Run flat tires can cost as much as double what equivalent conventional tires cost. What is the disadvantage of a run flat tire? These specialized tires offer continued mobility after a puncture, but they come with substantial drawbacks that every driver needs to understand before making the investment.

Run flat tires allow you to drive up to 50 miles at speeds up to 50 mph after losing air pressure[-2]. This emergency capability provides real peace of mind. However, the trade-offs extend well beyond the higher price tag. These tires typically wear out up to 6,000 miles sooner than standard tires due to their reinforced construction and tendency toward uneven wear patterns. The rigid sidewalls that enable post-puncture driving create a noticeably harsher ride quality, particularly noticeable on vehicles with larger wheels.

The drawbacks don't stop there. When you experience a catastrophic tire failure, you might still find yourself stranded without a spare tire. This situation becomes especially problematic in rural areas where replacement options are scarce. Even luxury car manufacturers who initially championed run flat technology are now reconsidering their approach. Customer feedback about comfort issues and long-term costs has prompted many brands to explore alternatives.

Most drivers know that sinking feeling when a tire suddenly goes flat. Run-flat tires are specially engineered to continue functioning even after losing air pressure. Unlike conventional tires that collapse immediately when punctured, run-flat technology enables you to keep driving safely until you reach a service station.

The engineering behind run-flat tires lies in their specialized construction. These tires maintain their shape and performance for a limited distance after a puncture occurs, giving drivers valuable time to reach a service location rather than being stranded on the roadside.

The most common run-flat design utilizes a self-supporting sidewall system. These tires feature reinforced sidewalls that are significantly thicker than standard tires—approximately ¾" thick compared to just ⅛" thick on conventional tires. This robust sidewall construction prevents the tire from being crushed between the road surface and the wheel rim during a puncture event.

The strengthened sidewalls are manufactured using firm, solid materials that keep the tire from collapsing when deflated. This design enables the tire to support your vehicle's weight without air pressure. When a puncture occurs, the reinforced structure bears the load that would normally be supported by air pressure in standard tires.

Most self-supporting run-flat tires are marked with specific codes on the sidewall. You might see "RF" (run-flat) before the rim diameter, such as 205/55 RF 16. Other manufacturers use their own terminology—ZP (Zero Pressure), EMT (Extended Mobility Tire), SSR (Self-Supporting Run-flat), or ROF (Run On Flat).

The support ring system, also known as the auxiliary supported system, represents a different approach to run-flat technology. Instead of reinforced sidewalls, this design incorporates an additional support structure within the tire.

This system utilizes a rigid ring attached to or mounted inside the wheel. When a tire loses air pressure, this specialized ring provides crucial support to prevent the tire from collapsing. The support ring effectively distributes the vehicle's weight across the tire's surface, reducing structural damage risk.

Support ring systems are less common in passenger vehicles but are frequently used in high-performance cars, military vehicles, and armored vehicles. One notable advantage of this system is its ability to support the vehicle for longer distances compared to self-supporting tires, although still at reduced speeds.

Military and executive protection vehicles often employ this technology because it offers superior ability to carry heavy loads for long distances at high speeds even after tire damage. The Rodgard system, for example, consists of two rings fitted into the tire—an inner ring that centers the run-flat and prevents the tire from leaving the rim, and an outer ring that supports the deflated tire.

Run-flat tires require vehicles to be equipped with a Tire Pressure Monitoring System (TPMS). This requirement exists because drivers might not immediately notice when a run-flat tire loses pressure. Without this alert system, you could unknowingly continue driving beyond the tire's safety limitations.

The TPMS continuously monitors air pressure in all tires and immediately alerts you when pressure drops below safe levels. This notification allows you to take appropriate action—such as reducing speed and planning to visit a service station—before the tire sustains permanent damage.

The increasing prevalence of run-flat tires played a significant role in the adoption of TPMS in modern vehicles. During the early 1990s, General Motors' Low Tire Pressure Warning System allowed Chevrolet to offer run-flats on the Corvette for the first time.

Run-flat technologies have evolved significantly since their commercial introduction in 1935. Today's systems provide remarkable capability, allowing continued operation after pressure loss for approximately 50 miles at speeds up to 50 mph. This technology delivers crucial peace of mind, particularly in hazardous situations or remote locations where changing a tire would be dangerous or impractical.

Run-flat tires bring several trade-offs that many drivers find problematic. Understanding these drawbacks helps you decide whether these specialized tires align with your needs and budget.

The cost difference between run-flat and conventional tires presents a significant financial consideration. Run-flat tires typically command prices 25-100% higher than their standard counterparts—a premium that adds up quickly over the life of your vehicle.

Take a popular luxury sedan as an example. A set of conventional tires might cost $600-800, while equivalent run-flat tires could range from $1,000-1,600. This substantial price gap affects not just your initial purchase but every replacement cycle throughout vehicle ownership.

The financial impact extends beyond sticker price. Run-flat tires generally wear out approximately 6,000 miles sooner than regular tires. If conventional tires provide 50,000 miles of service, you might only get 44,000 miles from run-flats. Combined with their higher cost, this shorter lifespan creates a compound financial disadvantage that persists throughout vehicle ownership.

The reinforced sidewalls that enable run-flat functionality create noticeable comfort penalties. These stiffened sidewalls transmit more road vibrations and impacts directly to the vehicle's cabin, producing a harsher, less refined ride quality compared to conventional tires.

This ride quality degradation becomes especially apparent on rough pavement, expansion joints, and potholed roads. The tire's inability to flex and absorb impacts means passengers feel more of the road's imperfections. Vehicles equipped with larger wheels (19 inches and above) experience particularly pronounced harshness since there's less sidewall height to cushion impacts.

Many luxury vehicle owners—particularly BMW drivers—report dissatisfaction with the harsh ride characteristics of factory-installed run-flat tires. This feedback has become so prevalent that numerous owners replace their run-flats with conventional tires as their first vehicle modification, prioritizing comfort over the emergency mobility capability.

When a conventional tire suffers a puncture, repair often represents a cost-effective solution. Run-flat tires, however, typically cannot be repaired after losing pressure—even if the puncture itself appears minor and repairable.

The issue stems from internal structural damage that occurs when driving on a deflated or underinflated run-flat tire. The reinforced sidewalls undergo stress and potential damage during post-puncture operation that's difficult to detect through external inspection. Manufacturers generally recommend complete replacement after any significant air loss to ensure continued safety and performance.

This no-repair policy eliminates a significant cost-saving option available with conventional tires. A simple nail puncture in a regular tire might cost $20-30 to repair, while the same incident with a run-flat tire necessitates a $250-400 replacement. Over the life of your vehicle, these mandatory replacements instead of repairs substantially increase your tire-related expenses.

Some tire shops refuse to service run-flat tires altogether due to liability concerns and specialized equipment requirements. This limitation can create frustration when seeking service, particularly in smaller communities where tire selection may already be limited.

Run-flat tires typically weigh more than conventional tires due to their reinforced construction. This additional weight—typically 1-2 pounds per tire—increases your vehicle's unsprung mass and rolling resistance.

The impact on fuel economy varies depending on vehicle type and driving conditions but generally ranges from 1-3% reduction in fuel efficiency. While this might seem modest, it compounds over time and adds to the already higher operating costs of run-flat tires.

The stiffer sidewalls also contribute to increased rolling resistance. Unlike conventional tires that flex and deform to minimize road contact friction, run-flat tires maintain their rigid structure, creating more resistance as they roll. This increased resistance requires your engine to work harder, consuming more fuel to maintain the same speed.

Finding replacement run-flat tires can prove difficult, especially in rural areas or smaller cities. Many tire retailers stock limited run-flat inventory due to lower demand and the specialized nature of these products.

This availability issue creates practical problems when you need urgent replacement. While conventional tires are typically available at virtually any tire shop or automotive retailer, run-flat options often require special ordering with wait times of several days to weeks. This delay can leave you without transportation or force you to accept whatever limited run-flat options happen to be locally available.

The selection problem extends beyond availability. Run-flat tires are manufactured in fewer sizes and models compared to conventional tires. If you drive a vehicle with uncommon tire specifications or prefer specific performance characteristics, you might find your options severely restricted in the run-flat category.

Some tire manufacturers have reduced or discontinued their run-flat tire lines in response to market demand and profitability concerns. This industry trend further limits your choices and raises questions about long-term support for vehicles originally equipped with run-flat tires.

Run-flat technology provides valuable emergency mobility after typical punctures, but it offers no protection against catastrophic tire failure. Sidewall damage, severe impacts, or complete tread separation can render a run-flat tire just as useless as a conventional tire in similar circumstances.

This limitation creates a problematic situation for many run-flat-equipped vehicles since manufacturers often eliminate the spare tire to save weight and increase cargo space. Without a spare tire and facing damage beyond the run-flat's capability, you're stranded and dependent on roadside assistance—exactly the situation run-flat technology was supposed to prevent.

The temporary mobility capability also requires specific conditions. You can typically drive up to 50 miles at speeds not exceeding 50 mph after pressure loss. Exceeding these limitations can cause catastrophic tire failure or wheel damage. If you're farther than 50 miles from service or need to travel at highway speeds, the run-flat advantage disappears.

Temperature extremes can also affect run-flat performance. Very cold conditions may reduce the distance capability, while extremely hot weather can accelerate tire degradation during post-puncture operation. These environmental factors add uncertainty to the 50-mile range estimate.

Run-flat tires continue supporting vehicle weight even when significantly underinflated, which means drivers often can't tell when a tire has lost pressure by visual inspection or driving feel alone. This characteristic makes a functioning Tire Pressure Monitoring System (TPMS) essential rather than optional.

The problem becomes serious when TPMS malfunctions or displays inaccurate readings. Without reliable pressure monitoring, you might unknowingly drive on an underinflated run-flat tire, causing internal structural damage that compromises safety and necessitates premature replacement.

Regular pressure checks become more critical with run-flat tires, yet their rigid construction makes manual pressure verification less intuitive. Unlike conventional tires that visibly bulge when underinflated, run-flats maintain their appearance even at significantly reduced pressure. This deceptive characteristic can lead to neglected maintenance and unexpected failures.

TPMS battery life presents another consideration. These systems typically last 5-10 years before requiring sensor replacement. When TPMS batteries fail, you lose the crucial early warning system that makes run-flat tires practical. Sensor replacement can cost $200-500 for all four wheels, adding another maintenance expense to run-flat tire ownership.

Deciding whether run-flat tires are right for your vehicle comes down to your specific driving conditions and priorities. The choice isn't always clear-cut, so let's break down when these tires make sense.

Run-flat tires deliver genuine value for drivers who face safety concerns during tire changes. If you frequently travel busy freeways, poorly lit roads, or high-crime neighborhoods, the ability to continue driving after a puncture provides real peace of mind. They're also perfect for vehicles with limited trunk space where storing a spare tire creates storage challenges.

Luxury vehicles and performance cars often come equipped with run-flats from the factory, including models from BMW, Mercedes-Benz, and Mini. For those seeking quality run-flat tires with reliable performance, Performance Plus Tire offers an extensive selection of options to match your vehicle's specifications.

The economics often favor conventional tires. Run-flat tires typically cost 25-100% more than conventional tires, making standard options attractive for budget-conscious drivers. Rural drivers should especially consider conventional tires due to limited tire service availability in smaller communities.

High-mileage drivers and comfort-focused motorists usually prefer standard tires. Run-flats wear out approximately 6,000 miles sooner than regular tires, making conventional options more economical long-term. Vehicles without tire pressure monitoring systems aren't suitable candidates for run-flats anyway.

BMW's shift away from run-flat technology tells the real story. Consumer feedback has highlighted significant comfort issues, with many BMW owners reporting "atrocious" ride quality and immediately replacing factory-installed run-flats.

The harsh ride created by rigid sidewalls, particularly over rough surfaces, has reduced customer satisfaction. BMW dealers report that numerous customers replace run-flats with conventional tires as their first modification. This consumer pushback, combined with alternative technologies like self-sealing tires, has prompted manufacturers to reconsider their commitment to run-flat technology.

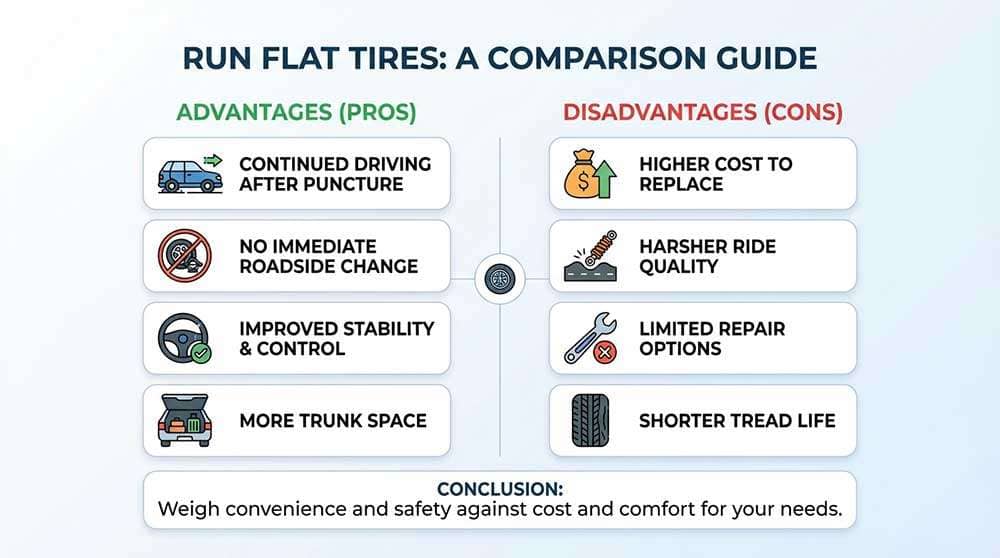

Run-flat tires provide peace of mind during unexpected punctures, allowing drivers to reach safety without immediate roadside tire changes. However, the substantial drawbacks make them a questionable investment for most vehicle owners. The significantly higher purchase price combined with shorter tread life creates substantially higher long-term ownership costs compared to conventional tires. The compromised ride comfort, reduced fuel efficiency, and limited repair options further reduce their appeal for everyday driving.

These specialized tires make sense for drivers who frequently travel through dangerous areas or own vehicles with limited trunk space. Most drivers will find conventional tires more practical and economical for their needs. The trend of luxury manufacturers like BMW moving away from run-flat technology demonstrates the widespread customer satisfaction issues these tires create.

Drivers who prioritize comfort, longevity, and value will typically find standard tires the superior choice. Consider your specific driving conditions, budget, and comfort preferences before making your decision. Those specifically seeking quality run-flat options can explore the extensive selection available at Performance Plus Tire, where we carry various brands and models to match your vehicle's requirements.

Run-flat technology serves a purpose in certain situations, but understanding both its capabilities and limitations helps you make an informed choice that aligns with your driving needs and expectations.

Run-flat tires promise continued mobility after punctures, but come with significant trade-offs that every driver should understand before making the investment.

• Higher costs throughout ownership: Run-flats cost 25-100% more upfront and wear out 6,000 miles sooner than standard tires, making them expensive long-term.

• Compromised ride comfort: Reinforced sidewalls create a noticeably harsher, stiffer ride quality, especially on rough roads and larger wheel sizes.

• Limited repair options: Most run-flats cannot be patched after punctures and must be completely replaced, eliminating cost-saving repair possibilities.

• Reduced fuel efficiency: Heavier construction increases rolling resistance, leading to higher fuel consumption compared to conventional tires.

• Availability challenges: Finding replacements in rural areas can be difficult, and many tire shops refuse to service or stock run-flat options.

While run-flats excel in emergency situations by allowing 50 miles of driving after punctures, their drawbacks often outweigh benefits for everyday drivers. Even luxury automakers like BMW are reconsidering their commitment to this technology due to customer complaints about comfort and costs.

Run-flat tires typically have a higher cost, provide a stiffer ride quality, offer reduced fuel efficiency, and have a shorter tread life compared to conventional tires. They also have limited repair options and can be challenging to find replacements for, especially in rural areas.

Run-flat tires use reinforced sidewalls or support ring systems to maintain their shape and allow continued driving after a puncture. However, they typically only allow driving for about 50 miles at speeds up to 50 mph after losing air pressure. Exceeding these limits can cause irreparable damage to the tire.

The value of run-flat tires depends on individual needs. They can be beneficial for those frequently traveling in areas where changing a tire would be dangerous or impractical. However, for most drivers, the higher costs and compromised ride comfort may outweigh the benefits, especially if they prioritize economy and performance.

Most run-flat tires cannot be repaired after a puncture due to potential internal structural damage that's difficult to detect. Manufacturers generally recommend replacement after any significant air loss, making them less cost-effective in the long run compared to conventional tires that can often be patched.

Some automakers, like BMW, are reconsidering their use of run-flat tires due to customer feedback. Many drivers report dissatisfaction with the harsher ride quality, higher replacement costs, and limited repair options. As a result, some manufacturers are exploring alternative technologies or returning to conventional tire setups to improve overall customer satisfaction.