Selecting the right trailer tire affects more than just your wallet — it determines whether you arrive safely at your destination. Here's something most people don't know: trailer tires must be inflated to their maximum pressure to reach their full carrying capacity. Unlike the tires on your car or truck, trailer tires face unique demands both on the road and during storage.

These specialized tires maintain higher air pressure to reduce sidewall flex. They also feature lower initial tread depth, typically around 8/32 of an inch. You'll encounter various load ratings when shopping — C, D, E, F, and G ratings handle standard applications, while H and G-rated models tackle the heaviest loads. When you choose wider tires, you'll reduce trailer sway and enjoy a safer, more stable towing experience.

We've designed this guide to walk you through every step of selecting trailer tires that match your specific needs. Whether you're hauling a travel trailer, boat trailer, or utility trailer, understanding the right specifications saves you money and prevents dangerous roadside failures. Our expert recommendations will help you choose tires that protect both your investment and your safety on every trip.

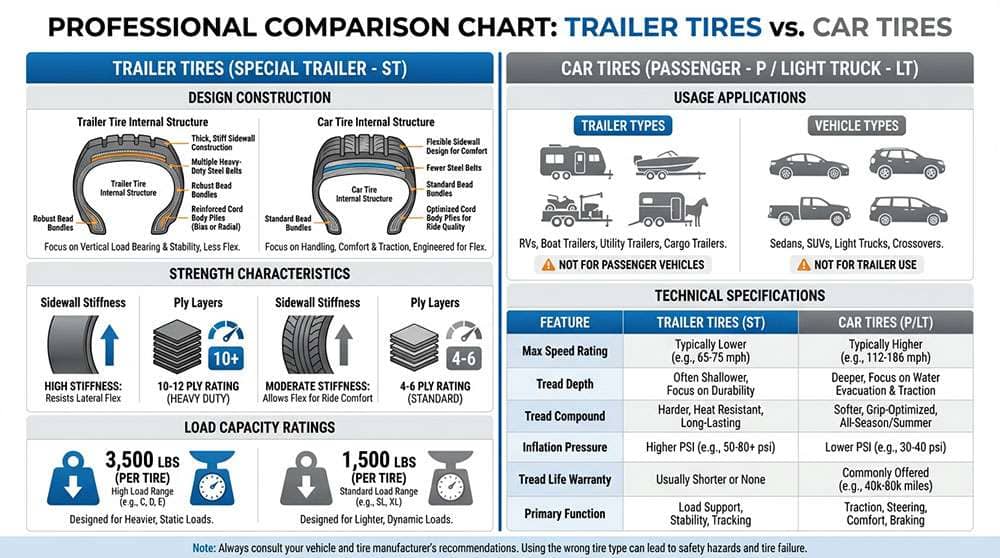

Trailer tires look similar to car tires, but they're built for entirely different jobs. Car tires need to handle steering, braking, and acceleration while providing a comfortable ride. Trailer tires focus on one primary mission: carrying heavy loads safely without steering or providing traction.

The construction differences between these tire types are significant. Car tires prioritize comfort, handling, traction, and all-weather performance. Trailer tires are engineered specifically for load-carrying capacity, stability, low rolling resistance, and durability.

ST (Special Trailer) tires feature much stiffer sidewalls compared to passenger or light truck tires. These reinforced sidewalls prevent trailer sway and maintain stability under heavy loads. You'll also notice ST tires have narrower tread widths to reduce rolling resistance, plus shallower tread depths that improve tracking by minimizing "tread squirm".

The load capacity difference is remarkable. ST tires must carry 10% more weight than comparable light truck (LT) tires and 40% more than passenger (P) tires of the same size. This superior capacity comes from specialized construction featuring different steel belts, stronger plies, and reinforced beads with thicker cords and larger diameter wire.

Regular passenger tires cannot withstand the constant vertical pressure and loading that trailers demand. ST tires don't need to steer, transmit engine power, or swerve around obstacles – jobs that car tires must perform every day.

ST tire construction accommodates free-rolling axles with minimal traction requirements, since your towing vehicle handles grip and steering. The stiff structure and stable footprint work together to optimize handling and eliminate dangerous swaying that causes accidents.

ST tires also use specialized rubber compounds that resist environmental damage during storage. This matters because trailer tires often sit unused for months, exposed to UV radiation, exhaust ozone, and oxidation that can weaken standard tire compounds.

Heat management determines trailer tire performance and lifespan. Under-inflation causes most trailer tire failures by creating excessive heat through sidewall and tread flexing. This heat damages the tire's inner liner, casing, and sidewall – often invisibly until catastrophic failure occurs.

Trailer tires operate at higher pressures than car tires, reducing sidewall flex and minimizing deflection (how much the tire compresses under load). Higher pressure improves load capacity while reducing heat buildup that causes premature wear.

The pressure number on your ST tire sidewall shows the minimum pressure needed to carry maximum load. When you see "Max load single: 3000 lbs at 65 psi cold," that 65 psi represents the minimum cold-inflation pressure required to support that weight safely. Operating below 80% of recommended pressure for your load causes serious internal damage.

All tires lose air naturally through molecular diffusion (1-3 PSI monthly), making regular pressure checks essential. Check tire pressure every two weeks, before long trips, and every morning during multi-day journeys – always when tires are cold (driven less than one mile).

Understanding these differences helps you select the right tires for your trailer's specific needs, ensuring safer travels and longer tire life.

Understanding your trailer's specifications comes first. You can't select safe, appropriate tires without knowing exactly what your trailer demands in terms of weight capacity and size requirements.

Start by finding your trailer's VIN plate or certification label. You'll typically find this plate mounted on the front left side of your trailer. This plate shows critical weight capacity information that determines your tire requirements.

The Gross Vehicle Weight Rating (GVWR) tells you the maximum weight your trailer can safely carry when fully loaded. This includes the trailer's own weight plus everything you load onto it. The Gross Axle Weight Rating (GAWR) shows the maximum weight each individual axle can handle.

Both numbers are essential for selecting the right load range. Exceeding these ratings puts you at serious risk — it's dangerous and illegal in most areas. When you overload your trailer, excessive heat builds up in the tires, which dramatically increases your chances of experiencing a blowout.

Here's our safety rule: your tire's load capacity should exceed your trailer's maximum loaded weight by at least 20%. This safety margin helps protect you even under challenging conditions.

Trailer tire sizes use a standardized code system. Take "ST225/75R15" as an example:

"ST" indicates Special Trailer classification – never substitute passenger (P) or light truck (LT) tires

"225" represents the tire's width in millimeters from sidewall to sidewall

"75" shows the aspect ratio (sidewall height as a percentage of width)

"R" means radial construction (the most common type today)

"15" indicates wheel rim diameter in inches

The load range letter (C, D, E, etc.) follows the size code and determines maximum air pressure and load capacity. Each subsequent letter can handle more weight and requires higher inflation pressure.

You can't simply swap tire sizes without consequences. When you install a smaller tire than specified, you risk exceeding its load capacity. Larger tires may not fit properly within your trailer's wheel wells or fenders.

Check the sidewall of your existing tires for complete specifications. Look for numbers stamped into the rubber on both sides of the tire. Write down the complete size code, load range, and maximum load capacity.

If your tires are too worn to read, check your trailer's owner manual or contact the manufacturer. Many trailer makers also place a label near the VIN plate showing recommended tire specifications.

Don't make assumptions based on what "looks right" or fits your wheel rim. Your trailer's suspension, axle capacity, and frame design all factor into proper tire selection.

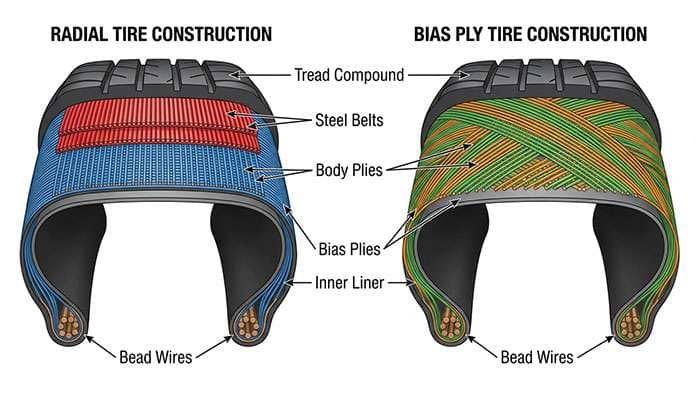

Choosing between radial and bias ply construction determines how your trailer handles, how long your tires last, and how much you'll spend on replacements. Each construction type offers distinct advantages for specific applications.

Radial tires deliver superior performance for highway travel and frequent use. Their construction features cord plies that run perpendicular to the direction of travel, creating a more flexible sidewall that absorbs road impacts better than bias ply alternatives.

Heat dissipation ranks as radial tires' strongest advantage. The flexible sidewalls allow the tread to stay cooler during extended highway driving, significantly extending tire life. You'll notice less rolling resistance too, which translates to better fuel economy when towing.

Radial construction provides smoother rides at highway speeds with reduced vibration and noise. The tread pattern maintains consistent contact with the road surface, offering better traction and more predictable handling characteristics.

Modern trailer tires predominantly use radial construction for good reason – they last longer and perform better under typical towing conditions. Expect to pay more upfront, but the extended lifespan and improved fuel economy typically offset the higher initial cost.

Bias ply tires feature cord plies that run diagonally across the tire at 30-40 degree angles. This crisscross pattern creates stiffer sidewalls that resist punctures and impact damage on rough terrain.

The rigid sidewall construction makes bias ply tires ideal for applications involving gravel roads, construction sites, or agricultural use. When you're navigating rough terrain with sharp objects or debris, bias ply construction provides better protection against sidewall damage.

Lower purchase prices make bias ply tires attractive for trailers used infrequently or seasonally. If your trailer sits unused most of the year or you only take short local trips, bias ply tires deliver adequate performance at reduced cost.

The stiffer sidewalls also help prevent overloading damage by maintaining their shape under heavy vertical loads. This characteristic proves valuable for heavy-duty work trailers that frequently operate at maximum capacity.

Your typical usage patterns should guide your decision. Choose radial tires if you:

Travel primarily on highways and paved roads

Tow frequently or for extended distances

Want maximum tire life and fuel efficiency

Prioritize ride comfort and handling

Select bias ply tires when you:

Navigate rough terrain, gravel roads, or construction sites regularly

Use your trailer infrequently or seasonally

Need to minimize upfront costs

Carry extremely heavy loads that stress sidewalls

Most trailer owners benefit from radial construction. The improved heat management, longer tread life, and better fuel economy make radials the smart choice for regular highway use. However, don't overlook bias ply tires if your specific application involves rough terrain or infrequent use where their strengths shine.

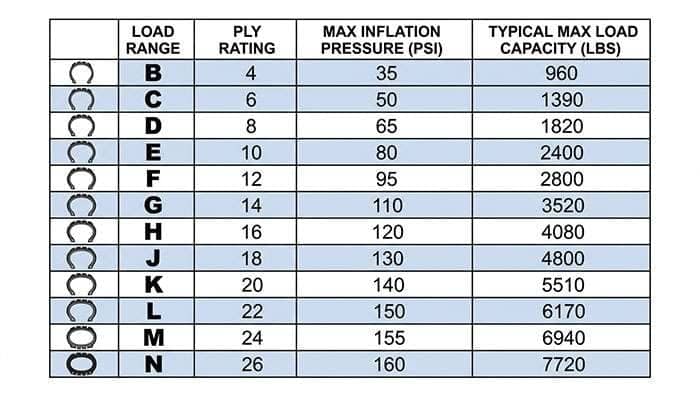

Load range letters determine how much weight your trailer tires can safely carry. Understanding these ratings prevents dangerous overloading and ensures your tires perform reliably under your specific hauling requirements.

Load range classifications use letters (B, C, D, E, F, G, etc.) that correspond to specific ply ratings and maximum air pressures. Each subsequent letter indicates stronger construction capable of handling more weight:

Load Range B: 4-ply rated, 35 PSI maximum pressure

Load Range C: 6-ply rated, 50 PSI maximum pressure

Load Range D: 8-ply rated, 65 PSI maximum pressure

Load Range E: 10-ply rated, 80 PSI maximum pressure

The "ply rating" doesn't mean the tire actually contains that many physical layers. Modern tires use fewer, stronger materials that provide equivalent strength to older multi-ply designs. The ply rating serves as a strength index rather than a literal layer count.

Higher load ranges require higher inflation pressures to achieve their rated capacity. A Load Range D tire inflated to only 50 PSI cannot carry its full Load Range D capacity – it would perform similar to a Load Range C tire instead.

Calculate your total tire load capacity needs by dividing your trailer's GVWR by the number of tires. Remember to add that 20% safety margin we mentioned earlier.

Here's a practical example: Your trailer has a 5,000 lb GVWR with two axles (four tires total). Divide 5,000 by 4 to get 1,250 lbs per tire. Add 20% safety margin (1,250 × 1.20 = 1,500 lbs). You need tires rated for at least 1,500 lbs each at their maximum inflation pressure.

Check the tire's sidewall to find its maximum load capacity at maximum pressure. These numbers must meet or exceed your calculated requirements for safe operation.

Never install tires with insufficient load capacity, even if they fit your wheels. Under-rated tires generate excessive heat, wear prematurely, and risk catastrophic failure at highway speeds.

Maximum inflation pressure delivers the tire's full load capacity. Running below maximum pressure reduces weight-carrying ability, increases rolling resistance, and generates heat that destroys tires.

Check pressure regularly with a quality gauge when tires are cold for accurate readings.

Different trailers require specific tire designs to handle their unique demands. Matching the right tire to your trailer type ensures optimal performance and safety on every trip.

The Goodyear Endurance leads the RV trailer tire category with its rounded profile, symmetric tread design, and scaffold guard molded into the sidewall. This tire delivers an N speed rating of 87 mph, exceeding standard trailer tire capabilities. The Carlisle Radial Trail HD offers exceptional heat-resistant compounds and optimized tread patterns for extended highway travel. For heavy-duty applications, the Maxxis M8008 ST Radial features double steel-belted construction that handles demanding loads.

Check out Performance Plus Tire's selection for reliable, high-quality trailer tires that match your specific RV requirements.

Travel trailers benefit most from tires designed for stability, fuel efficiency, and reduced swaying during highway cruising. Utility trailers face different challenges, requiring tires that resist cuts, abrasions, and rough terrain damage. Both applications perform best with ST-rated tires rather than LT alternatives.

Boat trailers demand tires with superior stability, heavy-load capacity, and minimal swaying characteristics. Livestock trailers need smooth-riding tires that ensure animal comfort while providing excellent heat management to prevent dangerous blowouts. Both applications require tires that maintain cooler operating temperatures under sustained loads.

Choosing the right trailer tires comes down to matching specifications to your specific hauling needs. ST tires provide the specialized construction your trailer requires — stronger sidewalls, higher load capacity, and better heat management than passenger tires.

Your trailer's GVWR and axle ratings determine the minimum load capacity you need. Add a 20% safety margin to this figure for reliable performance under challenging conditions. Radial construction offers superior highway performance and longer life, while bias ply tires handle rough terrain better at a lower cost.

Different trailers require different tire characteristics. RV trailers need stability and reduced sway. Boat trailers demand heavy-load capacity and water resistance. Utility trailers require durability and heat management under varied conditions.

We recommend browsing Performance Plus Tire's selection of trailer tires to find options that match your specific requirements. Our huge selection includes all the major brands at competitive prices, ensuring you get the right tires for your application.

Regular maintenance protects your investment and keeps you safe. Check tire pressure every two weeks when tires are cold. Inspect for wear patterns, cracks, or damage. Replace tires every five years from the manufacturing date, regardless of remaining tread depth.

Proper tire selection and maintenance prevent roadside emergencies and extend the life of both your tires and trailer. When you choose the right specifications and maintain them properly, your trailer tires will provide reliable service mile after mile.

Master these essential steps to select trailer tires that ensure safety, performance, and longevity for your specific towing needs.

• Always choose ST (Special Trailer) tires over passenger tires - they carry 40% more load and handle trailer-specific demands like heat and constant loading

• Inflate trailer tires to maximum sidewall pressure (not recommended pressure) to achieve full load capacity and prevent dangerous heat buildup

• Match tire load ratings to your trailer's GVWR and axle ratings, adding a 20% safety margin to prevent overloading and potential blowouts

• Select radial tires for highway travel and frequent use, or bias ply for rough terrain and occasional hauling based on your typical routes

• Choose tire specifications based on trailer type - RV trailers need stability features while boat trailers require heavy-load capacity and water resistance

Regular pressure checks and proper tire selection based on your trailer's weight requirements and usage patterns are critical for safe towing. Remember that trailer tires face unique challenges including extended storage periods and constant loading, making specialized ST-rated tires essential rather than optional.

To choose the right trailer tires, first check your trailer's GVWR and axle ratings. Then, select ST (Special Trailer) tires that match your trailer's size requirements and have a load capacity exceeding your trailer's maximum loaded weight by at least 20%. Consider your typical usage (highway vs. rough terrain) when deciding between radial and bias ply tires.

Unlike passenger vehicle tires, trailer tires should always be inflated to their maximum pressure listed on the sidewall. This maximum inflation is necessary to achieve the tire's full load capacity and prevent excessive heat buildup, which is the primary cause of tire failure.

Trailer tires typically need replacement every five years from the manufacturing date, regardless of tread depth. However, it's important to regularly inspect your tires for signs of wear, damage, or aging, and replace them sooner if necessary.

Radial tires offer better heat dissipation, longer tread life, and improved fuel efficiency, making them ideal for highway travel and frequent use. Bias ply tires have stiffer sidewalls that resist punctures on rough terrain and are often less expensive, making them suitable for infrequent use or off-road applications.

Yes, ST (Special Trailer) rated tires are essential for most trailers. They are specifically designed to handle the unique demands of trailers, including higher load capacities, constant loading, and free-rolling axle applications. ST tires can carry 40% more load than equivalently sized passenger tires, making them crucial for trailer safety and performance.