Did you know that wheels designed for Jeeps can weigh anywhere from 2,000 to 3,500 pounds? Custom wheels represent far more than just visual appeal – they directly impact your vehicle's performance, handling, and safety on every drive.

The choice between forged vs cast wheels affects everything from fuel economy to cornering ability. Cast aluminum wheels offer affordability and design flexibility, while steel beadlock wheels deliver exceptional durability for hardcore off-roading. Flow formed wheels provide greater load capacity and lighter weight than standard cast options, making them popular among performance enthusiasts. Beadlock wheels prevent tire bead separation during intense launches and allow off-roaders to run lower tire pressures without the risk of debeading.

At Performance Plus Tire, we understand that selecting the right wheels requires more than browsing pretty pictures. Wheel materials, construction methods, and specifications work together to determine whether your investment enhances or hinders your driving experience. We'll break down everything you need to know about wheel materials, construction types, and essential specifications so you can make the right choice for your vehicle and driving style.

Image Source: Forged Wheels

Wheel materials determine everything from how your vehicle handles to how much you'll spend on replacements. The manufacturing process creates distinct performance characteristics that directly impact your driving experience, making material selection crucial for matching wheels to your specific needs.

Cast aluminum wheels dominate the market for good reason, accounting for approximately 90% of original equipment wheels found on most vehicles. The casting process involves pouring molten aluminum into molds and allowing it to cool, creating an affordable manufacturing method that keeps costs reasonable for most drivers.

Cost-effectiveness stands as the primary advantage of cast wheels. They also offer exceptional design flexibility, allowing manufacturers to create complex shapes and intricate styling options that would be impossible with other construction methods. Cast wheels absorb shock and vibration effectively, contributing to a smoother, more comfortable ride quality.

The casting process creates inherent limitations. Cooling aluminum can form tiny air pockets (porosity) that weaken the overall structure, making cast wheels more susceptible to cracking under extreme stress. Manufacturers compensate for these structural weaknesses by adding extra material, resulting in cast wheels that weigh significantly more than forged alternatives.

Forged wheels represent the highest level of wheel technology available today. The forging process subjects solid aluminum blocks (typically aerospace-grade 6061-T6 alloy) to extreme heat and pressure, compressing and aligning the metal's grain structure to create exceptional strength-to-weight ratios.

Weight reduction delivers the most noticeable benefit – forged wheels typically weigh 25-30% less than comparable cast wheels. This weight savings translates directly into improved handling, faster acceleration, and shorter braking distances. Forged wheels also dissipate heat more effectively, helping maintain consistent performance during demanding driving conditions.

Premium performance commands premium pricing. Forged wheels range from $380 to over $1,000 per wheel, representing a substantial investment for most enthusiasts. The manufacturing process explains the cost – a typical 18-inch forged wheel begins as a 100-pound aluminum blank that's precision-machined down to approximately 19.5 pounds.

Flow formed (also called rotary forged) wheels bridge the gap between cast and forged construction. This process starts with casting the wheel center, then uses high-pressure spinning and heat to shape and strengthen the barrel section.

This hybrid manufacturing approach creates wheels that are 15-25% lighter than fully cast alternatives while retaining much of the strength benefits found in forged wheels. The spinning process aligns the grain structure in the barrel area, significantly improving structural integrity over standard cast construction.

Pricing for flow formed wheels falls between cast and forged options, typically starting around $120 per wheel. This makes them an excellent choice for performance enthusiasts who want noticeable improvements without the expense of fully forged construction.

Steel wheels deliver unmatched durability and value. When subjected to extreme impacts, steel wheels bend rather than crack like aluminum, making them ideal for heavy-duty applications, serious off-roading, and vehicles that regularly encounter harsh conditions.

Aluminum alloy wheels provide significant weight advantages – they're approximately 2.5-3 times lighter than comparable steel wheels. This weight reduction improves fuel efficiency, handling responsiveness, and acceleration. Aluminum wheels also resist corrosion better than steel options, making them more suitable for coastal areas and harsh winter conditions.

Your driving conditions should guide your material choice. For daily driving and performance applications, aluminum alloy wheels offer the best combination of weight savings, appearance, and performance benefits. For heavy-duty work, extreme off-roading, or budget-conscious applications, steel wheels remain the superior choice for durability and repairability.

Image Source: Forged Wheels

The way wheels are constructed affects everything from durability to customization options. Understanding these construction methods helps you choose wheels that match your specific performance needs and budget.

One-piece wheels dominate the market because they offer simplicity and reliability. Manufactured from a single piece of material, these wheels provide excellent structural integrity while requiring minimal maintenance. They typically weigh less than multi-piece alternatives and resist damage better due to their unified construction. When problems do occur, you must replace the entire wheel.

Multi-piece wheels take a different approach entirely. Two-piece wheels feature a center section attached to an outer barrel through welding or bolting, while three-piece wheels include separate inner and outer rim halves bolted together. This construction allows precise offset adjustments and custom width specifications tailored to your vehicle. Damaged components can be replaced individually, making repairs more economical. The trade-off? Multi-piece wheels typically cost three times more than comparable one-piece options.

Beadlock wheels solve a specific problem for serious off-roaders. They physically lock the tire's bead to the wheel rim, preventing tire dismounting when running extremely low air pressures. Standard wheels rely solely on air pressure to hold the tire bead against the rim. With beadlocks, you can safely reduce tire pressure to 5-7 psi without risking bead separation.

Originally developed as military "combat wheels," beadlocks now serve civilian off-road enthusiasts. The locking mechanism consists of an outer ring secured with 16-32 bolts that clamp the tire bead mechanically. This creates a physical bond rather than depending on air pressure alone.

Most beadlock wheels are not DOT-approved for street use. They also require regular maintenance, including checking and retorquing bolts before every off-road trip.

Billet wheels represent precision manufacturing at its finest. Machined from solid aluminum blocks using Computer Numerical Control (CNC) technology, the term "billet" refers to carving away material from a solid chunk. The process begins with aluminum alloy sections that are subsequently machined into wheel centers or complete wheels.

The key advantage of billet wheels is exceptional strength. They retain the grain structure of the extruded stock material, providing superior structural integrity compared to cast wheels without adding weight. Boyd Coddington developed billet wheels in 1979, offering customization options like custom backspacing and lug patterns.

Most "billet wheels" on today's market are actually billet centers bolted or welded to stamped or spun rim halves. This construction method balances customization possibilities with manageable production costs.

Image Source: Crawlpedia

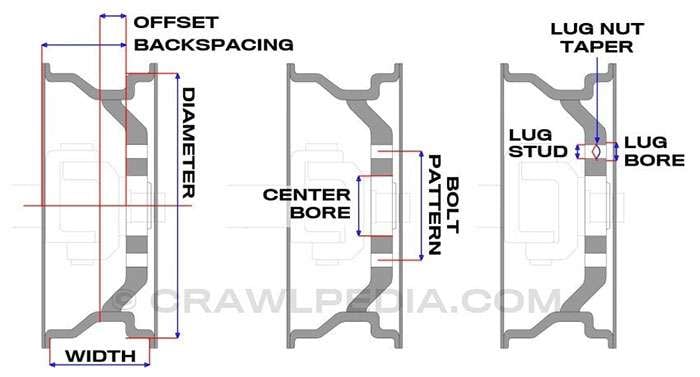

Understanding wheel specifications isn't optional when choosing custom wheels. These measurements determine whether your new wheels will actually fit your vehicle and perform safely. Get them wrong, and you risk dangerous vibrations, component damage, or wheels that simply won't bolt on.

The bolt pattern describes how many lug nuts secure your wheel and the diameter of the circle they form. Written as "5x114.3," the first number indicates five lug holes while the second measures the diameter of their imaginary circle in millimeters. This specification is non-negotiable—deviating even by 1mm prevents proper wheel seating, potentially causing dangerous vibration.

Center bore represents the machined opening in the wheel's center that fits over your vehicle's hub. Proper center bore alignment ensures the wheel centers precisely, minimizing vibration and stress. Many aftermarket wheels feature larger center bores and use centering rings to create a proper fit. These small adapters fill the gap between your hub and the wheel's center bore, ensuring a hub-centric fit rather than relying solely on lug nuts for centering.

Wheel width measures from bead seat to bead seat where the tire seals to the rim. Here's something most people don't know: the actual wheel width is typically one inch wider than advertised—a 9-inch wide wheel measures about 10 inches from flange to flange. This specification directly affects what tire width works with your setup.

Diameter determines how much wheel face is visible from the side. Common sizes range from 16 to 22 inches, though variations from 12 to 24 inches exist. Selecting the correct diameter ensures proper brake caliper clearance and appropriate tire sidewall height. For performance applications, the smallest wheel that fits over your brakes often provides the best balance of weight and strength.

Offset and backspacing represent the most misunderstood yet critical measurements. Offset measures the distance between the wheel's mounting surface and its centerline in millimeters. It can be:

Positive offset: Mounting surface is toward the outside of the wheel, tucking it inward

Zero offset: Mounting surface aligns with the centerline

Negative offset: Mounting surface is toward the inside, pushing the wheel outward

Backspacing measures the distance from the mounting surface to the inner wheel lip in inches. These related measurements determine how your wheel sits within the fender well, affecting clearance for suspension components and brakes. A wheel with inadequate backspacing might contact suspension parts, while excessive backspacing could cause tire rubbing against fenders.

Custom wheels affect more than just your vehicle's appearance. The right wheel choice ensures reliable performance and safety under real-world driving conditions, while the wrong choice can create dangerous situations.

Load rating determines the maximum weight a wheel can safely support without structural failure. This rating cannot be exceeded – it's essential for maintaining stability during cornering and emergency maneuvers. Calculate your minimum required load rating by dividing your vehicle's heaviest gross axle weight rating by two. A front axle rated at 2,400 lbs requires each wheel to handle at least 1,200 lb capacity. Performance tires often reduce effective load capacity—a wheel rated at 1,000 lbs might only support 800 lbs with 200 treadwear tires.

The relationship between wheel weight and strength requires careful consideration. Heavier wheels typically offer greater strength when comparing identical designs and manufacturing processes. However, reducing wheel weight by 10 lbs per corner equals removing 100 lbs from the chassis in terms of suspension responsiveness. This trade-off directly impacts acceleration, handling, and fuel efficiency. Visit https://www.performanceplustire.com/ to explore wheels with proper load ratings and safety certifications.

The Department of Transportation doesn't mandate specific performance standards for aftermarket wheels, but many jurisdictions enforce strict regulations on wheel modifications. JWL/VIA certification standards ensure wheels withstand impact, side loads, and fatigue testing. Non-compliant wheels can result in fines up to $1,000 per violation or vehicle confiscation. Beadlock wheels lack DOT approval for street use despite their off-road advantages.

Selecting custom wheels requires matching your specific driving habits to the right wheel characteristics. The perfect wheel for weekend trail runs differs dramatically from what works best for daily commuting or track days.

Daily drivers benefit most from lighter wheels that improve fuel economy and provide better suspension response over bumps. Flow-formed aluminum wheels offer the sweet spot of performance, durability, and value for commuter vehicles. These wheels reduce unsprung weight without the premium cost of forged construction.

Off-road enthusiasts face different challenges. Steel wheels withstand rock hits that would crack aluminum, making them ideal for serious rock crawling. When you're bouncing off boulders, repairability matters more than weight savings.

Track enthusiasts should invest in forged wheels that deliver 0.3-0.4 seconds faster times even on small courses. The reduced rotating mass improves acceleration, braking, and handling response that competitive drivers demand.

Follow this fundamental rule: wheel diameter should be no larger than half the tire height. Running 15 or 16-inch wheels with 33-inch tires creates the perfect balance between ground clearance and sidewall protection.

Proper backspacing prevents both fender rubbing and steering problems that make trail driving miserable. Most serious off-roaders perform best with wheel diameters between 15-20 inches paired with widths from 7-12 inches.

Your investment should align with your driving needs:

Entry-level ($800-1,200/set): Cast aluminum wheels with modest 2-4 pound weight savings per wheel

Mid-range ($1,200-2,500/set): Flow-formed wheels offering significant 4-8 pound reductions

Premium ($2,500-5,000+/set): Forged construction with maximum weight savings exceeding 8 pounds per wheel

The key is matching your budget to how you actually use your vehicle. Weekend warriors might find mid-range flow-formed wheels provide the best value, while serious racers benefit from the premium forged option.

Ready to find the perfect custom wheels for your specific driving needs? Performance Plus Tire offers expert guidance to help you make the right choice.

Custom wheels represent one of the most impactful upgrades you can make to your vehicle. The right wheels enhance performance, improve handling, and transform your vehicle's appearance.

Material selection drives everything else. Cast aluminum wheels deliver affordability and design variety for daily drivers. Forged wheels provide maximum performance benefits for enthusiasts who demand the lightest, strongest option. Flow-formed wheels offer excellent value for drivers seeking performance improvements without premium pricing.

Construction type determines functionality and customization potential. One-piece wheels offer reliability and lower maintenance for most applications. Multi-piece wheels provide unlimited customization for specific builds. Beadlock wheels enable extreme off-road performance by preventing tire separation at low pressures.

Specifications matter more than appearance. Bolt pattern, center bore, offset, and backspacing determine whether your wheels fit properly and perform safely. Getting these measurements wrong creates dangerous vibration and clearance problems.

Your driving environment should guide your choice. Daily commuters benefit from lighter aluminum wheels that improve fuel economy. Off-road enthusiasts need durable steel construction that withstands impacts. Track drivers find forged wheels worth the investment for their weight savings and strength.

The best wheel balances your budget with your actual needs. Basic cast wheels serve most drivers well. Performance-focused drivers should consider flow-formed options. Serious enthusiasts will appreciate forged wheel benefits.

Ready to upgrade your ride? Our expert team can help you select wheels that match your vehicle, driving style, and budget. We carry the best selection of custom wheels at competitive prices, with the fitment expertise to ensure your investment performs exactly as intended.

Selecting custom wheels requires balancing material properties, construction methods, and specifications to match your specific driving needs and budget.

• Material choice impacts performance: Cast aluminum offers affordability, forged provides 25-30% weight reduction with superior strength, while flow-formed wheels deliver a cost-effective middle ground.

• Wheel specifications are non-negotiable: Bolt pattern, center bore, offset, and backspacing must match your vehicle exactly to prevent dangerous vibration and clearance issues.

• Construction type determines functionality: One-piece wheels offer reliability for daily use, while beadlock wheels enable extreme off-road performance by preventing tire separation at low pressures.

• Match wheels to driving conditions: Daily drivers benefit from lighter aluminum wheels for fuel economy, off-roaders need durable steel construction, and track enthusiasts should invest in forged wheels.

• Load rating ensures safety: Always verify your wheel's load capacity exceeds half your vehicle's axle weight rating to maintain structural integrity during cornering and emergency maneuvers.

The key to successful wheel selection lies in understanding that the cheapest option isn't always the most economical long-term, while the most expensive isn't necessarily the best fit for your specific application.

Cast aluminum wheels are affordable and offer design flexibility, while forged wheels provide superior strength-to-weight ratios. Flow-formed wheels offer a middle ground, balancing performance and cost-effectiveness.

One-piece wheels offer simplicity and reliability, ideal for daily driving. Multi-piece wheels allow for customization and easier repairs but come at a higher cost. They're popular among enthusiasts seeking specific fitments.

Offset is the distance between the wheel's mounting surface and centerline. It determines how the wheel sits within the fender well, affecting clearance for suspension components and brakes. Proper offset ensures optimal fitment and performance.

Consider your primary use: daily drivers benefit from lighter aluminum wheels, off-roaders may prefer durable steel wheels, and track enthusiasts should invest in forged wheels for maximum performance. Always ensure the wheels meet your vehicle's load rating requirements.

Most beadlock wheels are not DOT-approved for street use. They're designed for off-road use, allowing extremely low tire pressures without risking bead separation. Always check local regulations before using beadlock wheels on public roads.