Smart tires equipped with embedded sensors and IoT connectivity represent a major advancement in road safety by enabling direct communication between tires and vehicles. These intelligent systems go far beyond traditional tire functions, actively monitoring critical conditions that impact driver safety and vehicle performance. Leading facilities report productivity improvements of 45-60% when implementing digital tire monitoring systems. Smart tire operations deliver 30-40% lower operating costs through better energy efficiency and reduced unplanned maintenance.

Smart car tire technology continues advancing rapidly across the automotive industry. Modern smart tires send real-time data to both drivers and vehicle computer systems, ensuring maintenance happens when needed rather than when problems develop. Smart tires report essential health metrics including pressure and temperature readings, allowing drivers to address potential issues before they create dangerous situations. Manufacturers like Goodyear are developing smart tire systems that detect road conditions and adjust tire performance accordingly. This technology proves especially valuable for electric vehicles, which require low rolling resistance tires for optimal range - capabilities expected to expand significantly with new materials and construction methods by 2025.

We'll explore how these intelligent tire systems enhance vehicle safety through advanced sensor technology, predictive maintenance capabilities, and connected monitoring features.

Tire monitoring has changed significantly over the past decade. Advanced sensors built directly into tire structures now enable vehicles to detect and respond to road conditions with precision that was impossible just years ago. These intelligent systems create safety advantages that go well beyond what traditional monitoring could offer.

Tire Pressure Monitoring Systems (TPMS) became mandatory in all new U.S. vehicles starting in 2008, providing basic safety alerts when tire pressure drops below safe levels. Smart tires deliver capabilities that extend far beyond these baseline requirements. Traditional TPMS focuses only on pressure readings, while smart tires use sensor arrays built directly into the tire structure itself.

The difference between these systems is significant. Direct TPMS relies on individual pressure sensors for accurate readings, while indirect systems estimate pressure changes by measuring wheel rotation speeds through the ABS system. Embedded sensor arrays in smart tires monitor multiple parameters simultaneously through sensors integrated within the tire's structure or inner lining.

Smart tire systems use advanced materials, electronics, and wireless communications to detect strain, wear, road friction, vibration, temperature, and dynamic load. Continental's ContiSense™ technology demonstrates this approach by embedding sensors in a conductive rubber layer that measures inflation pressure, tread depth, and both tire and road temperature.

Continuous, real-time monitoring forms the foundation of smart tire technology. Traditional systems only provide warnings after problems develop, but smart sensors maintain constant vigilance during vehicle operation.

Modern sensor systems transmit tire pressure and temperature data through cloud connections to monitoring platforms. When problems arise, these systems send warning emails or text messages, enabling drivers to address issues before they become critical. This immediate feedback prevents potential blowouts and other tire failures.

Smart tire sensors offer benefits beyond basic safety monitoring. These systems can detect temperature changes that indicate moisture conditions like snow, rain, or ice on road surfaces. They can also identify when nails or road debris puncture the tire, providing nearly instant alerts before catastrophic failure occurs.

Some systems include yard-based monitoring where tire sensors mounted on valve stems send pressure and temperature data to wireless receivers, generating reports every 5 minutes when vehicles are within range.

Smart tire health reporting shifts vehicle maintenance from reactive to proactive approaches. These systems provide detailed insights that include:

Tread depth monitoring with alerts when replacement becomes necessary

Instant notifications about punctures or unusual wear patterns

Early warnings about potential blowouts before damage develops

The practical benefits for drivers are substantial. Research shows that tire-related crashes account for approximately 6% of passenger car accidents. Smart tire technology can prevent many of these incidents through early detection and intervention.

Economic benefits make smart tire monitoring even more valuable. Maintaining optimal tire pressure improves fuel efficiency and increases tire mileage. Detecting small leaks before they require expensive repairs reduces maintenance costs while extending tire life.

Hot weather conditions demonstrate why this technology matters. When road temperatures exceed 60°C, continuous temperature monitoring becomes essential for preventing heat-related blowouts. Smart tire health reporting changes how drivers maintain and interact with their vehicles, making safety a proactive concern rather than a reactive response.

Artificial intelligence takes smart tire technology beyond basic monitoring into powerful predictive systems. AI algorithms anticipate tire problems before they become critical, changing how drivers approach tire maintenance and safety.

Machine learning models detect and forecast tire wear patterns with remarkable precision. Convolutional neural networks (CNN) analyze tire data to achieve exceptional accuracy. Research shows 1D-CNN algorithms reach error rates as low as 5.2% (approximately 0.42 mm) using only acceleration signals. These prediction errors improve by 11.5% when systems integrate tire pressure and vertical load data, resulting in a 4.6% error rate.

Multi-sensor data acquisition modules collect triaxial acceleration and deformation information from tires under various operating conditions. AI algorithms process these vibration and deformation signals to identify wear levels through detailed spectral analysis.

Tire wear detection proves critical when considering NHTSA data showing vehicles with worn tires are three times more likely to be involved in collisions, with approximately 11,000 accidents annually caused by tire failures.

Smart tire systems offer unprecedented maintenance foresight for drivers. Michelin's Smart Predictive Tire technology predicts when tires will reach critical pressure levels, enabling proactive maintenance scheduling instead of roadside emergencies. Revvo's platform connects directly with vehicles to establish automated predictive maintenance alerts that inform both drivers and tire retailers about potential issues.

These systems deliver significant operational benefits. Fleet managers report an 80% reduction in unplanned failures and 50% decrease in maintenance costs after implementing predictive tire systems. One waste disposal company equipped 15 refuse trucks with Revvo's AI-powered system, monitoring approximately 62,000 miles of operation. By addressing just 22 critical underinflation issues identified by the system, they achieved an estimated $5,000 in combined savings through reduced fuel consumption, extended tire life, and avoided roadside service events.

AI tire technologies include sophisticated risk prediction systems that protect drivers from dangerous blowouts. Advanced failure probability models combine multiple algorithms to forecast tire failure risks with up to 94% accuracy. These systems prevent an impressive 91% of potential breakdowns by analyzing patterns in sensor data, operational conditions, and maintenance history.

Tires account for over 50% of roadside breakdowns, making this technology essential for driver safety. Systems like Uptake's Tire Insights detect potential issues such as leaks, sensor anomalies, and pressure drops one month earlier than conventional monitoring approaches. This early detection capability reduces tire-related failures by more than 83%.

Government agencies recognize these benefits. Utah transportation officials employ roadway sensors and AI at truck inspection stations to detect tire problems before vehicles reach highways, identifying more than 20 flat tires on the first day of implementation at one location.

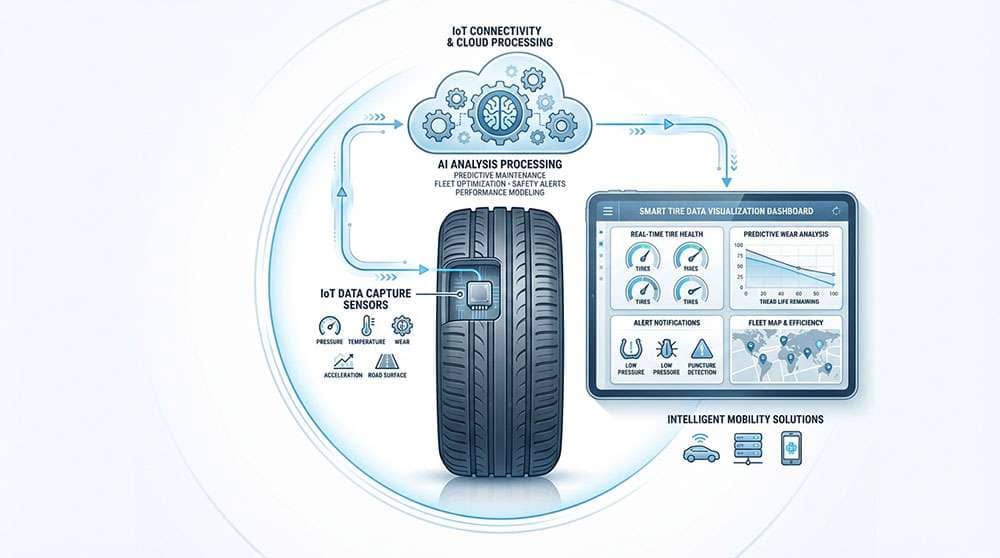

Connectivity serves as the foundation that enables smart tire technology to function effectively. IoT systems have converted tires from basic rubber components into intelligent data sources that actively participate in vehicle safety and performance management.

Smart tires rely on specialized communication protocols to share data with vehicle electronics. Standard TPMS sensors transmit tire pressure and temperature readings every five seconds. These basic communications represent just the starting point for more advanced capabilities. The Pirelli-Bosch intelligent tire system demonstrates this evolution by equipping each tire with integrated sensors that connect directly to vehicle electronics, allowing the car to adjust its setup based on real-time tire data.

Most systems use Bluetooth Low Energy (BLE) for data transmission, providing an optimal balance between power consumption and communication range. These protocols enable tires to share crucial information beyond basic pressure readings with vehicle systems. Smart tire data feeds directly into Advanced Driver Assistance Systems (ADAS), improving autonomous driving capabilities.

Smart tire ecosystems extend well beyond individual vehicles through cloud-based platforms. Continental's ContiConnect™ system collects sensor information, analyzes the data, and generates immediate notifications for urgent tire issues. This approach prevents tire-related breakdowns by addressing problems before they develop into failures.

Fleet managers gain significant advantages from cloud-based tire monitoring:

Real-time status updates and alerts that increase productivity

Automated email notifications for emergency situations

Detailed event history accessible by wheel position

Predictive maintenance capabilities that reduce downtime

Tirecheck's INFLEET digital monitoring solution addresses a critical need, considering tires affect up to 53% of fleet operational costs. These platforms convert sensor data into actionable work orders using real-time information from the field.

Smart tires increasingly operate as components within larger vehicle management systems. Michelin has developed solutions that utilize tire data without requiring dedicated tire-mounted sensors, instead working with existing vehicle architecture. This integration allows tire monitoring to function alongside other vehicle systems seamlessly.

The market reflects growing integration potential, with the global Smart Tire Market projected to reach USD 200 billion by 2033, expanding at a 7.8% CAGR over the next decade. Goodyear's SightLine system exemplifies this trend, providing tailored solutions for fleets and autonomous vehicles with high-precision data for performance optimization. These connected systems create a complete approach to vehicle management where tires serve as both information sources and performance enhancers.

Computer vision capabilities extend smart tire functionality well beyond basic sensor monitoring. Visual analysis systems enable tires to interpret road surfaces and adjust performance accordingly, creating an entirely new level of safety awareness.

The Pirelli Cyber Tire demonstrates how visual intelligence enhances road safety through real-time surface analysis. These advanced systems monitor both tire condition and road surface characteristics simultaneously. The integrated electronics endure extreme forces exceeding 3,500 G during normal driving operations. Road texture recognition happens continuously as tires rotate, with sensors detecting surface roughness and asphalt irregularities through sophisticated data analysis.

Modern intelligent tires distinguish between different surface conditions with impressive accuracy. Current systems identify paved roads, wet surfaces, snow coverage, and icy conditions. This precision comes from analyzing three-dimensional waveform patterns created when tires compress against various surfaces. Gravel roads produce distinct waveform signatures as wheels experience slight spinning and traction changes on loose stones, allowing immediate surface identification.

Surface detection covers nearly all road types including dry asphalt, wet pavement, snow, ice, gravel, and concrete. Analysis speed is remarkable - smart tires examine real-time surface information and transmit data to the vehicle's ECU within approximately one second.

Multiple visual input sources optimize tire grip through adaptive control systems. Camera technology identifies hazardous conditions like snow, ice, and standing water, while radar systems detect subtle road texture variations. This visual feedback enables immediate tire performance adjustments based on current conditions.

Racing applications showcase the precision of tire monitoring through infrared sensors positioned near each wheel. These sensors measure temperature distribution across tire contact patches. Heat map displays overlay video feeds, showing exactly how tire compounds respond during braking, cornering, and acceleration phases. Drivers can identify tire lockup situations instantly and modify their driving technique for optimal performance.

Manufacturing quality control relies heavily on visual inspection systems. The Vision Tire System 3D® creates detailed three-dimensional tire models using laser profilometry. Advanced algorithms identify, classify, and measure surface defects while ensuring compliance with manufacturing standards. Combined rule-based software and deep learning models detect visual defects during production processes.

Electric vehicles and autonomous systems demand specialized tire technology that goes far beyond conventional designs. These advanced platforms create unique challenges that require smart tire solutions specifically engineered for their performance requirements.

Goodyear's ElectricDrive 2 stands out as a breakthrough in EV tire technology. This all-season tire incorporates SoundComfort Technology foam inserts that significantly reduce interior vehicle noise—essential for the quiet operation that electric vehicle owners expect. The tire features at least 50% sustainable materials, including soybean oil and rice husk ash silica, addressing environmental concerns important to EV drivers. Its asymmetric tread pattern delivers superior grip on both wet and dry surfaces while providing the durable tread compound necessary to handle the instant torque that electric motors deliver.

Autonomous driving systems increasingly depend on tire intelligence for critical safety decisions. Continental's smart tires include built-in sensors that automatically connect with vehicle electronics, detecting temperature abnormalities, identifying punctures, and predicting potential hazards. Goodyear's SightLine technology, currently implemented in Gatik's autonomous trucks, provides real-time road condition and tire health data through continuous feedback loops. This tire-to-vehicle communication allows autonomous systems to "react like a driver would" when encountering changing road conditions.

Low rolling resistance tires play a crucial role in EV efficiency—using non-optimized tires can reduce driving range by 10-15%. Continental's EcoContact 6 addresses this challenge through precise balance between tire size and component distribution. The specialized rubber compounds create strong connections between silica and rubber materials, adapting to different road conditions while maintaining improved rolling resistance.

When selecting tires for electric vehicles, consider both range optimization and the unique performance characteristics that EVs require. The right tire choice can significantly impact both your vehicle's efficiency and your overall driving experience.

Smart tire technology marks a significant advancement from traditional tires to intelligent safety systems. These smart systems actively monitor critical vehicle conditions and provide real-time communication between tires and vehicles, creating new possibilities for driver safety and vehicle performance.

The progression from basic TPMS alerts to advanced sensor networks represents a major improvement in tire monitoring capabilities. Modern smart tire sensors track multiple parameters simultaneously, including pressure, temperature, tread wear, and road surface conditions. This means drivers get early warnings about potential problems instead of dealing with dangerous situations after they develop.

Smart tire systems with AI capabilities take safety protection further. Machine learning algorithms predict tread wear patterns with high accuracy, while automated maintenance alerts help prevent up to 80% of unexpected tire failures. Risk assessment models can predict tire blowouts with 94% accuracy, potentially preventing thousands of accidents each year.

Connected monitoring through IoT systems creates direct communication links between tires and vehicle computers. Real-time data exchange protocols work with cloud-based monitoring dashboards to provide detailed tire health information. This connected approach changes tires from passive vehicle components into active safety participants.

Computer vision technology adds another layer of protection through road surface recognition and automatic grip adjustment. Smart tires can identify different road conditions within seconds and modify performance settings to maintain optimal traction regardless of weather or terrain changes.

Electric and autonomous vehicles gain special advantages from smart tire technology. Specialized tire designs like Goodyear's ElectricDrive 2 address the unique requirements of electric vehicles, while tire feedback systems provide essential data for self-driving vehicle operations. Low rolling resistance technology designed for electric vehicles prevents range losses of 10-15%.

Smart tire technology continues advancing as manufacturers develop more sophisticated safety features and better vehicle integration. While still evolving, these systems already demonstrate significant potential for improving vehicle safety through early warning capabilities, predictive maintenance, and adaptive performance adjustments.

Smart tire technology delivers what drivers need most: safer roads, fewer accidents, and better vehicle reliability. The change from reactive tire maintenance to proactive safety monitoring represents a fundamental improvement in vehicle safety - one that will continue expanding as these technologies become standard equipment.

Smart tire technology is revolutionizing road safety by transforming passive rubber into intelligent safety systems that actively monitor conditions and predict problems before they become dangerous.

• Smart tires use embedded sensors to monitor pressure, temperature, tread wear, and road conditions in real-time, preventing up to 91% of potential breakdowns through early detection.

• AI-powered predictive systems can forecast tire wear with 94% accuracy and reduce maintenance costs by 50% through proactive alerts and maintenance scheduling.

• IoT connectivity enables seamless vehicle-to-tire communication, creating comprehensive cloud-based monitoring dashboards that transform reactive maintenance into proactive safety management.

• Computer vision technology allows tires to recognize road surface conditions within seconds and automatically adjust grip control for optimal performance across various terrains.

• Electric and autonomous vehicles benefit significantly from smart tire integration, with specialized designs preventing 10-15% range reduction while providing crucial feedback loops for self-driving systems.

The transition from traditional TPMS to comprehensive smart tire ecosystems represents a fundamental shift in automotive safety. With tire-related crashes accounting for 6% of passenger car accidents, these intelligent systems offer unprecedented potential to save lives through predictive maintenance, real-time monitoring, and adaptive performance optimization.

Smart tires use embedded sensors to monitor pressure, temperature, tread wear, and road conditions in real-time. They can predict potential issues, provide early warnings, and communicate with vehicle systems to enhance safety and performance.

Smart tires can prevent up to 91% of potential breakdowns through early detection of issues. They use AI-powered predictive systems to forecast tire wear with high accuracy and provide proactive maintenance alerts, significantly reducing the risk of tire-related accidents.

Smart tires designed for electric vehicles, like Goodyear's ElectricDrive 2, offer low rolling resistance to optimize range, handle instant torque demands, and incorporate noise reduction technology. They can prevent a 10-15% reduction in EV range compared to non-optimized tires.

Smart tires provide crucial feedback loops for self-driving systems. They communicate real-time data about road conditions and tire health, enabling autonomous vehicles to adjust their behavior based on tire information, essentially allowing the vehicle to "react like a driver would."

AI in smart tire systems analyzes data from tire sensors to predict wear patterns, schedule maintenance, and assess blowout risks. Machine learning algorithms can forecast tire wear with up to 94% accuracy and help reduce maintenance costs by 50% through proactive alerts and scheduling.