patch. The shallower grooves improve fuel economy and help trailer tires run cooler, since hauling generates considerable heat.

Trailer tires use two main construction methods. Bias-ply tires feature plies in a crisscross pattern at 30-45 degree angles, creating overlapped layers that form a thick, less flexible structure capable of carrying heavier loads with reduced trailer sway. Radial tires have steel belts running at 90-degree angles to the centerline, allowing the sidewall and tread to function independently. Bias-ply models provide superior load durability and damage resistance, while radial trailer tires offer better pressure durability, fuel efficiency, and longer tread life.

Tire markings clearly identify their intended application. ST stands for "Special Trailer" and designates tires specifically engineered for trailer use. P indicates "Passenger" tires designed for passenger vehicles, while LT means "Light Truck" tires for vehicles capable of carrying heavy loads. ST tires maintain higher air pressure than P tires, which typically operate around 35 PSI compared to ST tires that handle over 100 PSI depending on load range. ST tires deliver approximately 10% more load capacity than equivalent LT tires and 40% more than passenger tires of the same size.

The real differences between trailer tires and car tires emerge when examining their performance under actual working conditions. These performance metrics reveal why proper tire selection becomes critical for safe towing.

Load capacity of trailer tires significantly exceeds passenger tire capabilities. Trailer tires feature dual load indices (like 129/125), showing how capacity changes based on axle configuration. With this rating, each tire supports up to 4,079 pounds in single-axle setups, or 3,638 pounds per tire when configured as dual axles. Even modest trailers can safely transport substantial cargo with this capacity.

Passenger car tires operate at much lower capacities. Most carry load indices below 100, while SUV tires range between 100-115, handling only 1,000-2,600 pounds per tire. Trailer tires are engineered specifically for heavy-duty applications, while passenger tires serve everyday driving conditions.

Trailer tires with ST designation carry speed ratings of 65 mph maximum under normal load conditions. Most trailer tires feature L speed ratings (75 mph), with some carrying M ratings (81 mph). Industry standards permit increasing speed capability to 75 mph by adding 10 PSI to recommended cold inflation pressure, provided this doesn't exceed the wheel's maximum rated pressure.

Passenger car tires handle significantly higher speeds—typically T (118 mph), H (130 mph), or V (149 mph), with performance models reaching W ratings (168 mph). This speed difference reflects the fundamental design priorities between tire types.

Trailer tires incorporate specialized rubber compounds specifically formulated to manage heat buildup during extended highway towing. These compounds resist the heat generated by sustained heavy loads better than standard passenger tire materials. Car tires use different compound formulations optimized for grip, comfort, and tread life under normal driving conditions.

Heat management becomes critical because trailer tires experience constant stress without the cooling benefits that powered axles provide. The friction and flexing that occurs during towing generates significant heat that can compromise tire integrity if not properly managed through appropriate compound selection.

Putting car tires on trailers creates real safety hazards that go far beyond simple performance issues. The dangers include sudden tire failures, loss of vehicle control, and accidents that could have been prevented with proper tire selection.

Car tires on trailers face significantly higher blowout risk because their flexible sidewalls cannot handle the constant stress of heavy loads. Passenger tire sidewalls are designed to flex during turns and cornering, but this same flexibility becomes a liability when supporting static trailer weight. The continuous stress causes sidewall deterioration that leads to sudden, dangerous failures.

Trailer tires are specifically engineered with reinforced sidewalls that resist this type of failure. Their construction maintains structural integrity under loads that would quickly compromise passenger tire sidewalls.

Car tires contribute to dangerous trailer sway because they lack the sidewall stiffness needed to maintain stable tracking. When a trailer begins swaying, flexible passenger tire sidewalls amplify the motion rather than dampening it. This can quickly escalate into uncontrollable fishtailing that leads to jackknifing or rollovers.

Trailer tires combat sway through their rigid construction. The stiff sidewalls resist lateral forces and help maintain straight tracking, even when wind gusts or passing vehicles create destabilizing forces.

Using car tires on trailers increases stopping distances because the tires cannot effectively transfer braking forces under heavy loads. The mismatch between tire capability and actual load creates longer stopping distances that can be the difference between a safe stop and a collision.

Trailer tires are designed to work within the specific parameters of trailer braking systems. Their construction and compounds optimize braking performance under the heavy loads that trailers carry.

Understanding the financial aspects of trailer tires versus car tires helps you make informed purchasing decisions. While the numbers might suggest car tires offer better value, the specialized engineering of trailer tires provides protection that justifies their different cost structure.

Trailer tires and car tires occupy different price ranges based on their specialized construction. Quality trailer tires represent a worthwhile investment in safety and reliability, even when their per-mile cost appears higher than passenger alternatives. The specialized materials and construction methods required for trailer tires justify their pricing.

Car tires deliver significantly longer tread life than trailer tires—often 60,000-80,000 miles compared to 15,000-20,000 miles for trailer applications. However, this comparison misses the point. Trailer tires aren't designed for maximum mileage; they're engineered for maximum safety under heavy loads.

The shorter mileage life of trailer tires results from their specialized compounds and construction priorities. Heat resistance and load support take precedence over tread longevity because trailer applications demand these characteristics.

Trailer tires follow time-based replacement schedules rather than wear-based ones. Even with minimal miles, trailer tires should be replaced every 3-5 years because rubber compounds degrade over time. Car tires typically follow wear-based replacement, lasting until tread depth reaches minimum levels.

This time-based approach reflects the reality that trailer tires experience stress even when stored. UV exposure, ozone, and temperature fluctuations cause rubber deterioration regardless of actual use.

Selecting the correct tires for your trailer involves matching tire capabilities to your specific hauling requirements. The right choice depends on what you're towing, how far you're traveling, and the conditions you'll encounter.

Start by determining your trailer's Gross Vehicle Weight Rating (GVWR) and divide by the number of tires to find minimum per-tire load requirements. Always select tires with load ratings that exceed this calculated minimum to provide a safety margin for uneven load distribution or unexpected weight additions.

Never choose tires based solely on physical fit. A tire that mounts correctly may still be dangerously undersized for your actual load requirements.

Long-distance towers benefit from premium trailer tires with superior heat management and load ratings. Frequent highway use demands tires built to withstand sustained speeds and continuous heat buildup. Occasional or short-distance use may allow for different tire choices, though safety should never be compromised for cost savings.

Consider where you'll be towing when selecting trailer tires. Highway-focused applications benefit from tires optimized for smooth surfaces and sustained speeds. Mixed-use scenarios that include gravel or unpaved roads may require different tread patterns or construction types to handle varied conditions safely.

Proper maintenance extends tire life and ensures safe operation. Trailer tires and car tires have different maintenance needs that reflect their distinct applications and stress patterns.

Trailer tires require inflation to their maximum sidewall-rated pressure for proper load support. Unlike car tires, which use vehicle-specific pressures often below maximum ratings, trailer tires need full inflation to achieve their rated load capacity. Under-inflation causes excessive sidewall flex, heat buildup, and premature failure.

Check trailer tire pressure before every trip when tires are cold. Pressure readings taken after driving will be elevated and provide inaccurate guidance.

Inspect trailer tires before every use, looking for cracks, bulges, punctures, or uneven wear patterns. Check sidewalls carefully since this is where trailer tire failures typically originate. Look for weather checking—small cracks that indicate rubber deterioration from age or UV exposure.

Regular inspections catch developing problems before they cause roadside failures.

Store your trailer in cool, dry locations away from direct sunlight. Placing trailers on jack stands removes weight stress from the tires. Covering tires provides additional protection against UV damage and extends their useful life.

Trailer tires need replacement after 3-4 years regardless of how they look. This replacement schedule is necessary because trailer tires lose approximately one-third of their strength after just 3 years. Age matters more than appearance when it comes to trailer tire safety.

When choosing between trailer tires and car tires, the specifications tell the complete story. This side-by-side comparison reveals why using the right tire type matters for your safety and performance.

Feature |

Trailer Tires (ST) |

Car Tires (P) |

|---|---|---|

Sidewall Construction |

Thick, rigid sidewalls |

Flexible sidewalls |

Initial Tread Depth |

8/32" |

17/32" - 18/32" |

Typical Air Pressure |

Up to 100+ PSI |

Around 35 PSI |

Speed Rating |

L or M (75-81 mph) |

T/H/V (118-149 mph) |

Load Index |

129/125 (up to 4,079 lbs) |

Below 100 (1,000-2,600 lbs) |

Service Life |

3-4 years |

6+ years |

Primary Purpose |

Load support and straight tracking |

Handling, comfort, and performance |

Heat Management |

Specialized heat-resistant compounds |

Standard heat management |

Load Capacity vs Size |

40% more than passenger tires |

Base reference |

Recommended Speed Limit |

65 mph (standard) |

Varies by rating (118+ mph) |

Main Design Focus |

Stability and load bearing |

Handling and comfort |

Replacement Threshold |

4/32" tread depth |

Not specified in article |

The numbers make it clear – trailer tires and car tires serve completely different purposes. Trailer tires sacrifice longevity and speed capability for superior load capacity and heat resistance. Car tires prioritize handling and comfort over heavy-duty applications.

Understanding these specifications helps you make the right choice for your specific needs. Whether you're towing heavy cargo or commuting to work, selecting tires designed for your application ensures optimal safety and performance.

This comparison shows that trailer tires and car tires serve completely different purposes, making proper tire selection a critical safety decision. The structural differences are clear – trailer tires feature thicker sidewalls, specialized construction, and heat-resistant compounds designed specifically for heavy loads and straight tracking. Car tires excel at handling, comfort, and performance for daily driving where flexibility and responsiveness matter most.

The safety risks of using the wrong tire type are serious. Blowouts, trailer sway, compromised stability, and extended stopping distances create real dangers that can lead to accidents. Anyone who tows regularly needs to understand these differences to protect themselves and others on the road.

Maintenance requirements differ significantly between these tire types. Trailer tires need maximum inflation pressure, regular inspection, proper storage, and replacement every 3-4 years regardless of appearance. These practices ensure your safety while maximizing tire performance.

The choice comes down to using the right tire for the right job. Trailer tires might need replacing sooner than passenger tires, but this shorter lifespan is a small price for the specialized protection they provide. We believe in helping you make informed decisions about tire selection – your safety depends on choosing the correct tire type for your specific needs.

At Performance Plus Tire, we understand that proper tire selection matters. Whether you need trailer tires for heavy hauling or passenger tires for daily driving, our expert team can help you find the perfect match for your vehicle and ensure you're getting the best value for your investment.

Understanding the critical differences between trailer and car tires can prevent dangerous accidents and ensure optimal performance for your specific hauling or driving needs.

• Never use car tires on trailers - Passenger tires lack the rigid sidewalls and heat resistance needed for heavy loads, leading to dangerous blowouts and trailer sway at highway speeds.

• Trailer tires require maximum PSI inflation - Unlike car tires at 35 PSI, trailer tires need their full sidewall-rated pressure (often 100+ PSI) for proper load support and stability.

• Replace trailer tires every 3-4 years regardless of tread - Trailer tires lose one-third of their strength after just 3 years, making age more critical than appearance for safety.

• Speed limits matter for trailer tires - Most trailer tires are rated for maximum 65-75 mph, while car tires handle 118+ mph, making proper tire selection crucial for highway safety.

• Load capacity differences are substantial - Trailer tires can support 40% more weight than equivalent passenger tires, with ratings up to 4,079 pounds per tire versus 1,000-2,600 pounds for car tires.

The bottom line: Using the wrong tire type isn't just inefficient—it's a serious safety hazard that can lead to catastrophic failures, accidents, and loss of vehicle control.

Car tires are not designed to handle the unique stresses of trailer use. They have thinner sidewalls that can't effectively support heavy trailer loads or resist swaying forces, potentially leading to dangerous blowouts and loss of control.

Trailer tires typically need replacement every 3-4 years, regardless of their appearance. This is because they lose about one-third of their strength after just 3 years of use, even if the tread still looks good.

Unlike car tires, trailer tires should be inflated to their maximum PSI as indicated on the sidewall. This is crucial for proper load support and stability, as it's the air inside that carries the load, not just the tire itself.

Yes, most trailer tires are rated for a maximum speed of 65-75 mph, significantly lower than car tires. Exceeding these speed limits can lead to dangerous heat buildup and potential tire failure.

Trailer tires have substantially higher load capacities than car tires. They can typically support up to 40% more weight than equivalent-sized passenger tires, with some trailer tires rated to carry up to 4,079 pounds per tire.