Tire wear patterns tell the real story about your vehicle's condition. Ignore these warning signs too long, and you're looking at dangerous hydroplaning, sudden blowouts, poor braking performance, and potential spinouts. These tread irregularities aren't just cosmetic issues—they're your vehicle's direct communication about serious mechanical problems developing under the hood.

Your tires work as diagnostic tools every time you drive. When inner or outer edges wear down faster than the center tread, wheel alignment problems are almost certainly the culprit. Cupped or scalloped dips scattered around the tire surface signal loose, worn, or bent suspension components that need immediate attention. Diagonal wear patches, appearing individually or in repeating patterns around the tire, represent warning signs that demand quick action.

We've developed this guide to help you decode what your tires are telling you about your vehicle's health. Learning to read these patterns like a professional mechanic saves money on tire replacements and prevents expensive repairs before they happen. Understanding these critical warning signs keeps your vehicle running safely and your wallet protected from unnecessary repair bills.

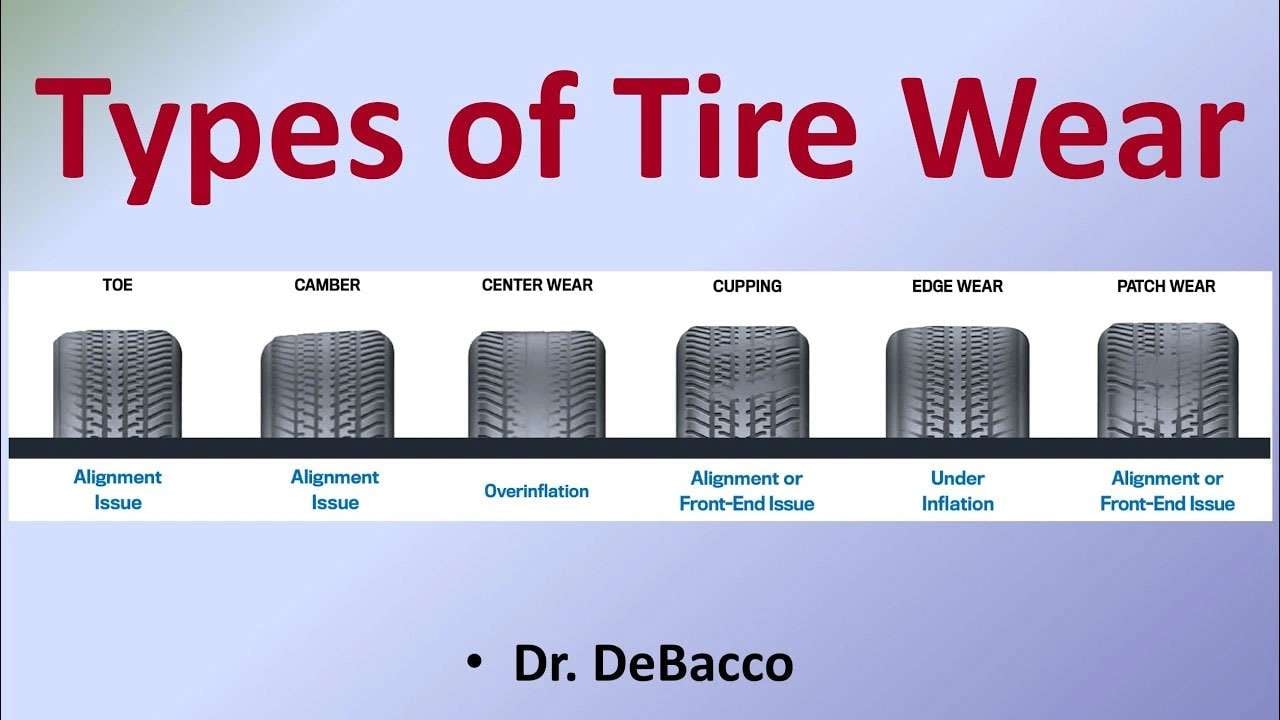

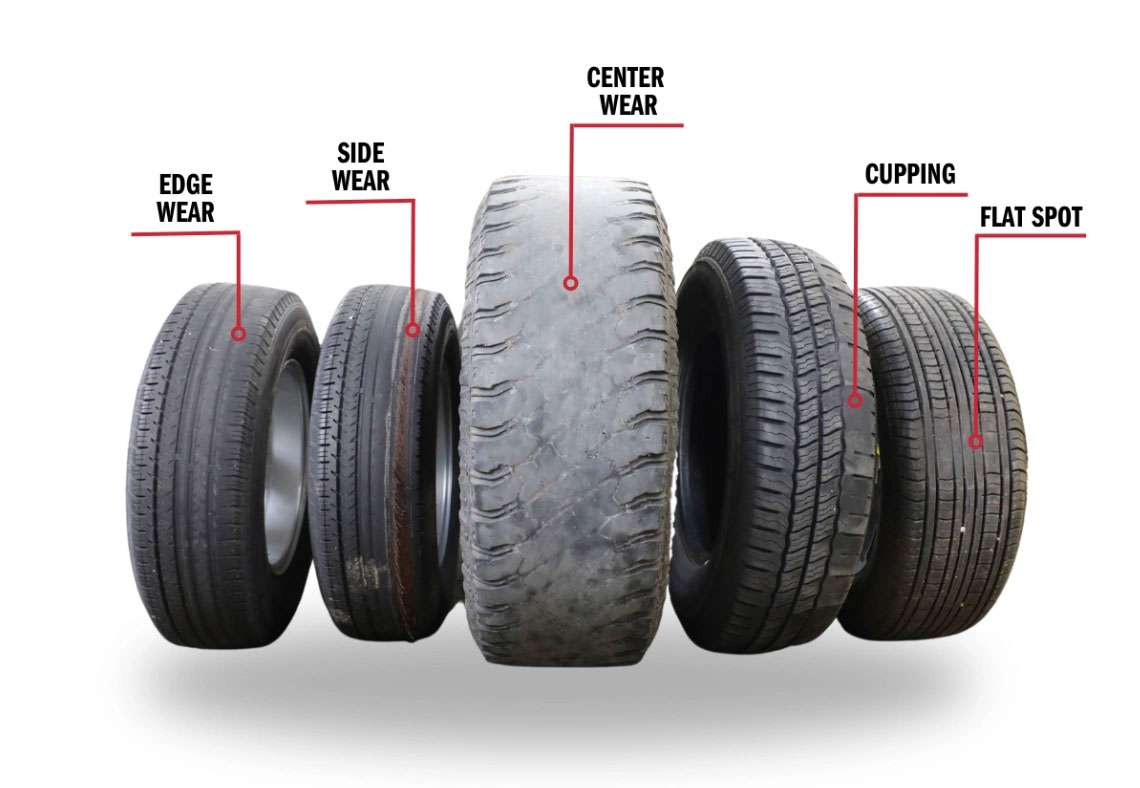

Tire treads reveal critical information about your vehicle's mechanical condition through specific wear patterns. Understanding these patterns helps you identify problems early and avoid costly repairs down the road.

Center wear develops when excessive air pressure causes the tire's middle section to bulge outward. This creates a smaller contact patch concentrated in the center, leading to accelerated wear in that area. Overinflated tires deliver poor traction and a harsh, bouncy ride quality while wearing out prematurely along the center strip.

Edge wear affects both tire shoulders when insufficient air pressure causes the tire to flatten excessively. This shifts weight distribution toward the outer edges, creating accelerated wear on both sides. The pattern significantly reduces tire lifespan and compromises vehicle handling. Aggressive cornering and frequent hard turns also contribute to edge wear, even when tire pressure remains correct.

Single-sided wear patterns typically indicate wheel alignment issues affecting your vehicle's geometry. Improper camber settings (tire angle when viewed from the front) or incorrect toe alignment (tire direction when viewed from above) create uneven contact with the road surface. Misalignment causes your vehicle to pull to one side and accelerates tire replacement needs.

Cupping creates irregular dips or scalloped depressions across the tire tread surface. This pattern develops when tires bounce instead of maintaining smooth road contact due to worn suspension components. Failing shocks, struts, bushings, or ball joints allow excessive tire movement, creating the distinctive cupped appearance. You'll often hear rhythmic thumping sounds or feel vibrations before the wear pattern becomes visible.

Feathering produces a sawtooth pattern across individual tread ribs. Running your hand across a feathered tire reveals sharp edges on one side and smooth surfaces on the other. Incorrect toe alignment primarily causes this wear pattern, though worn suspension components can contribute to the problem.

Flat spots appear when hard braking locks the wheels or emergency skidding flattens specific tire sections. This creates uneven wear patches that produce bumping noises or vibrations that change with vehicle speed. Vehicles equipped with anti-lock braking systems rarely develop flat spots since the system prevents wheel lockup.

Image Source: YouTube

Every tire wear pattern has a root cause that points to specific mechanical issues. Understanding these causes helps you address problems at their source instead of just treating symptoms.

Tire pressure determines how your tires make contact with the road surface. When tires are overinflated, the center section bulges outward and carries most of the vehicle's weight, creating faster wear in that area. Underinflated tires work differently—they flatten out and shift weight distribution to both edges, causing premature wear along the shoulders. Both conditions affect more than just tire life. Overinflated tires bounce over road imperfections and reduce your contact patch, while underinflated tires flex too much during driving and generate excessive heat.

Your suspension system connects your vehicle to the road through the tires. When suspension parts wear out, they can't maintain proper tire contact with the road surface. Shocks and struts that lose their damping ability allow tires to bounce, creating the distinctive cupping or scalloped wear pattern. Control arm bushings work like cushions between metal parts—when they deteriorate, the control arm can't stay in proper position. This leads to accelerated wear on one side of the tire. Springs, ball joints, and tie rods also play crucial roles in keeping your tires positioned correctly, and when they fail, uneven wear patterns develop quickly.

Wheel alignment involves three critical angles that must stay within manufacturer specifications. Toe alignment refers to whether your wheels point straight ahead or angle inward or outward when viewed from above. When toe settings are incorrect, tires scrub against the road surface and wear on both inner and outer edges. Camber angle describes how much your wheels tilt inward or outward when viewed from the front. Improper camber causes uneven wear across the tire's width. Alignment problems don't just wear out tires faster—they also reduce traction and make your vehicle pull to one side, especially noticeable in wet driving conditions.

Tire and wheel assemblies must be perfectly balanced to rotate smoothly. When the weight distribution is off, the assembly hops or wobbles as it spins. This irregular motion translates into patchy wear patterns or diagonal wear streaks around the tire. Bent wheels, often caused by hitting potholes or curbs, create similar problems by introducing vibrations that prevent smooth rotation and even tire wear.

Image Source: Dexter Group

Professional tire diagnosis requires systematic inspection methods that uncover mechanical problems before they become expensive repairs. We use visual inspection, precise measurements, and hands-on assessment techniques to identify issues in their early stages.

Professional mechanics start with standardized tire wear pattern charts that match specific wear patterns to their root causes. These visual references help identify problems quickly by comparing what you see on your tires to known patterns. One-sided wear typically points to alignment issues, while shoulder step wear often shows up on radial tires in slow-wearing conditions.

New car tires come with 10/32" or 11/32" tread depth, while light truck tires range between 11/32" and 19/32". We recommend tire replacement when tread reaches 2/32", following U.S. Department of Transportation guidelines. The penny test provides a quick check—insert Lincoln's head upside down between tread ribs. If you can see his entire head, replacement time has arrived.

Your hand reveals problems that visual inspection might miss. Run your hand across the tread surface to detect irregular patterns. Feathering creates a sawtooth texture where one side feels sharp and the opposite side feels smooth. Cupping produces noticeable dips or scalloped areas that indicate suspension problems.

Suspension component inspection reveals the source of many tire wear problems. Damaged bushings affect alignment and accelerate tire wear, even when the damage isn't immediately obvious. Worn shock absorbers can't properly control tire movement, allowing bouncing that creates cupping patterns.

Ride height measurement evaluates spring condition—the most reliable indicator of suspension system health. Even small tread depth variations of 1/32" across the tire surface signal alignment adjustment needs. Testing toe angle changes under simulated driving conditions exposes excessive play in steering components.

Image Source: Hillsborough CDJR

Prevention costs far less than repairs when it comes to tire wear problems. Smart maintenance practices extend tire life and protect you from expensive component failures down the road.

Rotate your tires every 5,000-8,000 miles to distribute wear evenly across all four tires. New tires need their first rotation by 5,000 miles because fresh tread compounds are more vulnerable to uneven wear patterns. This basic maintenance step adds thousands of additional miles to your tire investment.

Check tire pressure monthly with a reliable gauge when tires are cold. Just 20% underinflation cuts tread life by 30%, while 40% underinflation destroys tire life by half. Tire pressure changes with seasonal temperatures, so regular monitoring saves money and prevents premature replacement.

Schedule alignment inspections annually or every 12,000-15,000 miles. Always check alignment after hitting potholes, curbs, or when mounting new tires. Poor alignment on trucks reduces fuel efficiency by up to 10% while accelerating tire wear.

Address suspension problems immediately because worn components create uneven tire wear that spreads to other parts. Failing shocks increase your stopping distance by 20%, creating safety hazards. Inspect suspension components every 12,000-15,000 miles to catch problems before they cascade into expensive repairs.

Match your tire selection to your actual driving environment. City drivers should prioritize longevity and fuel economy, while highway drivers need superior handling and ride comfort. The right tire for your conditions performs better and lasts longer.

Reading tire wear patterns represents one of the most valuable skills any vehicle owner can develop. We've shown you how these tread patterns serve as early warning systems for mechanical problems that could cost hundreds or thousands of dollars if ignored. Your tires constantly communicate the health of your alignment, suspension, and inflation systems.

The inspection techniques we've outlined—from visual pattern recognition to hands-on assessments—give you the same diagnostic capabilities professionals use every day. Knowing when center wear signals overinflation or when cupping indicates suspension failure puts you ahead of costly breakdowns. These skills help you catch problems while they're still manageable and affordable to fix.

We believe in empowering vehicle owners with professional-level knowledge. The maintenance schedule we've provided for rotations, pressure checks, and alignment services will extend your tire life significantly while keeping repair costs under control. Regular attention to these details protects both your investment and your safety on the road.

Your tires represent the only contact point between your vehicle and the road surface. Their condition affects everything from fuel economy to emergency braking capability. At Performance Plus Tire, we've seen how proper tire maintenance and early problem detection can save our customers thousands of dollars in premature replacements and related repairs.

Ready to put this knowledge to work? Start with a thorough inspection of your current tires using the patterns and techniques we've covered. Address any issues you discover promptly, and establish the maintenance routine that will keep your tires performing at their best for maximum mileage and safety.

Understanding tire wear patterns can save you hundreds of dollars in repairs while keeping your vehicle safe on the road.

• Center wear indicates overinflation - Excessive center tread wear means your tires have too much air pressure, reducing traction and ride comfort.

• Edge wear signals underinflation or alignment issues - When tire shoulders wear faster, check air pressure first, then wheel alignment if pressure is correct.

• Cupping patterns reveal suspension problems - Scalloped dips around the tire surface indicate worn shocks, struts, or other suspension components need replacement.

• Regular maintenance prevents costly repairs - Rotate tires every 5,000-8,000 miles, check pressure monthly, and get annual alignment checks to maximize tire life.

• Early detection saves money - Catching wear patterns early allows you to address root causes before they damage other expensive vehicle components.

By learning to read these warning signs like a professional mechanic, you'll extend tire life, improve safety, and avoid the cascade of expensive repairs that result from neglected tire maintenance.

You should replace your tires when the tread depth reaches 2/32 of an inch. A quick way to check is the penny test - insert a penny with Lincoln's head upside down into the tread. If you can see his entire head, it's time for new tires.

Center wear on your tires typically indicates overinflation. This causes the center of the tire to bulge outward, creating more contact and wear in the middle. Overinflated tires can reduce traction and provide a bumpier ride.

Edge wear on both sides of the tire usually points to underinflation. When tires don't have enough air pressure, the edges bear more of the vehicle's weight, causing faster wear. Aggressive cornering can also contribute to edge wear.

It's recommended to rotate your tires every 5,000 to 8,000 miles. For new tires, it's best to do the first rotation by 5,000 miles as fresh tread is more susceptible to uneven wear. Regular rotations can significantly extend your tires lifespan.

Cupping or scalloping, which appears as irregular dips around the tire tread, typically indicates suspension or shock issues. This pattern develops when tires bounce instead of maintaining consistent road contact, often due to worn shocks, struts, bushings, or ball joints.