Smart rim selection separates successful vehicle upgrades from costly mistakes. Poor decisions create serious problems, from decreased fuel efficiency to dangerous safety risks.

Custom wheels affect far more than your vehicle's appearance. Offset stands as one of the most critical specifications to get right if you want your new rims to look great and fit properly. Wrong wheel sizes change the rolling diameter, which directly impacts handling, safety, and speedometer accuracy. Before making this significant investment, you need to understand the common pitfalls that catch many car enthusiasts off guard.

Currently, 17-inch-diameter wheels offer the most options and fit over most brake packages, but choosing rims involves much more than size and style. You must have the correct number of lugs and proper hub bore size. Get these wrong, and you'll face returns, frustration, and potentially dangerous fitment issues.

We've seen countless customers learn these lessons the hard way. That's why we're sharing the most important mistakes to avoid when buying rims for your vehicle.

Image Source: Blackcircles Canada

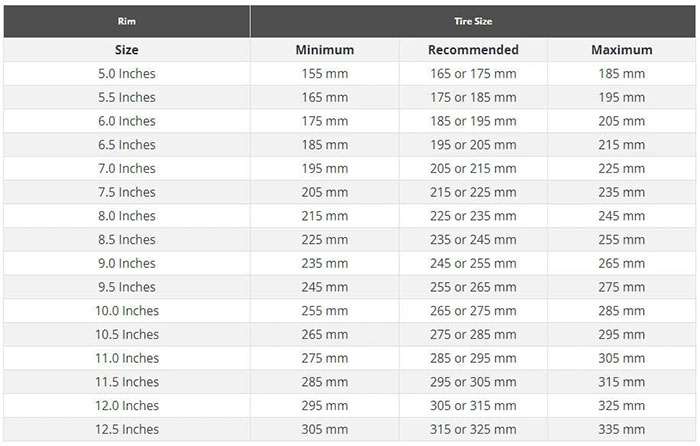

The bolt pattern serves as the foundation for proper wheel mounting. Car owners often focus on rim size and style while overlooking this crucial specification. This oversight creates significant problems that proper understanding can prevent.

The bolt pattern, also known as the pitch circle diameter (PCD), consists of two essential measurements: the number of lug holes and the diameter of the imaginary circle they form. A "5x114.3mm" designation means the wheel has five bolts positioned equally around a circle with a 114.3mm diameter. This specification is non-negotiable when selecting new rims.

Matching your bolt pattern exactly is critical because incorrect patterns create serious safety concerns. When the bolt pattern doesn't align perfectly with your vehicle's hub, it leads to:

Dangerous mounting situations

Vibrations during driving

Accelerated wear on components

Compromised vehicle handling

Potential wheel detachment while driving

Even minor discrepancies between similar patterns (like 5×100 versus 5×112) have major consequences for wheel security and performance. This measurement system ensures that wheels align perfectly with the vehicle's hub, providing a secure and balanced connection that maintains vehicle safety.

Your vehicle's bolt pattern is the first criteria that needs consideration when determining wheel compatibility. You can only buy rims that match your vehicle-specific bolt pattern.

Several errors commonly occur when shopping for new rims:

PCD confusion: Mistaking similar patterns for one another (e.g., 5×100 versus 5×112)

Measurement errors: Measuring from incorrect points on the lug holes instead of their centers

Assumption of universality: Believing all wheels with the same lug count are interchangeable—the spacing between lugs matters just as much

Relying on rough estimates: Making installation decisions based on approximations rather than precise measurements

Overlooking manufacturer specifications: Failing to consult vehicle documentation for exact pattern requirements

One particularly dangerous misconception is thinking that "close enough" will suffice for wheel fitment. Incorrect bolt patterns result in wheels not sitting flush on the hub, leading to vibrations, handling issues, and potential safety hazards.

Many people incorrectly assume that bolt pattern is the only factor affecting compatibility. While it's fundamental, other factors like hub bore size, offset, and brake clearance must also be considered.

Measuring your vehicle's bolt pattern accurately before purchasing new rims is essential. The measurement technique varies depending on the number of lugs:

For even-numbered patterns (4, 6, 8 lugs):

Measure from the center of one lug hole directly across to the center of the opposite hole

This straight-across measurement gives you the bolt circle diameter

For odd-numbered patterns (especially 5-lug):

For a 5-lug wheel, measure from the center of one lug to the imaginary outboard plane that would bridge the opposite two lugs together

Alternatively, measure from the outside of one lug to the center of the opposing lug

Since 5-lug patterns are particularly challenging to measure accurately without specialized tools, consider these verification methods:

Consult vehicle documentation: Check your owner's manual for exact specifications

Use a bolt pattern gage: This specialty tool provides the most accurate measurements

Reference bolt pattern charts: These help confirm your measurements and convert between inches and millimeters

Look for wheel markings: Many wheels have the bolt pattern stamped or engraved on the back or inside

Utilize online databases: Many websites provide bolt pattern information based on vehicle make, model, and year

When taking measurements, ensure your tape measure includes increments like eighths and quarters for precise readings. For a 5-lug wheel, note the measurement in inches, specifying the bolt pattern (e.g., five and four and three-quarters).

Professional consultation remains valuable, particularly with 5-lug patterns where precision is critical. Remember that identifying the correct bolt pattern is only the first step—you'll still need to verify other compatibility factors like center bore, offset, and brake clearance.

Understanding bolt pattern compatibility and taking the time to verify measurements before purchase helps you avoid one of the most common pitfalls when buying new rims and ensures a safe, proper fit for your vehicle.

Image Source: KIPARDO

Center bore fitment represents another critical specification that many buyers ignore until problems arise. This circular opening on your wheel's back might appear inconsequential, but it directly affects your vehicle's performance, comfort, and safety.

The center bore, often labeled as "DIA" or "D" in wheel specifications, is the machined opening that centers your wheel precisely on your vehicle's hub. This detail functions like a guide pin that keeps your wheel perfectly centered.

When center bore fitment goes wrong, you'll experience:

Significant vibrations at speeds over 80 km/h that make your vehicle uncontrollable

Uneven tire wear that affects performance, safety, and tire longevity

Steering wheel vibrations that accelerate wear on steering components

Body vibrations that compromise vehicle comfort and stability

Understanding center bore compatibility matters because improper sizing creates dangerous handling conditions at high speeds. Your wheel struggles to maintain proper alignment, and even perfect bolt pattern matching won't save you from an incompatible center bore that renders your rims unsafe.

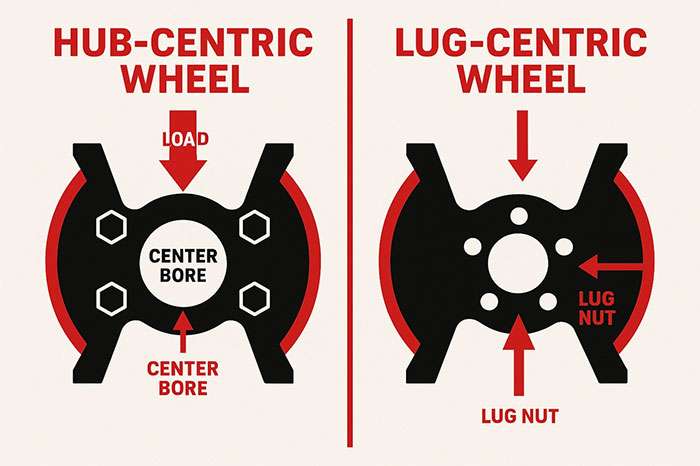

Choosing between hub-centric and lug-centric rims affects how your wheels mount and perform on your vehicle.

Hub-centric wheels feature center bores precisely matched to your vehicle's hub diameter. The weight of your vehicle distributes evenly across the hub rather than relying on lug nuts for support. Most OEM wheels use this approach, creating benefits like:

Reduced vibration risk

Enhanced driving stability

Superior ride quality

Proper weight distribution

Lug-centric wheels center on your vehicle using lug nuts instead of the hub. Many aftermarket wheels fall into this category because manufacturers design them with larger hub diameters to fit multiple vehicles. This versatility comes with drawbacks:

Complete reliance on lug nuts for centering

Potential vibration issues at higher speeds

Increased stress on lug studs during impacts

Possible damage to the wheel's center bore

Off-road driving on lug-centric wheels can apply considerable shear force to lug studs, sometimes exceeding their design capacity. This may cause studs to bend, creating vibration as the wheel shifts on the mounting plate.

While some drivers report no noticeable difference between hub-centric and lug-centric setups, the majority consensus among professionals supports proper hub centering for optimal performance and safety.

Accurate center bore measurement ensures proper wheel fitment. Follow this process for reliable results:

Place the wheel face down on a protected surface

Use digital calipers for precise measurement

Position the caliper jaws inside the center hole

Gently expand until they touch both sides

Read the measurement in millimeters

Take three measurements from different angles for accuracy

For your vehicle's hub:

Measure the raised center section of the hub

Take measurements at different points

Record all numbers for comparison

The hub measurement should be slightly smaller than the wheel's center bore by 0.1 to 0.5 millimeters. Inconsistent readings usually mean you're measuring at an angle rather than straight across.

Two scenarios emerge when measurements don't match:

If the center bore is too large for your hub, you'll need hub-centric rings (also called spigot rings). These rings:

Fill the gap between the vehicle hub and wheel bore

Eliminate vibrations caused by oversized wheel bores

Keep wheels truly centered

Prevent lug nuts from loosening as you drive

To determine the correct hub ring size, you need:

Outer Diameter = Center bore of your wheels

Inner Diameter = Hub diameter of your vehicle

If the center bore is too small for your hub, the opening must be enlarged using a milling machine or precise drill. This typically requires professional service at a specialty workshop.

When shopping for aftermarket wheels, look for center bores that match your vehicle's hub specifications. If unavailable, choose wheels with slightly larger center bores and use hub-centric rings for a reliable solution that balances style with safety.

Professional consultation remains valuable when you're uncertain about measurements or compatibility. The small cost of expert advice prevents expensive vibration damage and safety issues from improper wheel fitment.

Image Source: Specialty Performance Parts

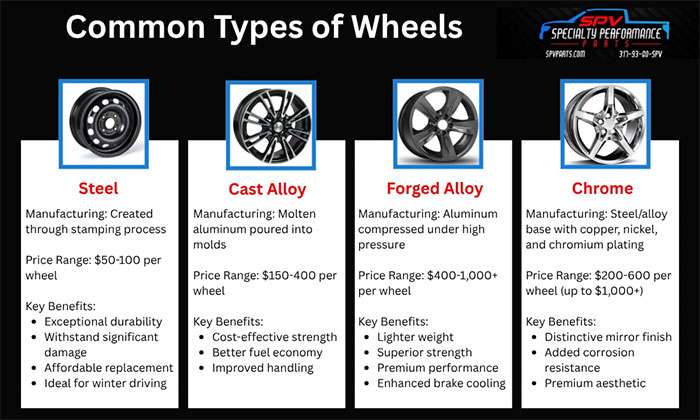

The temptation to choose rims based on looks alone affects nearly every vehicle owner. Wheel manufacturers understand this desire and market accordingly, showcasing aggressive designs and eye-catching finishes. Giving in to this temptation creates significant performance problems, unnecessary expenses, and serious safety concerns.

Custom wheels transform your vehicle's appearance, but looks should never drive your buying decision. According to automotive experts, while esthetics matter, they shouldn't be the only consideration when purchasing wheels. Wheels directly affect multiple performance aspects:

Handling and stability

Fuel efficiency

Braking effectiveness

Acceleration capability

Overall ride comfort

Larger wheels chosen for visual impact decrease fuel economy by approximately 10% in city driving and reduce 0-60 acceleration times by 4%. Your engine works harder to move the additional weight, increasing both drag and friction.

The width, load rating, and offset of wheels impact performance far beyond appearance. Too narrow a wheel causes tires to crown, creating accelerated center tread wear. Choosing wheels based solely on aggressive styling might leave you with insufficient load rating for your vehicle's needs.

The right tire and wheel combination enhances your vehicle's performance, handling, and reliability—creating both safer and more enjoyable driving.

Style-focused decisions create problems that many buyers don't discover until it's too late:

Performance degradation: Oversized wheels often result in poor handling characteristics and reduced acceleration capability. Many vehicle owners report significant performance losses after installing large, stylish wheels without considering mechanical implications.

Premature suspension wear: Extreme wheel offsets that prioritize appearance strain suspension and steering components, causing faster wear and tear. The resulting expensive repairs far outweigh any esthetic benefits.

Safety compromises: Defects and design flaws in stylish but poorly engineered wheels can cause deformation and structural collapse under real-world conditions. Each wheel acts as a primary suspension unit, absorbing static and dynamic stresses during travel.

Higher costs: Stylish, larger wheels typically cost at least 30% more than functional alternatives, excluding expenses from potential repairs and replacements. Low-priced but stylish rims often use poor quality materials that prove dangerous over time.

Reduced comfort: Vehicles fitted with oversized stylish wheels frequently sacrifice ride quality. One enthusiast noted that although his friend's truck "looks mean," it delivers a harsh ride with "no get up and go".

Using the wrong offset due to esthetic preferences leads to poor handling, premature suspension wear, tire rubbing, and component damage.

Finding the sweet spot between appealing esthetics and optimal performance requires understanding key principles:

Wheel diameter matters significantly. Many automotive experts recommend wheel diameter should be less than half the overall tire diameter—a 17-inch wheel works as the maximum recommended size for a 35-inch tire. Currently, 17-inch-diameter wheels offer the most options and fit over most brake packages.

Consider vehicle purpose alongside appearance. Off-roading requires smaller wheels that provide more sidewall flex for protection, while pavement driving allows "plus sizing" to improve both appearance and handling.

Prioritize critical specifications while allowing style flexibility:

Match bolt pattern exactly (non-negotiable)

Ensure proper center bore fitment

Choose appropriate load rating for your vehicle

Select suitable width for intended use

Consider offset impact on handling and component clearance

Some vehicles have specific limitations. Certain cars, particularly classics, actually look better with smaller wheels due to their proportional design.

Professional installation remains crucial regardless of wheel choice. Incorrect installation of even properly sized wheels can lead to uneven tire wear and potential accidents.

The automotive industry practice of "plus sizing" shows how professionals balance these factors. This approach allows larger, more stylish wheels while maintaining proper overall diameter by reducing tire sidewall height. This preserves speedometer accuracy and gear ratios while enhancing appearance.

Wheels experience both static and dynamic stresses during driving. The design must distribute load appropriately to maintain structural integrity. A wheel that fails under normal driving conditions creates catastrophic safety risks regardless of how attractive it appears.

Image Source: Tinker DIY

The used rim market attracts many buyers with appealing prices, but these savings often come with hidden dangers. Purchasing pre-owned wheels without proper inspection can turn a bargain into a costly and dangerous mistake.

Used rims carry hidden problems that compromise your vehicle's performance and road safety. Damaged wheels create genuine hazards that affect critical vehicle functions, not just appearance issues.

Cracked or structurally compromised rims can lead to catastrophic failures at high speeds. All rim assemblies face loads and forces that create structural fatigue over time. These weaknesses often remain invisible until a wheel suffers catastrophic failure while driving.

Bent rims—even slight bends—affect balance and handling, creating vibrations throughout your vehicle. Even minor bends create balancing nightmares and can produce vibrations severe enough to make your vehicle uncontrollable above 80 km/h.

Damaged rims negatively impact multiple vehicle systems:

Reduced fuel efficiency from increased rolling resistance

Compromised steering response and accuracy

Decreased resale value for your entire vehicle

Persistent air leaks requiring constant refilling

Safety system interference affecting anti-lock braking and traction control

Climate extremes and harsh road conditions contribute to rim damage over time. Cold temperatures make rims brittle and crack-prone, while gravel roads, speed bumps, and potholes create potential structural issues.

Physical inspection serves as your primary defense against problematic used wheels. Examine the entire rim under good lighting—many sellers clean wheels thoroughly to hide hairline cracks and damage.

Check these critical areas carefully:

Structural integrity — Examine the wheel thoroughly for cracks, especially around the lip, lug holes, and valve stem areas. Even hairline cracks are irreparable damage that grows over time. Small cracks are never harmless—they create serious rim failure risks during driving, particularly at high speeds.

Physical damage assessment — Look for bends, dents, and deformities indicating previous impacts. Bent rims can be difficult to spot visually. Test by placing the wheel on a flat surface and rolling it—wobbling or hopping indicates bending issues.

Surface examination — While cosmetic damage like curb rash, scratches, and paint issues may not affect performance, deep gouges exceeding 4mm or visible imbalances indicate structural problems.

Previous repairs — Watch for signs of prior repairs or welding. Welded areas on aluminum wheels need thorough inspection, as improper repairs often fail under stress. Welding weakens wheel structure, and properly repaired cracks frequently reopen or cause new cracks nearby.

Resonance testing — Use the tap test: gently strike the wheel with a small hammer and listen. A clear ring suggests structural integrity, while dull or flat sounds indicate internal damage or weak spots.

Follow this systematic approach to evaluate used rims thoroughly:

Visual inspection

Check for cracks around lug holes, valve stems, and wheel lip

Look for bent sections, especially around outer edges

Examine for repair signs (different paint, weld lines)

Inspect for excessive corrosion or rust weakening integrity

Physical testing

Roll test: Place on flat surface and roll to detect wobbling

Resonance test: Tap wheel to listen for unusual sounds

Spin test: Mount temporarily and spin to check for trueness

Measurement verification

Confirm bolt pattern matches your vehicle exactly

Verify center bore dimensions

Check for oval lug holes indicating previous overtightening

Measure backspacing to ensure proper fitment

Seller questioning

Ask about wheel history and previous vehicle application

Inquire about any repairs or refinishing work

Request documentation for OEM purchases if claimed as original equipment

Professional evaluation

Consider having wheels inspected by specialists before mounting

Request leak testing for tubeless rims

Verify proper balancing capability

With used rims, "you get what you pay for" often proves accurate. Junkyards and online marketplaces offer the cheapest options but rarely provide assurances about wheel age, origin, or condition. The gamble of buying uninspected wheels rarely justifies initial savings, given potential costs for repairs, replacements, or accidents.

Always prioritize safety over savings when considering used wheel purchases. Your vehicle's connection to the road deserves thorough verification, not rushed decisions based solely on price.

Choosing the perfect rims means nothing if they're installed incorrectly. Many vehicle owners make a critical error by attempting DIY installation to save money. This approach might seem cost-effective initially, but the consequences often create far bigger expenses and serious safety risks.

Professional wheel installation delivers more than convenience—it provides essential safety assurance. Technicians use specialized equipment like calibrated torque wrenches and wheel balancing machines that DIY setups simply can't match. These tools achieve precise measurements that household equipment can't replicate.

Professional installers bring technical expertise that ensures wheels are mounted correctly the first time. Their knowledge goes beyond basic installation to include proper torque specifications, which vary by vehicle. They understand the difference between hub-centric and lug-centric mounting techniques, applying this knowledge to your specific vehicle.

Professional installation often preserves warranty coverage. Many rim manufacturers require professional installation to maintain warranty protection. This requirement exists for good reason—improper mounting can damage both wheels and vehicle components.

The peace of mind alone justifies professional installation costs. As one industry expert notes, "Having your wheels professionally installed by someone who knows what they're doing is simply an investment in yourself and your car's safety".

DIY wheel installation risks extend far beyond minor inconvenience. Improperly mounted wheels create several serious problems:

Catastrophic safety hazards: Incorrectly installed wheels risk separation or tire blowouts while driving. These failures happen with alarming frequency—approximately three to five wheel separation incidents occur daily nationwide.

Vehicle damage: DIY efforts using improvised tools can puncture or weaken tire structure. Even unnoticeable damage may create conditions for future blowouts.

Compromised handling: Failing to balance or align tires after installation misdirects wheel rotation, reducing vehicle control.

Shortened component life: Improper installation causes uneven tire wear, significantly reducing tire longevity and requiring premature replacement.

Persistent vibrations: Incorrectly installed wheels create uncomfortable vibrations throughout the vehicle, especially at higher speeds. These vibrations damage steering components and suspension systems.

Under-tightening wheel fasteners—a common DIY mistake—usually results from failing to follow recommended practices or using proper tools. Excessive torque damages both lug nuts and wheels.

Selecting the right professional for wheel installation requires research and attention to specific qualities.

First, verify certifications and training credentials. Professional installers should have relevant qualifications that demonstrate expertise. Organizations like the Tire Industry Association (TIA) offer training programs specifically for tire technicians, with multiple certification levels.

Second, examine online reviews and ratings from previous customers. Google and Yelp reviews offer valuable insights into others' experiences. Look for consistently positive feedback about installation quality and customer service.

Third, evaluate equipment quality used by potential installers. Professional-grade wheel balancers, torque wrenches, and lifting equipment indicate commitment to proper service.

Fourth, ask about inspection procedures. Reliable professionals conduct thorough assessments, checking for damage, maintaining proper inflation, and ensuring secure mounting.

Prior to committing, inquire about warranties or guarantees on installation services. Quality installers stand behind their work, offering protection should issues arise.

Professional installation represents an essential investment rather than an optional expense. As vehicle systems become increasingly complex, the knowledge and specialized equipment required for proper wheel installation become more critical. Professional installation safeguards both your rim investment and your safety on the road.

| Issue | Main Risk/Issue | Key Consequences | Verification/Prevention Methods | Professional Recommendation |

|---|---|---|---|---|

| Ignoring Bolt Pattern Compatibility | Incorrect wheel mounting and security | - Dangerous vibrations - Accelerated wear - Compromised handling - Potential wheel detachment |

- Use bolt pattern gage - Measure from center of lug holes - Consult vehicle documentation |

Exact bolt pattern match is non-negotiable; no "close enough" allowed |

| Overlooking Center Bore Fitment | Improper wheel alignment with vehicle hub | - Significant vibrations above 80 km/h - Uneven tire wear - Steering wheel vibrations - Body vibrations |

- Use digital calipers - Take multiple measurements - Check hub specifications |

Use hub-centric rings if center bore is too large; consult professionals for precise measurements |

| Choosing Style Over Functionality | Performance and safety compromises | - Reduced fuel efficiency - Poor handling - Premature suspension wear - Higher maintenance costs |

- Match wheel diameter to tire size - Consider vehicle purpose - Verify load ratings - Check offset specifications |

17-inch wheels currently offer best balance of options and brake clearance |

| Buying Used Rims Without Inspection | Hidden structural damage and safety risks | - Catastrophic failures - Balance issues - Reduced fuel efficiency - Air leaks - Safety system impairment |

- Visual inspection - Physical testing - Measurement verification - Resonance testing |

Have wheels professionally inspected before purchase; prioritize safety over savings |

| Skipping Professional Installation | Improper mounting and safety hazards | - Risk of wheel separation - Vehicle damage - Compromised handling - Shortened component life - Persistent vibrations |

- Verify installer certifications - Check equipment quality - Read customer reviews - Confirm warranty coverage |

Professional installation is essential for safety and warranty preservation |

Smart rim selection comes down to understanding five critical mistakes that separate successful upgrades from costly disasters. Bolt pattern compatibility forms your foundation for safe mounting. Center bore fitment prevents dangerous vibrations at highway speeds. Performance specifications matter more than flashy looks when you want reliable handling and fuel efficiency. Used rim inspection protects you from hidden structural damage that could cause catastrophic failures. Professional installation ensures everything works correctly from day one.

You don't need to become a wheel expert to make smart choices. The key is knowing what to verify before you buy and where to get reliable advice.

At Performance Plus Tire, we understand that your vehicle deserves wheels that deliver both style and safety. Our extensive selection includes properly fitted rims that meet your vehicle's exact specifications. We carry the best selection of custom wheels at the lowest prices, with expert guidance to help you avoid these common pitfalls.

Your wheels connect your vehicle to the road—that connection demands quality, compatibility, and professional installation. When you choose the right rims and have them properly installed, you'll enjoy improved appearance, enhanced performance, and peace of mind for years to come.

Ready to upgrade your ride? Let our team help you find the perfect wheels that combine style with safety and performance.

When buying rims, avoiding these critical mistakes ensures both safety and performance while protecting your investment.

Verify bolt pattern compatibility exactly - Even minor discrepancies between similar patterns (like 5×100 vs 5×112) can cause dangerous vibrations and potential wheel detachment.

Match center bore dimensions precisely - Incorrect center bore fitment creates severe vibrations above 80 km/h; use hub-centric rings if the bore is too large for your vehicle's hub.

Prioritize functionality over esthetics - Oversized stylish wheels can reduce fuel economy by 10% and decrease acceleration while compromising ride quality and safety.

Thoroughly inspect used rims before purchase - Check for cracks, bends, and structural damage; even hairline cracks are irreparable and present serious safety risks during driving.

Always use professional installation services - DIY mounting risks catastrophic wheel separation, vehicle damage, and warranty voiding; proper torque and balancing require specialized equipment.

The key to successful rim purchasing lies in understanding that wheels are critical safety components, not just esthetic upgrades. Taking time to verify specifications, inspect condition, and ensure professional installation prevents costly mistakes and dangerous situations on the road.

The key factors are bolt pattern compatibility, center bore fitment, proper sizing for your vehicle, and overall quality. Ensure the bolt pattern matches your vehicle exactly, the center bore fits correctly (using hub-centric rings if needed), and the rim size is appropriate for your tires and vehicle specifications. Always prioritize functionality and safety over pure esthetics.

Carefully inspect used rims for cracks, bends, or structural damage, especially around lug holes and the wheel lip. Check for signs of previous repairs or welding. Perform a roll test on a flat surface to detect wobbling. Listen for unusual sounds when gently tapping the rim. If possible, have a professional inspect the rims before buying.

It's strongly recommended to have new rims professionally installed. Professional installers have the specialized equipment and expertise to ensure proper mounting, torquing, and balancing. DIY installation risks improper fitment, potential damage to the rims or vehicle, and safety hazards like wheel separation. Professional installation also often preserves warranty coverage.

Prioritizing style over functionality can lead to reduced fuel efficiency, poor handling, premature suspension wear, and compromised safety. Oversized or improperly fitted rims may cause vibrations, uneven tire wear, and decreased vehicle performance. Always ensure the rims meet your vehicle's specifications and performance needs before considering esthetics.

Rim size impacts various aspects of vehicle performance. Larger rims can improve handling and esthetics but may reduce acceleration and fuel efficiency. They can also lead to a harsher ride quality. Smaller rims generally provide better acceleration and fuel economy but may limit brake clearance. The ideal rim size balances performance, comfort, and style while meeting your vehicle's specifications.